lock JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1735 of 2490

10

.

Disconnect the fuel feed and return pipes from the fuel tank

F

it special tool JD-203 around

the pipe as shown. Press

the tool in between the fuel pipe and tank connector to

release the quick-fit tangs. While holding the tool firmly in,

pull out the fuel pipe.

Repeat

for the second pipe.

Plu

g the tank outlet connectors and the fuel pipes.

11

.

From the underside of the vehicl e, release the fuel filler latch

box drain pipe from the clip on the spare wheel well.

12

.

Disconnect and reposition the tr unk harness if it is routed

between the filler tube and the ta nk breather or pressure relief

pipe.

1. Disconnect the lefthand re ar lamp harness connector.

2. Disconnect the fuel flap lock actuator connector.

3. If fitted, disconnect the lefthand side marker lamp

connector and harness fro m the underside of the

vehicle. Withdraw the marker lamp harness and

grommet through the trunk floor access hole.

4. Release the harness securi ng clip from the mounting

bracket.

Wi

thdraw the trunk harness from between the filler tube

and the breather pipe or pressure relief pipe.

13. Disconnect the tank harness connections.

Page 1738 of 2490

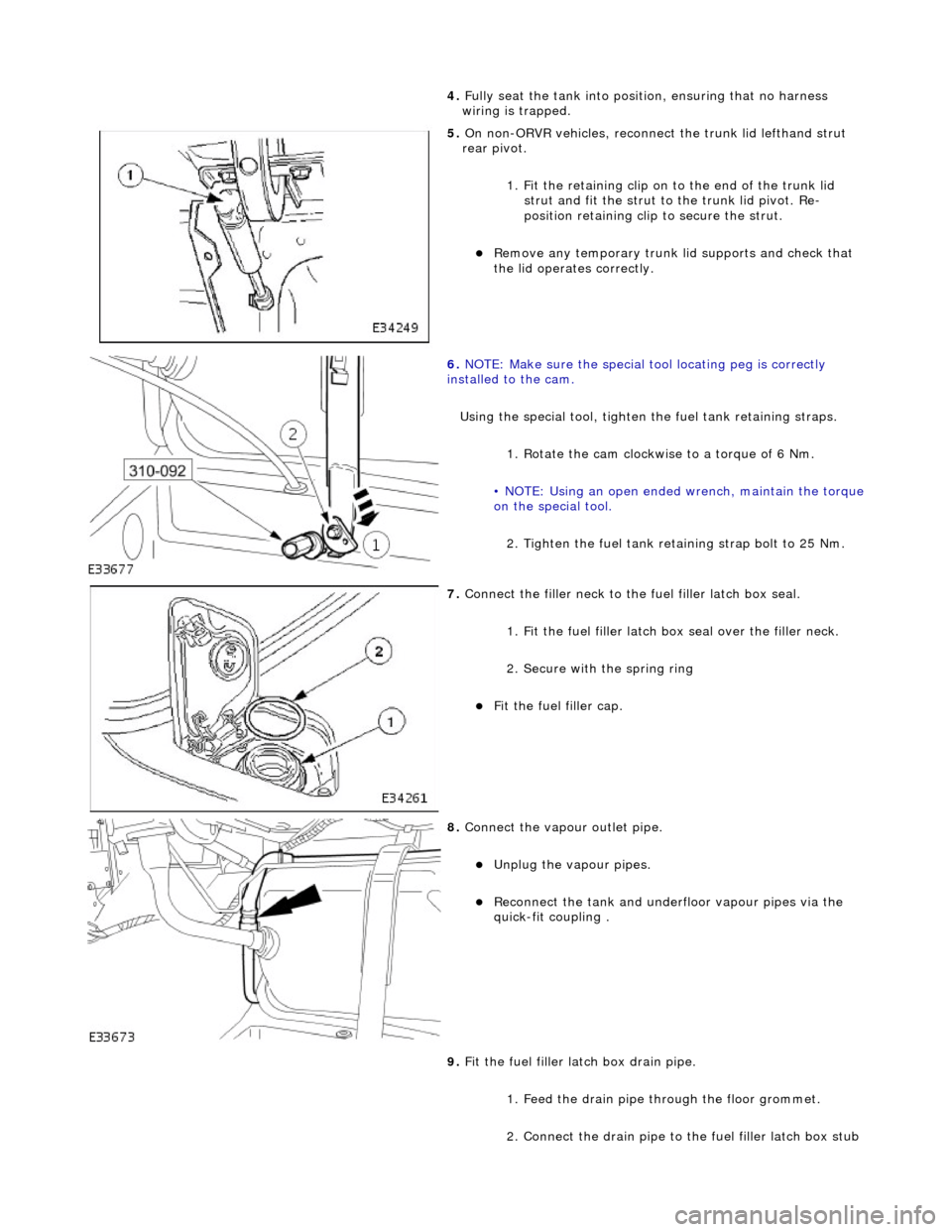

4. Full

y seat the tank into positi

on, ensuring that no harness

wiring is trapped.

5. On non-

ORVR vehicles, reconnec

t the trunk lid lefthand strut

rear pivot.

1. Fit the retaining clip on to the end of the trunk lid strut and fit the strut to the trunk lid pivot. Re-

position retaining clip to secure the strut.

Re

move any temporary trunk lid supports and check that

the lid operates correctly.

6. NOTE

: Make sure the special tool locating peg is correctly

installed to the cam.

Using the special tool, tighten the fuel tank retaining straps.

1. Rotate the cam clockwise to a torque of 6 Nm.

• NOTE: Using an open ended wrench, maintain the torque

on the special tool.

2. Tighten the fuel tank reta ining strap bolt to 25 Nm.

7. Connect the fi

ller neck to the fuel filler latch box seal.

1. Fit the fuel filler latch box seal over the filler neck.

2. Secure with the spring ring

F i

t the fuel filler cap.

8. Connect the vapour outlet pip

e.

Unplug the v

a

pour pipes.

Reconn

ect th

e tank and underfloor vapour pipes via the

quick-fit coupling .

9. Fit the fuel filler latch box drain pipe.

1. Feed the drain pipe th rough the floor grommet.

2. Connect the drain pipe to the fuel filler latch box stub

Page 1739 of 2490

pipe.

3

. Tie the drain pipe to th

e filler tube using a ratchet

strap. Trim strap.

10

.

Reconnect the trunk harness connections.

1. If fitted, connect the wi ring to the accelerometer.

2. Connect the wiring to the fuel level sensor harness.

3. Connect the wiring to th e fuel pump connector.

4. If fitted, connect the wiring to the pressure sensor connector.

11

.

Reconnect the lefthand side trunk harness if it has been

necessary to move it for access. Route the harness behind both

the filler tube and breather or pressure relief pipe.

1. Fit the harness securing cl ip to the mounting bracket.

2. Connect the fuel flap lock actuator connector.

3. Connect the lefthand rear lamp harness connector.

4. If applicable, feed the side marker lamp harness through the access hole in the floor and reseat the

sealing grommet.

On

the underside of the vehicl

e, fit the side marker lamp

connector and fix the harness to the securing clips.

12

.

On the underside of the vehicle, fit the drain pipe to the

securing clip.

13. On the underside of the vehicle, reconnect the fuel feed and

return pipes.

R

emove the plugs from the tank

and fuel feed and return

Page 1743 of 2490

Accelerati

on Control - Accelerator Cable Adjustment

Gen

eral Procedures

1.

Load the Approved Jaguar Diagno stic System with power train

data logger.

2. Connect the Approved Jaguar Diag nostic System to the vehicle.

3. W

ith 'Disable Network Integrity Test - YES/ NO' displayed on

the screen select YES.

4. With new menu displayed on the screen, select ' Engine

Management'.

5. Turn the ignition to ON.

R

emove any previously selected data logger parameters.

6. On data logger select PPS11 an d PPS2 (Pedal demand sensors

1 and 2).

7. On Sedan models only, remove the bulkhead covers on both

sides and the engine compartment rear cover.

8. Cut, remove and discard the ra tchet strap which retains the

throttle cable to the abutment bracket.

9. Ensure there is no tension on the throttle cable by releasing

the throttle cable adjustment nut from the abutment bracket.

10. Record the voltages for both sensors, PPS11 and PPS2.

11. Partially insert the throttle cable adjustment nut into the

abutment bracket.

12. Recheck the voltages for both sensors, PPS11 and PPS2.

13. Where the voltages at step 12 are higher than the voltages

taken at step 10, contin ue to step 15 below.

14. Where the voltages at step 12 are the same as the voltages

taken at step 10, contin ue to step 16 below.

15. Rotate the adjustment nut clockwise (as viewed from the

front of the vehicle) until the same voltages are indicated as in

step 10. Continue to turn thro ugh a part revolution until the

sides of the nut are vertical. Tu rn through a further 90 degrees,

then fully insert the nut into the abutment bracket.

16. Rotate the adjustment nut anti-clockwise (as viewed from the

front of the vehicle) until the indicated voltage starts to

increase. Then rotate the nut clockwise through a part

revolution until the sides are ve rtical. Turn through a further 90

degrees, then fully insert the nut into the abutment bracket.

17. Fit a new ratchet strap to secure the throttle cable adjusting

nut to the abutment bracket.

18. Operate the throttle pedal through 20 full cycles to settle the

cable. Check the voltages now shown, remain the same as in

steps 15 and 16.

19. Check and where necessary adjust the kickdown switch. For

additional information, refer to Section 307

-05A Automatic Transmissi

on/Transaxle External Controls

Sectio

n

307

-05

B

Au

tomatic Transmission/Tra

nsaxle External Controls

.

20

.

On Sedan models only, refit the engine compartment rear

cover and the bulkhead co vers on both sides.

21. Switch the ignition OFF and disconnect the Approved Jaguar

Diagnostic System.

Page 1756 of 2490

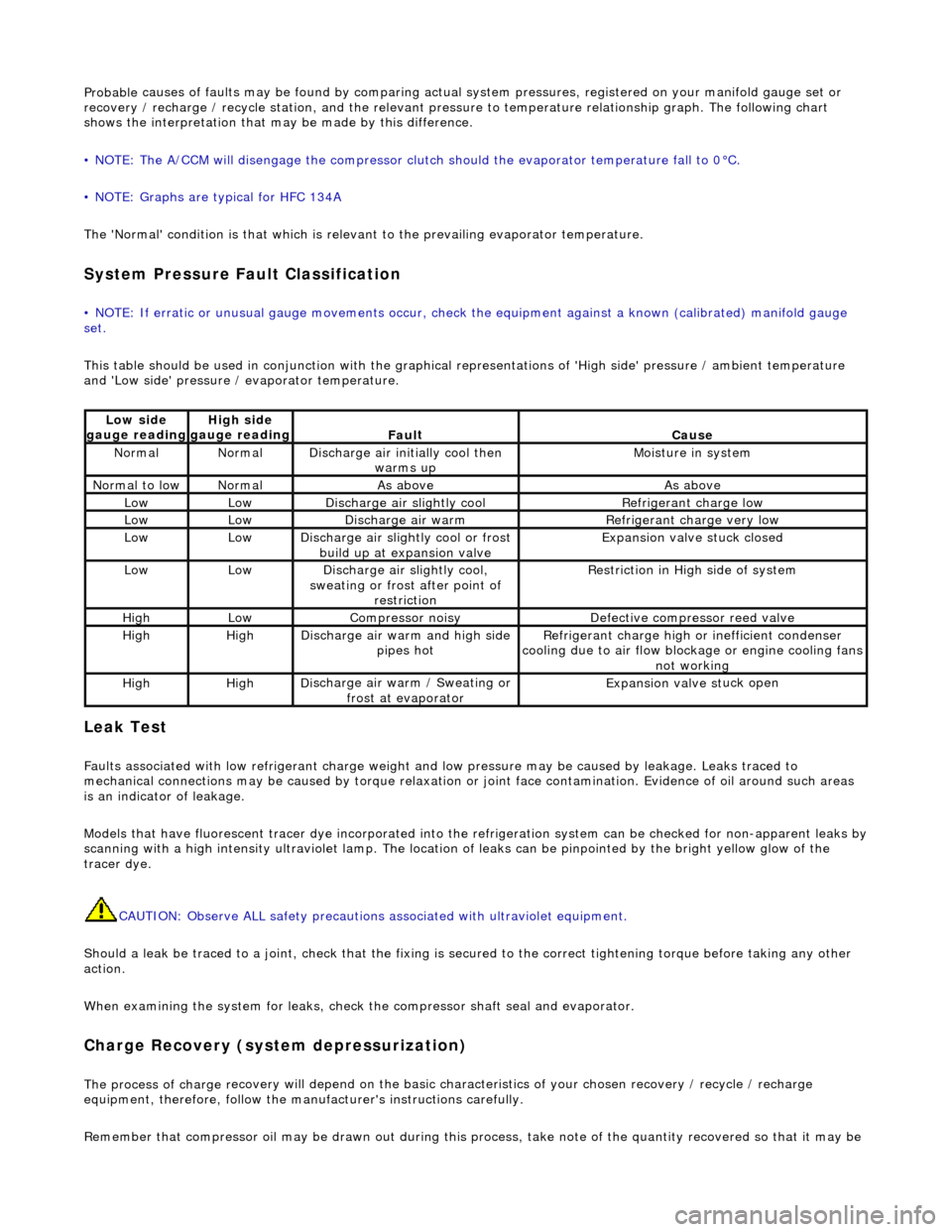

Probable

causes of faults may be found by comparing actual

system pressures, registered on your manifold gauge set or

recovery / recharge / recycle station, and the relevant pressure to temperature relationship graph. The following chart

shows the interpretation that ma y be made by this difference.

• NOTE: The A/CCM will disengage the compressor clutch should the evaporator temperature fall to 0°C.

• NOTE: Graphs are typical for HFC 134A

The 'Normal' condition is that which is relevant to the prevailing evaporator temperature.

System Pressure Fault Classification

• NOTE

: If erratic or unusual gauge move

ments occur, check the equipment against a known (calibrated) manifold gauge

set.

This table should be used in conjunction with the graphical representations of 'High side' pressure / ambient temperature

and 'Low side' pressure / evaporator temperature.

Leak

Test

F

a

ults associated with low re

frigerant charge weight and low pressure ma y be caused by leakage. Leaks traced to

mechanical connections may be caused by to rque relaxation or joint face contamination. Evidence of oil around such areas

is an indicator of leakage.

Models that have fluorescent tracer dye incorporated into the refrigeration system can be checke d for non-apparent leaks by

scanning with a high intensity ultraviolet lamp. The location of leaks can be pinpointed by the bright yellow glow of the

tracer dye.

CAUTION: Observe ALL safety precautions associated with ultraviolet equipment.

Should a leak be traced to a joint, check that the fixing is secured to the correct tightening torque before taking any other

action.

When examining the system for leaks, chec k the compressor shaft seal and evaporator.

Charge Re

covery (system depressurization)

The process of

charge r

ecovery will depe

nd on the basic characteristics of your chosen recovery / recycle / recharge

equipment, therefore, follow the manu facturer's instructions carefully.

Remember that compressor oil may be drawn out during this process, take note of the quantity recovered so that it may be

Lo

w side

gauge reading

High s i

de

gauge reading

Fau l

t

Cause

No

r

mal

No

r

mal

Di

sc

harge air initially cool then

warms up

Mois

ture in system

N

ormal

to low

No

r

mal

As aboveAs above

LowLowD

i

scharge air slightly cool

Ref

r

igerant charge low

LowLowDi

scharge air warm

Refr

igerant charge very low

LowLowDi

scharge air slightly cool or frost

build up at expansion valve

Expansion valve st

uck closed

LowLowDi

scharge air slightly cool,

sweating or frost after point of restriction

Restri

ction in High side of system

HighLowCompressor noisyDe

fe

ctive compressor reed valve

HighHighD

i

scharge air warm and high side

pipes hot

Refri

gerant charge high or inefficient condenser

cooling due to air flow blockage or engine cooling fans

not working

HighHighD i

scharge air warm / Sweating or

frost at evaporator

Expans ion valve st

uck open

Page 1757 of 2490

re

placed.

E

vacuating the System

This process, the removal

of un

wanted air and moisture, is crit ical to the correct operation of the air conditioning system.

Moisture in the system can be highly de structive and may cause internal blockages due to freezing; water suspended in the

lubricating oil will dama ge the compressor. Once the system has been dismantled, or the refrigerant charge recovered, all

traces of moisture must be removed before recharging.

Specific procedures will vary depending on the individual characteristics of the recovery / recycle / recharge equipment, and

must be carried out exactly in accordance with the manufacturer 's instructions. However, it is recommended that initially

only the high-side valve be opened at the start of the procedure. After a short time a small depression should be seen on

the low-side, at which point the low-side valve may be opened and the evacuation process completed. If a vacuum is not

registered on the low-side, it may indicate that the expansion valve is permanently closed or that the system is blocked.

This simple check may save time and effort when the system is recharged.

Page 1759 of 2490

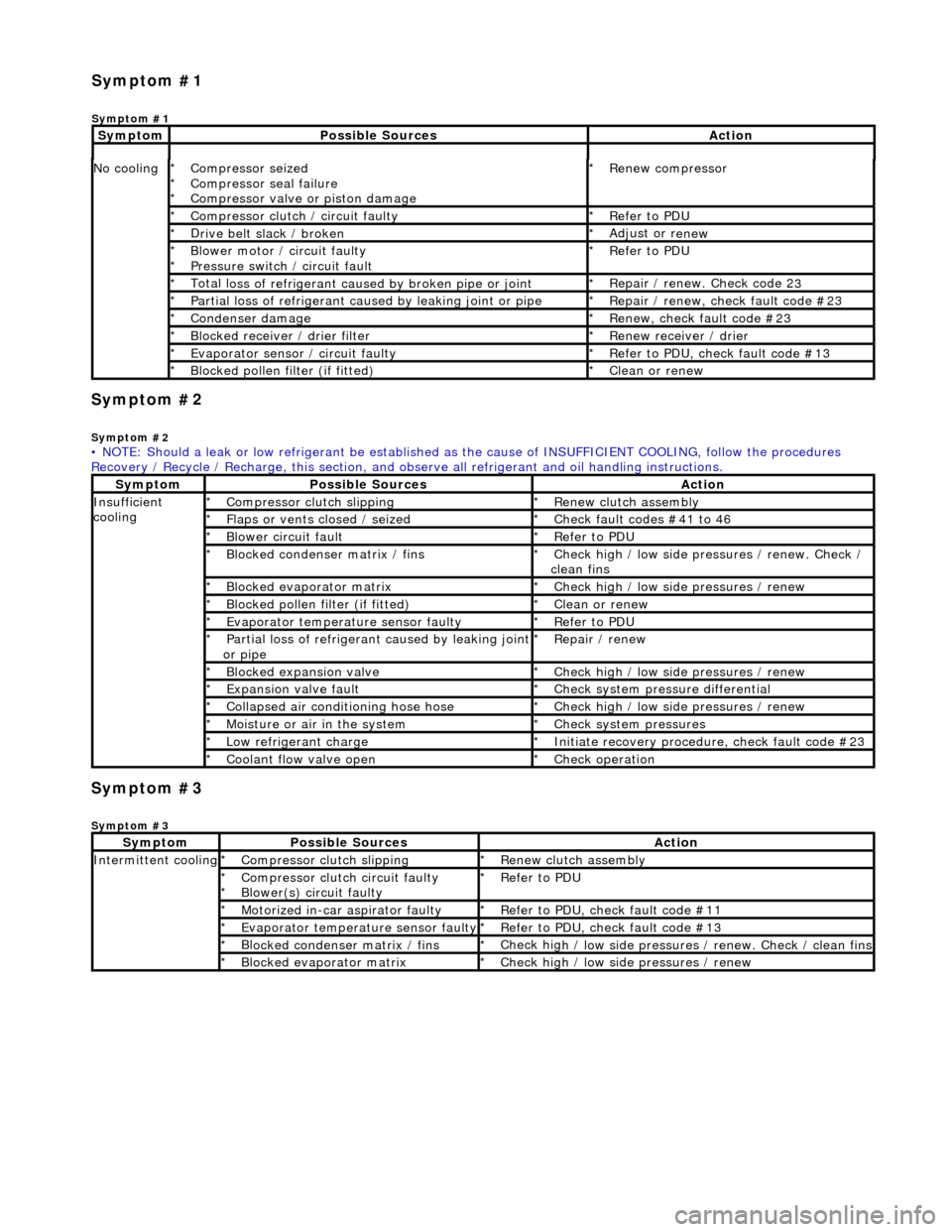

Sym

ptom #2

Sy

mptom #2

Sym

ptom #3

Sy

mptom #3

No

cooling

Compressor sei

zed

Compressor seal failure

Compressor valve or piston damage

*

*

*

R

enew compressor

*

Compressor cl

utch / circuit faulty

*

R

efer to PDU

*

D

rive belt slack / broken

*

Adjust or r

enew

*

B

lower motor / circuit faulty

Pressure switch / circuit fault

*

*

R

efer to PDU

*

Total l

oss of refrigerant caused by broken pipe or joint

*

Repair / renew. Check code 2

3

*

P

artial loss of refrigerant caused by leaking joint or pipe

*

R

epair / renew, check fault code #23

*

Conden

ser damage

*

Re

new, check fault code #23

*

Bl

ocked receiver / drier filter

*

R

enew receiver / drier

*

Evaporator senso

r / circuit faulty

*

R

efer to PDU, check fault code #13

*

Bl

ocked pollen filter (if fitted)

*

Cle

an or renew

*

• NOTE: Should a leak or low refrigerant be established as the cause of INSUFFICIENT COOL ING, follow the procedures

Recovery / Recycle / Recharge, this section, and ob serve all refrigerant and oil handling instructions.

Sy

mptom

Possib

le Sources

Acti

on

Insuffi

cient

cooling

Compre

ssor clutch slipping

*

R

enew clutch assembly

*

Fl

aps or vents closed / seized

*

Check f

ault codes #41 to 46

*

Bl

ower circuit fault

*

R

efer to PDU

*

Bl

ocked condenser matrix / fins

*

Check hig

h / low side pr

essures / renew. Check /

clean fins

*

Bl

ocked evaporator matrix

*

Check hig

h / low side

pressures / renew

*

Bl

ocked pollen filter (if fitted)

*

Cle

an or renew

*

Evaporator temp

erat

ure sensor faulty

*

R

efer to PDU

*

P

artial loss of refrigerant caused by leaking joint

or pipe

*

R

epair / renew

*

Blocked expan

sion valve

*

Check hig

h / low side

pressures / renew

*

Expans

ion valve fault

*

Chec

k system pres

sure differential

*

C

ollapsed air conditioning hose hose

*

Check hig

h / low side

pressures / renew

*

Moi

sture or air in the system

*

Chec

k system pressures

*

Low r

efrigerant charge

*

Initiate recovery

procedure, check fault code #23

*

Coo

lant flow valve open

*

Chec

k operation

*

Sy

mptom

Possib

le Sources

Acti

on

Int

ermittent cooling

Compre

ssor clutch slipping

*

R

enew clutch assembly

*

Compressor cl

utch circuit faulty

Blower(s) circuit faulty

*

*

R

efer to PDU

*

Motorized in-car aspirator faulty

*

R

efer to PDU, check fault code #11

*

Evaporator temp

erature sensor faulty

*

R

efer to PDU, check fault code #13

*

Bl

ocked condenser matrix / fins

*

Check hig

h / low side pressures / renew. Check / clean fins

*

Bl

ocked evaporator matrix

*

Check hig

h / low side

pressures / renew

*

Sym

ptom #1

Sy

mptom #1

Sy

mptom

Possib

le Sources

Acti

on

Page 1760 of 2490

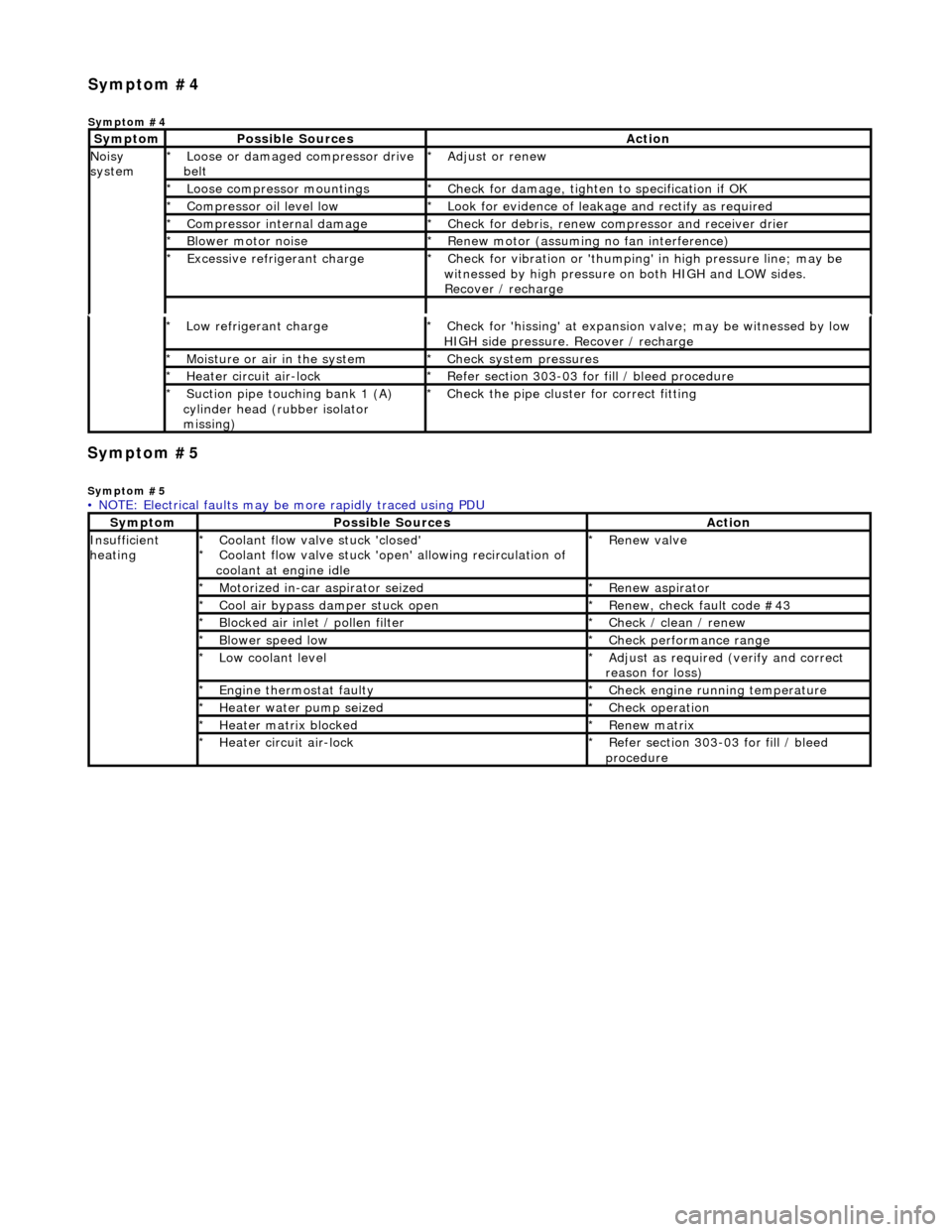

Symp

tom #5

Sy

m

ptom #5

Low r

e

frigerant charge

*

Check f or 'hissi

ng' at expansion

valve; may be witnessed by low

HIGH side pressure. Recover / recharge

*

Moi

s

ture or air in the system

*

Chec k syst

em pressures

*

Heat er ci

rcuit air-lock

*

R e

fer section 303-03 for fill / bleed procedure

*

Suct ion

pipe touching bank 1 (A)

cylinder head (rubber isolator

missing)

*

Check the pi

pe cluster for correct fitti

ng

*

• NOTE: Electrical faults may be more rapidly traced using PDU

Sym

ptom

Possib

l

e Sources

Acti

o

n

Insuffi

ci

ent

heating

Coo l

ant flow valve stuck 'closed'

Coolant flow valve stuck 'open' allowing recirculation of

coolant at engine idle

*

*

Re

new v

alve

*

Motorized in-car aspirator sei zed

*R e

new aspirator

*

Coo l

air bypass damper stuck open

*

Re new,

check fault code #43

*

B l

ocked air inlet / pollen filter

*

Chec k / cl

ean / renew

*

B l

ower speed low

*

Check performance range

*

Low cool ant

level

*

Adjust as req u

ired (verify and correct

reason for loss)

*

Engine

t

hermostat faulty

*

Check engine r u

nning temperature

*

Heater water pump seized

*Chec k op

eration

*

Heater ma trix

blocked

*

Re new m

atrix

*

Heater circui t

air-lock

*

R e

fer section 303-03 for fill / bleed

procedure

*

Sym

p

tom #4

Sym

ptom #4

Sy

m

ptom

Possib

l

e Sources

Acti

o

n

No

i

sy

system

Loose or damaged compressor drive

belt

*Adjust or r

e

new

*

Loose compressor mountings

*Check f o

r damage, tighten to specification if OK

*

Compressor oil level l

ow

*

Look for evidence of l

eakag

e and rectify as required

*

Compressor internal dama ge

*Check f o

r debris, renew compressor and receiver drier

*

B l

ower motor noise

*

Re new m

otor (assuming no fan interference)

*

Excessive refrige rant charge

*Check f o

r vibration or 'thumping'

in high pressure line; may be

witnessed by high pressure on both HIGH and LOW sides.

Recover / recharge

*

Page 1764 of 2490

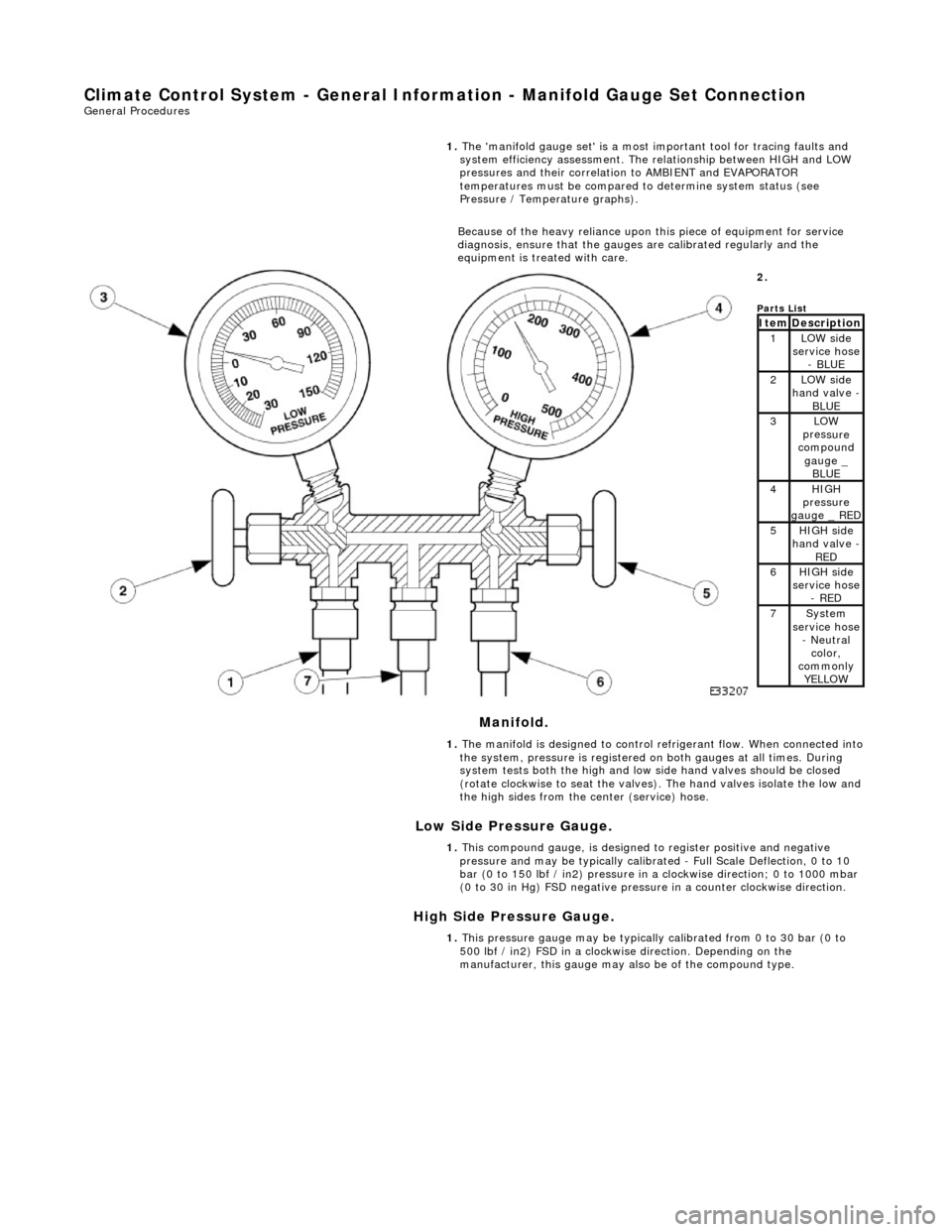

Clima

te Control System - General Inform

ation - Manifold Gauge Set Connection

Ge

neral Procedures

Mani

fol

d.

Low Side Pressure Gauge.

High Side Pressure Gauge.

1.

The 'ma

nifold gauge set' is a most important tool for tracing faults and

system efficiency assessment. The relationship between HIGH and LOW

pressures and their correlation to AMBIENT and EVAPORATOR

temperatures must be compared to determine system status (see

Pressure / Temperature graphs).

Because of the heavy reliance upon this piece of equipment for service

diagnosis, ensure that the gauges are calibrated regularly and the

equipment is treated with care.

2.

Parts

List

ItemDescri

ption1LOW side

serv

ice hose

- BLUE

2LOW side

ha

nd valve -

BL

UE3LOW

pres

sure

compound

gauge _ BLUE

4HI GH

pressure

gauge _ RED

5HI GH

side

hand valve -

RED6HI GH

side

service hose

- RED

7Sys t

em

service hose

- Neutral color,

commonly YELLOW

1. The manifold is designed to control refrigerant flow. When connected into

the system, pressure is registered on both gauges at all times. During

system tests both the high and low side hand valves should be closed

(rotate clockwise to seat the valves). The hand valves isolate the low and

the high sides from the center (service) hose.

1. This compound gauge, is designed to register positive and negative

pressure and may be typically calibrate d - Full Scale Deflection, 0 to 10

bar (0 to 150 lbf / in2) pressure in a clockwise direction; 0 to 1000 mbar

(0 to 30 in Hg) FSD negative pressu re in a counter clockwise direction.

1. This pressure gauge may be typically calibrated from 0 to 30 bar (0 to

500 lbf / in2) FSD in a clockwise direction. Depending on the

manufacturer, this gauge may also be of the compound type.

Page 1771 of 2490

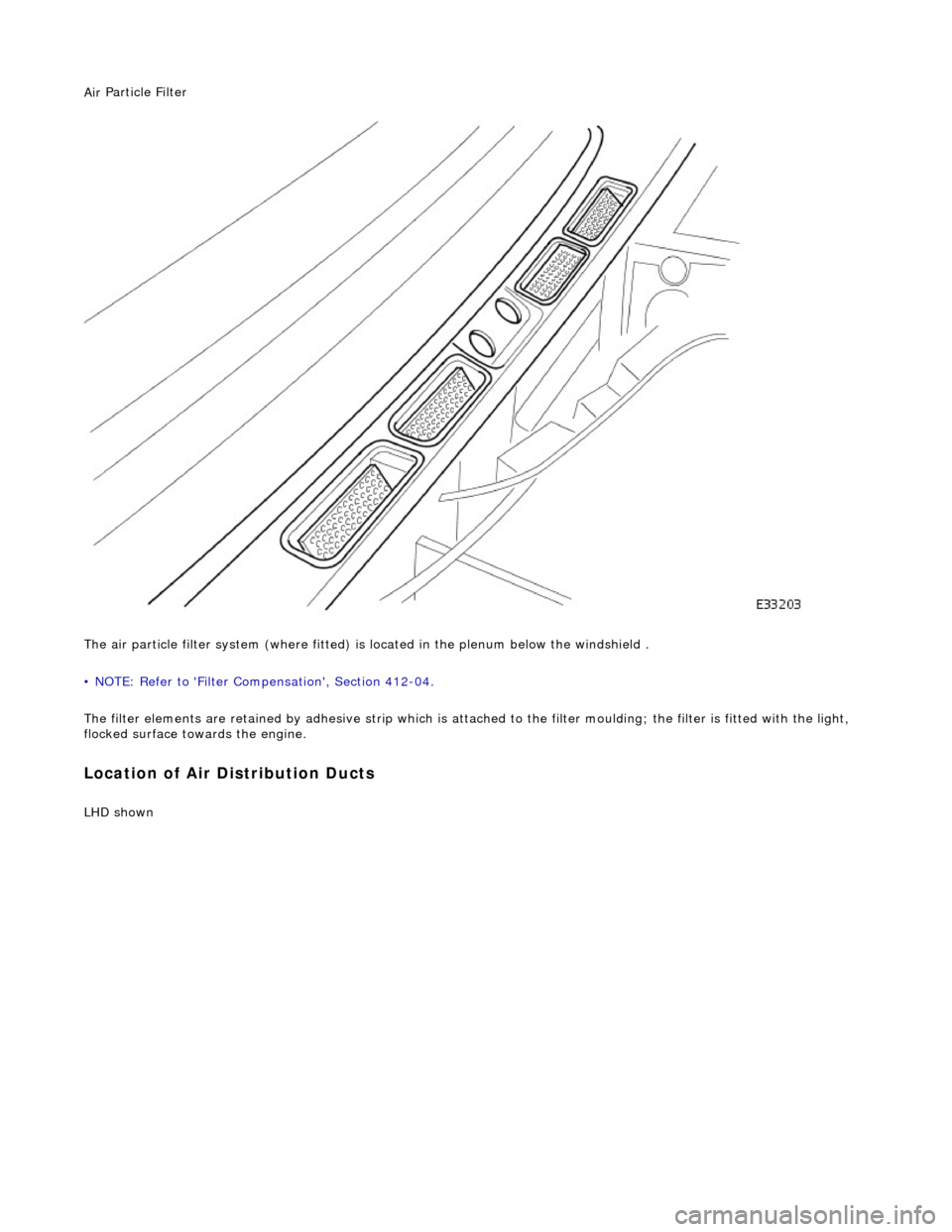

Air

Particle Filter

The air particle filter system (where fitted) is located in the plenum below the windshield .

• NOTE: Refer to 'Filter Compensation', Section 412-04.

The filter elements are retained by adhesive strip which is atta ched to the filter moulding; the filter is fitted with the light,

flocked surface towards the engine.

Loca

tion of Air Distribution Ducts

LHD s

hown