307 JAGUAR X308 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1434 of 2490

Installation

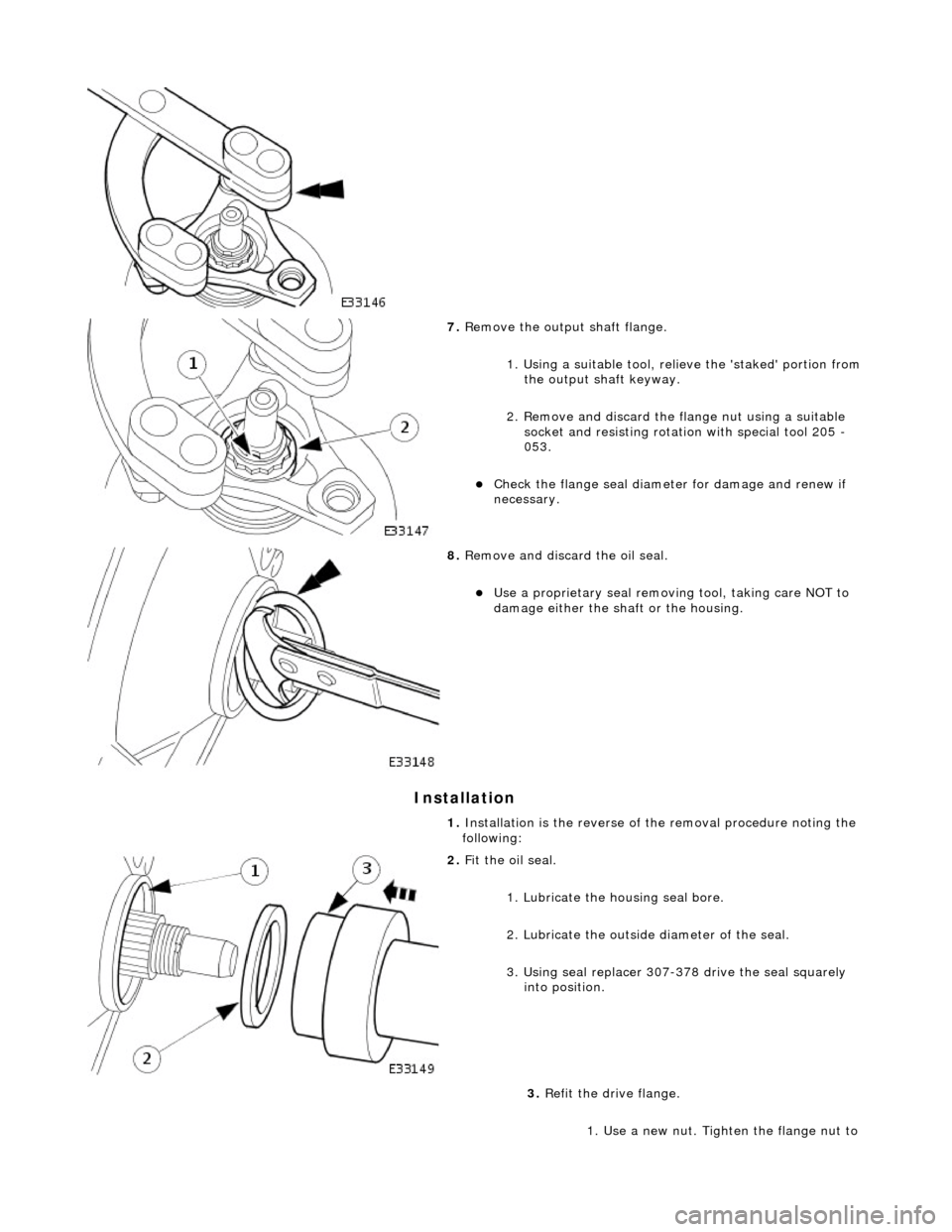

7. Remove the output shaft flange.

1. Using a suitable tool, reli eve the 'staked' portion from

the output shaft keyway.

2. Remove and discard the fl ange nut using a suitable

socket and resisting rotation with special tool 205 -

053.

пЃ¬Check the flange se al diameter for damage and renew if

necessary.

8. Remove and discard the oil seal.

пЃ¬Use a proprietary seal removing tool, taking care NOT to

damage either the shaft or the housing.

1. Installation is the re verse of the removal procedure noting the

following:

2. Fit the oil seal.

1. Lubricate the housing seal bore.

2. Lubricate the outside diameter of the seal.

3. Using seal replacer 307-378 drive the seal squarely into position.

3. Refit the drive flange.

1. Use a new nut. Tighten the flange nut to

Page 1448 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Transmission

Removal

Removal

Special Tool(s)

Engine support

303-021

Engine lifting brackets

303-536

1. Select N gear position.

2. Disconnect the battery ground lead.

3. Remove the engine covers. Re fer to Operation 12.30.06.

4. Remove the air intake tube, MAFM and air cleaner cover

assembly. Refer to Operation 19.10.30.

5. Disconnect the transmission link lead connector.

1. Release the connector fr om its mounting bracket.

2. Disconnect the multiplug.

6. Remove the EMS harness mounting bracket.

пЃ¬Release the bolt, bracket to cylinder head.

7. Fit engine lifting bracket 307 - 536 at the rear RH.

Page 1449 of 2490

8. Remove the centre trim panel from the engine compartment.

1. Remove the left hand side enclosure panel.

2. Remove the centre trim panel.

9. Move the coolant header tank for access.

1. Disconnect the bleed pipe, header tank to radiator .

2. Remove the header tank fixings.

10. Fit engine lifting bracket 307 - 536 at the rear LH.

11. Support the engine using 307 - 021.

1. Adjust and locate the side support brackets to fit into

the LH and RH body channels and tighten the beam

fixings.

2. Engage the support hooks in to the engine rear lifting

Page 1456 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Input Shaft Seal

Disassembly and Assembly of Subassemblies

Special Tool(s)

Oil seal replacer

307-378

1. Disconnect the battery ground lead.

2. Remove the air intake / MAFM assembly, refer to Operation

19.10.30.

3. Raise the vehicle for access.

4. Remove the front muffler, 30.10.18

5. Remove the RH and LH catalytic converters, refer to Operation

17.50.09 and 17.50.10.

6. Drain the transmission fluid, refer to Operation 44.24.02.

7. Remove the transmission unit, refer to Operation 44.20.01.

8. Remove the torque converter fro m the transmission unit, refer

to Operation 44.17.07.

9. Remove the front oil seal.

пЃ¬Using a proprietary tool remove the seal, taking care not

to damage the shaft or bore diameters.

10. Installation is the reverse of the removal procedure noting

that:

11. Fit the oil seal.

1. Lubricate the housing seal bore.

2. Lubricate the outside diameter of the seal.

3. Using seal replacer 307 - 379, drive the seal squarely into place.

Page 1457 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Torque Converter

Disassembly and Assembly of Subassemblies

CAUTION: If the transmission is to be renewed, renew the to rque converter also.

Special Tool(s)

Torque converter lifting handles

307-139

1. Remove the transmission unit from the vehicle; refer to

Operation 44.20.01.

2. Remove the torque converter from the transmission unit.

пЃ¬Fit lifting handles 307 - 139 ( JD-105).

3. Remove lifting handles 307 - 139 (JD-105) from the torque

converter.

4. Clean the torque conver ter and mating faces.

5. CAUTIONS:

Use extreme care NOT to damage the oil seal with the

converter spigot.

Ensure that the conver ter is fully located.

Fit the torque converter.

1. Fit lifting handles 307 - 139 (JD-105).

2. Lubricate the front pump seal.

пЃ¬To facilitate location, rotate the converter as it is being

fitted and feel for the engage ment of the splines and of

the oil pump drive.

6. Check that the converter fixing boss faces are approximately

8,0 mm proud of the transm ission mounting face.

7. Remove the lifting handles from the torque converter.

8. Install the transmission unit; refer to Operation 44.20.01.

Page 1465 of 2490

The Drive-to-fourth switch:

пЃ¬Detects when the gear selector lever is moved from Drive to Fourth. пЃ¬Is hard-wired to the transmission control module.

The Neutral position switch:

пЃ¬Is hard-wired to the body processor module. пЃ¬Detects when the gear selector lever is moved to the Neutral position.

The Park position switch:

пЃ¬Is hard-wired to the body processor module. пЃ¬Detects when the gear selector leve r is moved to the Park position.

The gear selector module:

пЃ¬Provides illumination of the gear sele ctor surround, which is dimmable via a CA N signal from the instrument cluster. пЃ¬Provides red illumination, on the gear selector surround, of the gear selected, by CAN signals from the instrument

cluster.

пЃ¬Illuminates the security system Active LED on the gear se lector surround, in response to an input from the body

processor module.

пЃ¬Is connected to the fascia harness via a 12-way connector. Refer to Connec tor Pins Identification, 307-01A.

The gear selector interlock solenoid:

пЃ¬Prevents the gear selector lever from be ing moved from the Park position, unless th e ignition switch is in position II,

and the brake pedal is depressed.

пЃ¬Is controlled by an input from the body processor module.

The seven gear selector positions are:

пЃ¬P : The transmission is mechanically locked (starting available). пЃ¬R : Reverse gear. пЃ¬N : No power to the rear wh eels (starting available). пЃ¬D : All 5 forward gears available. пЃ¬4 : Upshift to 4th gear only. пЃ¬3 : Upshift to 3rd gear only. пЃ¬2 : Upshift to 2nd gear only.

Performance Mode Pushbutton

The performance mode pushbutton:

пЃ¬Is mounted on the gear selector surround. пЃ¬Selects Normal or Sport mode when pressed by the driver. пЃ¬Is illuminated when Sport mode is selected.

Page 1470 of 2490

Move the selector lever slowly from P to 2 and back,

noting the illumination / positi on relationship as follows: 1

Does state illumination match the lever position in each

direction of travel?

Yes

GO to A4

No GO to A3

No With lever at D (when moving from 2 to P ) is 3 or 4

illuminated?

Yes GO to A3

No GO to A5

No With lever moved from P , to position 4 , is D illuminated?

Yes GO to A4

No GO to A5

A3: CHECK SELECTOR CABLE ADJUSTMENT

Verify and correct as requ ired the selector cable

adjustment 1

OK?

Yes GO to A4

No Correct adjustment error, see 44.15.07 Workshop Manual

307-05A and test the system for normal operation.

A4: CHECK HARNESS SIGNAL CONTINUITY - D TO 4 SWITCH

Page 1506 of 2490

No GO to A5

No With lever moved from P , to position 4 , is D illuminated?

Yes GO to A4

No GO to A5

A3: CHECK SELECTOR CABLE OR LINEAR SWITCH ADJUSTMENT

Verify and correct as required the selector cable or linear

switch adjustment 1

OK?

Yes GO to A4

No Correct adjustment error, see 44.15.07 Workshop Manual

307-05B and test the system for normal operation.

A4: CHECK HARNESS SIGNAL CONT INUITY - DUAL LINEAR SWITCH

With EM0 61 and CC008 disconnected, measure the

resistance between CC00 8/001 and EM061 /028

пЃ¬Repeat for

1

CC008/008 and EM061/027 2

CC008/006 and EM061/026 3

CC008/007 and EM061/025 4

Is the resistance < 0.5 OHM?

Yes GO to A5

No Inspect EM061, EM063 and CC008 for corrosion, bent /

pushed back pins or locate harness. Repair as necessary

and test the system for normal operation.

A5: CHECK HARNESS SWITCH GROUND CONTINUITY

Page 1743 of 2490

Accelerati

on Control - Accelerator Cable Adjustment

Gen

eral Procedures

1.

Load the Approved Jaguar Diagno stic System with power train

data logger.

2. Connect the Approved Jaguar Diag nostic System to the vehicle.

3. W

ith 'Disable Network Integrity Test - YES/ NO' displayed on

the screen select YES.

4. With new menu displayed on the screen, select ' Engine

Management'.

5. Turn the ignition to ON.

пЃ¬R

emove any previously selected data logger parameters.

6. On data logger select PPS11 an d PPS2 (Pedal demand sensors

1 and 2).

7. On Sedan models only, remove the bulkhead covers on both

sides and the engine compartment rear cover.

8. Cut, remove and discard the ra tchet strap which retains the

throttle cable to the abutment bracket.

9. Ensure there is no tension on the throttle cable by releasing

the throttle cable adjustment nut from the abutment bracket.

10. Record the voltages for both sensors, PPS11 and PPS2.

11. Partially insert the throttle cable adjustment nut into the

abutment bracket.

12. Recheck the voltages for both sensors, PPS11 and PPS2.

13. Where the voltages at step 12 are higher than the voltages

taken at step 10, contin ue to step 15 below.

14. Where the voltages at step 12 are the same as the voltages

taken at step 10, contin ue to step 16 below.

15. Rotate the adjustment nut clockwise (as viewed from the

front of the vehicle) until the same voltages are indicated as in

step 10. Continue to turn thro ugh a part revolution until the

sides of the nut are vertical. Tu rn through a further 90 degrees,

then fully insert the nut into the abutment bracket.

16. Rotate the adjustment nut anti-clockwise (as viewed from the

front of the vehicle) until the indicated voltage starts to

increase. Then rotate the nut clockwise through a part

revolution until the sides are ve rtical. Turn through a further 90

degrees, then fully insert the nut into the abutment bracket.

17. Fit a new ratchet strap to secure the throttle cable adjusting

nut to the abutment bracket.

18. Operate the throttle pedal through 20 full cycles to settle the

cable. Check the voltages now shown, remain the same as in

steps 15 and 16.

19. Check and where necessary adjust the kickdown switch. For

additional information, refer to Section 307

-05A Automatic Transmissi

on/Transaxle External Controls

Sectio

n

307

-05

B

Au

tomatic Transmission/Tra

nsaxle External Controls

.

20

.

On Sedan models only, refit the engine compartment rear

cover and the bulkhead co vers on both sides.

21. Switch the ignition OFF and disconnect the Approved Jaguar

Diagnostic System.

Page 1815 of 2490

15. Remove the temporary wooden support strut and reconnect

gas struts to the hood.

16. Check transmission fluid level an d top up as required; refer to

307A-01 (N/A) or 307B-01 (S/C), operation 44.24.02.

17. Refill the cooling system; refer to 26.10.01 or (SC) 26.10.01.

18. Recharge air conditioning system; refer to 82.30.30.

19. Reconnect battery ground cable (IMPORTANT, see SRO

86.15.15 for further information).