JAGUAR X308 1998 2.G Repair Manual

X308 1998 2.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7640/w960_7640-0.png

JAGUAR X308 1998 2.G Repair Manual

Page 1279 of 2490

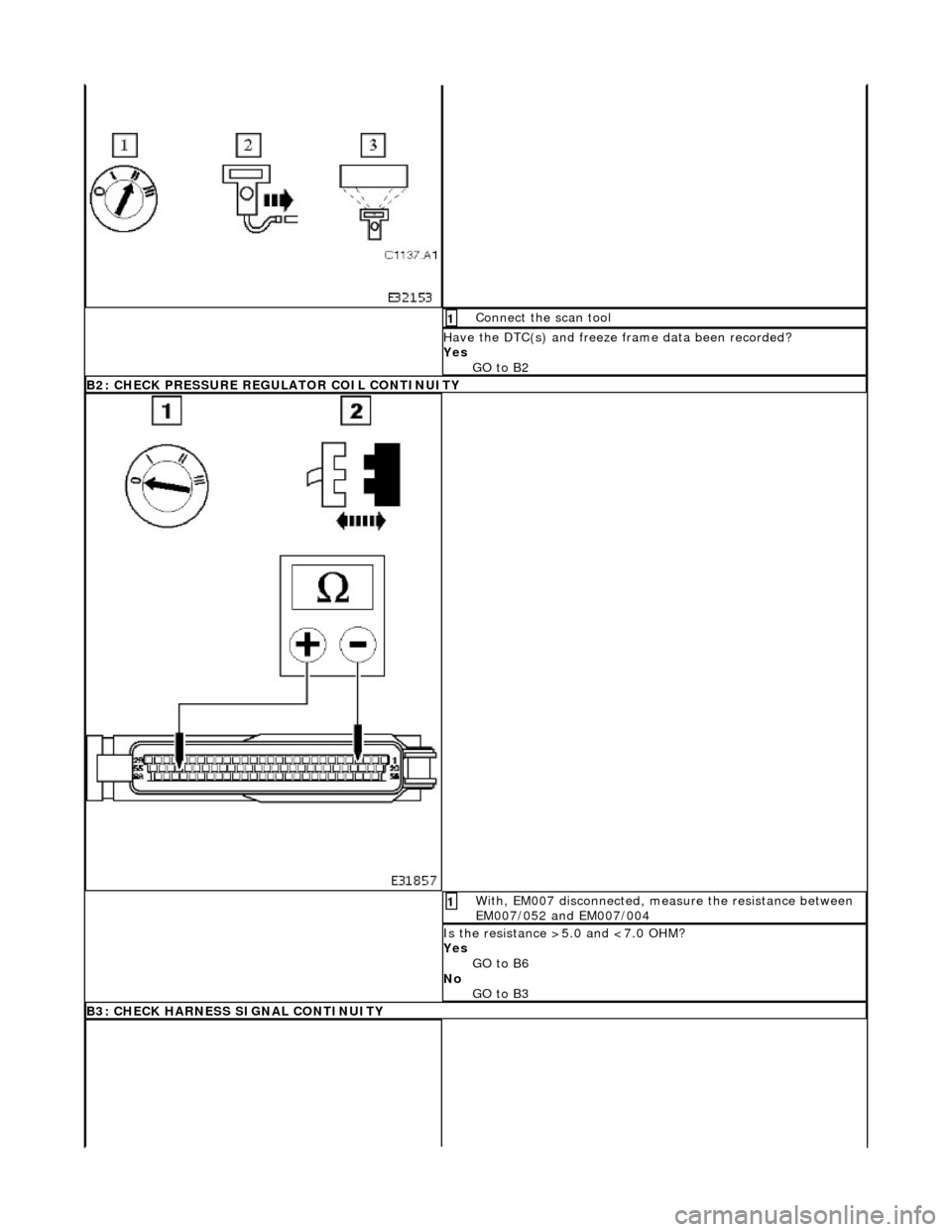

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to B2

B2: CHECK PRESSURE REGULATOR COIL CONTINUITY

With, EM007 disconnected, measure the resistance between

EM007/052 and EM007/004 1

Is the resistance >5.0 and <7.0 OHM?

Yes

GO to B6

No GO to B3

B3: CHECK HARNESS SIGNAL CONTINUITY

Page 1308 of 2490

With EM007 and EM046 disconnected, measure the

resistance between EM046/010 and EM007/044 1

Is the resistance < 0.5 OHM?

Yes GO to E4

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

E4: CHECK OUTPUT SPEED SENSOR COIL CONTINUITY

Page 1313 of 2490

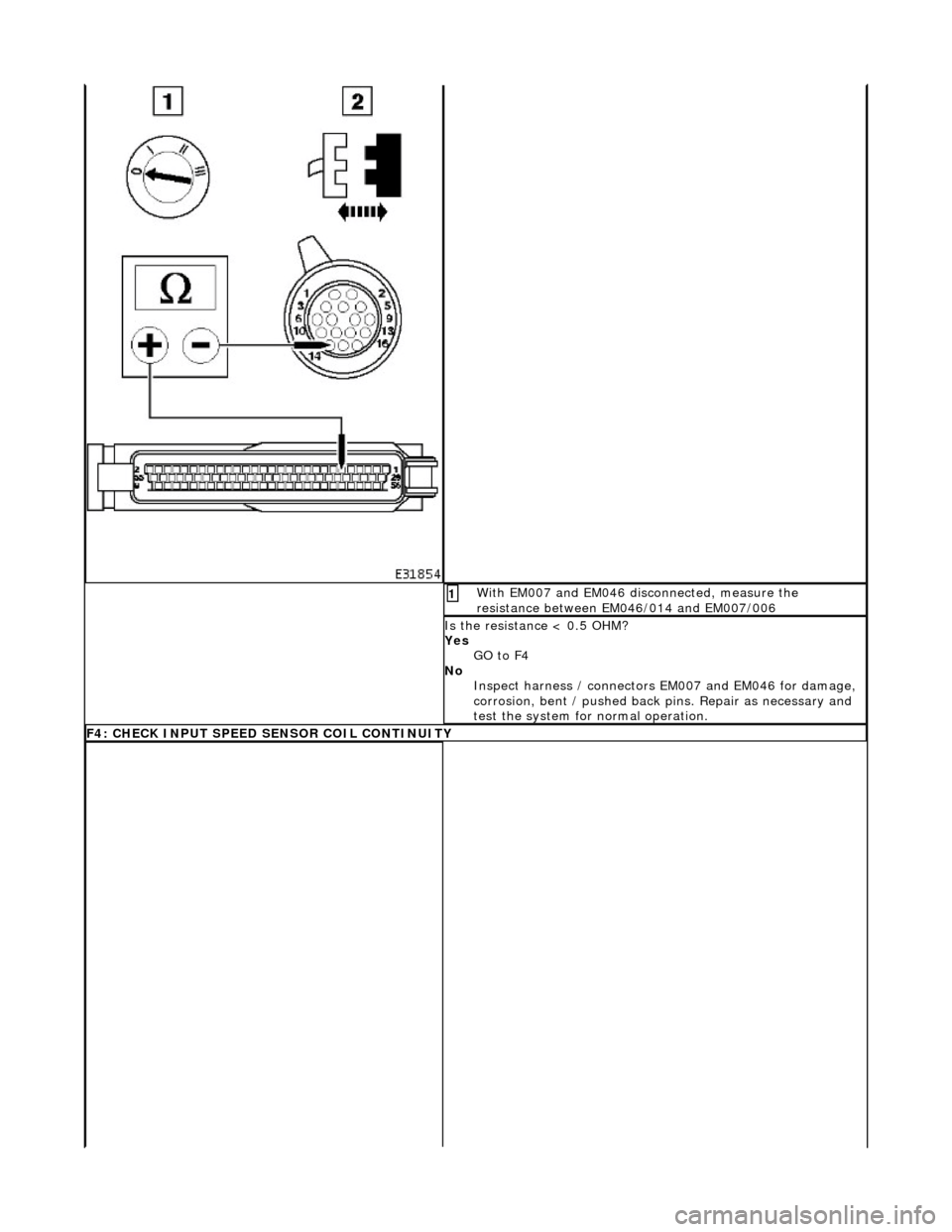

With EM007 and EM046 disconnected, measure the

resistance between EM046/014 and EM007/006 1

Is the resistance < 0.5 OHM?

Yes GO to F4

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

F4: CHECK INPUT SPEED SENSOR COIL CONTINUITY

Page 1318 of 2490

With EM007 and EM046 disconnected, measure the

resistance between EM046/010 and EM007/044 1

Is the resistance < 0.5 OHM?

Yes GO to G4

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

G4: CHECK OUTPUT SPEED SENSOR COIL CONTINUITY

Page 1323 of 2490

With EM007 and EM046 disconnected, measure the resistance between EM046/014 and EM007/006 1

Is the resistance < 0.5 OHM?

Yes GO to I4

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

I4: CHECK INPUT SPEED SENSOR COIL CONTINUITY

Page 1326 of 2490

With EM007 and EM046 disconnected, measure the resistance between EM046/010 and EM007/044 1

Is the resistance < 0.5 OHM?

Yes GO to I7

No Inspect EM007 and EM046 for corrosion, bent / pushed back

pins or locate and repair th e harness Test the system for

normal operation

I7: CHECK OUTPUT SPEED SENSOR COIL CONTINUITY

Page 1336 of 2490

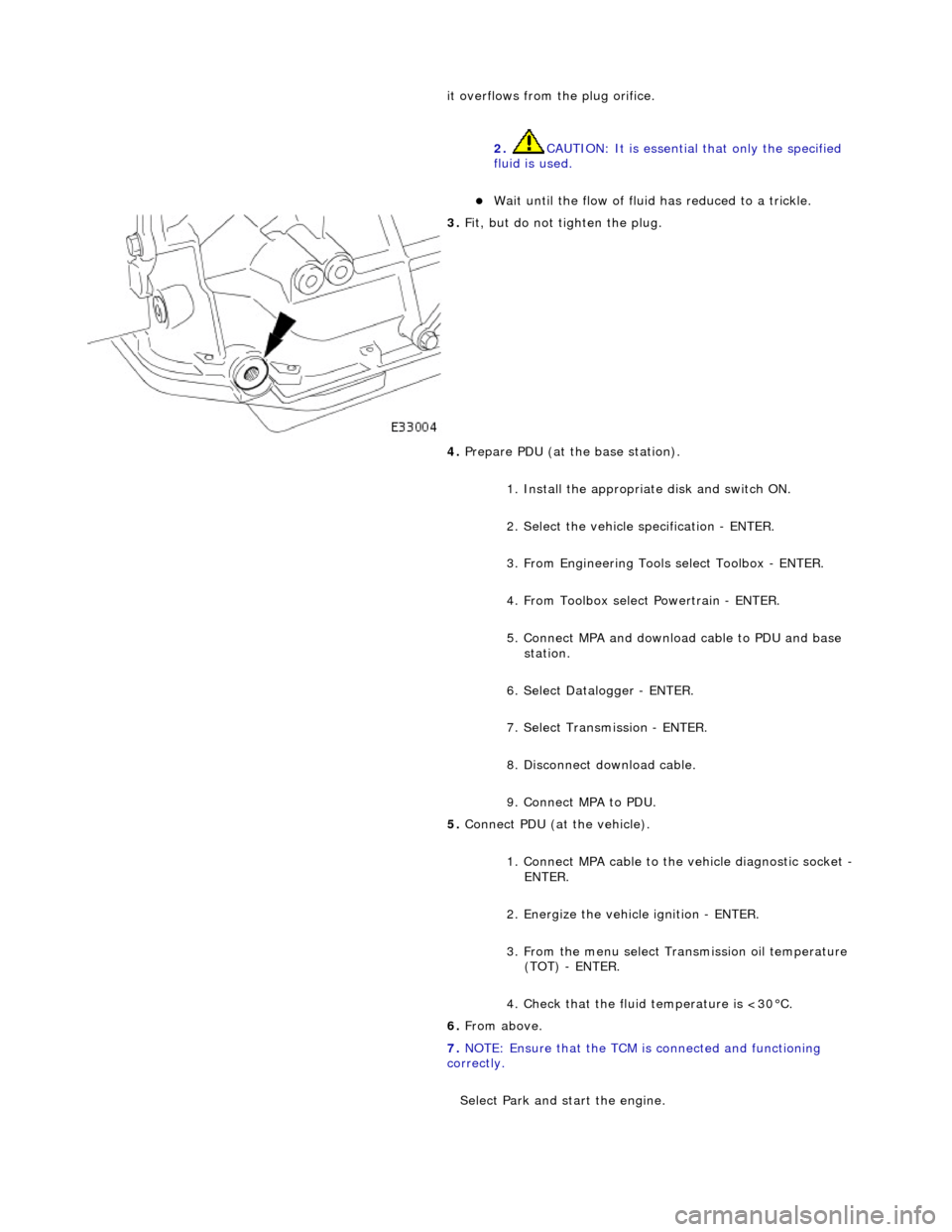

it overflows from the plug orifice. 2. CAUTION: It is essential that only the specified

fluid is used.

пЃ¬Wait until the flow of fluid has reduced to a trickle.

3. Fit, but do not tighten the plug.

4. Prepare PDU (at the base station).

1. Install the appropriat e disk and switch ON.

2. Select the vehicle specification - ENTER.

3. From Engineering Tools select Toolbox - ENTER.

4. From Toolbox select Powertrain - ENTER.

5. Connect MPA and download cable to PDU and base station.

6. Select Datalogger - ENTER.

7. Select Transmission - ENTER.

8. Disconnect download cable.

9. Connect MPA to PDU.

5. Connect PDU (at the vehicle).

1. Connect MPA cable to the vehicle diagnostic socket -

ENTER.

2. Energize the vehicle ignition - ENTER.

3. From the menu select Transmission oil temperature (TOT) - ENTER.

4. Check that the fluid temperature is <30В°C.

6. From above.

7. NOTE: Ensure that the TCM is connected and functioning

correctly.

Select Park and start the engine.

Page 1382 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Torque Converter

Disassembly and Assembly of Subassemblies

Special Tool(s)

Lifting handle

307-139

1. Remove the transmission unit from the vehicle; 44.20.01.

2. Remove the torque converter from the transmission unit.

пЃ¬Install lifting handles 307 - 139.

3. Remove lifting handles 307 - 139 from the torque converter.

4. Clean the torque conver ter and mating faces.

5. CAUTIONS:

Use extreme care NOT to damage the oil seal with the

converter spigot.

Ensure that the conver ter is fully located.

Install the torque converter.

1. Install lifting handles 307 - 139.

2. Lubricate the front pump seal.

пЃ¬To facilitate location, rotate the converter as it is being

fitted and note the engagement of splines and oil pump

drive.

6. Check that the three conver ter fixing boss faces are

approximately 8,0 mm proud of the transmission mounting

face.

7. Remove lifting handles 307 - 139 from the torque converter.

8. Install the transmission unit; refer to Operation 44.20.01,

noting especially the alignment instructions.

Page 1401 of 2490

Pinpoint test A: P0740

DTC P0730 Incorrect gear ratioEngaged gear implausible / transmission

slipping Oil level low

Valve body assembly faulty

Transmission faulty

*

*

*

*GO to Pinpoint Test H *

DTC P0780 Shift malfunctionValve body assembly faulty

Transmission faulty

*

*GO to Pinpoint Test H *

PINPOINT TEST A : P0740

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

A1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to A2

A2: CHECK TORQUE CONVERTER CLUTCH SOLENOID RESISTANCE

With, EM062 disconnected, measure the resistance between 1

Page 1434 of 2490

Installation

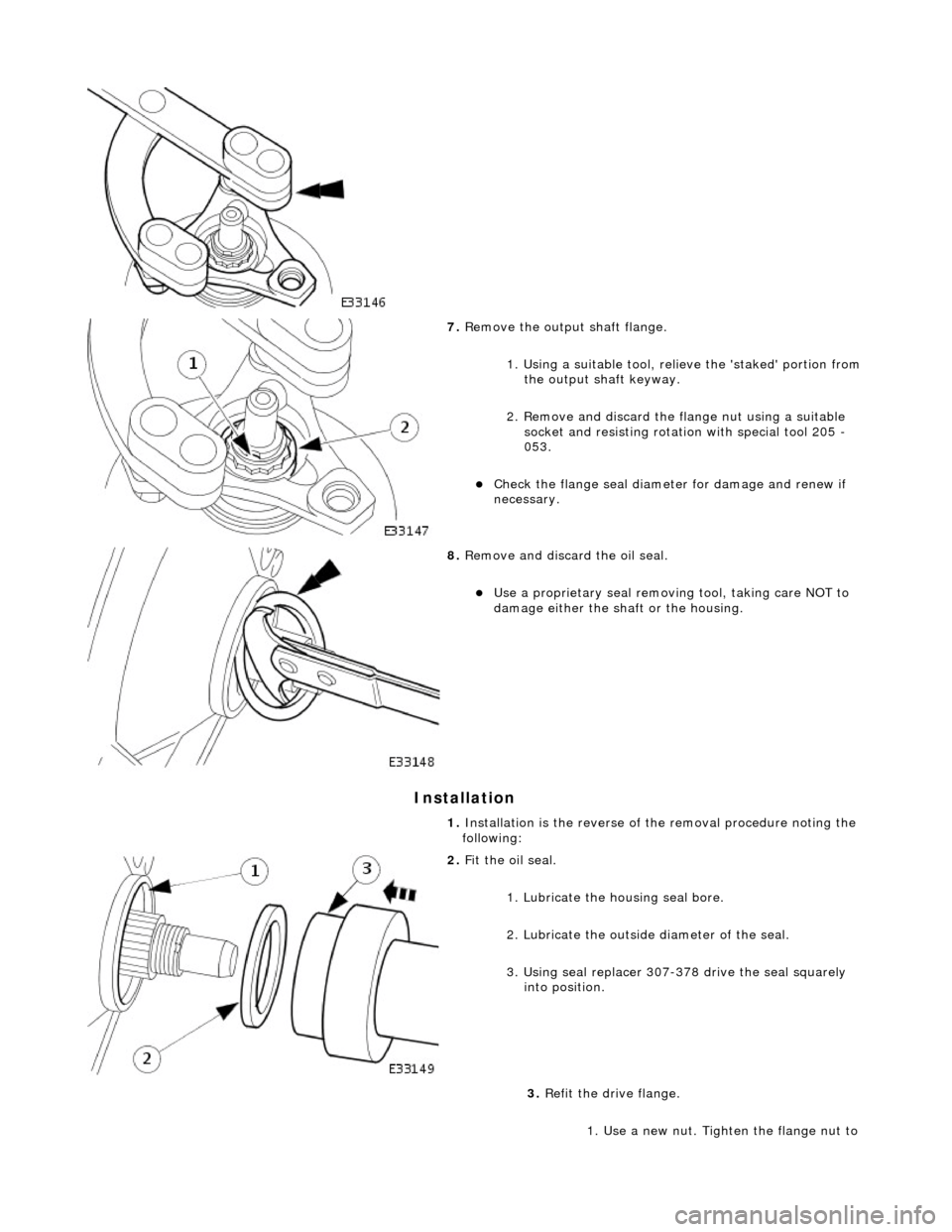

7. Remove the output shaft flange.

1. Using a suitable tool, reli eve the 'staked' portion from

the output shaft keyway.

2. Remove and discard the fl ange nut using a suitable

socket and resisting rotation with special tool 205 -

053.

пЃ¬Check the flange se al diameter for damage and renew if

necessary.

8. Remove and discard the oil seal.

пЃ¬Use a proprietary seal removing tool, taking care NOT to

damage either the shaft or the housing.

1. Installation is the re verse of the removal procedure noting the

following:

2. Fit the oil seal.

1. Lubricate the housing seal bore.

2. Lubricate the outside diameter of the seal.

3. Using seal replacer 307-378 drive the seal squarely into position.

3. Refit the drive flange.

1. Use a new nut. Tighten the flange nut to