check oil JAGUAR X308 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 950 of 2490

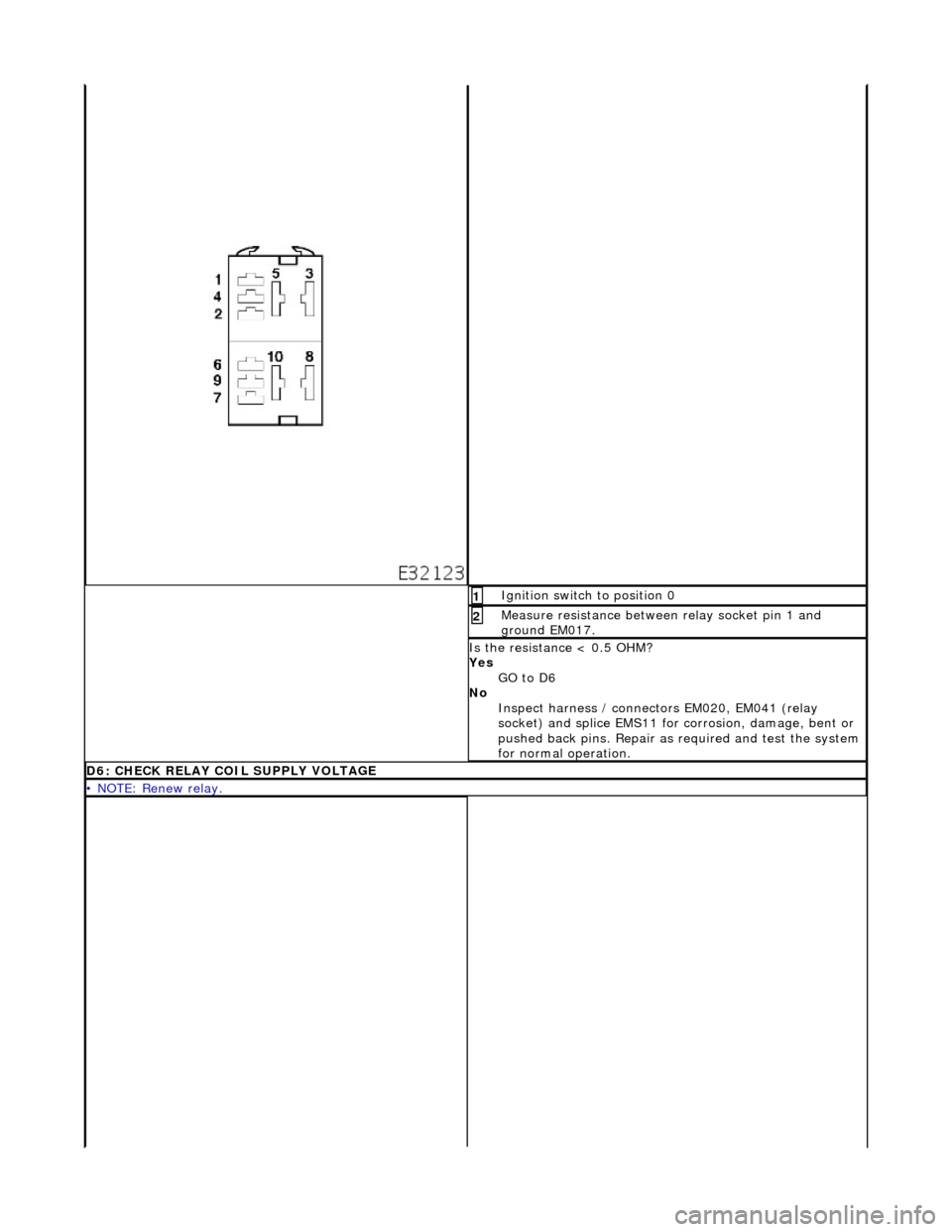

Ig

nition switch to position 0

1

Meas

ure re

sistance between relay socket pin 1 and

ground EM017.

2

I s

the resistance < 0.5 OHM?

Yes GO to D6

No Inspect harness / connec tors EM020, EM041 (relay

socket) and splice EMS11 for corrosion, damage, bent or

pushed back pins. Repair as required and test the system

for normal operation.

D6: CHECK

RELAY COIL SUPPLY VOLTAGE

• NO

TE: Renew relay.

Page 1020 of 2490

Fuel Char

ging and Controls - Fuel Charging and Controls

D

iagn

osis and Testing

I

n

spection and Verification

1.

1. Veri fy the customer concern.

2. 2. Confi

rm which, if any, warning li

ghts and/or messages were displayed on the instrument cluster.

• NOTE: If any warning lights and/or me ssages were displayed when the fault occurred, refer to the Driver Information

table for DTCs associated with the display, then to the DTC index table for possible sources and actions. Some warnings will

appear to clear when the ignition is cycl ed. This is often because the warning has flagged as a resu lt of one of the vehicle's

on-board diagnostic routines having run to detect the fault. If the same routine is not run when the ignition is switched ON,

the warning will not reflag until the routine does run. See the DTC summaries for drive cycle routines.

3. 3. Visually inspect for obvious signs of mechanical or electrical damage.

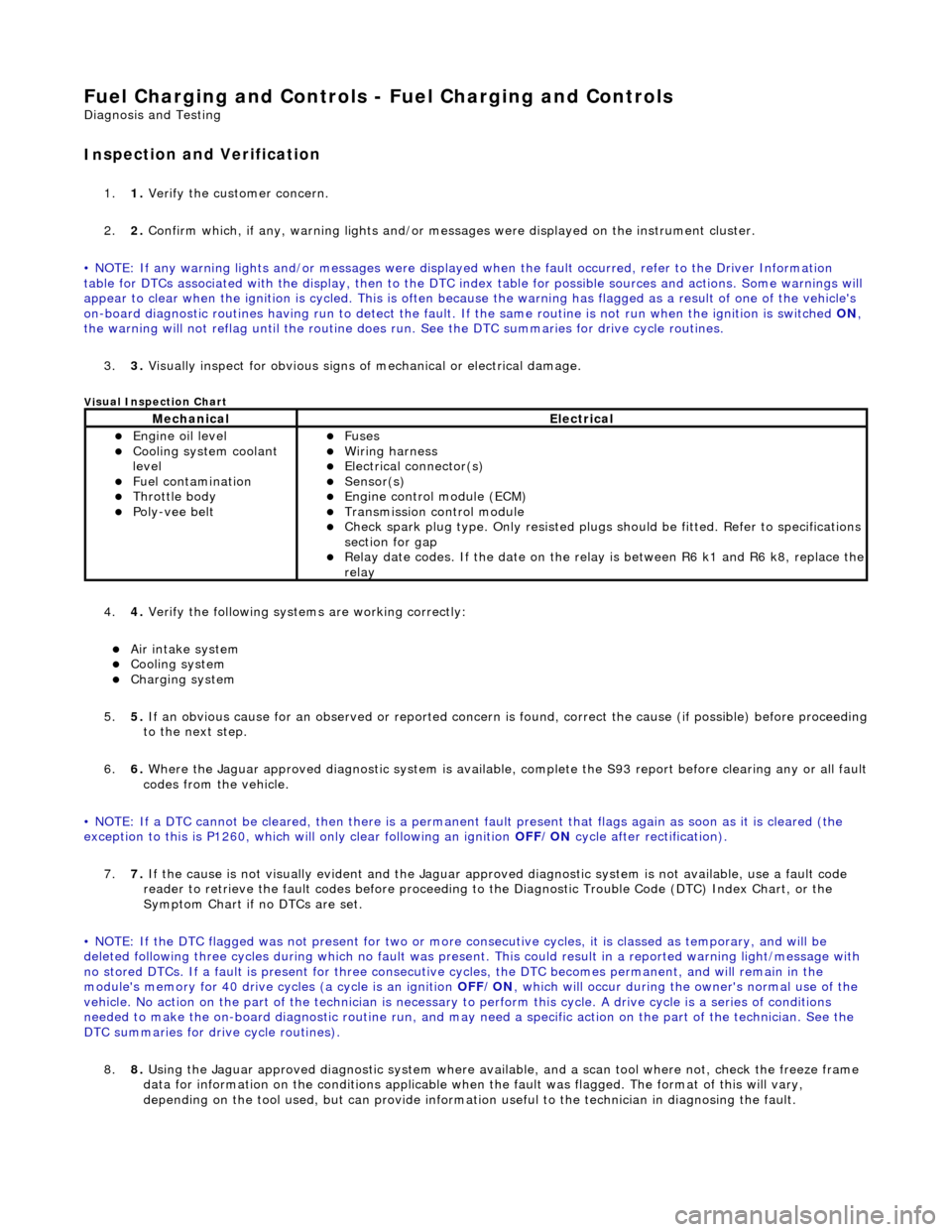

Vi

sual Inspection Chart

4.

4. Veri fy the foll

owing syst

ems are working correctly:

пЃ¬Air intake

system

пЃ¬Cooling system

пЃ¬Charging system

5. 5. If

an obvious cause for an observed or

reported concern is found, correct th e cause (if possible) before proceeding

to the next step.

6. 6. Where the Jaguar approved diagnostic sy stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared (the

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

7. 7. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

• NOTE: If the DTC flagged was not present for two or more co nsecutive cycles, it is classed as temporary, and will be

deleted following three cycl es during which no fault was present. This could result in a reported wa rning light/message with

no stored DTCs. If a fault is present for three consecutive cycles, the DTC becomes permanent, and will remain in the

module's memory for 40 drive cycl es (a cycle is an ignition OFF/ON, which will occur during the owner's normal use of the

vehicle. No action on the part of the technician is necessary to perform this cycle. A drive cycle is a series of conditions

needed to make the on-board diagnostic ro utine run, and may need a specific action on the part of the technician. See the

DTC summaries for drive cycle routines).

8. 8. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

depending on the tool used, but can pr ovide information useful to the technician in diagnosing the fault.

MechanicalElectrical

пЃ¬Engine

oil level

пЃ¬Coo

ling system coolant

lev

el

пЃ¬Fuel contamination

пЃ¬Throttle body пЃ¬Poly-ve

e belt

пЃ¬Fu

ses

пЃ¬W

i

ring harness

пЃ¬E

l

ectrical connector(s)

пЃ¬Sens

o

r(s)

пЃ¬Engine

control module (E

CM)

пЃ¬Tran

s

mission control module

пЃ¬Check spark plu

g type. Only r

e

sisted plugs should be fitted. Refer to specifications

section for gap

пЃ¬Relay date codes. I

f the date on the rela

y is between R6 k1 and R6 k8, replace the

relay

Page 1021 of 2490

CAUTI

ON: When probing connectors to take

measurements in the course of the pinpoint tests, use the adaptor kit,

part number 3548-1358-00.

• NOTE: When performing electrical voltag e or resistance tests, always use a digital multimeter (DMM) accurate to 3

decimal places, and with an up-t o-date calibration certificate. When testing resistance, always take the resistance of the

DMM leads into account.

• NOTE: Check and rectify basic faults before beginning diagnostic ro utines involving pinpoint tests.

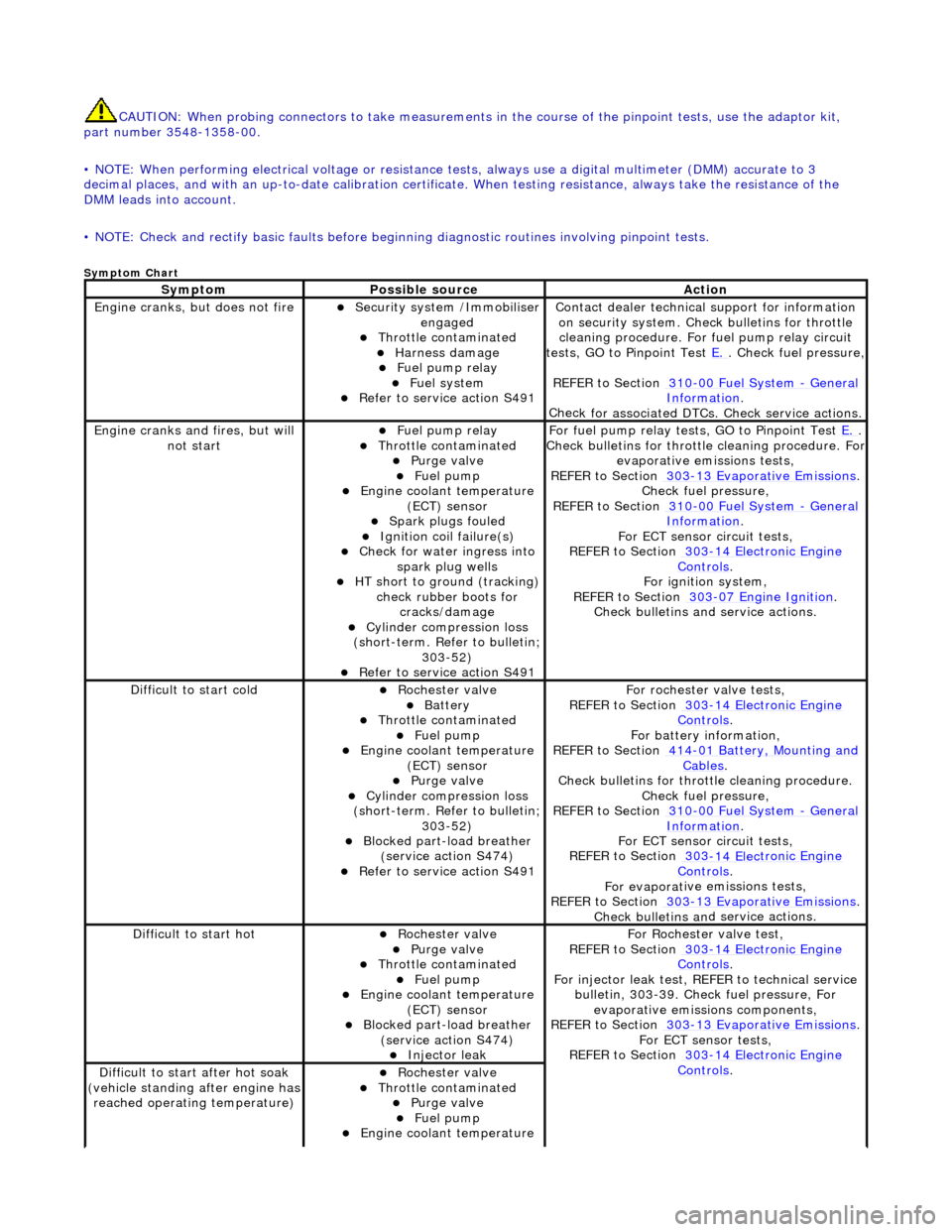

Sy

mptom Chart

Sy

mptom

Possib

le source

Acti

on

Engine

cranks, but does not fire

пЃ¬Secu

rity system /Immobiliser

engaged

пЃ¬Thr

ottle contaminated

пЃ¬Harness damage

пЃ¬F

uel pump relay

пЃ¬Fue

l system

пЃ¬R

efer to service action S491

Contact dealer techn

ical

support for information

on security system. Chec k bulletins for throttle

cleaning procedure. For fuel pump relay circuit

tests, GO to Pinpoint Test E.

.

Check fuel pressure,

REFER to Section 310

-00

Fuel System

- Gen

eral

Informati

on

.

Chec

k for associated DTCs

. Check service actions.

Engine

cranks and fires, but will

not start

пЃ¬F

uel pump relay

пЃ¬Thr

ottle contaminated

пЃ¬Purge

valve

пЃ¬Fue

l pump

пЃ¬Engine coolan

t temperature

(ECT) sensor

пЃ¬Spark plugs

fouled

пЃ¬Ignition coil

failure(s)

пЃ¬Check f

or water ingress into

spark plug wells

пЃ¬HT sho

rt to ground (tracking)

check rubber boots for cracks/damage

пЃ¬Cyl

inder compression loss

(short-term. Refer to bulletin;

303-52)

пЃ¬R

efer to service action S491

F

or fuel pump relay tests,

GO to Pinpoint Test E.

.

Check bull

etins for throttle cleaning procedure. For

evaporative emissions tests,

REFER to Section 303

-1

3 Evaporative Emissions

. Chec

k fuel pressure,

REFER to Section 310

-00

Fuel System

- Ge

neral

Informati

on

.

F

or ECT sensor circuit tests,

REFER to Section 303

-14 Elec

tronic Engine

Controls.

For ign

ition system,

REFER to Section 303

-07

Engine Ignition

.

Check bulletins an d service

actions.

D

ifficult to start cold

пЃ¬Roc

hester valve

пЃ¬Batt

ery

пЃ¬Thr

ottle contaminated

пЃ¬Fue

l pump

пЃ¬Engine coolan

t temperature

(ECT) sensor

пЃ¬Purge

valve

пЃ¬Cyl

inder compression loss

(short-term. Refer to bulletin;

303-52)

пЃ¬Blocked part-load breather (

service action S474)

пЃ¬R

efer to service action S491

F

or rochester valve tests,

REFER to Section 303

-14 Elec

tronic Engine

Controls.

F

or battery information,

REFER to Section 414

-0

1 Battery, Mounting and

Cables.

Check bull

etins for throttle cleaning procedure.

Check fuel pressure,

REFER to Section 310

-00

Fuel System

- Ge

neral

Informati

on

.

F

or ECT sensor circuit tests,

REFER to Section 303

-14 Elec

tronic Engine

Controls.

For evaporat

ive emissions tests,

REFER to Section 303

-1

3 Evaporative Emissions

. Check bulletins an

d

service actions.

D

ifficult to start hot

пЃ¬Roc

hester valve

пЃ¬Purge

valve

пЃ¬Thr

ottle contaminated

пЃ¬Fue

l pump

пЃ¬Engine coolan

t temperature

(ECT) sensor

пЃ¬Blocked part-load breather (

service action S474)

пЃ¬Injec

tor leak

F

or Rochester

valve test,

REFER to Section 303

-14 Elec

tronic Engine

Controls.

Fo

r injector leak test, REFER to technical service

bulletin, 303-39. Check fuel pressure, For evaporative emissions components,

REFER to Section 303

-1

3 Evaporative Emissions

. F

or ECT sensor tests,

REFER to Section 303

-14 Elec

tronic Engine

Controls. D

ifficult to start after hot soak

(vehicle standing after engine has

reached operating temperature)

пЃ¬Roc

hester valve

пЃ¬Thr

ottle contaminated

пЃ¬Purge

valve

пЃ¬Fue

l pump

пЃ¬Engine coolan

t temperature

Page 1022 of 2490

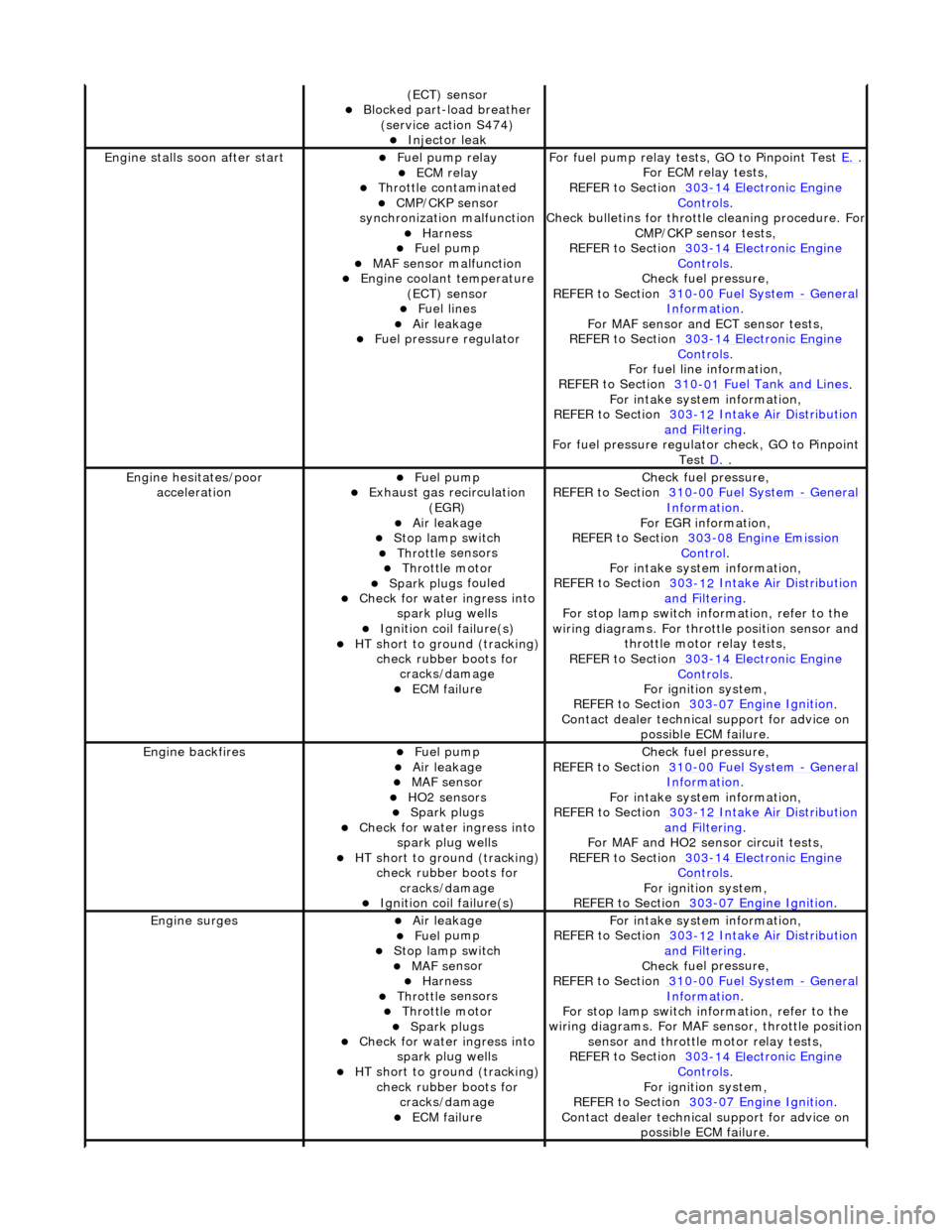

(ECT) se

nsor

пЃ¬Blocked part-load breather

(s

ervice action S474)

пЃ¬Injec

t

or leak

Engine stalls

soon

after start

пЃ¬F

u

el pump relay

пЃ¬ECM relay пЃ¬Thr

o

ttle contaminated

пЃ¬CMP/CKP sen

s

or

synchronization malfunction

пЃ¬Harness пЃ¬Fuel

pump

пЃ¬MAF

s

ensor malfunction

пЃ¬Engine coolan

t

temperature

(ECT) sensor

пЃ¬Fue l

lines

пЃ¬Air leakage пЃ¬Fu

el pressure regulator

F

o

r fuel pump relay tests,

GO to Pinpoint Test E.

.

F or ECM

relay tests,

REFER to Section 303

-14 Elec tronic En

gine

Controls.

Check bull etins for throttl

e cleaning procedure. For

CMP/CKP sensor tests,

REFER to Section 303

-14 Elec tronic En

gine

Controls.

Chec k fu

el pressure,

REFER to Section 310

-00 Fu

el System

- Ge

n

eral

Informati

o

n

.

F or MAF sensor and

ECT sensor tests,

REFER to Section 303

-14 Electronic En

gine

Controls.

For fuel l

ine information,

REFER to Section 310

-01

Fuel Tank and Lines

.

F or i

ntake system information,

REFER to Section 303

-1 2

Intake Air Distribution

and F

ilt

ering

.

F o

r fuel pressure regulato

r check, GO to Pinpoint

Test D.

.

Engine h e

sitates/poor

acceleration

пЃ¬Fue l

pump

пЃ¬Exhaus

t gas

recirculation

(EGR)

пЃ¬Air leakage пЃ¬Stop lamp swi t

ch

пЃ¬Throttl

e

sensors

пЃ¬Throttl

e

motor

пЃ¬Spark plugs

fouled

пЃ¬Check f

o

r water ingress into

spark plug wells

пЃ¬Ignition coil fail

ure(s)

пЃ¬HT sho

rt to ground (tracking)

check rubber

boots for

cracks/damage

пЃ¬ECM failu r

e

Chec

k fu

el pressure,

REFER to Section 310

-00 Fu

el System

- Ge

n

eral

Informati

o

n

.

F o

r EGR information,

REFER to Section 303

-08 En gin

e Emission

Control.

F or i

ntake system information,

REFER to Section 303

-1 2

Intake Air Distribution

and F

ilt

ering

.

F or stop l

amp switch in

formation, refer to the

wiring diagrams. For throttle position sensor and throttle motor relay tests,

REFER to Section 303

-14 Elec tronic En

gine

Controls.

For ign i

tion system,

REFER to Section 303

-07 En

gine Ignition

.

Contact dealer techn i

cal

support for advice on

possible ECM failure.

Engine ba ckfiresпЃ¬Fuel

pump

пЃ¬Air leakage пЃ¬MAF s

e

nsor

пЃ¬HO2 sensors пЃ¬Spark plugs

пЃ¬Check fo

r water ingress into

spark plug wells

пЃ¬HT short to ground (tracking) check rubber

boots for

cracks/damage

пЃ¬Ignition coil fail

ure(s)

Chec

k fu

el pressure,

REFER to Section 310

-00 Fu

el System

- Ge

n

eral

Informati

o

n

.

F or i

ntake system information,

REFER to Section 303

-1 2

Intake Air Distribution

and F

ilt

ering

.

For MAF and HO2

sensor circuit tests,

REFER to Section 303

-14 Electronic En

gine

Controls.

For igni

tion system,

REFER to Section 303

-07 En

gine Ignition

.

Engine

s

urges

пЃ¬Air leakage пЃ¬Fue

l

pump

пЃ¬Stop lamp swi

t

ch

пЃ¬MAF s

e

nsor

пЃ¬Harness пЃ¬Throttl

e

sensors

пЃ¬Throttl

e

motor

пЃ¬Spark plugs

пЃ¬Check fo

r water ingress into

spark plug wells

пЃ¬HT sho rt to ground (tracking)

check rubber

boots for

cracks/damage

пЃ¬ECM failu r

e

F

or i

ntake system information,

REFER to Section 303

-1 2

Intake Air Distribution

and F

ilt

ering

.

Chec k fu

el pressure,

REFER to Section 310

-00 Fu

el System

- Gen

e

ral

Informati

o

n

.

F or stop l

amp switch in

formation, refer to the

wiring diagrams. For MAF se nsor, throttle position

sensor and throttle motor relay tests,

REFER to Section 303

-14 Elec tronic En

gine

Controls.

For ign i

tion system,

REFER to Section 303

-07 En

gine Ignition

.

Contact dealer techn i

cal

support for advice on

possible ECM failure.

Page 1026 of 2490

REFE

R to Section 310

-00

Fu

el

Sy

ste

m

- General

Information

.

Check f o

r DTCs indicating a sensor

fault,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

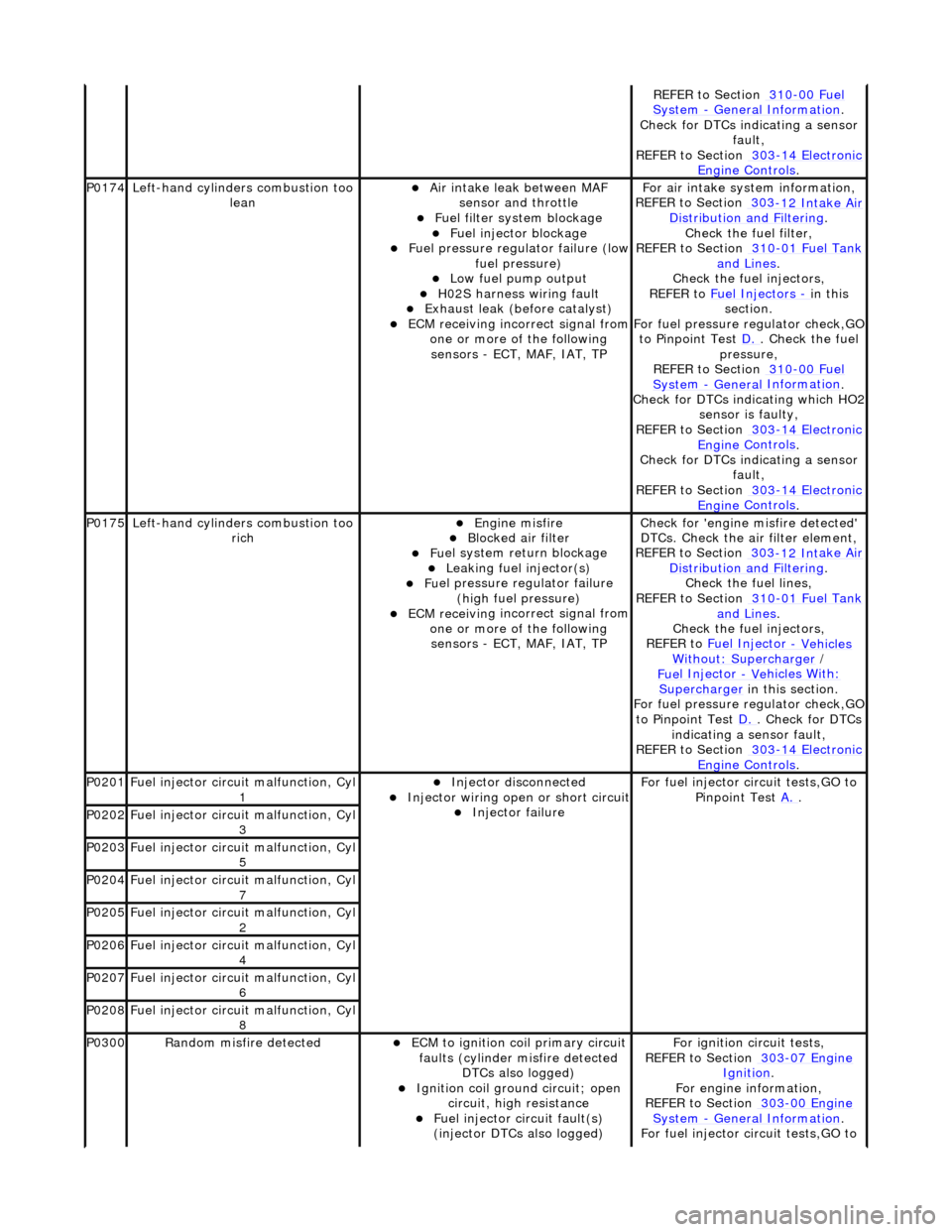

P0174

Left-hand cyl i

nders combustion too

lean

пЃ¬Air in

take leak between MAF

sensor and throttle

пЃ¬F u

el filter system blockage

пЃ¬F

u

el injector blockage

пЃ¬F

u

el pressure regulator failure (low

fuel pressure)

пЃ¬Low f u

el pump output

пЃ¬H0

2S harness wiri

ng fault

пЃ¬E

x

haust leak (before catalyst)

пЃ¬ECM receivi

n

g incorrect signal from

one or more of the following sensors - ECT, MAF, IAT, TP

F o

r air intake sy

stem information,

REFER to Section 303

-12 Int

ake Air

Distribu tion and Filterin

g

.

Check the fuel fi lter,

REF

ER to Section 310

-01

Fu

el Tank

and Lines.

Chec k the

fuel injectors,

REFER to Fuel Injectors

- in t h

is

section.

For fuel pressure regulator check,GO

to Pinpoint Test D.

. Ch

eck the fuel

pressure,

REFER to Section 310

-00 Fu

el

Sy

ste

m

- General

Information

.

Check f o

r DTCs indicating which HO2

sensor is faulty,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

Check f o

r DTCs indicating a sensor

fault,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

P0175Left-hand cyli

nders combustion too

rich

пЃ¬Engine m

isfire

пЃ¬Bl

ocked air

filter

пЃ¬F

u

el system return blockage

пЃ¬Leak

i

ng fuel injector(s)

пЃ¬F

u

el pressure regulator failure

(high fuel pressure)

пЃ¬ECM receivi n

g incorrect signal from

one or more of the following sensors - ECT, MAF, IAT, TP

Check for 'en

gine misfire detected'

DTCs. Check the air filter element,

REFER to Section 303

-12 Int

ake Air

Distribu tion and Filterin

g

.

Chec k the

fuel lines,

REFER to Section 310

-01 Fu

el Tank

and Lines.

Chec k the

fuel injectors,

REFER to Fuel Injector

- Vehicles Wi

thout: Supercharger

/

Fue

l Injector

- Ve

hicles With

:

Supercharger

in this

section.

For fuel pressure regulator check,GO

to Pinpoint Test D.

. Check for DT

Cs

indicating a sensor fault,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

P0201F

u

el injector circuit malfunction, Cyl

1

пЃ¬Injector discon n

ected

пЃ¬Inject

or wir

ing open or short circuit

пЃ¬Injector fail

ure

F

o

r fuel injector circuit tests,GO to

Pinpoint Test A.

.

P0202Fu

el injector circuit malfunction, Cyl

3

P0203F u

el injector circuit malfunction, Cyl

5

P0204F u

el injector circuit malfunction, Cyl

7

P0205Fu

el injector circuit malfunction, Cyl

2

P0206Fu

el injector circuit malfunction, Cyl

4

P0207F u

el injector circuit malfunction, Cyl

6

P0208F u

el injector circuit malfunction, Cyl

8

P0300Ran d

om misfire detected

пЃ¬ECM t

o

ignition coil primary circuit

faults (cylinder misfire detected DTCs also logged)

пЃ¬Ignition coil ground circuit; open

ci

rcuit, high resistance

пЃ¬F

u

el injector circuit fault(s)

(injector DTCs also logged)

F o

r ignition circuit tests,

REFER to Section 303

-07 En

gine

Ignition.

F or engi

ne information,

REFER to Section 303

-00 En

gine

Sy

ste

m

- General

Information

.

F o

r fuel injector circuit tests,GO to

Page 1027 of 2490

пЃ¬Ignition coil

failure(s)

пЃ¬HT sho

rt to ground (tracking)

check rubber boots for cracks/damage

пЃ¬Spark plug

failure/fouled/incorrect

gap

пЃ¬Cy

linder compression low

пЃ¬F

uel delivery pressure (low/high)

пЃ¬F

uel injectors restricted/leaking

пЃ¬Fuel contamination

пЃ¬P

AS pulley bolts loose (see Service

Action S462)

пЃ¬W

orn camshaft/broken valve

springs

P

inpoint Test

A.

.

Check fuel

pressure,

REFER to Section 310

-00

Fuel

Sy

stem

- General

Information

.

Chec

k fuel injectors,

REFER to Fuel Injectors

- in t

his

section.

Check service actions.

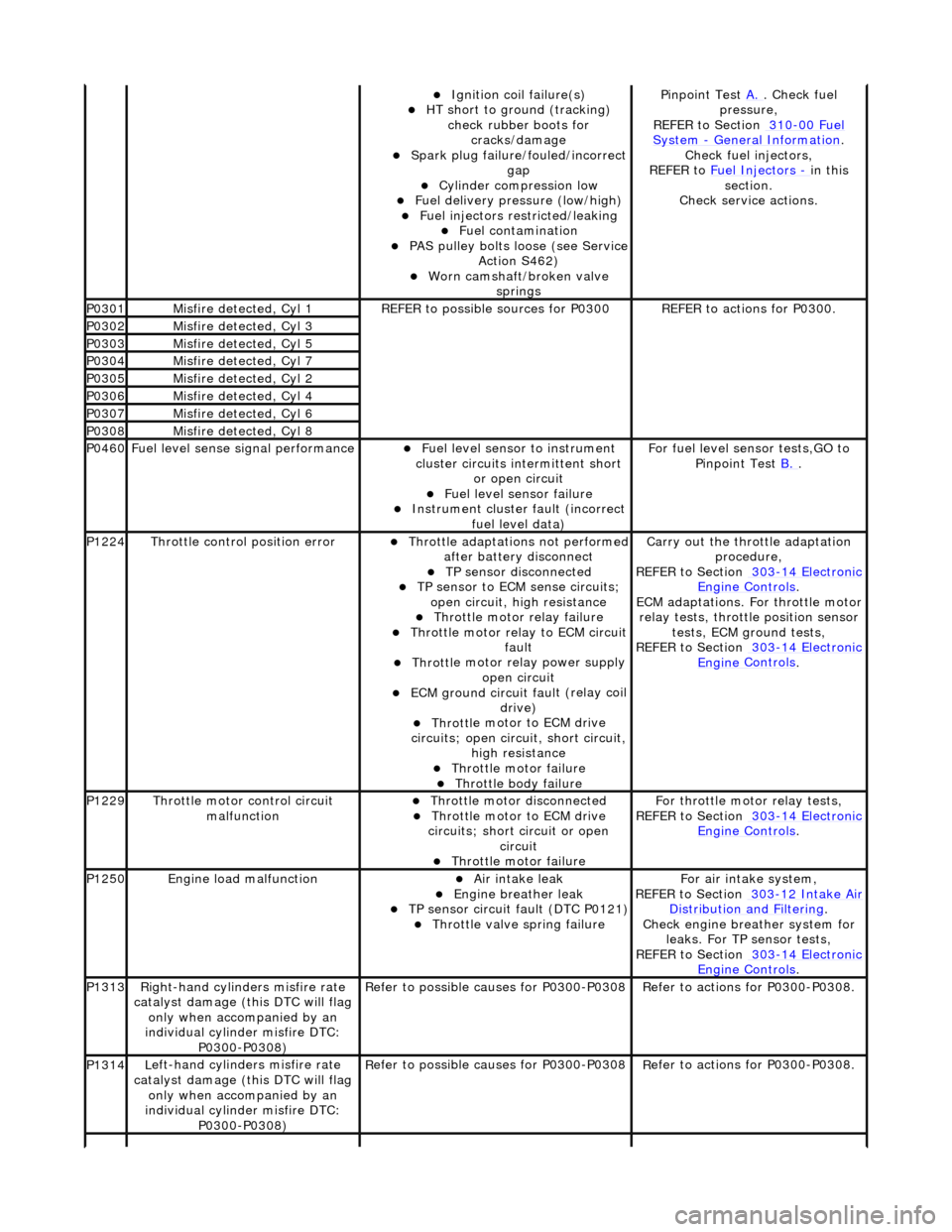

P0301Misfire

detected, Cyl 1

R

EFER to possible sources for P0300

R

EFER to actions for P0300.

P0302Misfire

detected, Cyl 3

P0303Misfire

detected, Cyl 5

P0304Misfire

detected, Cyl 7

P0305Misfire

detected, Cyl 2

P0306Misfire

detected, Cyl 4

P0307Misfire

detected, Cyl 6

P0308Misfire

detected, Cyl 8

P0460F

uel level sense signal performance

пЃ¬Fue

l level sensor

to instrument

cluster circuits in termittent short

or open circuit

пЃ¬F

uel level sensor failure

пЃ¬Instrument cluster

faul

t (incorrect

fuel level data)

F

or fuel level sensor tests,GO to

Pinpoint Test B.

.

P1224Throttl

e control position error

пЃ¬Thro

ttle adaptations not performed

after battery disconnect

пЃ¬TP se

nsor disconnected

пЃ¬TP se

nsor to ECM sense circuits;

open circuit, hi gh resistance

пЃ¬Throttl

e motor relay failure

пЃ¬Th

rottle motor relay to ECM circuit

fault

пЃ¬Throttl

e motor relay power supply

open circuit

пЃ¬ECM ground circuit faul

t (relay coil

drive)

пЃ¬Throttl

e motor to ECM drive

circuits; open circuit, short circuit, high resistance

пЃ¬Throttl

e motor failure

пЃ¬Throttl

e body failure

Carry

out the throttle adaptation

procedure,

REFER to Section 303

-14

Electronic

Engine

Controls

.

ECM adaptations. For

throttle motor

relay tests, throttle position sensor tests, ECM ground tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

P1229Throttl

e motor control circuit

malfunction

пЃ¬Throttl

e motor disconnected

пЃ¬Throttl

e motor to ECM drive

circuits; short circuit or open circuit

пЃ¬Throttl

e motor failure

Fo

r throttle moto

r relay tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

P1250Engine

load malfunction

пЃ¬Air

intake leak

пЃ¬Engine

breather leak

пЃ¬TP se

nsor circuit fault (DTC P0121)

пЃ¬Throttl

e valve spring failure

F

or air intake system,

REFER to Section 303

-12

Intake Air

Distribu

tion and Filtering

.

Chec

k engine breather system for

leaks. For TP sensor tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

P1313Right-hand cylinders misfire rate

cat

alyst damage (this DTC will flag

only when accompanied by an

individual cylinder misfire DTC: P0300-P0308)

R

efer to possible causes for P0300-P0308

R

efer to actions for P0300-P0308.

P1314L

eft-hand cylinders misfire rate

catalyst damage (this DTC will flag only when accompanied by an

individual cylinder misfire DTC: P0300-P0308)

R

efer to possible causes for P0300-P0308

R

efer to actions for P0300-P0308.

Page 1028 of 2490

Pinpoint Tests

P1316Mi

sfire excess emission (this DTC

will flag only when accompanied by an individual cylinder misfire DTC: P0300-P0308)

Re

fer to possible causes for P0300-P0308

R

e

fer to actions for P0300-P0308.

P1611Thr

o

ttle angle malfunction

пЃ¬TP sensor

ci

rcuit fault

пЃ¬APP sensor circuit faul

t пЃ¬Throttle

assembly failure

пЃ¬ECM failu

r

e

F

or TP and APP

sens

or circuit tests,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

F o

r throttle assembly information,

refer to throttle body in this section.

Contact dealer technical support for advice on possible ECM failure.

P1612Throttl e

offset malfunction

пЃ¬TP sensor

ci

rcuit fault

пЃ¬APP sensor circuit faul

t пЃ¬Throttle

assembly failure

пЃ¬ECM failu

r

e

F

or TP and APP

sens

or circuit tests,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

F o

r throttle assembly information,

refer to throttle body in this section.

Contact dealer technical support for advice on possible ECM failure.

P1646Fu

el pump 2 relay malfunction (this

DTC applies only to the

supercharger secondary fuel pump)

пЃ¬Fu

el pump 2 relay failure

пЃ¬Fu

el pump 2 relay to ECM circuit

fault

пЃ¬Fu

el pump 2 relay coil power

supply open circuit

пЃ¬ECM ground circuit faul t (relay coil

drive)

For fuel pump 2 r

elay circuit tests,

GO to Pinpoint Test C.

.

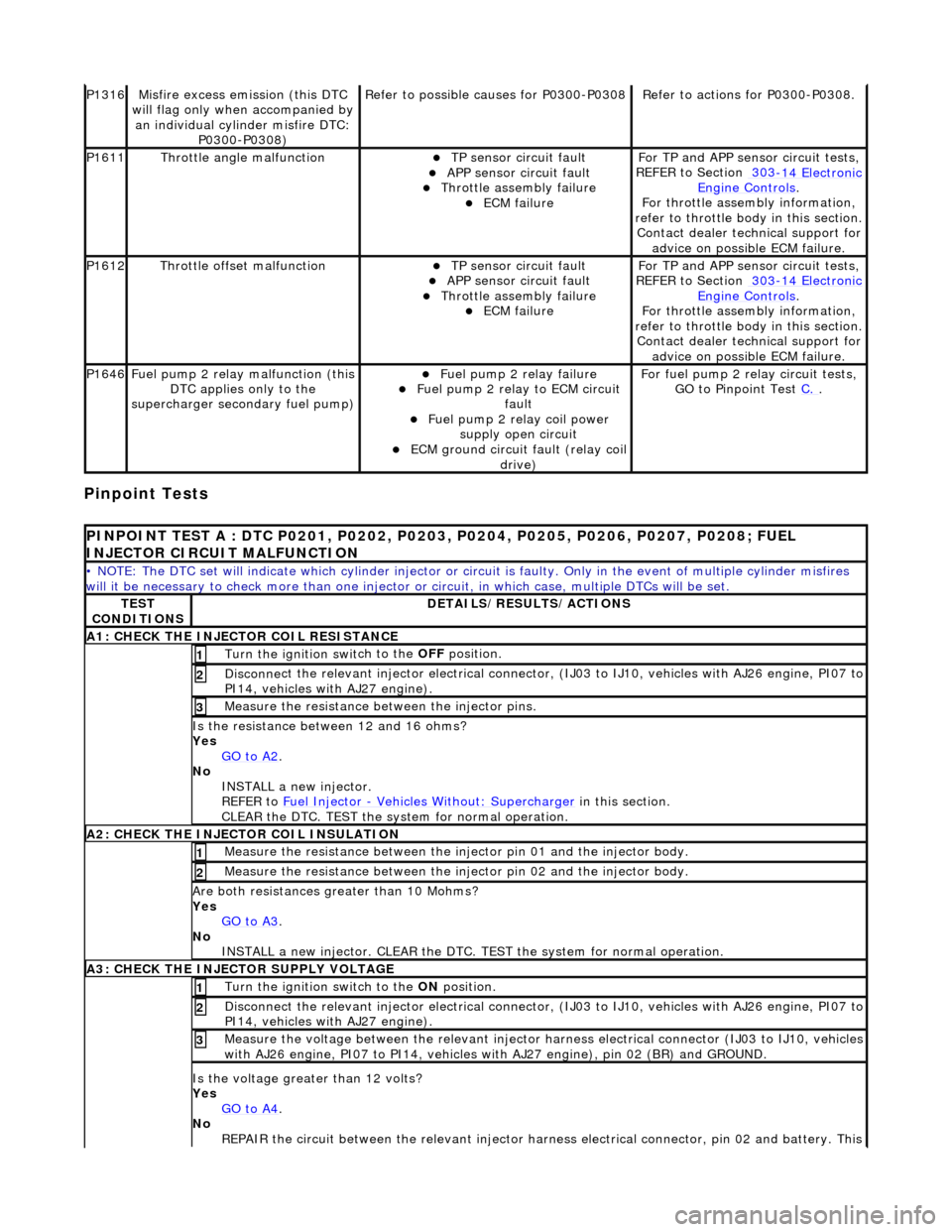

PI

NPOINT TEST A : DTC P0201, P0202, P0203, P0204, P0205, P0206, P0207, P0208; FUEL

INJECTOR CIRCUIT MALFUNCTION

• NOTE

: The DTC set will indicate which cylinder injector or circ

uit is faulty. Only in the event of multiple cylinder misfires

will it be necessary to chec k more than one injector or circuit, in which case, multiple DTCs will be set.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

A1

: CH

ECK THE INJECTOR COIL RESISTANCE

Turn the ignition swi

t

ch to the OFF

position.

1

Disconne

ct the relevant injector electrical connector

, (IJ03 to IJ10, vehicles with AJ26 engine, PI07 to

PI14, vehicles with AJ27 engine).

2

Meas ure t

he resistance between the injector pins.

3

Is

t

he resistance between 12 and 16 ohms?

Yes GO to A2

.

No

INST

ALL a new injector.

REFER to Fuel Injector

- Ve hicles With

out: Supercharger

in this

section.

CLEAR the DTC. TEST the system for normal operation.

A2: CHECK

THE INJECTOR COIL INSULATION

Meas

ure t

he resistance between the inje

ctor pin 01 and the injector body.

1

Measure t

he resistance between the inje

ctor pin 02 and the injector body.

2

Are both re

sistances greater than 10 Mohms?

Yes GO to A3

.

No

INST

ALL a new injector. CLEAR the DTC. TE

ST the system for normal operation.

A3: CHECK THE INJECTOR

SUPPLY VOLTAGE

Turn the ignition swi

t

ch to the ON

position.

1

Disconne

ct the relevant injector electrical connector

, (IJ03 to IJ10, vehicles with AJ26 engine, PI07 to

PI14, vehicles with AJ27 engine).

2

Meas ure t

he voltage between the relevant injector harness electrical connector (IJ03 to IJ10, vehicles

with AJ26 engine, PI07 to PI 14, vehicles with AJ27 engine), pin 02 (BR) and GROUND.

3

Is the volt

age greater than 12 volts?

Yes GO to A4

.

No

R

EPAIR the circuit between the relevant injector harn

ess electrical connector, pin 02 and battery. This

Page 1067 of 2490

Pinpoint Tests

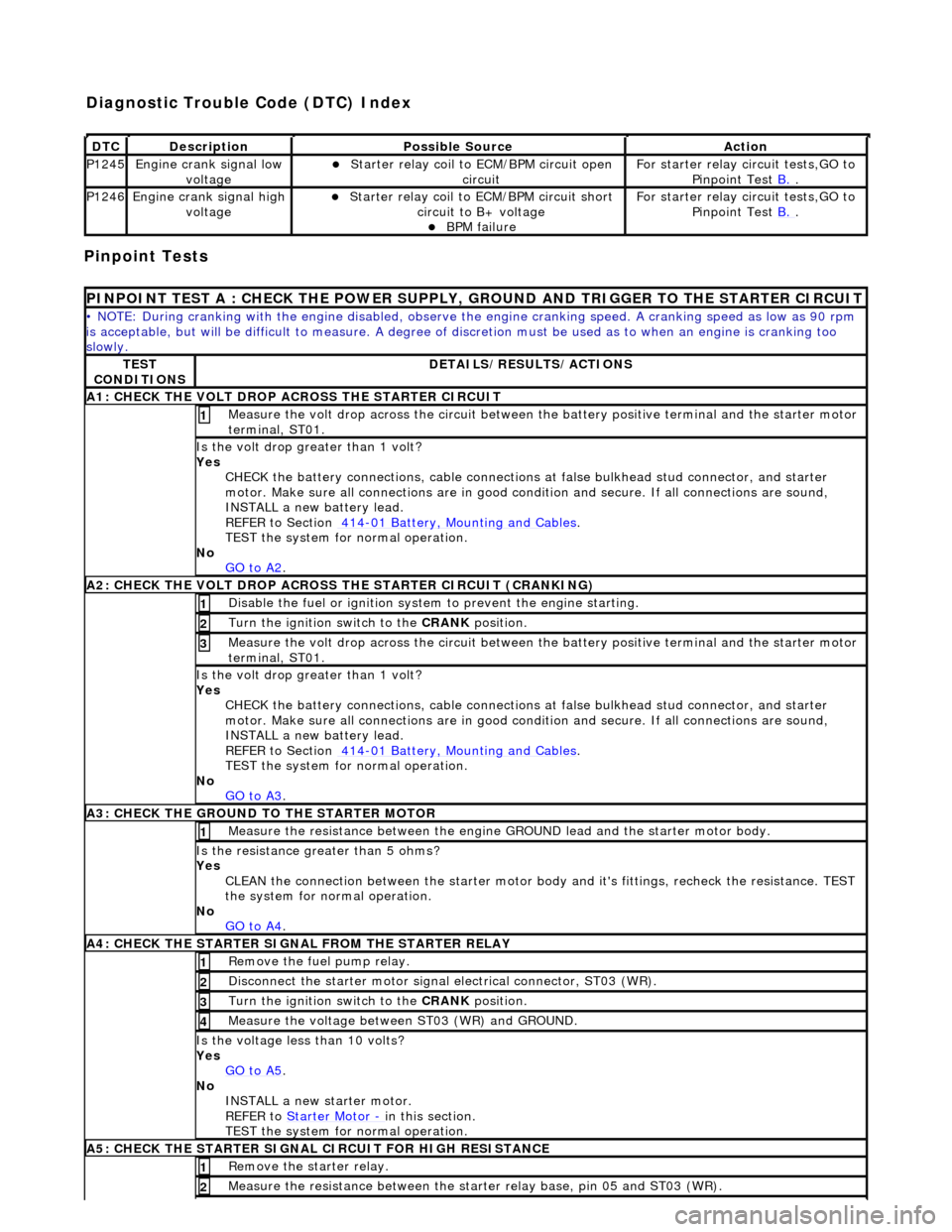

DT

C

De

scription

Possib

le Source

Acti

on

P1245Engine

crank signal low

voltage

пЃ¬Starter relay

coil to

ECM/BPM circuit open

circuit

F

or starter relay circuit tests,GO to

Pinpoint Test B.

.

P1246Engine

crank signal high

voltage

пЃ¬Starter relay

coil to ECM/BPM circuit short

circuit to B+ voltage

пЃ¬B

PM failure

F

or starter relay circuit tests,GO to

Pinpoint Test B.

.

P

INPOINT TEST A : CHECK THE

POWER SUPPLY, GROUND AND TRI GGER TO THE STARTER CIRCUIT

•

NOTE: During cranking with the engine disabled, observe the engine cranking speed. A cranking speed as low as 90 rpm

is acceptable, but will be difficult to measure. A degree of discretion must be used as to when an engine is cranking too

slowly.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1: CHECK

THE VOLT DROP AC

ROSS THE STARTER CIRCUIT

M

easure the volt drop across the circuit between the battery positive terminal and the starter motor

terminal, ST01.

1

Is the vol

t drop greater than 1 volt?

Yes CHECK the battery connections, cable connections at false bulkhead stud connector, and starter

motor. Make sure all connections are in good co ndition and secure. If all connections are sound,

INSTALL a new battery lead.

REFER to Section 414

-0

1 Battery, Mounting and Cables

.

TEST the system

for normal operation.

No GO to A2

.

A2: CHECK

THE VOLT DROP ACROSS

THE STARTER CIRCUIT (CRANKING)

Di

sable the fuel or ignition system to prevent the engine starting.

1

Turn the ignition swi

tch to the CRANK

position.

2

M

easure the volt drop across the circuit between the battery positive terminal and the starter motor

terminal, ST01.

3

Is the vol

t drop greater than 1 volt?

Yes CHECK the battery connections, cable connections at false bulkhead stud connector, and starter

motor. Make sure all connections are in good co ndition and secure. If all connections are sound,

INSTALL a new battery lead.

REFER to Section 414

-0

1 Battery, Mounting and Cables

.

TEST the system

for normal operation.

No GO to A3

.

A3:

CHECK THE GROUND TO THE STARTER MOTOR

Meas

ure the resistance between the engine GROUND lead and the starter motor body.

1

Is th

e resistance greater than 5 ohms?

Yes CLEAN the connection between the starter motor body and it's fittings, recheck the resistance. TEST

the system for normal operation.

No GO to A4

.

A4

: CHECK THE STARTER SIGNAL FROM THE STARTER RELAY

R

emove the fuel pump relay.

1

Di

sconnect the starter motor signal

electrical connector, ST03 (WR).

2

Turn the ignition swi

tch to the CRANK

position.

3

M

easure the voltage between ST03 (WR) and GROUND.

4

Is th

e voltage less than 10 volts?

Yes GO to A5

.

No

INSTALL a new starter motor.

REFER to Starter Motor

-

in t

his section.

TEST the system for normal operation.

A5

: CHECK THE STARTER SIGNAL CIRCUIT FOR HIGH RESISTANCE

R

emove the starter relay.

1

Meas

ure the resistance between the st

arter relay base, pin 05 and ST03 (WR).

2

Diagnostic Trouble Code (D

TC) Index

Page 1077 of 2490

Engine Igni

tion -

Engine Ignition

D

iagnosis and Testing

I

nspection and Verification

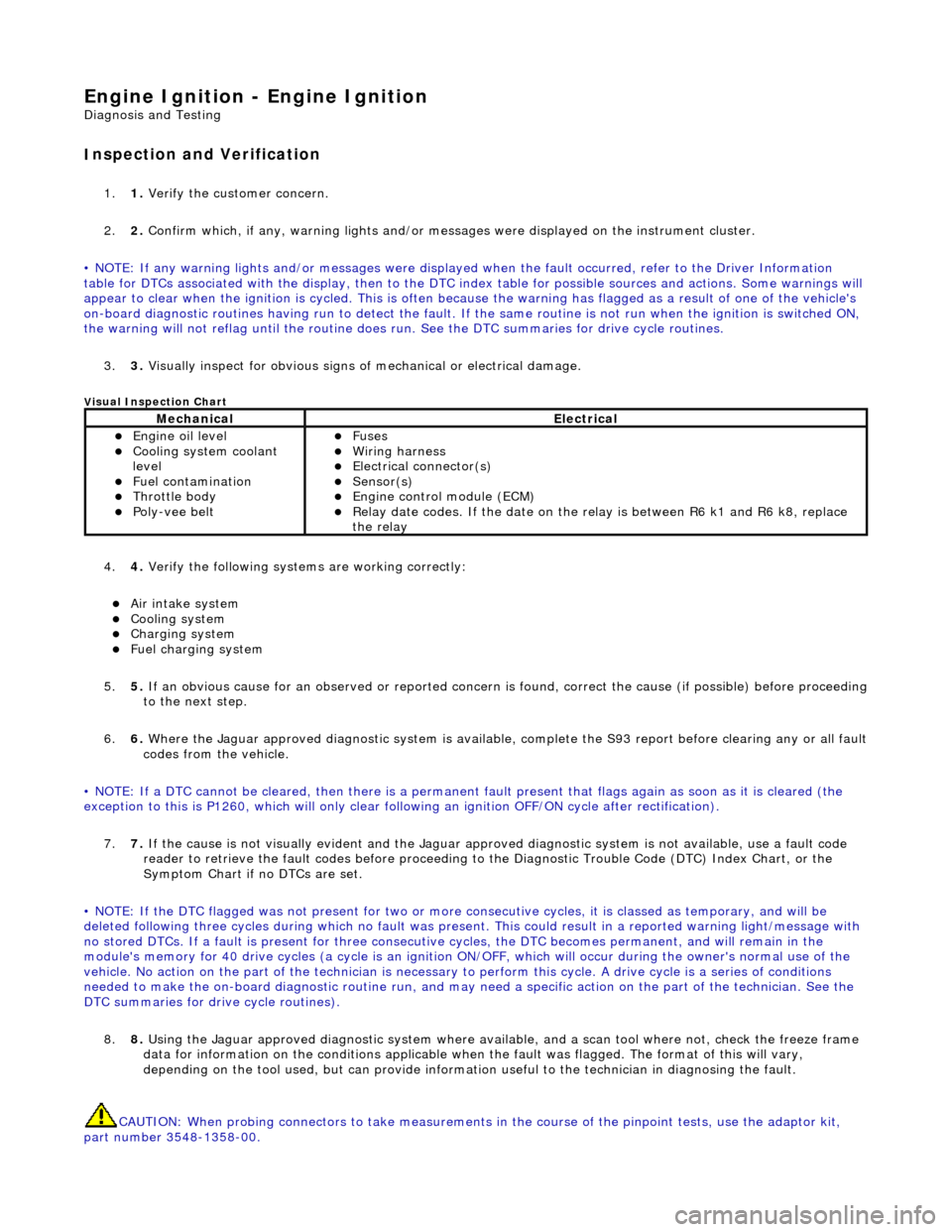

1.

1. Veri

fy the customer concern.

2. 2. Confirm which, if any, warning li ghts and/or messages were displayed on the instrument cluster.

• NOTE: If any warning lights and/or me ssages were displayed when the fault occurred, refer to the Driver Information

table for DTCs associated with the display, then to the DTC index table for possible sources and actions. Some warnings will

appear to clear when the ignition is cycl ed. This is often because the warning has flagged as a resu lt of one of the vehicle's

on-board diagnostic routines having run to detect the fault. If the same routine is not run when the ignition is switched ON,

the warning will not reflag until the routine does run. See the DTC summaries for drive cycle routines.

3. 3. Visually inspect for obvious signs of mechanical or electrical damage.

V

isual Inspection Chart

4.

4. Veri

fy the following syst

ems are working correctly:

пЃ¬Air in

take system

пЃ¬Coo

ling system

пЃ¬Charging system

пЃ¬F

uel charging system

5. 5. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding

to the next step.

6. 6. Where the Jaguar approved diagnostic sy stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared (the

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

7. 7. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

• NOTE: If the DTC flagged was not present for two or more co nsecutive cycles, it is classed as temporary, and will be

deleted following three cycl es during which no fault was present. This could result in a reported wa rning light/message with

no stored DTCs. If a fault is present for three consecutive cycles, the DTC becomes permanent, and will remain in the

module's memory for 40 drive cycles (a cy cle is an ignition ON/OFF, which will occur during the owner's normal use of the

vehicle. No action on the part of the technician is necessary to perform this cycle. A drive cycle is a series of conditions

needed to make the on-board diagnostic ro utine run, and may need a specific action on the part of the technician. See the

DTC summaries for driv e cycle routines).

8. 8. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

depending on the tool used, but can pr ovide information useful to the technician in diagnosing the fault.

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit,

part number 3548-1358-00.

MechanicalElectrical

пЃ¬Engi

ne oil level

пЃ¬Coo

ling system coolant

level

пЃ¬Fuel contamination

пЃ¬Throttle body пЃ¬Poly

-vee belt

пЃ¬F

uses

пЃ¬W

iring harness

пЃ¬E

lectrical connector(s)

пЃ¬Sens

or(s)

пЃ¬Engine

control module (ECM)

пЃ¬Relay date codes.

If the date on the relay is between R6 k1 and R6 k8, replace

the relay

Page 1078 of 2490

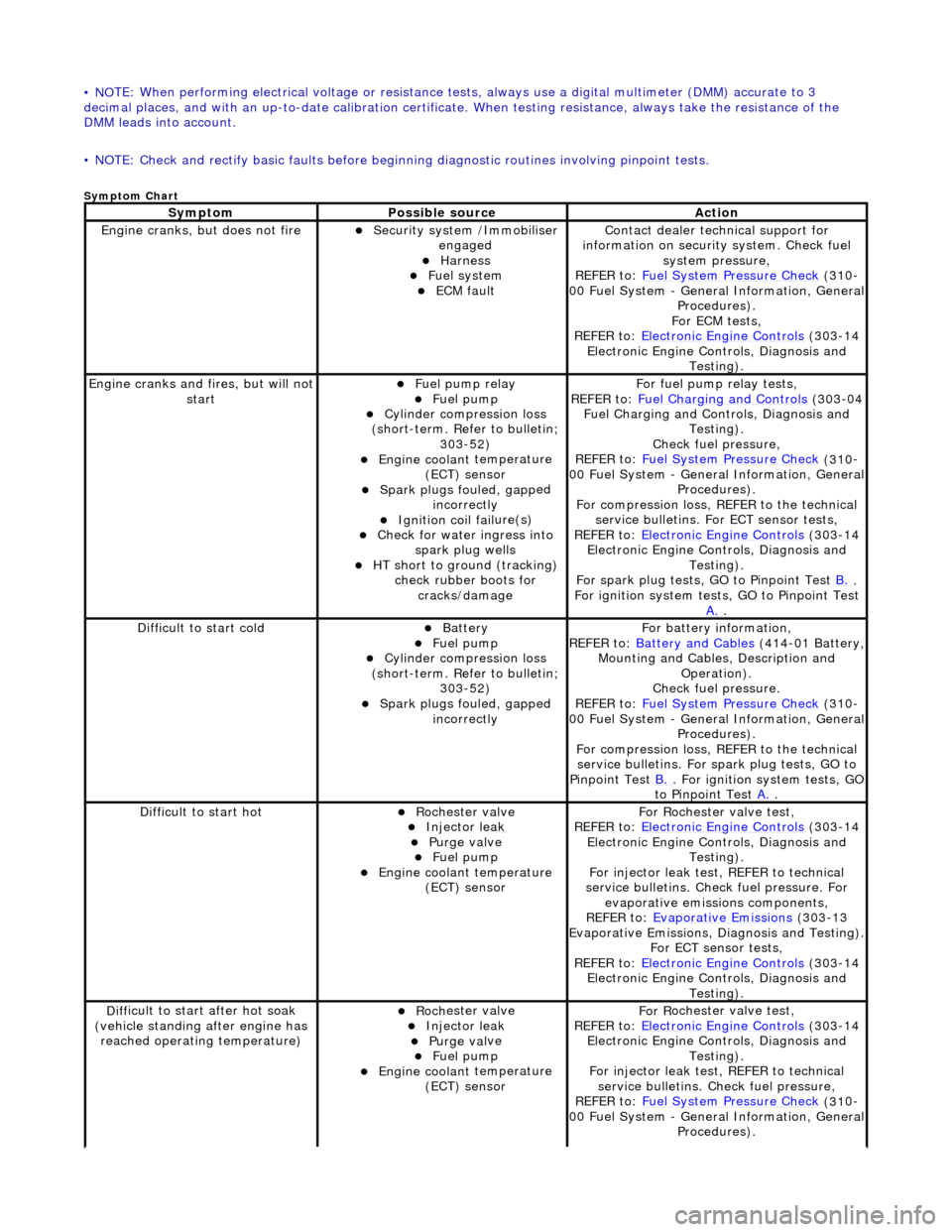

• NO

TE: When performing electrical voltag

e or resistance tests, always use a digital multimeter (DMM) accurate to 3

decimal places, and with an up-t o-date calibration certificate. When testing resistance, always take the resistance of the

DMM leads into account.

• NOTE: Check and rectify basic faults before beginning diagnostic ro utines involving pinpoint tests.

Sym

ptom Chart

Sy

m

ptom

Possib

l

e source

Acti

o

n

Engine

cranks, but does

not fire

пЃ¬Secu

rit

y system /Immobiliser

engaged

пЃ¬Harness пЃ¬Fue l

system

пЃ¬ECM fault

Contact deal er techni

cal support for

information on security system. Check fuel

system pressure,

REFER to: Fuel System Pressure Check

(310

-

00 Fuel System - Genera l Information, General

Procedures).

For ECM tests,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

Engine cranks and

fi

res, but will not

start

пЃ¬Fu

el pump relay

пЃ¬Fuel

pump

пЃ¬Cyl

i

nder compression loss

(short-term. Refer to bulletin; 303-52)

пЃ¬Engine coolan t

temperature

(ECT) sensor

пЃ¬Spark plugs fouled, gapp

ed

incorrectly

пЃ¬Ignition coil fail

ure(s)

пЃ¬Check f

o

r water ingress into

spark plug wells

пЃ¬HT sho rt to ground (tracking)

check rubber

boots for

cracks/damage

Fo

r fuel pump relay tests,

REFER to: Fuel Charging and Controls

(303

-04

Fuel Charging and Controls, Diagnosis and Testing).

Check fuel pressure,

REFER to: Fuel System Pressure Check

(310

-

00 Fuel System - Genera l Information, General

Procedures).

For compression loss, REFER to the technical service bulletins. For ECT sensor tests,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

For spark plug tests, GO to Pinpoint Test B.

.

For ign i

tion system tests, GO to Pinpoint Test

A.

.

Diff

icult to start cold

пЃ¬Batt

ery пЃ¬Fuel

pump

пЃ¬Cyl

i

nder compression loss

(short-term. Refer to bulletin; 303-52)

пЃ¬Spark plugs fouled, gapp

ed

incorrectly

F o

r battery information,

REFER to: Battery and Cables

(414

-01 Battery,

Mounting and Cables, Description and Operation).

Check fuel pressure.

REFER to: Fuel System Pressure Check

(310

-

00 Fuel System - Genera l Information, General

Procedures).

For compression loss, REFER to the technical service bulletins. For spark plug tests, GO to

Pinpoint Test B.

. For ig

nition system tests, GO

to Pinpoint Test A.

.

Diff

icult to start hot

пЃ¬Roc

h

ester valve

пЃ¬Injec

t

or leak

пЃ¬Purge

val

ve

пЃ¬Fue

l

pump

пЃ¬Engine coolan

t

temperature

(ECT) sensor

F or R

ochester

valve test,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

For injector leak test, REFER to technical

service bulletins. Check fuel pressure. For evaporative emissions components,

REFER to: Evaporative Emissions

(303

-13

Evaporative Emissions, Diagnosis and Testing).

For ECT sensor tests,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

D iff

icult to start after hot soak

(vehicle standing after engine has reached operating temperature)

пЃ¬Roc h

ester valve

пЃ¬Injec

t

or leak

пЃ¬Purge

val

ve

пЃ¬Fue

l

pump

пЃ¬Engine coolan

t

temperature

(ECT) sensor

F or R

ochester

valve test,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

For injector leak test, REFER to technical service bulletins. Check fuel pressure,

REFER to: Fuel System Pressure Check

(310

-

00 Fuel System - Genera l Information, General

Procedures).