heater JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 915 of 2490

пЃ¬Connect

the front muffler to

the intermediate muffler,

noting the alignment of the indicator rings.

пЃ¬W

ith the front muffler positioned correctly, tighten the

clamps (left-hand and right-hand sides) to the catalytic

converter.

21

.

Tighten the clamps (left-hand and right-hand sides),

intermediate mufflers to front muffler.

22

.

Tighten the downpipe bracket se curing bolts to the correct

torque

23

.

Connect the oil cooler pipes (w here fitted) to the engine.

1. Remove the blanking plugs from the pipes and from the mating unions on the engine.

2. Fit new O-ring seals to the pipes and lubricate with new engine oil.

3. Connect the pipes to the engine and fit the clamping

plate and bolt.

24. Lower the vehicle on the ramp.

25. Connect the heater and brake servo hoses.

1. Connect the heat er return hose.

2. Connect the heater feed hose and secure the locking

lever.

Page 925 of 2490

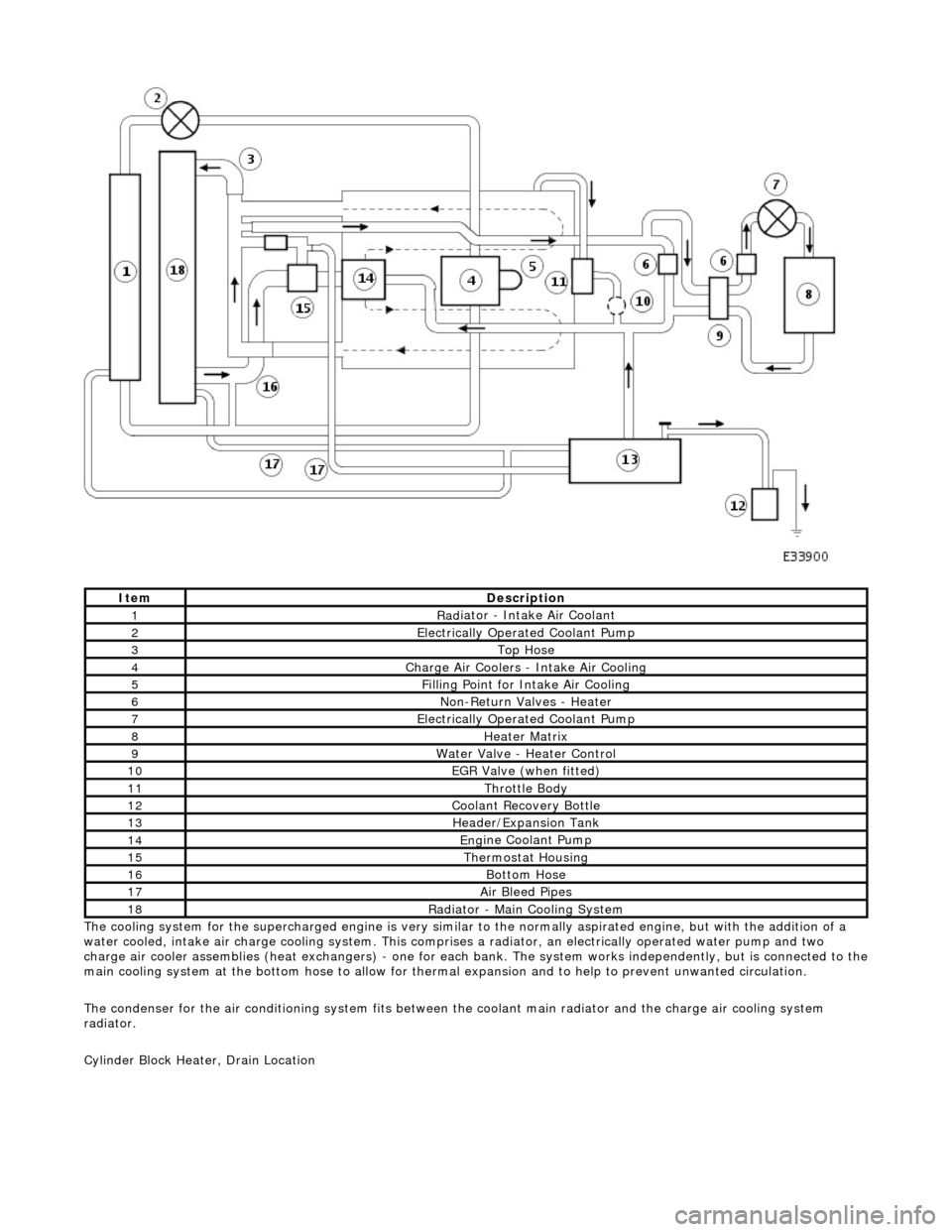

T

he cooling system for the supercharged engine is very similar

to the normally aspirated engine, but with the addition of a

water cooled, intake air charge cooling system. This comprises a radiator, an electrically operated water pump and two

charge air cooler assemblies (heat exchangers) - one for each bank. The system works independently, but is connected to the

main cooling system at the bottom hose to allow for therma l expansion and to help to prevent unwanted circulation.

The condenser for the air conditioning system fits between th e coolant main radiator and the charge air cooling system

radiator.

Cylinder Block Heater, Drain Location

ItemDe

scription

1Rad

iator - Intake Air Coolant

2Ele

ctrically Operated Coolant Pump

3Top Hose

4Charge Air Coo

lers -

Intake Air Cooling

5Fi

lling Point for Intake Air Cooling

6N

on-Return Valves - Heater

7Ele

ctrically Operated Coolant Pump

8Hea

ter Matrix

9Wate

r Valve - Heater Control

10EGR V

alve (when fitted)

11Thr

ottle Body

12Coolan

t Recovery Bottle

13H

eader/Expansion Tank

14Eng

ine Coolant Pump

15The

rmostat Housing

16Bottom

Hose

17Air Bleed

Pipes

18Rad

iator - Main Cooling System

Page 926 of 2490

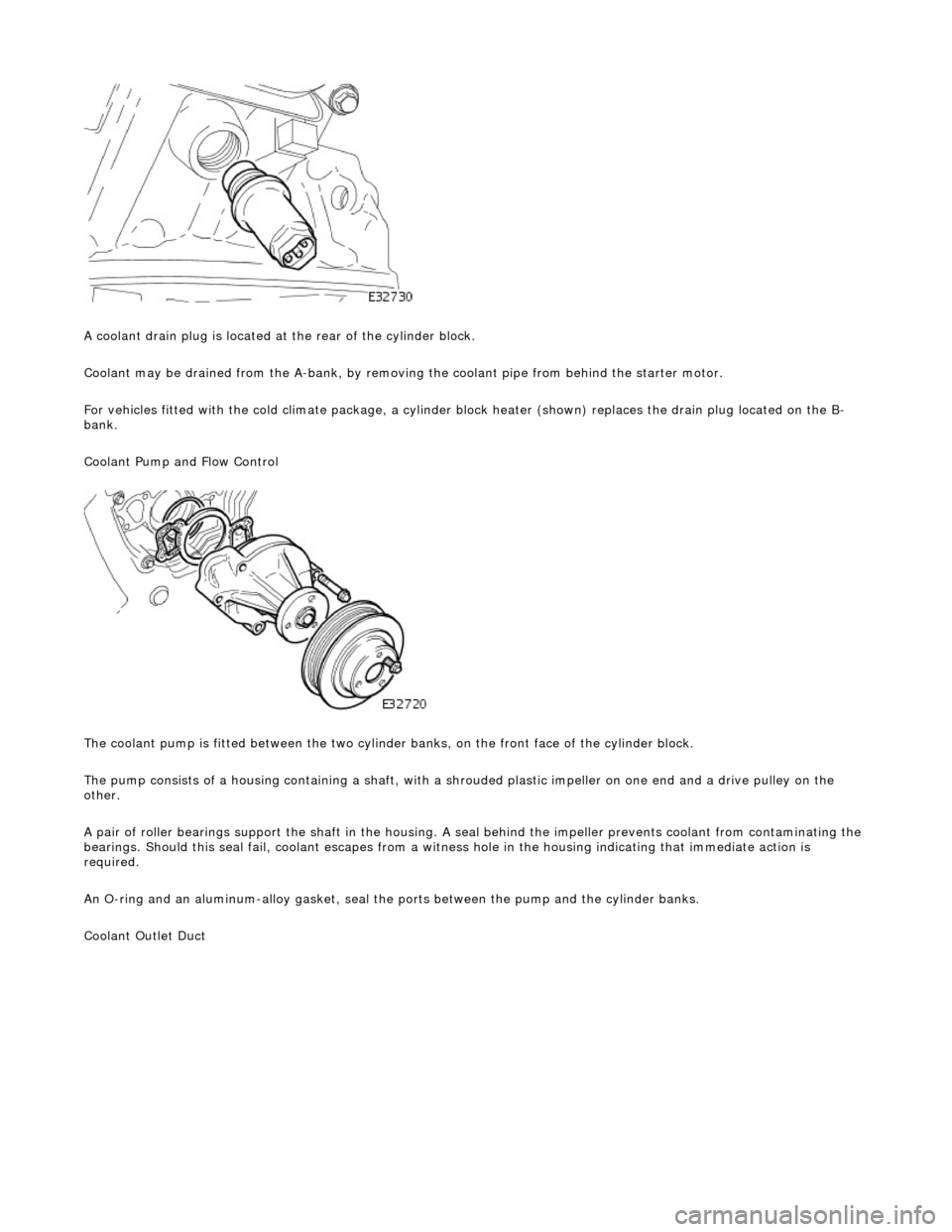

A coola n

t drain plug is located at the rear of the cylinder block.

Coolant may be drained from the A-bank, by removing the coolant pipe from behind the starter motor.

For vehicles fitted with the cold climate package, a cylinder block heater (shown) replaces the drain plug located on the B-

bank.

Coolant Pump and Flow Control

The coolant pump is fitted between the two cylinder banks, on the front face of the cylinder block.

The pump consists of a housing containing a shaft, with a sh rouded plastic impeller on one end and a drive pulley on the

other.

A pair of roller bearings support the shaft in the housing. A seal behind the impeller prevents coolant from contaminating the

bearings. Should this seal fail, coolant escapes from a witness hole in the housin g indicating that immediate action is

required.

An O-ring and an aluminum-alloy gasket, seal the ports between the pump and the cylinder banks.

Coolant Outlet Duct

Page 927 of 2490

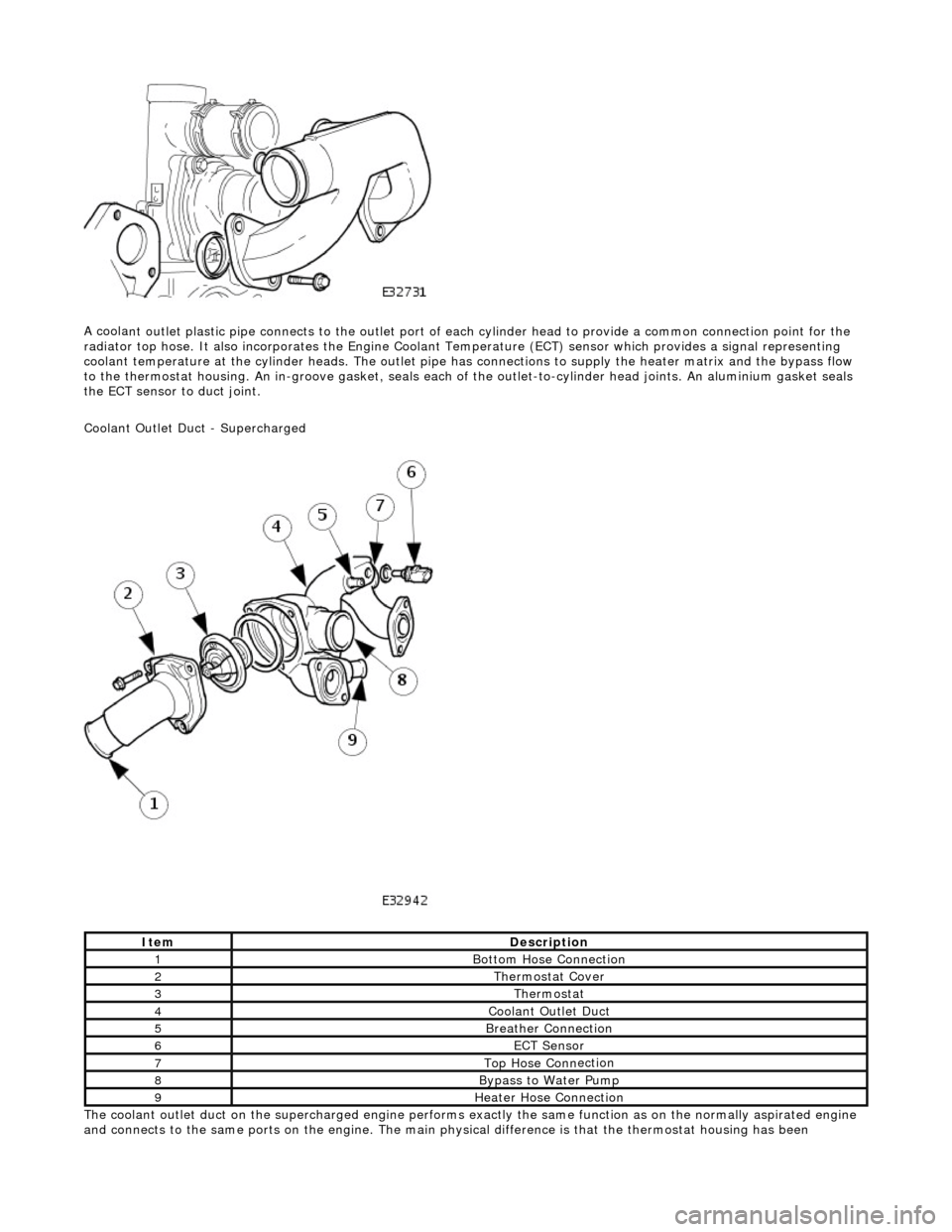

A coola

nt outlet plastic pipe connects to the outlet port of ea

ch cylinder head to provide a common connection point for the

radiator top hose. It also incorporates the Engine Coolant Te mperature (ECT) sensor which provides a signal representing

coolant temperature at the cylinder heads. The outlet pipe has connections to supply the heater matrix and the bypass flow

to the thermostat housing. An in-groove ga sket, seals each of the outlet-to-cylinder head joints. An aluminium gasket seals

the ECT sensor to duct joint.

Coolant Outlet Duct - Supercharged

The coolant outlet duct on the supercharged engine performs exactly the same function as on the normally aspirated engine

and connects to the same ports on the engine. The main physical difference is that the thermostat housing has been

ItemDe

scription

1Bottom

Hose Connection

2The

rmostat Cover

3The

rmostat

4Coolan

t Outlet Duct

5B

reather Connection

6ECT Se

nsor

7Top Hose Conn

ection

8Bypa

ss to Water Pump

9Hea

ter Hose Connection

Page 930 of 2490

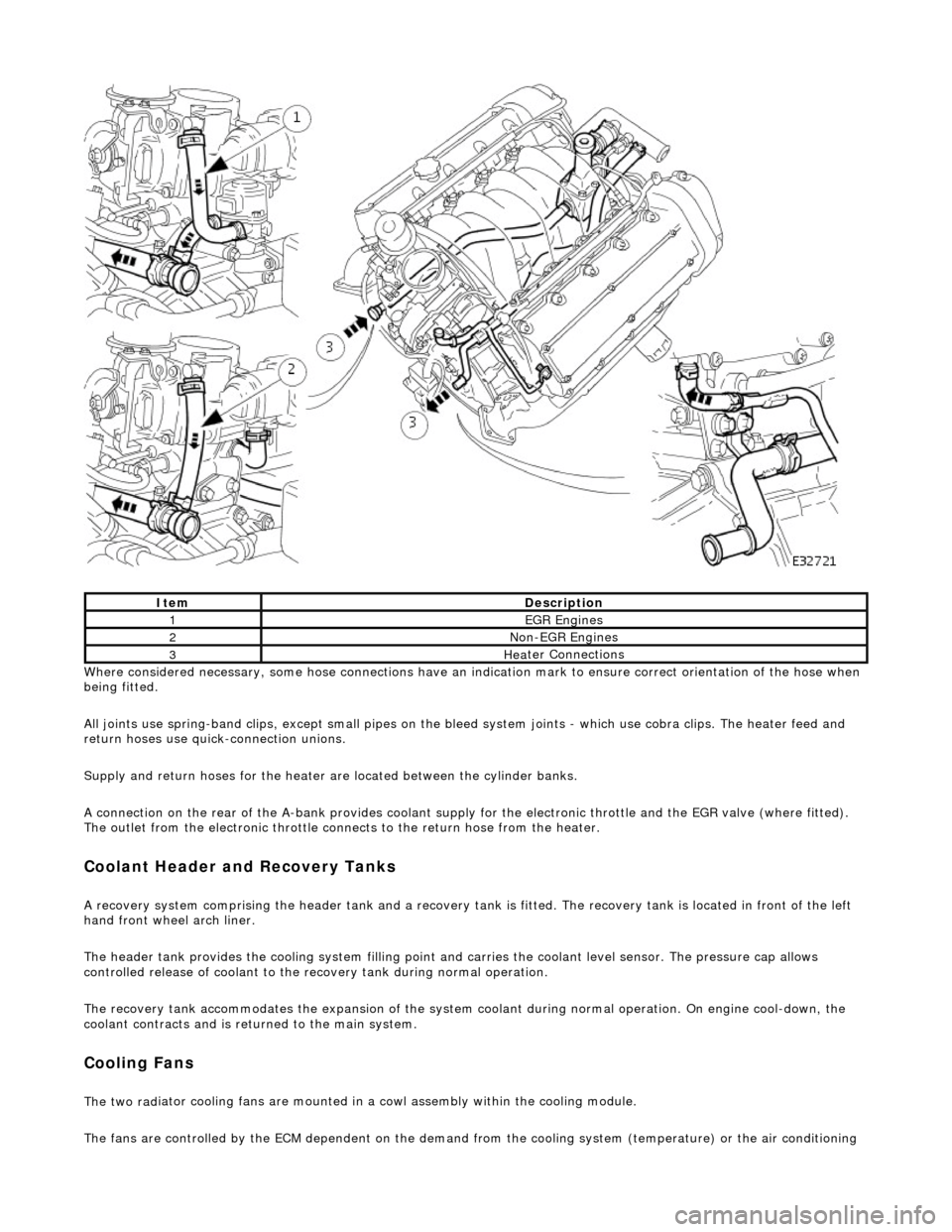

Whe r

e considered necessary, some hose conn

ections have an indication mark to ensure correct orientation of the hose when

being fitted.

All joints use spring-band clips, except small pipes on the bleed system joints - which use cobra clips. The heater feed and

return hoses use quick-connection unions.

Supply and return hoses for the heater are located between the cylinder banks.

A connection on the rear of the A-bank provides coolant supply for the electronic throttle and the EGR valve (where fitted).

The outlet from the electronic throttle connects to the return hose from the heater.

Cool

ant Header and Recovery Tanks

A recovery system comp

rising the header tank

and a recovery tank is fitted. The recove ry tank is located in front of the left

hand front wheel arch liner.

The header tank provides the cooling system filling point and carries the coolant level sensor. The pressure cap allows

controlled release of coolant to the re covery tank during normal operation.

The recovery tank accommodates the expansion of the system coolant during normal operation. On engine cool-down, the

coolant contracts and is returned to the main system.

Coo lin

g Fans

The two

rad

iator cooling fans are mounted in

a cowl assembly within the cooling module.

The fans are controlled by the ECM dependent on the demand fr om the cooling system (temperature) or the air conditioning

ItemDescrip

tion

1EGR

E

ngines

2Non

-

EGR Engines

3Hea

ter Connections

Page 957 of 2490

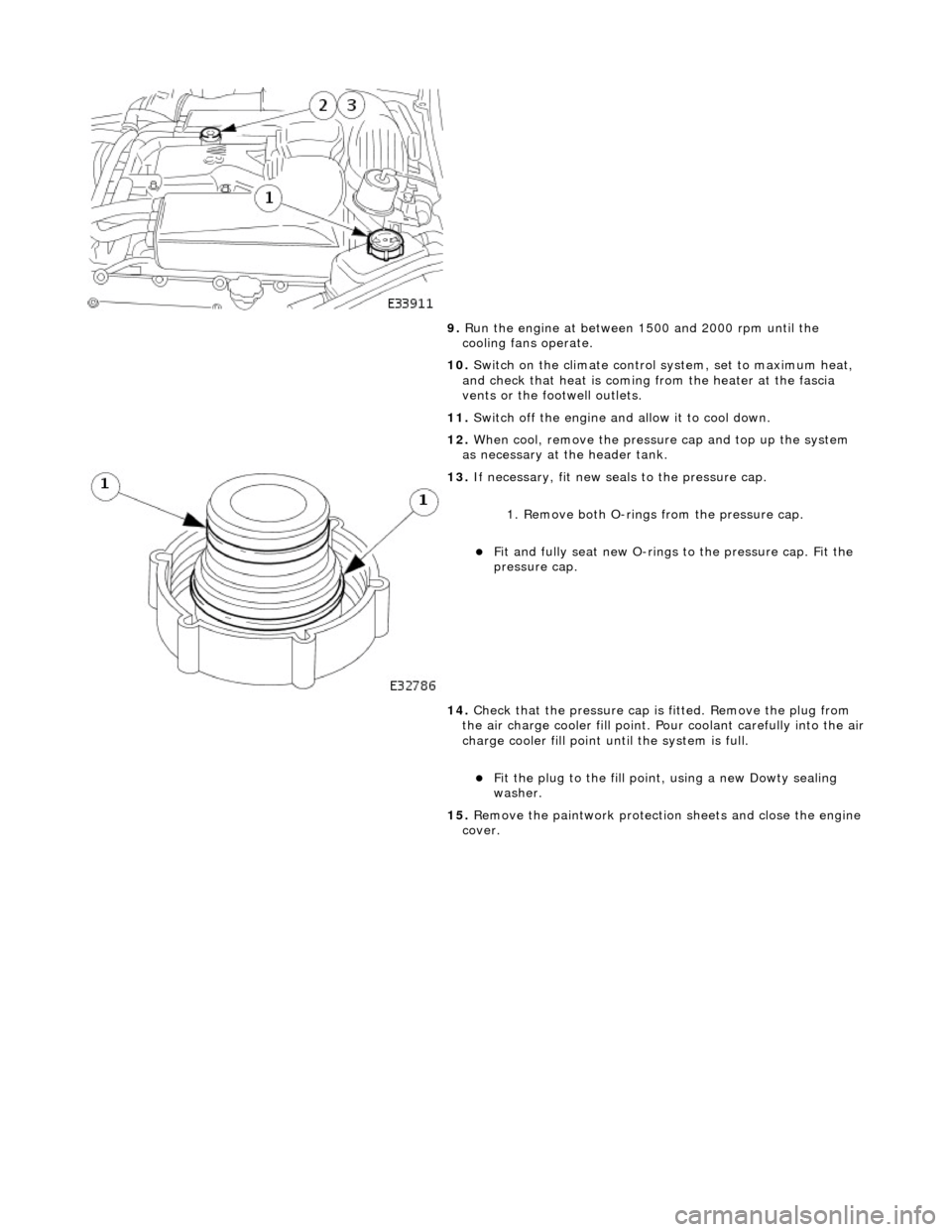

9.

R

un the engine at between 1500 and 2000 rpm until the

cooling fans operate.

10. Switch on the climate control system, set to maximum heat,

and check that heat is coming from the heater at the fascia

vents or the footwell outlets.

11. Switch off the engine and allow it to cool down.

12. When cool, remove the pressure cap and top up the system

as necessary at the header tank.

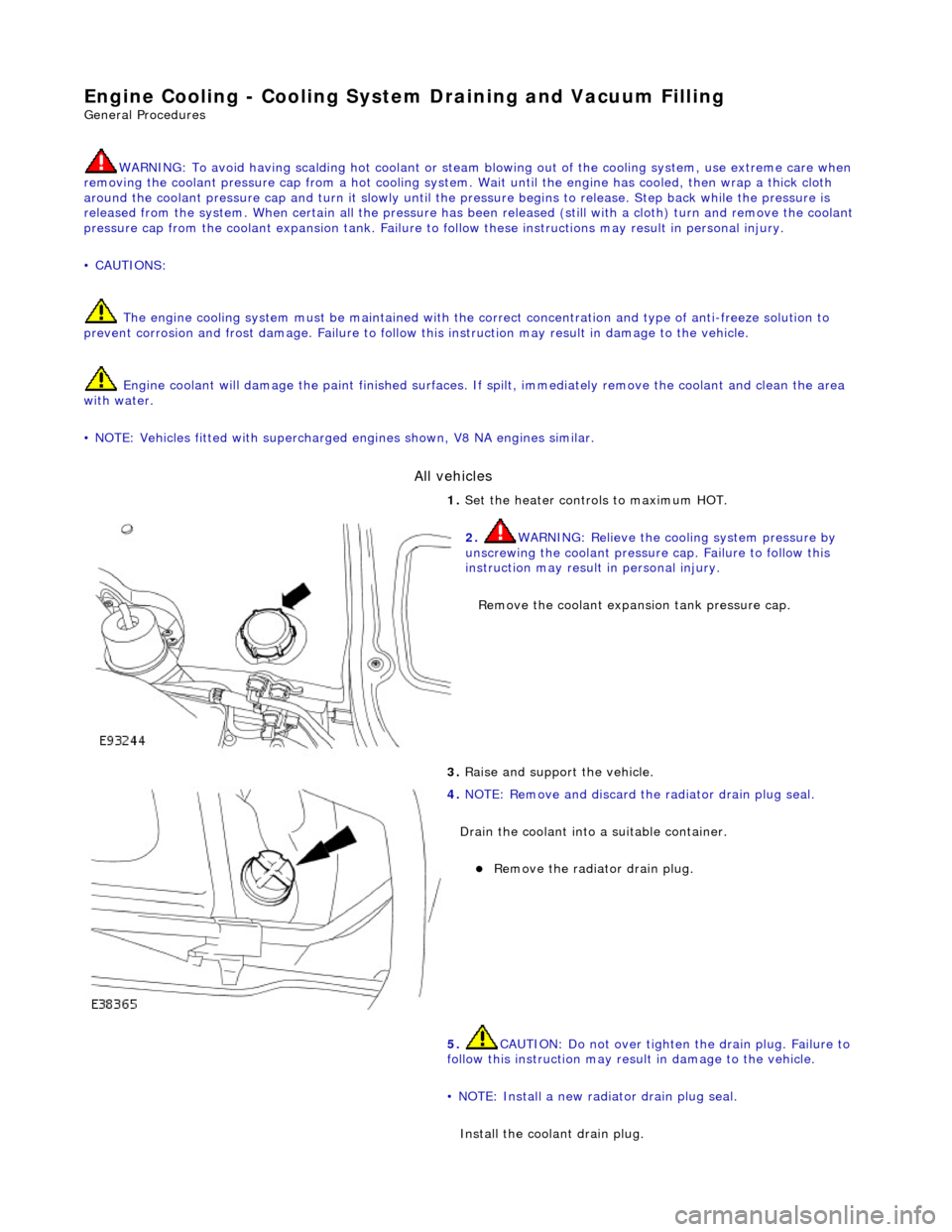

13

.

If necessary, fit new seals to the pressure cap.

1. Remove both O-rings from the pressure cap.

пЃ¬Fit and

fully seat new O-rings

to the pressure cap. Fit the

pressure cap.

14. Check that the pressure cap is fitted. Remove the plug from

the air charge cooler fill point. Pour coolant carefully into the air

charge cooler fill point until the system is full.

пЃ¬F

it the plug to the fill poin

t, using a new Dowty sealing

washer.

15. Remove the paintwork protection sheets and close the engine

cover.

Page 958 of 2490

Engine Cooling - Cooling System Draining and Vacuum Filling

Gene

ral Procedures

WARNING: To avoid having scalding ho t coolant or steam blowing out of the cooling system, use extreme care when

removing the coolant pressure cap from a hot cooling system. Wait until the engine has cooled, then wrap a thick cloth

around the coolant pressure cap and turn it slowly until the pressure begins to release. Step ba ck while the pressure is

released from the system. When certain al l the pressure has been released (still with a cloth) turn and remove the coolant

pressure cap from the coolant expansion tank. Failure to fo llow these instructions may result in personal injury.

• CAUTIONS:

The engine cooling syst em must be maintained with the correct concentration and type of anti-freeze solution to

prevent corrosion and frost damage. Failure to follow th is instruction may result in damage to the vehicle.

Engine coolant will damage the paint finished surfaces. If spilt, immediately remove the coolant and clean the area

with water.

• NOTE: Vehicles fitted with supercharged engines shown, V8 NA engines similar.

All vehicles

1. Set

the heater controls to maximum HOT.

2. WARN

ING: Relieve the cooling system pressure by

unscrewing the coolant pressure cap. Failure to follow this

instruction may result in personal injury.

Remove the coolant expans ion tank pressure cap.

3. Raise a

nd support the vehicle.

4. NOTE : Remov

e and discard the

radiator drain plug seal.

Drain the coolant into a suitable container.

пЃ¬Remove the radiato

r drain plug.

5. CAUTION: Do not over tighten the drain plug. Failure to

follow this instruction may result in damage to the vehicle.

• NOTE: Install a new radiator drain plug seal.

Install the coolant drain plug.

Page 965 of 2490

Engine Cooling - Coolant Outlet Pipe

Re

moval and Installation

Remov

al

Installation

1.

O

pen the engine compartment and fit paintwork protection

sheets.

2. Drain the radiator. Refer to Ge neral Procedures. Retain the

coolant drain tray in position to catch any spillage when

removing the outlet pipe.

3. Di

sconnect the hoses and multi-plug from the coolant outlet

pipe.

1. Release and reposition th e hose clip, and disconnect

the top hose.

2. Release and reposition th e hose clip, and disconnect

the heater hose.

3. Disconnect the multi-plug from the temperature sensor and unscrew the sens or from the outlet pipe.

4. Release and reposition the hose clip along the bypass

hose.

4. R

emove the coolant outlet pipe.

1. Remove the four bolts which secure the outlet pipe.

2. Remove the outlet pipe from the bypass hose and

from the cylinder heads.

5. Remove and discard the sealing rings from the outlet pipe

grooves.

1. Installation is the reverse of the remova l procedure. Use new

sealing rings on the coolant outlet pipe.

2. Tighten the coolant outlet pipe bolts to 10-14 Nm If replacing

the coolant temperature sensor, tighten to 15-19 Nm.

3. Refill the cooling system as de scribed in General Procedures.

Page 966 of 2490

Engine Cooling - Coolant Outlet Pipe

Remo

val and Installation

Remov

a

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Drain the radiator. Refer to Ge neral Procedures. Retain the

coolant drain tray in position to catch any spillage when

removing the outlet pipe.

3. Disc onne

ct the top hose and br

eather pipe from the coolant

outlet pipe.

1. Release and reposition th e hose clip, and disconnect

the top hose.

2. Release and disconnect the breather pipe quick fit connector.

3. Disconnect the multi-plug from the temperature sensor and unscrew the sens or from the outlet pipe.

4. Release and reposition the hose clip along the bypass

hose.

4. Disc

onnect the bottom hose

from the thermostat housing.

1. Release and reposition th e hose clip along the hose.

2. Disconnect the bottom hose.

5. Disc

onnect the coolant outlet pipe from the cylinder heads.

1. Remove the four bolts which secure the outlet pipe.

2. Remove the outlet pipe from the bypass hose and

from the cylinder heads (still connected to the

heater hose).

6. Release and reposition the clip which secures the heater hose

to the outlet pipe and disconnect the hose. Remove the outlet

pipe.

7. Remove the thermostat from the outlet pipe.

1. Remove the three bolts which secure the thermostat cover to the outlet pipe.

2. Remove the thermostat cover, the thermostat and

the seal from the outlet pipe. Discard the seal.

Page 1196 of 2490

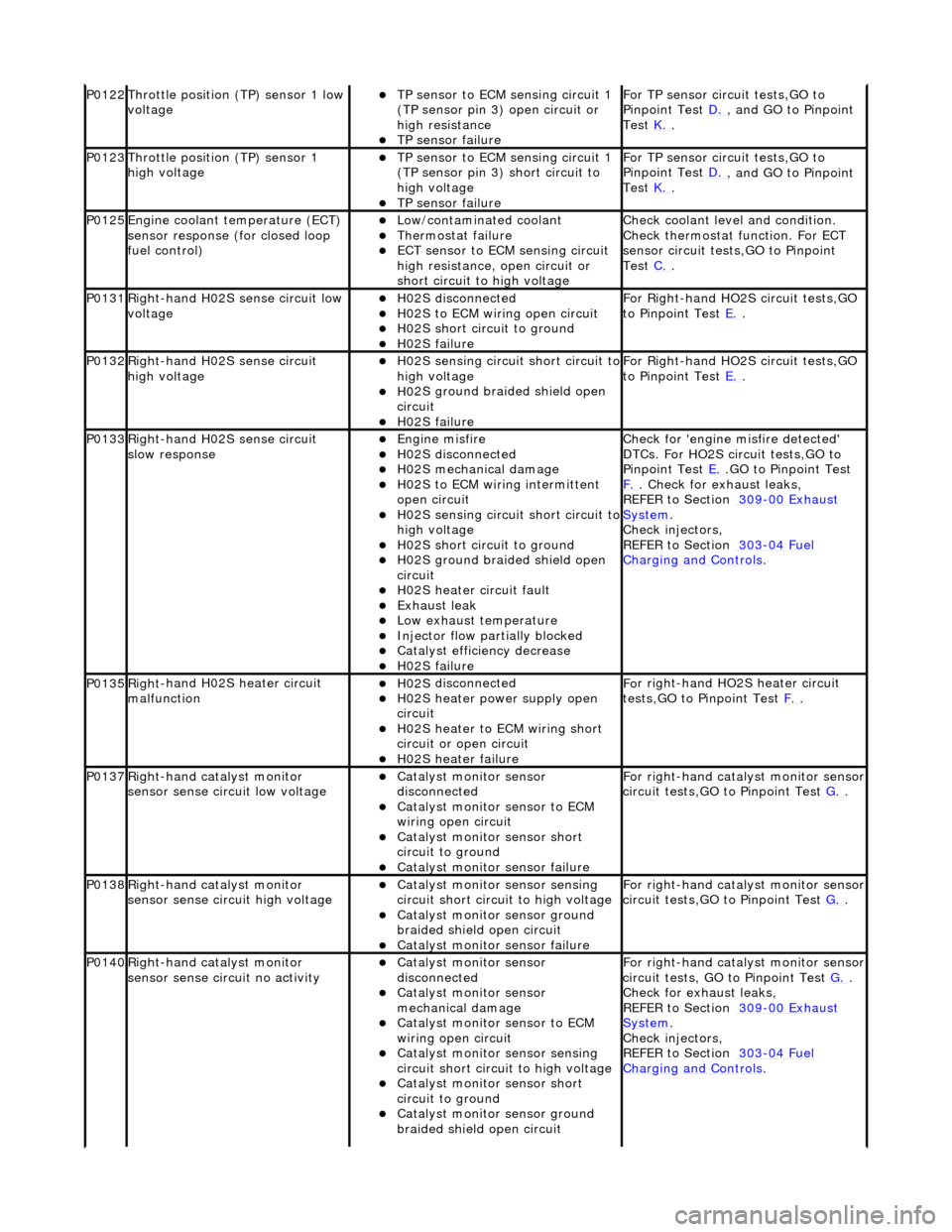

P0122Throttle

position (TP) sensor 1 low

voltage

пЃ¬TP se ns

or to ECM sensing circuit 1

(TP sensor pin 3) open circuit or

high resistance

пЃ¬TP sensor fail

ure

F

o

r TP sensor circ

uit tests,GO to

Pinpoint Test D.

, and GO

to Pinpoint

Test K.

.

P0123Throttl e

position (TP) sensor 1

high voltage

пЃ¬TP se ns

or to ECM sensing circuit 1

(TP sensor pin 3) short circuit to

high voltage

пЃ¬TP sensor fail

ure

F

o

r TP sensor circ

uit tests,GO to

Pinpoint Test D.

, and GO

to Pinpoint

Test K.

.

P0125En

gine coolant temperature (ECT)

sensor response (for closed loop

fuel control)

пЃ¬Low/contaminated coolant пЃ¬Therm o

stat failure

пЃ¬ECT se

ns

or to ECM sensing circuit

high resistance, open circuit or

short circuit to high voltage

Che c

k coolant level and condition.

Check thermostat function. For ECT

sensor circuit tests,GO to Pinpoint

Test C.

.

P0131Right -

hand H02S sense circuit low

voltage

пЃ¬H02 S

disconnected

пЃ¬H0

2S to

ECM wiring open circuit

пЃ¬H0

2S short ci

rcuit to ground

пЃ¬H0

2S fail

ure

F

or R

ight-hand HO2S circuit tests,GO

to Pinpoint Test E.

.

P0132Right-

hand H02S sense circuit

high voltage

пЃ¬H02 S

sensing circuit short circuit to

high voltage

пЃ¬H0 2S groun

d braided shield open

circuit

пЃ¬H0 2S fail

ure

F

or R

ight-hand HO2S circuit tests,GO

to Pinpoint Test E.

.

P0133Right-

hand H02S sense circuit

slow response

пЃ¬Engine m

isfire

пЃ¬H02

S

disconnected

пЃ¬H0

2S mechanical damage

пЃ¬H0

2S to

ECM wiring intermittent

open circuit

пЃ¬H02 S

sensing circuit short circuit to

high voltage

пЃ¬H02S short ci

rcuit to ground

пЃ¬H02S groun

d braided shield open

circuit

пЃ¬H0 2S heater circuit faul

t

пЃ¬Exhaus

t leak

пЃ¬Low e

x

haust temperature

пЃ¬Injector fl

ow parti

ally blocked

пЃ¬Catal

y

st efficiency decrease

пЃ¬H0

2S fail

ure

Chec

k for 'en

gine misfire detected'

DTCs. For HO2S circuit tests,GO to

Pinpoint Test E.

.G

O to Pinpoint Test

F.

. Check for exhaust leaks,

REF

ER to Section 309

-00

Ex

haust

Sy

ste

m

.

Chec k inje

ctors,

REFER to Section 303

-04 Fu

el

Charging and Cont

rols

.

P0135Right

-

hand H02S heater circuit

malfunction

пЃ¬H02 S

disconnected

пЃ¬H0

2S h

eater power supply open

circuit

пЃ¬H0 2S heater to ECM wi

ring short

circuit or open circuit

пЃ¬H0 2S heater fai

lure

F

o

r right-hand HO2S heater circuit

tests,GO to Pinpoint Test F.

.

P0137Right-

hand catalyst monitor

sensor sense circuit low voltage

пЃ¬Catal y

st monitor sensor

disconnected

пЃ¬Catal y

st monitor sensor to ECM

wiring open circuit

пЃ¬Catal y

st monitor sensor short

circuit to ground

пЃ¬Cat a

lyst monitor sensor failure

F

or ri

ght-hand catalyst monitor sensor

circuit tests,GO to Pinpoint Test G.

.

P0138Right -

hand catalyst monitor

sensor sense circuit high voltage

пЃ¬Catal y

st monitor sensor sensing

circuit short circuit to high voltage

пЃ¬Catalyst

monitor sensor ground

braided shield open circuit

пЃ¬Cata

lyst monitor sensor failure

F

or ri

ght-hand catalyst monitor sensor

circuit tests,GO to Pinpoint Test G.

.

P0140Right -

hand catalyst monitor

sensor sense circuit no activity

пЃ¬Catal y

st monitor sensor

disconnected

пЃ¬Catal y

st monitor sensor

mechanical damage

пЃ¬Catal y

st monitor sensor to ECM

wiring open circuit

пЃ¬Catal y

st monitor sensor sensing

circuit short circuit to high voltage

пЃ¬Cataly

st monitor sensor short

circuit to ground

пЃ¬Catalyst

monitor sensor ground

braided shield open circuit

F or ri

ght-hand catalyst monitor sensor

circuit tests, GO to Pinpoint Test G.

.

Check f o

r exhaust leaks,

REFER to Section 309

-00 Ex

haust

Sy

ste

m

.

Chec k inje

ctors,

REFER to Section 303

-04 Fu

el

Charging and Con

t

rols

.