battery JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1521 of 2490

Automatic Transmission/Transaxle External Contro ls - 4.0L SC V8 - AJ26 -

Selector Lever Knob

Removal and Installation

Removal

Installation

1.

Disconnect the vehicle battery ground lead.

2. Remove the select or lever knob.

1. Slacken the ferrule, rotate clockwise.

2. Rotate the knob coun ter-clockwise to remove.

1. Refer to the illustration.

1. Fit the knob.

2. Refer to the illustration.

Page 1534 of 2490

Pinpoint test A: P0131, P0132, P0135

between connections. ECM failure

*

DTC P0140 O2 sensor circuit no activity detected

(Bank 1 sensor 2)O2 sensor failure / out of spec

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. Low exhaust temperature

*

*

*

*

*GO to Pinpoint Test D

*

DTC P0420 Catalyst system efficiency below

threshold (bank 1)Downstream O2 sensor failure

Catalyst failure

Catalyst low temperature caused by

water splash

*

*

*GO to Pinpoint Test C

GO to Pinpoint Test D

*

*

DTC P0151 O2 sensor circuit low voltage (Bank 2

sensor 1)O2 sensor failure

Sensor ground fault

Harness failure

Connector pin(s) bent, loose or corroded

*

*

*

*GO to Pinpoint Test E

*

DTC P0152 O2 sensor circuit high voltage (Bank

2 sensor 1)O2 sensor failure to B+

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. O2 sensor failure

*

*

*

*

*GO to Pinpoint Test E

*

DTC P0153 O2 sensor circuit slow response

(Bank 2 sensor 1)O2 sensor heater failure / out of spec

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. Low exhaust temperature

O2 sensor failure

*

*

*

*

*

*GO to Pinpoint Test F

*

DTC P0155 O2 sensor heater circuit malfunction

(Bank 2 sensor 1)O2 sensor failure

Harness failure

Connector pin(s) bent or tracking

between connections. ECM failure

*

*

*

*GO to Pinpoint Test E

*

DTC P0157 O2 sensor circuit low voltage (Bank 2

sensor 2)O2 sensor failure

Sensor ground fault

Harness failure

Connector pin(s) bent, loose or corroded

*

*

*

*GO to Pinpoint Test G

*

DTC P0158 O2 sensor circuit high voltage (Bank

2 sensor 2)O2 sensor failure to B+

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. ECM failure

*

*

*

*

*GO to Pinpoint Test G

*

DTC P0160 O2 sensor circuit no activity detected

(Bank 2 sensor 2)O2 sensor failure / out of spec

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. Low exhaust temperature

*

*

*

*

*GO to Pinpoint Test H

*

DTC P0430 Catalyst system efficiency below

threshold (bank 2)Downstream O2 sensor failure

Catalyst failure

Catalyst low temperature caused by

water splash

*

*

*GO to Pinpoint Test G

GO to Pinpoint Test H

*

*

PINPOINT TEST A : P0131, P0132, P0135

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

A1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

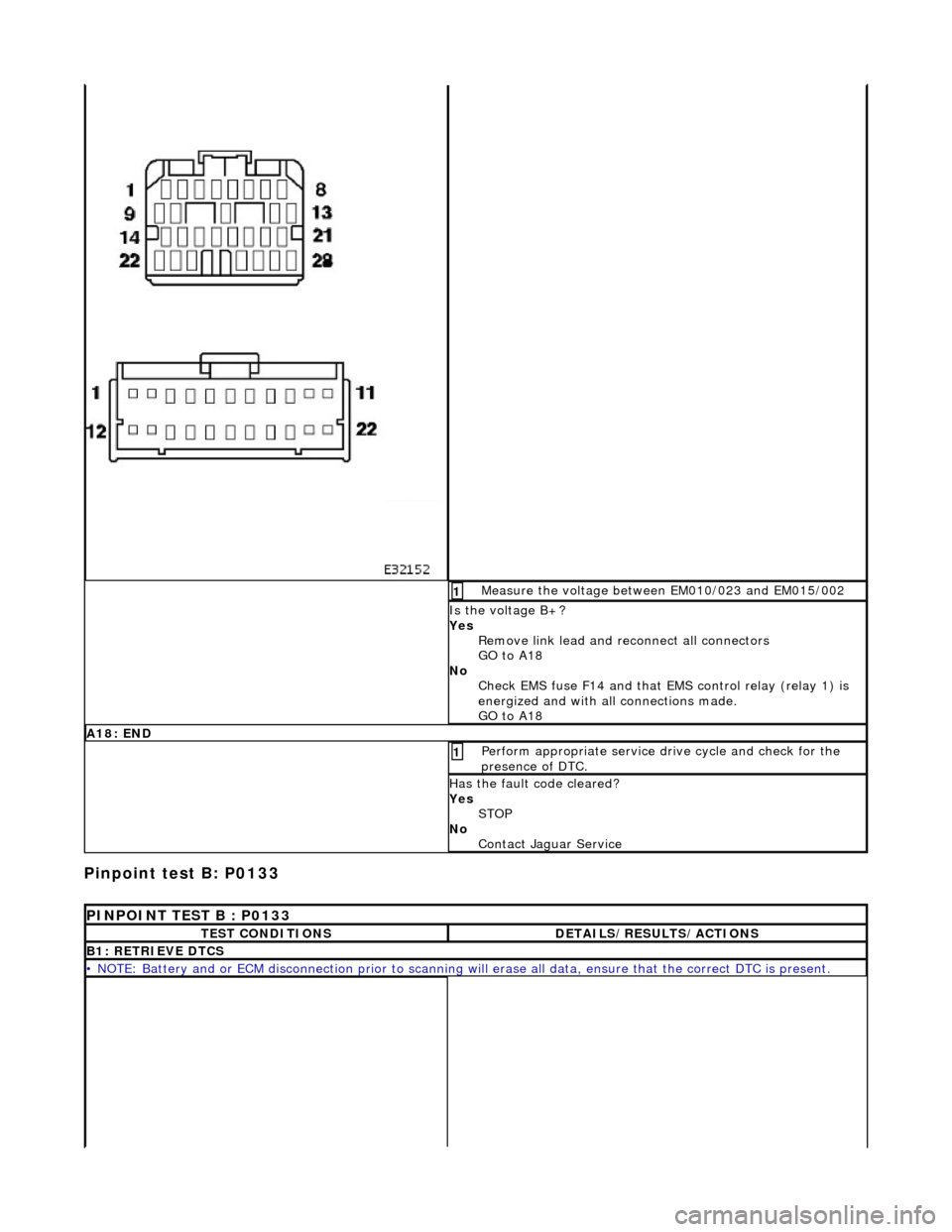

Page 1545 of 2490

Pinpoint test B: P0133

Measure the voltage between EM010/023 and EM015/002 1

Is the voltage B+?

Yes Remove link lead and reconnect all connectors

GO to A18

No Check EMS fuse F14 and that EMS control relay (relay 1) is

energized and with all connections made.

GO to A18

A18: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST B : P0133

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

B1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1557 of 2490

Pinpoint test C: P0137, P0138

Measure the voltage between EM010/023 and EM015/002. 1

Is the voltage B+?

Yes Remove link lead and reconnect all connectors.

GO to B19

No Check EMS fuse F14 and that EMS control relay (relay 1) is

energized and with all connections made.

GO to B19

B19: END

Perform appropriate service drive cycle and check for the

presence of DTC 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST C : P0137, P0138

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

C1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1569 of 2490

Pinpoint test D: P0140

Measure the insulation resistance between EM012/017 and

EM012/022. 1

Is the resistance > 10 MOHM?

Yes Reconnect all plugs

GO to C18

No Inspect harness / connector EM012 for corrosion, bent /

pushed back pins. Repair as re quired and reconnect plug(s).

GO to C18

C18: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes

STOP

No Contact Jaguar Service

PINPOINT TEST D : P0140

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

D1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1584 of 2490

Pinpoint test E: P0151, P0152, P0155

Measure the insulation resistance between EM012/017 and

EM012/022. 1

Is the resistance > 10 MOHM?

Yes Reconnect all plugs

GO to D21

No Inspect harness / connector EM012, EM015 and EM022 for

corrosion, bent / pushed back pins.

Repair as required an d reconnect plug(s).

GO to D21

D21: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST E : P0151, P0152, P0155

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

E1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1597 of 2490

Pinpoint test F: P0153

With EM010 and EM015 disconnected, measure the

voltage between EM010/023 and EM015/001. 1

Is the voltage B+?

Yes Remove link lead and reconnect all connectors.

GO to E18

No Check integrity of EMS fuse F1 4, EMS control relay (relay

1) is energized and all connections are made.

GO to E18

E18: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST F : P0153

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

F1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1609 of 2490

Pinpoint test G: P0157, P0158

With EM010 and EM015 disconnected, measure the

voltage between EM010/023 and EM015/002. 1

Is the voltage B+?

Yes Remove link lead and reconnect all connectors.

GO to F19

No Check integrity of EMS fuse F1 4, EMS control relay (relay

1) is energized and all connections made.

GO to F19

F19: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST G : P0157, P0158

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

G1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1624 of 2490

Pinpoint test H: P0160

Me

asure the insulation resistance between EM012/016 and

EM015/001.

1

I s

the resistance > 10 MOHM?

Yes Reconnect all plugs.

GO to G20

No Inspect harness / EM012, EM 015 and EM024 for corrosion,

bent / pushed back pins . Repair as necessary.

GO to G20

G2 0: END

Perform a

ppropriate service drive cycle and check for the

presence of DTC.

1

Has th

e fault code cleared?

Yes STOP

No Contact Jaguar Service

PI

NPOINT TEST H : P0160

T

E

ST CONDITIONS

D

E

TAILS/RESULTS/ACTIONS

H1

:

RETRIEVE DTCS

•

NOTE

: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

Page 1689 of 2490

Fuel System - General Information - Fuel System Pre

ssure Check

Gen

eral Procedures

WARNING: Working on the fuel system re sults in fuel and fuel vapor being present in the atmosphere. Fuel vapor is

extremely flammable, hence great care must be taken whilst working on the fuel system. Adhere strictly to the following

precautions:

пЃ¬D

o not smoke in the work area

пЃ¬Di

splay

NO SMOKING signs around the work area

пЃ¬D

isconnect the battery before

working on the fuel system

пЃ¬Av

oid sparks

пЃ¬Make sure sui

table fire ex

tinguishers are at hand

пЃ¬Make sure absor

bent material is at

hand to soak up any spillage

пЃ¬Make sure the work area is

well ventilated

пЃ¬M

ake sure that the gauge is correctly conn

ected, and that all connections are secure BEFORE starting the engine

пЃ¬DO N

OT

disconnect the gauge from the schrader valve while the engine is running

пЃ¬Make su

re the schrader valve reseals once the gauge is disconnected

• NOTE: Depending on the design of the ga uge set, there may be a drain valve and tube. Make sure this valve is closed, and

the drain tube placed in a suitable container BEFORE connecting the gauge to the schrader valve.

1. Make sure the vehi

cle is in

Park for vehicles with automatic

transmission, Neutral for vehicles with manual transmission.

2. Apply the parking brake.

3. Place suitable absorbent material around the schrader valve to

absorb any spillage when connecting the gauge set.

4. Remove the protective cap from the schrader valve.

5. Connect the gauge, using adaptors if required.

6. Remove the absorbent material and dispose of safely.

7. Disconnect and plug the vacuum hose from the pressure

regulator.

8. Start the engine and record the fuel pressure reading.

пЃ¬As a gui

de, the fuel pressu

re should be approximately 3.0

bar (44.1 psi) with the regulator disconnected.

9. With the engine still running, reconnect the vacuum hose to

the pressure regulator an d record the reading.

пЃ¬Th

e pressure should dr

op to approximately 2.6 bar (38

psi) when the vacuum hose is reconnected.

10. Switch off the engine.

11. Place more absorbent material around the schrader valve.

12. Where fitted, open the drain valve and allow the fuel from the

gauge and line to flow into the container to depressurize the

system.

13. Disconnect and remove the gauge set and any adaptors.

14. Clean up any fuel which may have been spilt and remove the

absorbent material. Dispose of safely.

15. Refit and secure the protective cap to the schrader valve.

16. Reconnect the fuel pressure regulator vacuum hose.

17. Start the engine and make sure there are no leaks.