ECU JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 870 of 2490

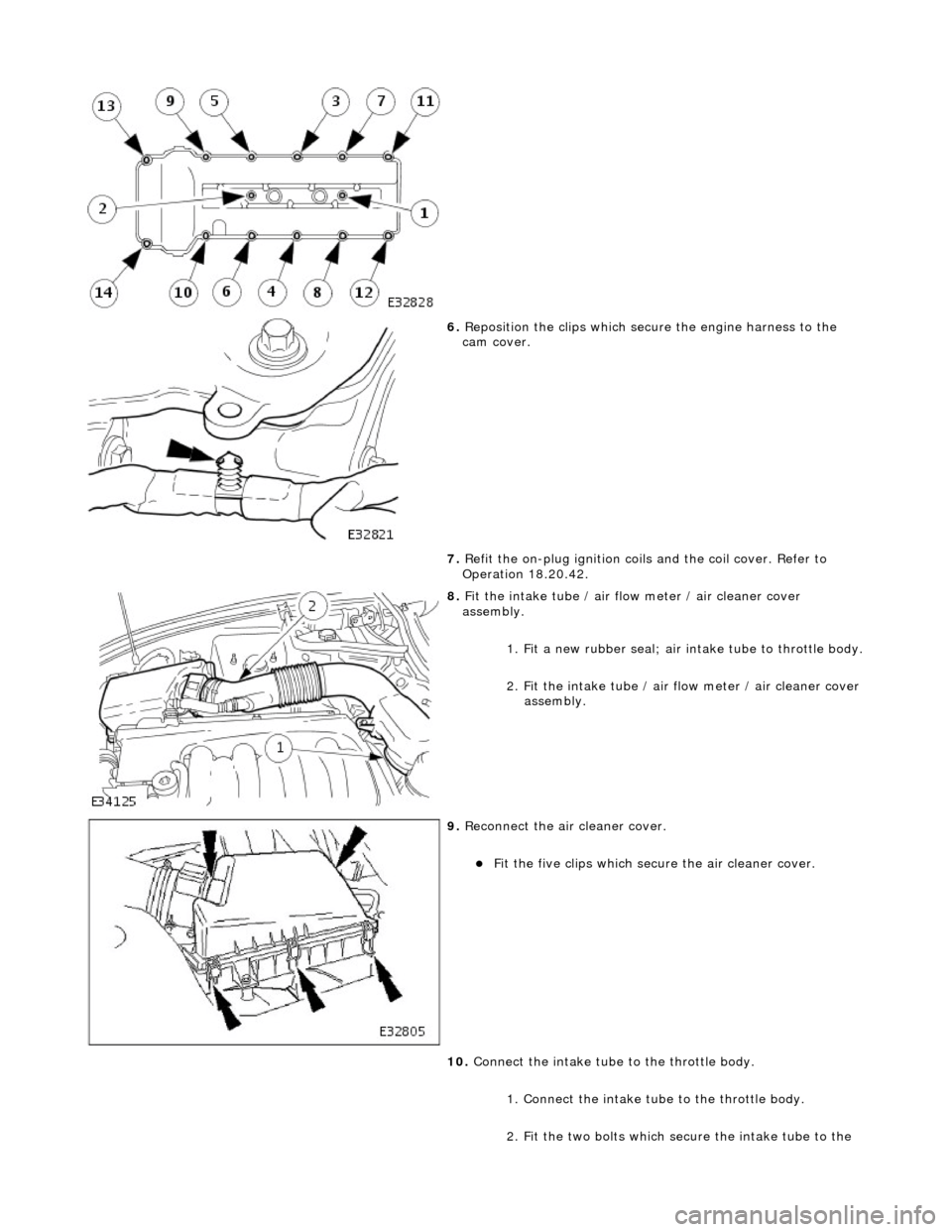

6. Reposition the clips which secure the engine harness to the

cam cover.

7. Refit the on-plug ignition coils and the coil cover. Refer to

Operation 18.20.42.

8. Fit the intake tube / air flow meter / air cleaner cover

assembly.

1. Fit a new rubber seal; air in take tube to throttle body.

2. Fit the intake tube / air flow meter / air cleaner cover

assembly.

9. Reconnect the air cleaner cover.

Fit the five clips which secu re the air cleaner cover.

10. Connect the intake tube to the throttle body.

1. Connect the intake tube to the throttle body.

2. Fit the two bolts which secure the intake tube to the

Page 872 of 2490

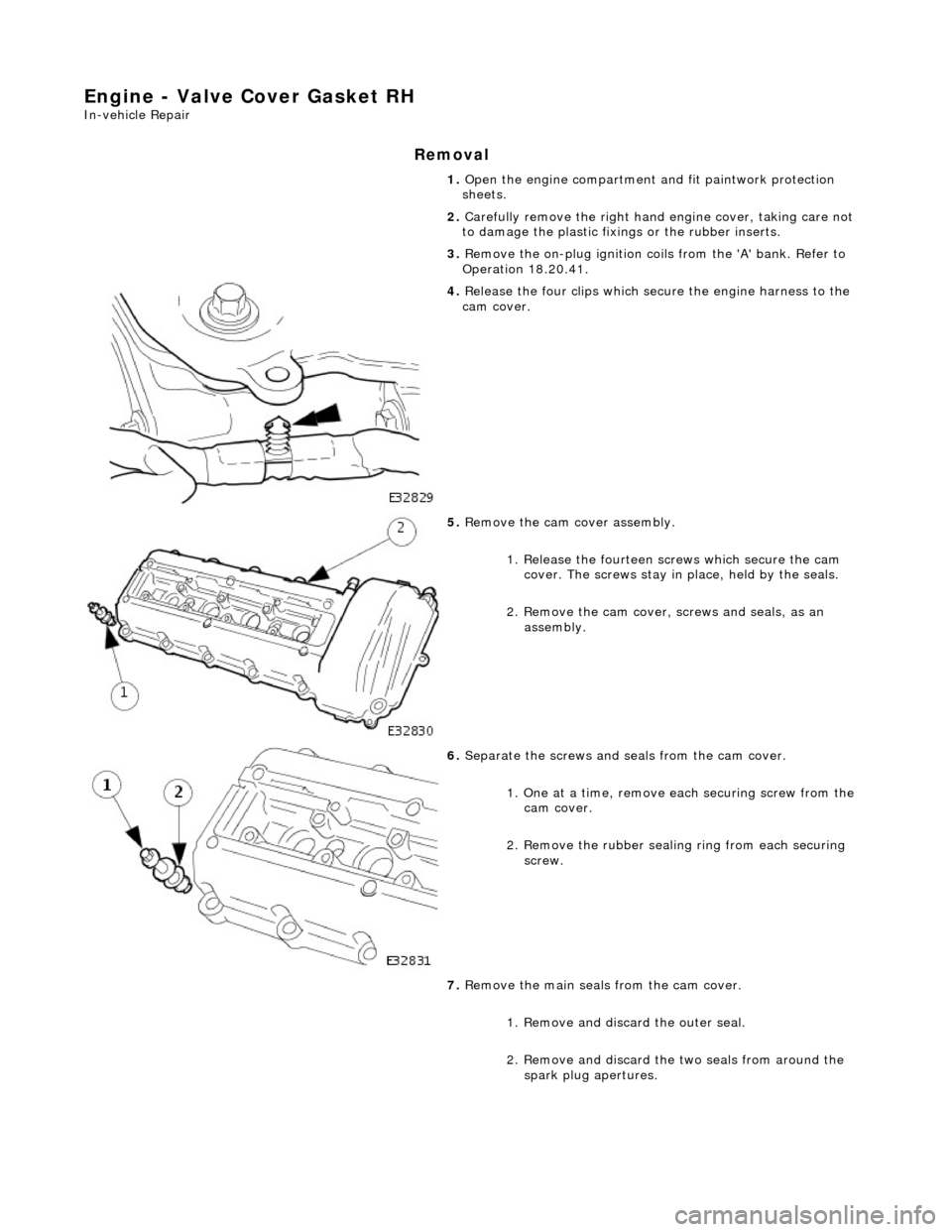

Engine - Valve Cover Gasket RH

In-vehicle Repair

Removal

1. Open the engine compartment and fit paintwork protection

sheets.

2. Carefully remove the right hand engine cover, taking care not

to damage the plastic fixi ngs or the rubber inserts.

3. Remove the on-plug ignition coils from the 'A' bank. Refer to

Operation 18.20.41.

4. Release the four clips which secure the engine harness to the

cam cover.

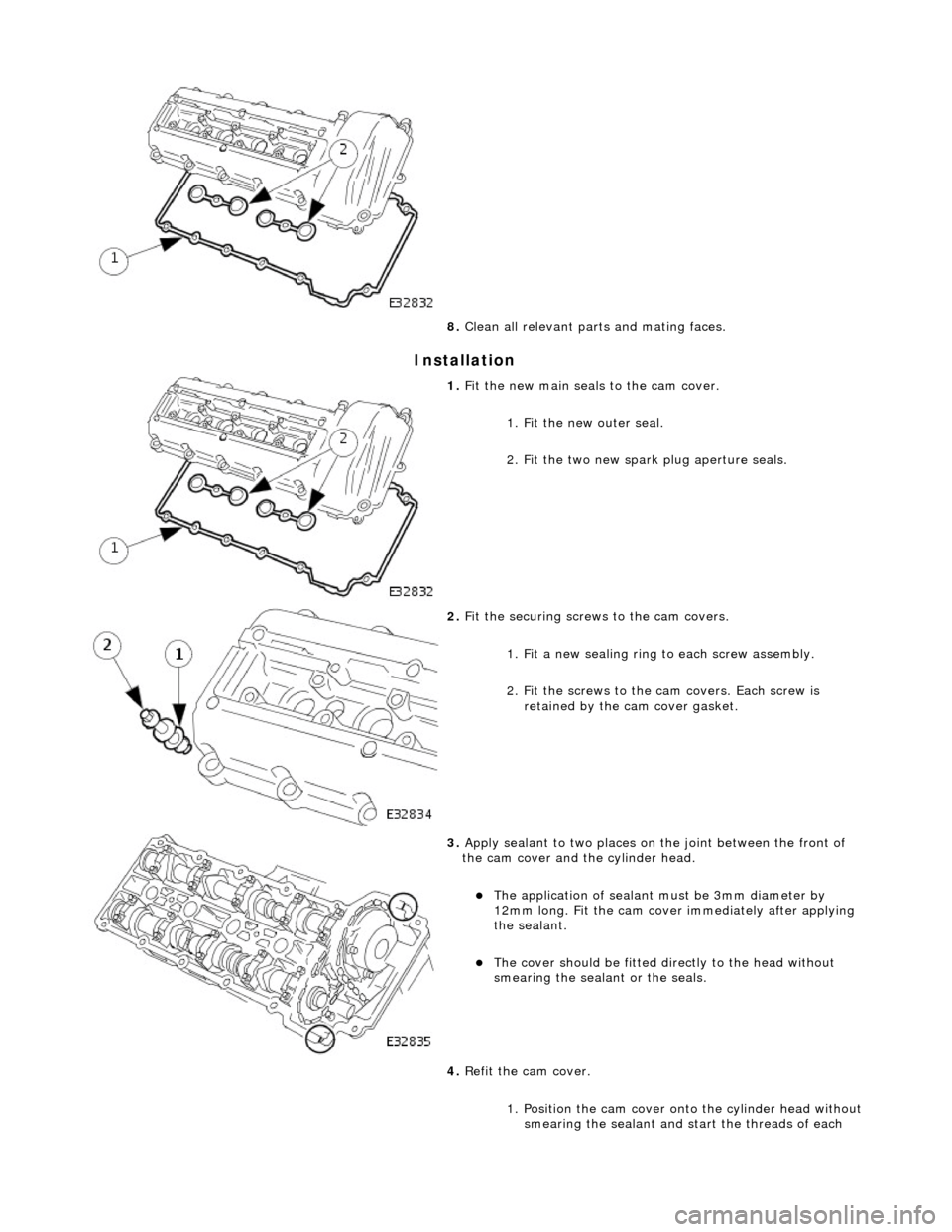

5. Remove the cam cover assembly.

1. Release the fourteen sc rews which secure the cam

cover. The screws stay in place, held by the seals.

2. Remove the cam cover, screws and seals, as an

assembly.

6. Separate the screws and se als from the cam cover.

1. One at a time, remove ea ch securing screw from the

cam cover.

2. Remove the rubber sealin g ring from each securing

screw.

7. Remove the main seals from the cam cover.

1. Remove and discard the outer seal.

2. Remove and discard the two seals from around the spark plug apertures.

Page 873 of 2490

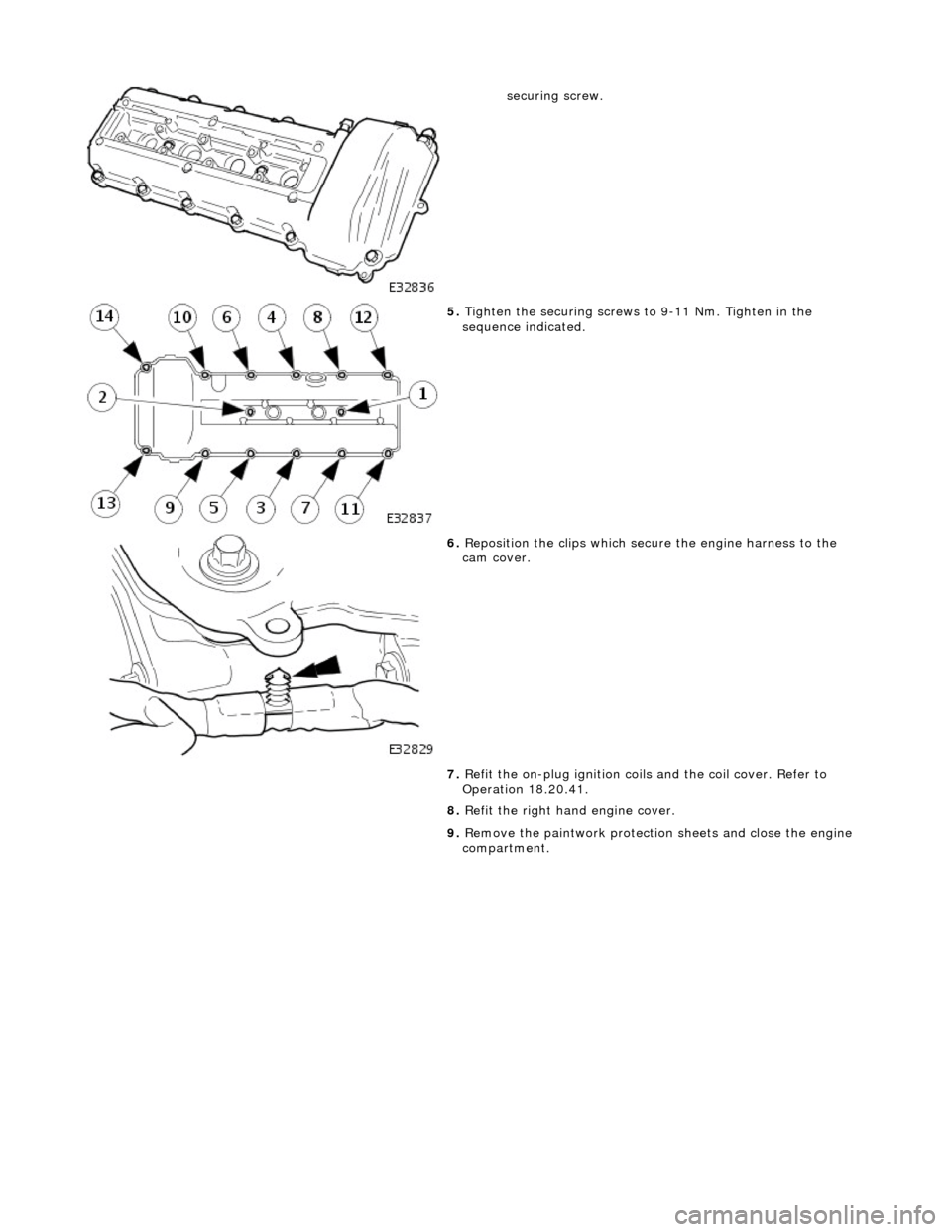

Installation

8. Clean all relevant parts and mating faces.

1. Fit the new main seals to the cam cover.

1. Fit the new outer seal.

2. Fit the two new spark plug aperture seals.

2. Fit the securing screws to the cam covers.

1. Fit a new sealing ring to each screw assembly.

2. Fit the screws to the cam covers. Each screw is retained by the cam cover gasket.

3. Apply sealant to two places on the joint between the front of

the cam cover and the cylinder head.

The application of sealant must be 3mm diameter by

12mm long. Fit the cam cover immediately after applying

the sealant.

The cover should be fitted di rectly to the head without

smearing the sealant or the seals.

4. Refit the cam cover.

1. Position the cam cover onto the cylinder head without smearing the sealant and start the threads of each

Page 874 of 2490

securing screw.

5. Tighten the securing screws to 9-11 Nm. Tighten in the

sequence indicated.

6. Reposition the clips which secure the engine harness to the

cam cover.

7. Refit the on-plug ignition coils and the coil cover. Refer to

Operation 18.20.41.

8. Refit the right hand engine cover.

9. Remove the paintwork protection sheets and close the engine

compartment.

Page 880 of 2490

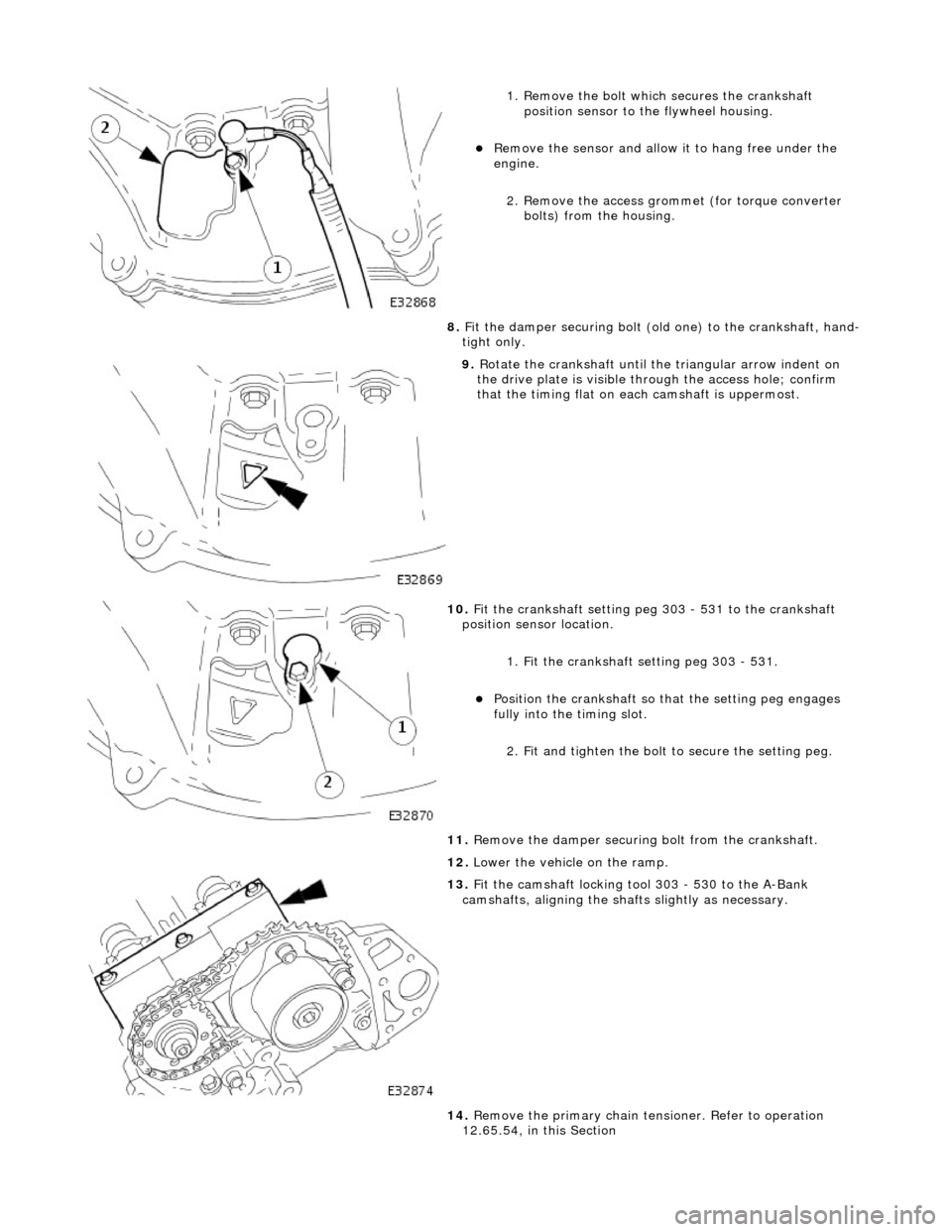

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

Remove the sensor and allow it to hang free under the

engine.

2. Remove the access grommet (for torque converter bolts) from the housing.

8. Fit the damper securing bolt (old one) to the crankshaft, hand-

tight only.

9. Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

10. Fit the crankshaft setting peg 303 - 531 to the crankshaft

position sensor location.

1. Fit the crankshaft setting peg 303 - 531.

Position the crankshaft so that the setting peg engages

fully into the timing slot.

2. Fit and tighten the bolt to secure the setting peg.

11. Remove the damper securing bolt from the crankshaft.

12. Lower the vehicle on the ramp.

13. Fit the camshaft locking tool 303 - 530 to the B-Bank

camshafts, aligning the shafts slightly as necessary.

14. Loosen the bolt which secures the sprocket to the exhaust

camshaft.

Page 881 of 2490

15. Loosen the bolt which secures the VVT unit.

Do not tamper with the three bolts which secure the VVT

mechanism to the sprockets. It is sealed at the factory to

the correct valve timing specif ication for the engine and is

supplied only as a complete unit.

16. Remove the primary chain tens ioner. Refer to operation

12.65.55, in this Section.

17. Remove the primary ch ain tensioner blade.

1. Remove the pivot bolt which secures the tensioner blade.

2. Remove the tensioner blade.

18. Reposition the VVT unit along the cam journal to allow the

chain to clear the head casting.

Disconnect the primary chain from the VVT unit and

reposition it against the crankshaft sprocket.

19. Remove the VVT unit.

1. Remove the securing bolt from the VVT unit and the exhaust cam sprocket.

2. Remove the VVT unit, exhaust sprocket and secondary chain as an asse mbly (release the chain

from the tensioner which is still secured to the

cylinder head).

Remove the secondary chain from the VVT unit and the

sprocket.

Page 882 of 2490

Installation

20. Clean and inspect all relevant components.

1. Push the tensioner piston (secon dary chain) into the body to

provide clearance for fitting.

1. Insert a thin rigid wire th rough the hole in the end of

the tensioner piston to displace the ball from the non-

return valve seat.

2. With the wire in position, press the piston fully into the tensioner body.

Remove the wire.

2. Fit the VVT unit to the engine.

Assemble the VVT unit, the exhaust camshaft sprocket

and the secondary chain, in pr eparation for fitting to the

engine.

1. Fit the above assembly to the camshafts with the chain correctly positioned over the tensioner; VVT

unit to the inlet and the sprocket to the exhaust.

2. Fit, but do not tighten, each bolt which secures the VVT unit and the exhaust sprocket to the camshafts.

Allow the VVT unit sufficien t space to fit the primary

chain, in a la ter operation.

3. Fit the chain tensioning tool 303 - 532 to the exhaust camshaft

sprocket.

Reposition the sprocket (and the VVT unit) for the most

advantageous position for use of the tool.

Remove the tool.

4. Refit the primary timing chain.

1. Lift the primary chain an d position it over the VVT

unit sprocket (the VVT unit mu st be pulled forward to

clear the cylinder head casting). There must be no

slack on the drive side of the primary chain and the

VVT unit must not be rotated on the camshaft.

2. Slide the VVT unit fully on to the camshaft.

5. Fit the primary chain tensioner blade.

1. Position the tensioner blade to the cylinder block.

Page 883 of 2490

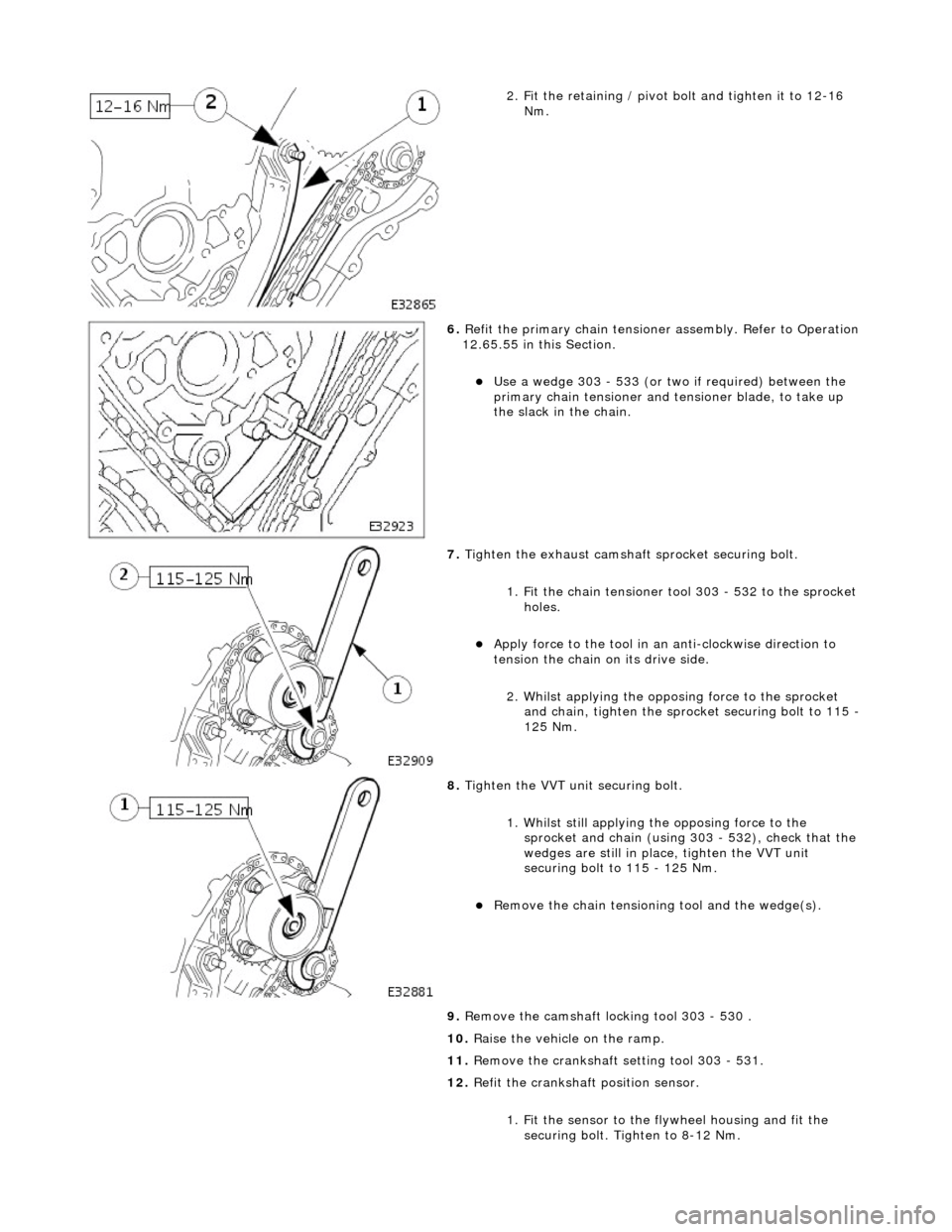

2. Fit the retaining / pivot bolt and tighten it to 12-16 Nm.

6. Refit the primary chain tensione r assembly. Refer to Operation

12.65.55 in this Section.

Use a wedge 303 - 533 (or two if required) between the

primary chain tensioner and te nsioner blade, to take up

the slack in the chain.

7. Tighten the exhaust camshaft sprocket securing bolt.

1. Fit the chain tensioner tool 303 - 532 to the sprocket holes.

Apply force to the tool in an anti-clockwise direction to

tension the chain on its drive side.

2. Whilst applying the opposing force to the sprocket and chain, tighten the sprock et securing bolt to 115 -

125 Nm.

8. Tighten the VVT unit securing bolt.

1. Whilst still applying the opposing force to the

sprocket and chain (using 303 - 532), check that the

wedges are still in place, tighten the VVT unit

securing bolt to 115 - 125 Nm.

Remove the chain tensioning tool and the wedge(s).

9. Remove the camshaft locking tool 303 - 530 .

10. Raise the vehicle on the ramp.

11. Remove the crankshaft setting tool 303 - 531.

12. Refit the crankshaft position sensor.

1. Fit the sensor to the fl ywheel housing and fit the

securing bolt. Tighten to 8-12 Nm.

Page 886 of 2490

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

Remove the sensor and allow it to hang free under the

engine.

2. Remove the access grommet (for torque converter bolts) from the housing.

8. Fit the damper securing bolt (old one) to the crankshaft, hand-

tight only.

9. Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

10. Fit the crankshaft setting peg 303 - 531 to the crankshaft

position sensor location.

1. Fit the crankshaft setting peg 303 - 531.

Position the crankshaft so that the setting peg engages

fully into the timing slot.

2. Fit and tighten the bolt to secure the setting peg.

11. Remove the damper securing bolt from the crankshaft.

12. Lower the vehicle on the ramp.

13. Fit the camshaft locking tool 303 - 530 to the A-Bank

camshafts, aligning the shafts slightly as necessary.

14. Remove the primary chain tens ioner. Refer to operation

12.65.54, in this Section

Page 887 of 2490

Installation

15. Remove the primary ch ain tensioner blade.

1. Remove the pivot bolt which secures the tensioner blade.

2. Remove the tensioner blade.

16. Disconnect the primary chain from the VVT unit and the

crankshaft sprocket, and remove it completely.

17. Do not tamper with the three bolts which secure the VVT

mechanism to the sprockets. It is sealed at the factory to the

correct valve timing specificatio n for the engine and is supplied

only as a complete unit.

18. Remove the VVT unit.

1. Remove the securing bolt from both the VVT unit and

the exhaust cam sprocket.

2. Remove the VVT unit, exhaust sprocket and secondary chain as an asse mbly (release the chain

from the tensioner which is still secured to the

cylinder head).

Remove the secondary chain from the VVT unit and the

sprocket.

19. Clean and inspect all relevant components.

1. Push the tensioner piston (secon dary chain) into the body to

provide clearance for fitting.

1. Insert a thin rigid wire th rough the hole in the end of

the tensioner piston to displace the ball from the non-

return valve seat.

2. With the wire in position, press the piston fully into the tensioner body.

Remove the wire.

2. Fit the VVT unit to the engine.

Assemble the VVT unit, the exhaust camshaft sprocket

and the secondary chain, in pr eparation for fitting to the

engine.

1. Fit the above assembly to the camshafts with the chain correctly positioned over the tensioner; VVT

unit to the inlet and the sprocket to the exhaust.

2. Fit, but do not tighten, each bolt which secures the VVT unit and the exhaust sprocket to the camshafts.