ECU JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 829 of 2490

Whilst applying the opposing force to the sprocket and

chain, tighten the sprocket securing bolt to 115-125 Nm.

Remove the chain tensioning tool.

6. Remove the tape and steel stri p from the timing cover upper

face. Wipe any residue of tape from the joint face.

7. Remove the camshaft locking tool.

8. Install the Cam Cover to Bank 1. Refer to Operation 12.29.44.

9. Raise the vehicle on the ramp.

10. Remove the crankshaft setting tool 303-531.

11. Install the crankshaft position sensor.

1. Install the sensor to the flywheel housing and fit the

securing bolt. Tighten to 8-12 Nm.

2. Install the access grommet to the housing.

12. Lower the ramp.

13. Remove the paint protection sheets and close the engine

compartment cover.

14. Connect the battery and in stall the battery cover.

Refer to the Battery Reconnection Procedure 86.15.15.

Page 830 of 2490

Engine - Upper Oil Pan3.2L NA V8 - AJ26

In-vehicle Repair

Removal

Special Tool(s)

Installer/remover, Oil Filter

303-752

1. Disconnect the batt ery ground cable.

Remove the battery cover.

2. Open the engine compartment and fit paintwork protection

sheets.

3. Set the engine compartment cover to the service access

position.

4. Remove the timing cover and al l associated components, as

detailed in Operation 12.65.01.

5. Remove both front wheel and tyre assemblies. Refer to

Operation 74.20.05.

6. Remove the undertray. Re fer to Operation 76.22.90.

7. Remove the two bolts which secu re the generator cooling duct

to the oil pan body and remove the duct.

8. Remove the front cross member for access. Refer to Operation

76.10.05.

9. Drain the engine oil.

1. Position the waste oil bowser.

2. Remove the drain plug from the oil pan and drain the engine oil.

Fit a new sealing washer to the drain plug.

Page 831 of 2490

Wipe the drain plug and install it to the oil pan to prevent

oil dripping.

Move the oil bowser away from the vehicle.

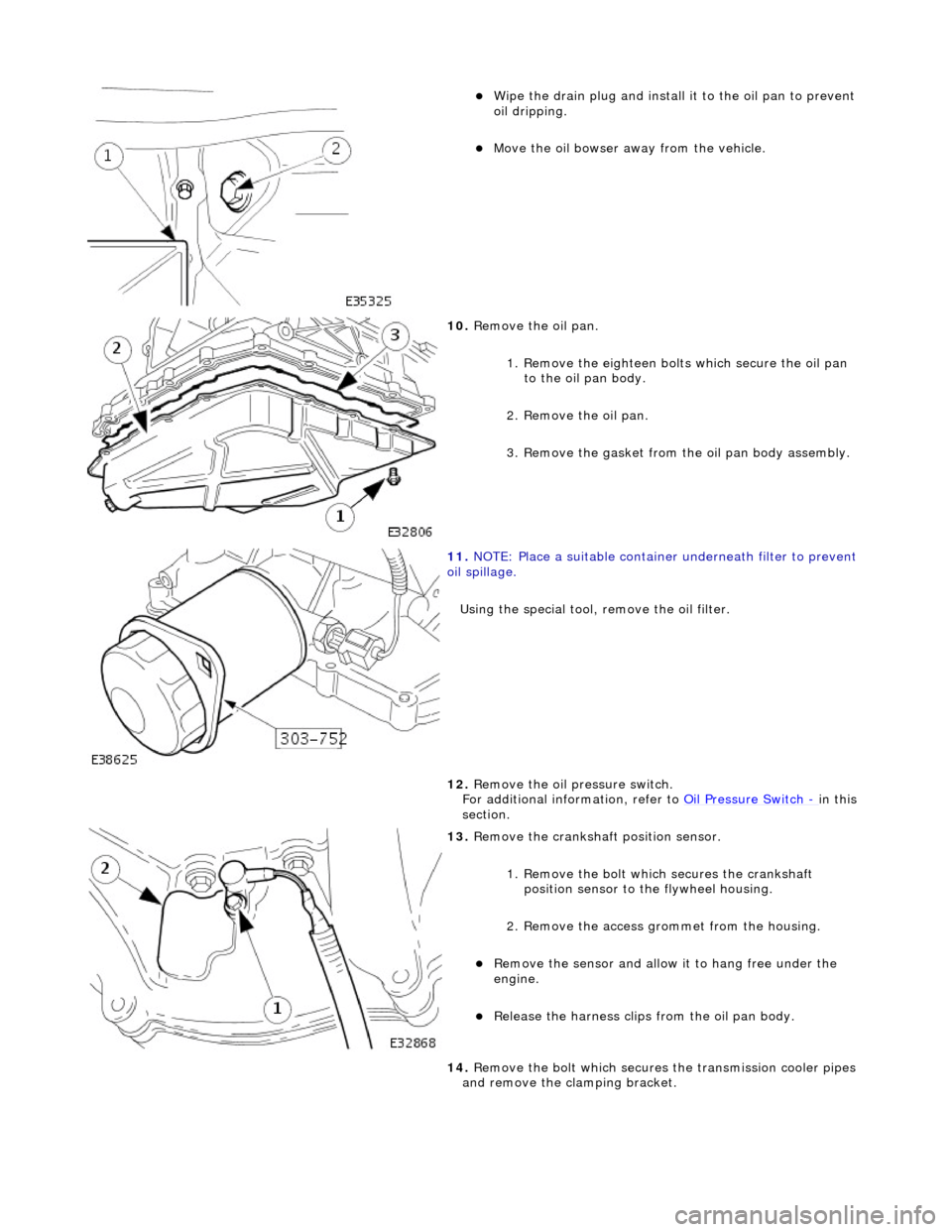

10. Remove the oil pan.

1. Remove the eighteen bolt s which secure the oil pan

to the oil pan body.

2. Remove the oil pan.

3. Remove the gasket from the oil pan body assembly.

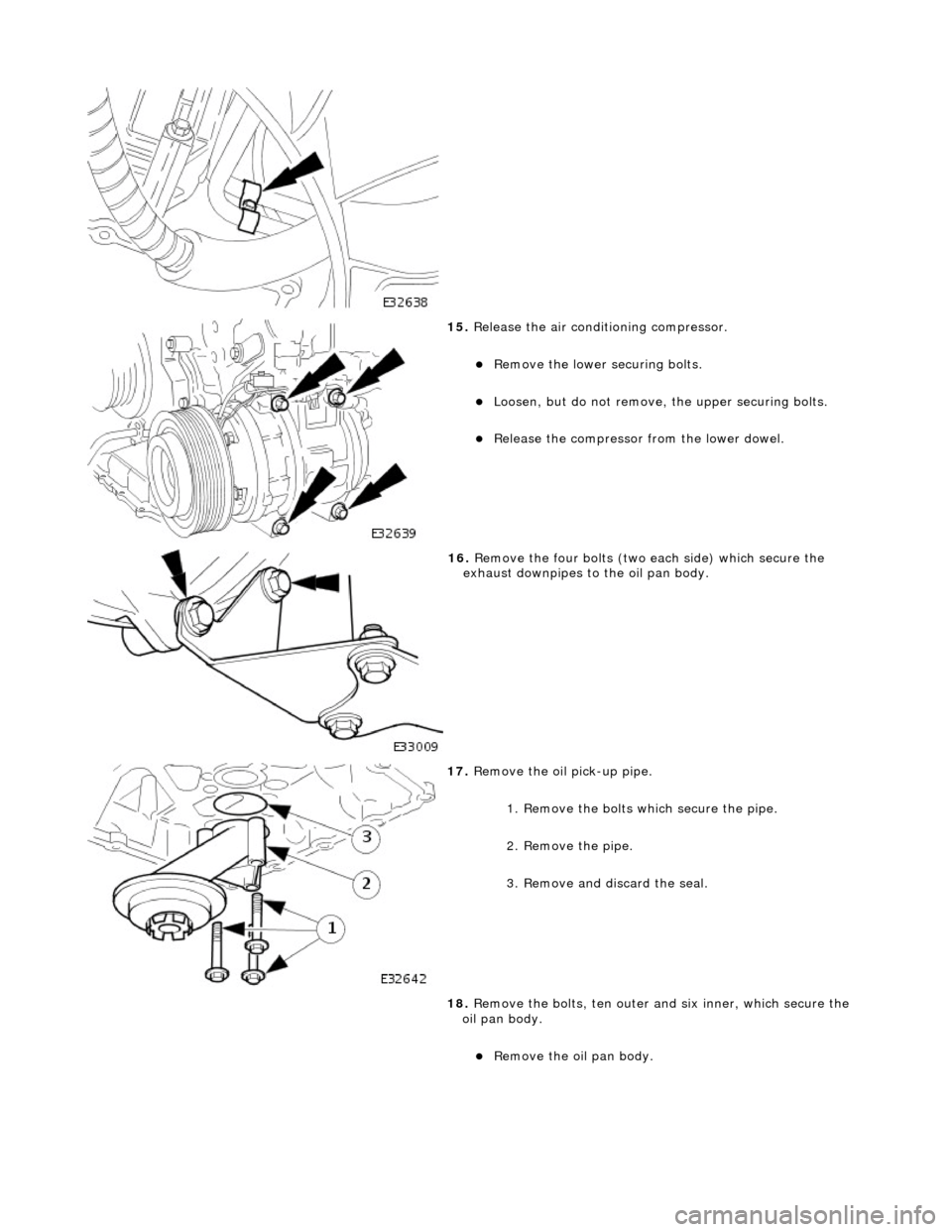

11. NOTE: Place a suitable container underneath filter to prevent

oil spillage.

Using the special tool, remove the oil filter.

12. Remove the oil pressure switch.

For additional information, refer to Oil Pressure Switch

- in this

section.

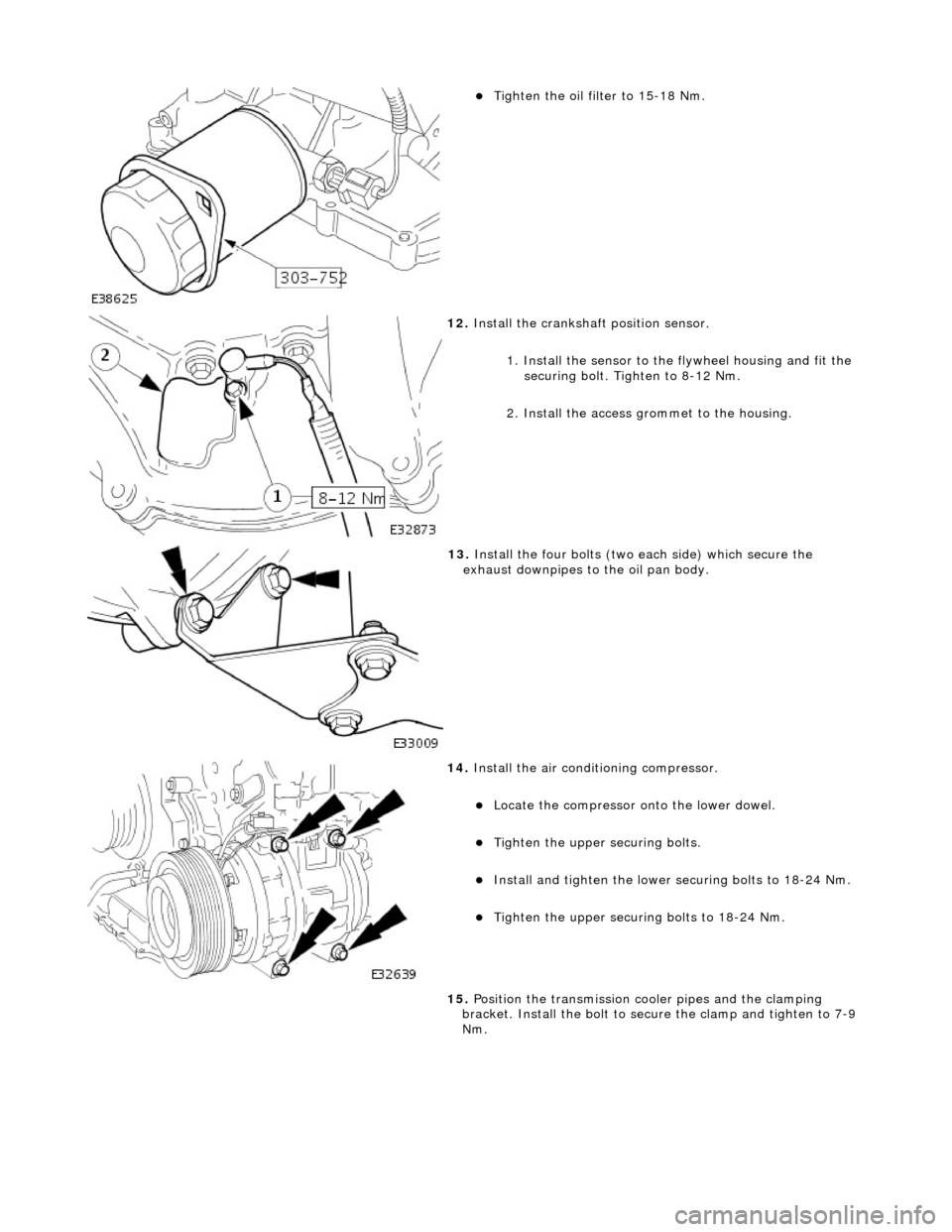

13. Remove the crankshaft position sensor.

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

2. Remove the access grommet from the housing.

Remove the sensor and allow it to hang free under the

engine.

Release the harness clips from the oil pan body.

14. Remove the bolt which secures the transmission cooler pipes

and remove the clamping bracket.

Page 832 of 2490

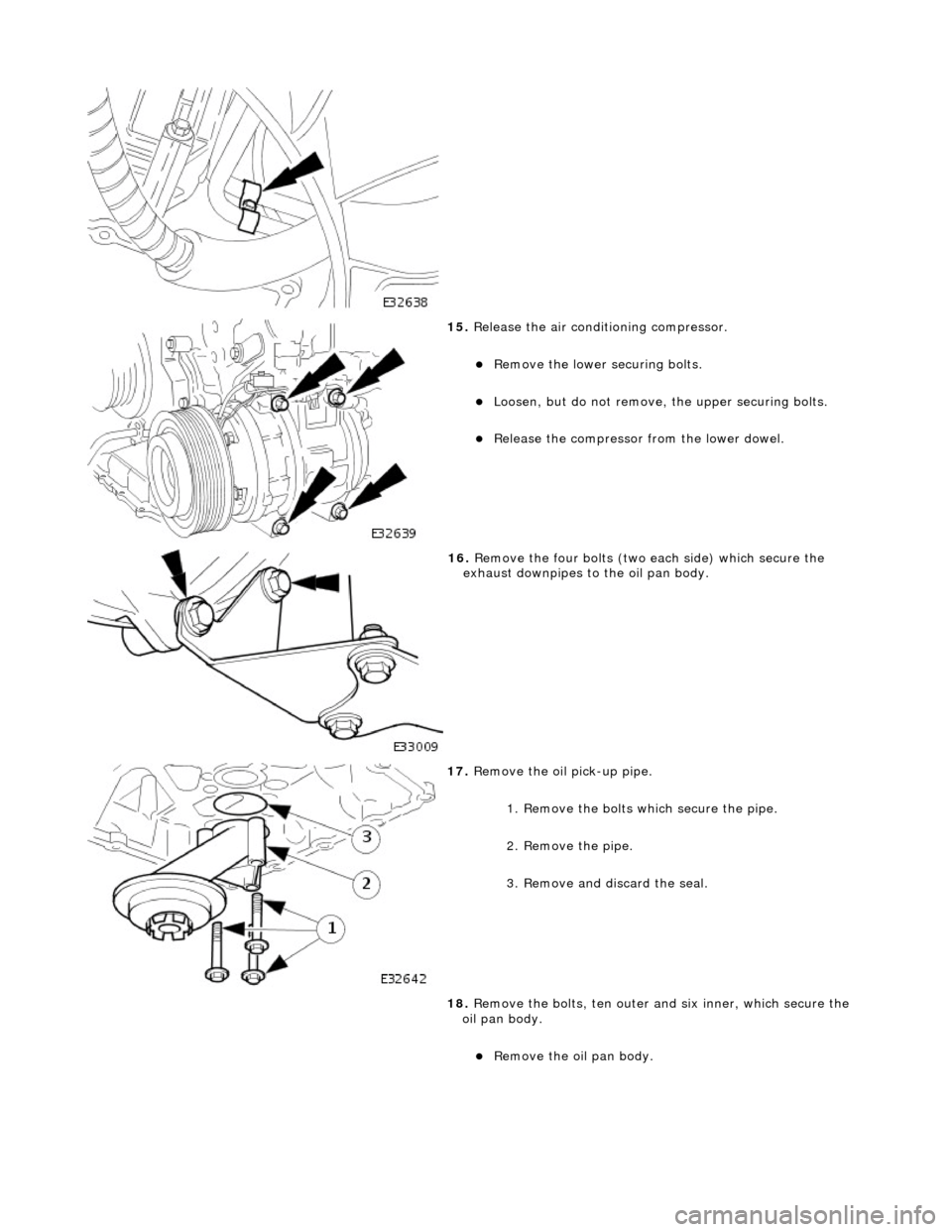

15. Release the air conditioning compressor.

Remove the lower securing bolts.

Loosen, but do not remove, th e upper securing bolts.

Release the compressor from the lower dowel.

16. Remove the four bolts (two each side) which secure the

exhaust downpipes to the oil pan body.

17. Remove the oil pick-up pipe.

1. Remove the bolts which secure the pipe.

2. Remove the pipe.

3. Remove and discard the seal.

18. Remove the bolts, ten outer an d six inner, which secure the

oil pan body.

Remove the oil pan body.

Page 836 of 2490

3. Install and tighten the bolts to 11-13 Nm.

7. Install the oil pan gasket to the oil pan body assembly.

Insert the seal into the locating positions in the groove,

working around from a corner.

Press in the remainder of th e seal, following the same

procedure.

8. Install the oil pan to the oil pan body.

1. Position and align the oil pan.

2. Install, but do not tighte n, all eighteen bolts which

secure the oil pan.

9. Tighten the bolts to the correct torque figure 11-13 Nm, in the

sequence indicated.

Tighten the drain plug to 30-40 Nm.

10. Install the oil pressure switch.

For additional information, refer to Oil Pressure Switch

- in this

section.

11. NOTE: Apply a suitable amount of clean engine oil to lubricate

the oil filter O-ring seal.

Using the special tool, install the oil filter.

Page 837 of 2490

Tighten the oil filter to 15-18 Nm.

12. Install the crankshaft position sensor.

1. Install the sensor to the flywheel housing and fit the

securing bolt. Tighten to 8-12 Nm.

2. Install the access grommet to the housing.

13. Install the four bolts (two each side) which secure the

exhaust downpipes to the oil pan body.

14. Install the air conditioning compressor.

Locate the compressor onto the lower dowel.

Tighten the upper securing bolts.

Install and tighten the lower securing bolts to 18-24 Nm.

Tighten the upper securing bolts to 18-24 Nm.

15. Position the transmission cooler pipes and the clamping

bracket. Install the bolt to secu re the clamp and tighten to 7-9

Nm.

Page 839 of 2490

Engine - Upper Oil Pan4.0L NA V8 - AJ27, 4.0L

In-vehicle Repair

Removal

Special Tool(s)

Installer/remover, Oil Filter

303-752

1. Disconnect the batt ery ground cable.

Remove the battery cover.

2. Open the engine compartment and fit paintwork protection

sheets.

3. Set the engine compartment cover to the service access

position.

4. Remove the timing cover and al l associated components, as

detailed in Operation 12.65.01.

5. Remove both front wheel and tyre assemblies. Refer to

Operation 74.20.05.

6. Remove the undertray. Re fer to Operation 76.22.90.

7. Remove the two bolts which secu re the generator cooling duct

to the oil pan body and remove the duct.

8. Remove the front cross member for access. Refer to Operation

76.10.05.

9. Drain the engine oil.

1. Position the waste oil bowser.

2. Remove the drain plug from the oil pan and drain the engine oil.

Fit a new sealing washer to the drain plug.

Page 840 of 2490

Wipe the drain plug and install it to the oil pan to prevent

oil dripping.

Move the oil bowser away from the vehicle.

10. Remove the oil pan.

1. Remove the eighteen bolt s which secure the oil pan

to the oil pan body.

2. Remove the oil pan.

3. Remove the gasket from the oil pan body assembly.

11. NOTE: Place a suitable container underneath filter to prevent

oil spillage.

Using the special tool, remove the oil filter.

12. Remove the oil pressure switch.

For additional information, refer to Oil Pressure Switch

- in this

section.

13. Remove the crankshaft position sensor.

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

2. Remove the access grommet from the housing.

Remove the sensor and allow it to hang free under the

engine.

Release the harness clips from the oil pan body.

14. Remove the bolt which secures the transmission cooler pipes

and remove the clamping bracket.

Page 841 of 2490

15. Release the air conditioning compressor.

Remove the lower securing bolts.

Loosen, but do not remove, th e upper securing bolts.

Release the compressor from the lower dowel.

16. Remove the four bolts (two each side) which secure the

exhaust downpipes to the oil pan body.

17. Remove the oil pick-up pipe.

1. Remove the bolts which secure the pipe.

2. Remove the pipe.

3. Remove and discard the seal.

18. Remove the bolts, ten outer an d six inner, which secure the

oil pan body.

Remove the oil pan body.

Page 845 of 2490

3. Install and tighten the bolts to 11-13 Nm.

7. Install the oil pan gasket to the oil pan body assembly.

Insert the seal into the locating positions in the groove,

working around from a corner.

Press in the remainder of th e seal, following the same

procedure.

8. Install the oil pan to the oil pan body.

1. Position and align the oil pan.

2. Install, but do not tighte n, all eighteen bolts which

secure the oil pan.

9. Tighten the bolts to the correct torque figure 11-13 Nm, in the

sequence indicated.

Tighten the drain plug to 30-40 Nm.

10. Install the oil pressure switch.

For additional information, refer to Oil Pressure Switch

- in this

section.

11. NOTE: Apply a suitable amount of clean engine oil to lubricate

the oil filter O-ring seal.

Using the special tool, install the oil filter.