lock JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1508 of 2490

Automatic Transmission/Transaxle External Contro ls - 4.0L SC V8 - AJ26 -

Brake Shift Interlock Actuator Manual Override

General Procedures

1. To override the gearshift interlock:

1. Unscrew the release catch blanking plug.

2. Insert the ignition key into the aperture, depress the release catch and simultan eously move the gear

selector lever from the Park position. The lever will

only move approximately 25 mm with the key

inserted.

3. Remove the ignition key and replace the blanking plug.

Page 1510 of 2490

Automatic Transmission/Transaxle External Contro ls - 4.0L SC V8 - AJ26 -

Selector Lever Cable Adjustment

General Procedures

1.

Disconnect the vehicle battery ground lead.

2. Position the gear sele ctor lever to N.

3. Remove the J-gate surround, Section 501-05.

4. Remove the console finisher ve neer panel, Section 501-12.

5. Remove the center console assembly, Section 501-12.

6. Slacken the selector cable lock ing nuts and screw them away

from the abutment.

7. Raise the vehicle for access.

8. Verify that the transmis sion selector lever is at position ( N ).

At the transmission, detach the inner cable from the

selector lever.

With the lever moved fully rearward, push the lever

forward two detents to achieve N.

1. Reconnect the inner cable.

9. NOTE: When setting the selector cable, ensure that the

transmission selector does no t move from the (N) position.

Adjust the selector cable from inside the vehicle. 1. Position the gear select or lever to the N detent.

2. Adjust the nuts to lock against the bracket without moving the set position of either the gear selector

lever or the select or lever on the transmission case.

3. Tighten to specification.

4. Verify the ( N ) setting.

10. Further installation is the reve rse of the removal procedure.

Page 1511 of 2490

Automatic Transmission/Transaxle External Contro ls - 4.0L SC V8 - AJ26 -

Brake Shift Interlock Actuator

Removal and Installation

Removal

Installation

1.

Disconnect the vehicle battery ground lead.

2. Remove the J-gate surround, Section 501-05.

3. Remove the console finisher ve neer panel, Section 501-12.

4. Remove the interlock so lenoid lever cover.

5. Remove the gearshift interlock solenoid.

1. Remove the (2) solenoid nuts.

2. Detach the solenoid from the latch pin.

3. Disconnect the solenoid multiplug.

1. Installation is th e reverse of the re moval procedure.

2. Refer to the illustration.

Page 1512 of 2490

Automatic Transmission/Transaxle External Contro ls - 4.0L SC V8 - AJ26 -

Kickdown Switch

Removal and Installation

Removal

Installation

1. Disconnect the kickdown switch multiplug.

Move the carpet for access.

2. Remove the kickdown switch.

Rotate counter-clockwise.

1. Installation is th e reverse of the re moval procedure.

2. The kickdown switch MUST be adjusted in accordance with

(44.15.38).

Page 1514 of 2490

Installation

2. Slacken the outer cable locknuts.

13. Push the outer cable grommet through the transmission

tunnel aperture.

14. Remove the selector cable assembly from the vehicle.

1. Assemble the cable to the gear shift assembly.

1. Locate the outer cable and fit the inner cable to the gear selector arm. Tighten to the specified torque

figure.

2. Position the abutment nuts to the approximate position, but do not tighten.

2. Fit the cable to the transmission and tighten the fixings to the

specified torque figure.

Page 1518 of 2490

Automatic Transmission/Transaxle External Contro ls - 4.0L SC V8 - AJ26 -

Transmission Control Switch (TCS)

Removal and Installation

Removal

Installation

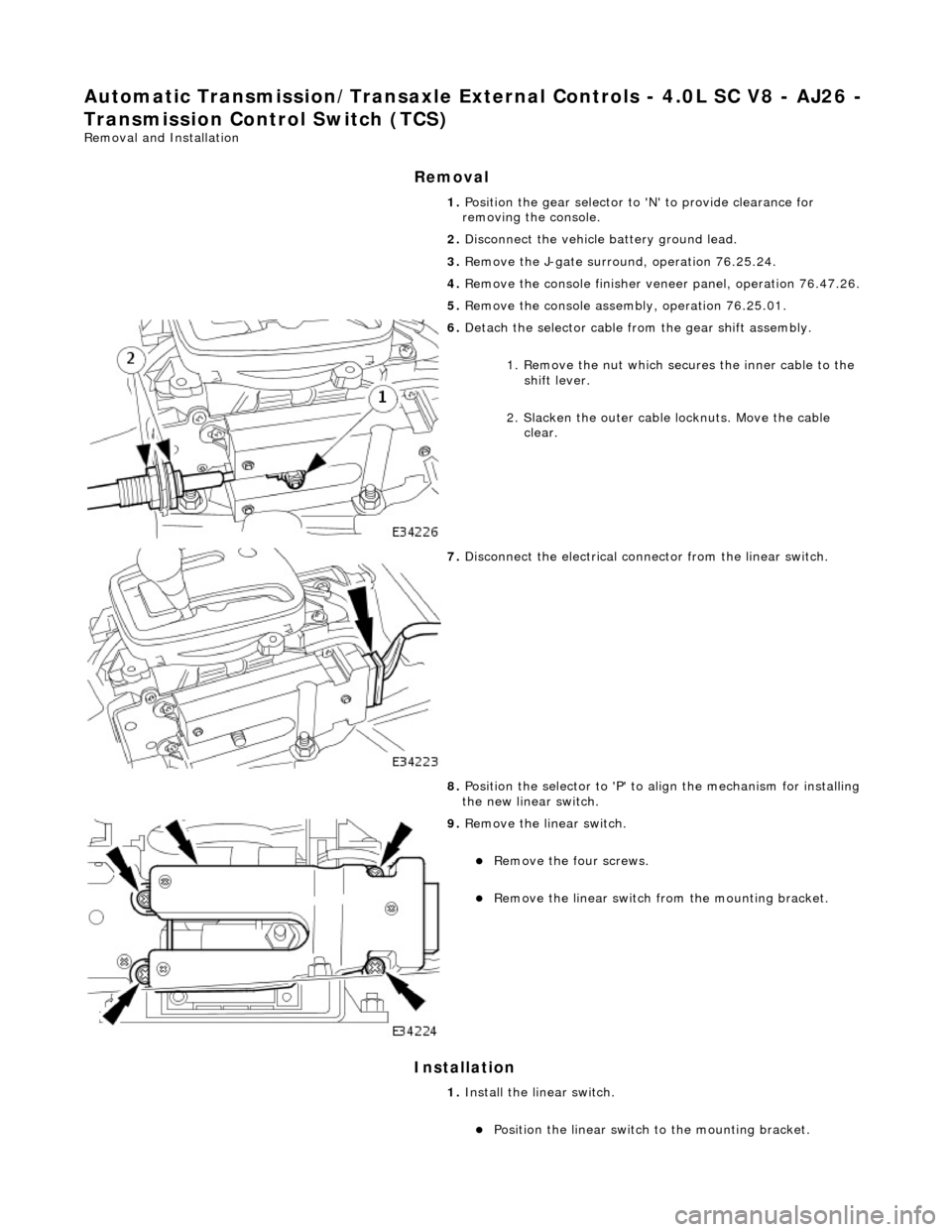

1. Position the gear selector to 'N' to provide clearance for

removing the console.

2. Disconnect the vehicle battery ground lead.

3. Remove the J-gate surroun d, operation 76.25.24.

4. Remove the console finisher vene er panel, operation 76.47.26.

5. Remove the console assembly, operation 76.25.01.

6. Detach the selector cable from the gear shift assembly.

1. Remove the nut which secures the inner cable to the shift lever.

2. Slacken the outer cable locknuts. Move the cable clear.

7. Disconnect the electrical conne ctor from the linear switch.

8. Position the selector to 'P' to align the mechanism for installing

the new linear switch.

9. Remove the linear switch.

Remove the four screws.

Remove the linear switch fro m the mounting bracket.

1. Install the linear switch.

Position the linear switch to the mounting bracket.

Page 1519 of 2490

Align the drive peg and lower sliding block of the switch to

the mating components of the selector mechanism.

2. Install the four screws, bu t do not fully tighten.

Remove the Ty-Strap from the dual linear switch.

Use the manual release and repo sition the selector to 'N'

for installation of the selector cable.

3. Connect the electrical connector to the linear switch.

4. Assemble the cable to the gear shift assembly.

1. Locate the outer cable and fit the inner cable to the gear selector arm. Tighten to 22-28 Nm.

2. Position the abutment nuts to the approximate position, but do not tighten.

5. NOTE: When setting the selector cable, ensure that the

selector lever on the transmission ca sing is still in the 'N' position.

Adjust the selector cable from inside the vehicle.

1. Confirm that the selector lever is in the 'N' position.

2. Adjust the nuts to lock against the bracket without

Page 1521 of 2490

Automatic Transmission/Transaxle External Contro ls - 4.0L SC V8 - AJ26 -

Selector Lever Knob

Removal and Installation

Removal

Installation

1.

Disconnect the vehicle battery ground lead.

2. Remove the select or lever knob.

1. Slacken the ferrule, rotate clockwise.

2. Rotate the knob coun ter-clockwise to remove.

1. Refer to the illustration.

1. Fit the knob.

2. Refer to the illustration.

Page 1693 of 2490

Filler Cap and P

ipe

The fuel

filler cap with bayonet-type fixi

ng is located beneath a remote-release sp ring-latched lid on the rear saddle panel

on the left-hand-side of the vehicle.

Fuel Pum

p

The fu

el pump(s) is energized by an ECM co

ntrolled relay. Fuel is drawn by this pu mp and supplied to the fuel injectors via

the fuel line, filter and fuel rails.

Servicing of the fuel pump re quires fuel tank removal.

Ev

aporative Loss Flange Assembly

The evaporative-loss flan

ge asse

mbly is mounted centrally on top of the tank. The flange assembly consists of a removeable

steel cap which mounts the evaporative emissions system vapor outlet valves and, if applicable, a pressure sensor. The

external electrical supply to th e fuel pump(s) is also made via a connector on the flange.

The flange assembly is fixed to the tank by a locking ring which is turned usin g special tool JD-174. A seal is fitted between

the flange assembly and the tank. Three di fferent flange assemblies are applicable according to the evaporative emission

system fitted to the vehicle. The fl ange size and fixing are identical fo r the three systems, as described.

Removal of the evaporative flange assembly is necessary to gain access to th e fuel pump(s) and other internal components.

To remove the evaporative fl ange assembly the fuel tank must first be removed.

The evaporative flange variant assemblies are described, together with service information, in Section 303-13.

Fuel R

eturn

Excess fuel

is directed back to

the fuel tank via a return line.

Fuel Pum

p Relay

The

fuel pump relay,

under control of the ECM, switches power to the fuel pump motor.

I

nertia Fuel Shutoff (IFS) Switch

The IF

S switch is located in the right-hand

side footwell behind the footboard carpet . When activated the switch isolates the

ignition system and fuel pump, releases any locked doors and disables unnecessary electrical systems. The system can be

reset by pressing down the flexible cover on the top of the switch.

• NOTE: The doors will not unlock if the IFS switch is tripped when the ignition switch is in position '0'.

Page 1694 of 2490

P a

rts List

The fuel level sensor is mounte d on the fuel tank vertical face and reacts to level changes via a float and pivot which is

connected to a potentiometer. As the fuel level drops the resistance increases.

The fuel level sensor can be serviced without removing the tank.

It e

m

Par

t

Number

De

scr

iption

1—Lockin

g rin

g

2—Fue

l

level sensor

3—Seal

Fuel

Level Sensor