engine JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1086 of 2490

PINPOINT TEST B : CHECK SPARK PLUG

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

B1

: CH

ECK SPARK PLUG

•

NOTE

: Some spark plug types cannot

be regapped and must be replaced.

Re

move the suspect spark plug(s).

REFER to: Spark Plugs

(30

3-07 Engine Ignition,

Removal and Installation).

1

Visuall

y inspect the spark plug for cracks, damage,

carbon buildup or wet fouling, check the condition

of the ground electrode, the center electrode tip and the spark plug HT contact and confirm that the

spark plug gap is correctly set usin g a wire gauge taking care not to cause damage to the center or

ground electrode tips.

REFER to: Specifications

(30

3-07 Engine Ignition, Specifications).

2

Is th

e s

park plug condition good,

and the spark plug gap correct ?

Yes Check ignition coil and circuits. See possible sources list for misfire.

No Install a new spark pl ug(s) as required.

REFER to: Spark Plugs

(30

3-07 Engine Ignition, Removal and Installation).

CLEAR the DTC. TEST the syst em for normal operation.

Page 1087 of 2490

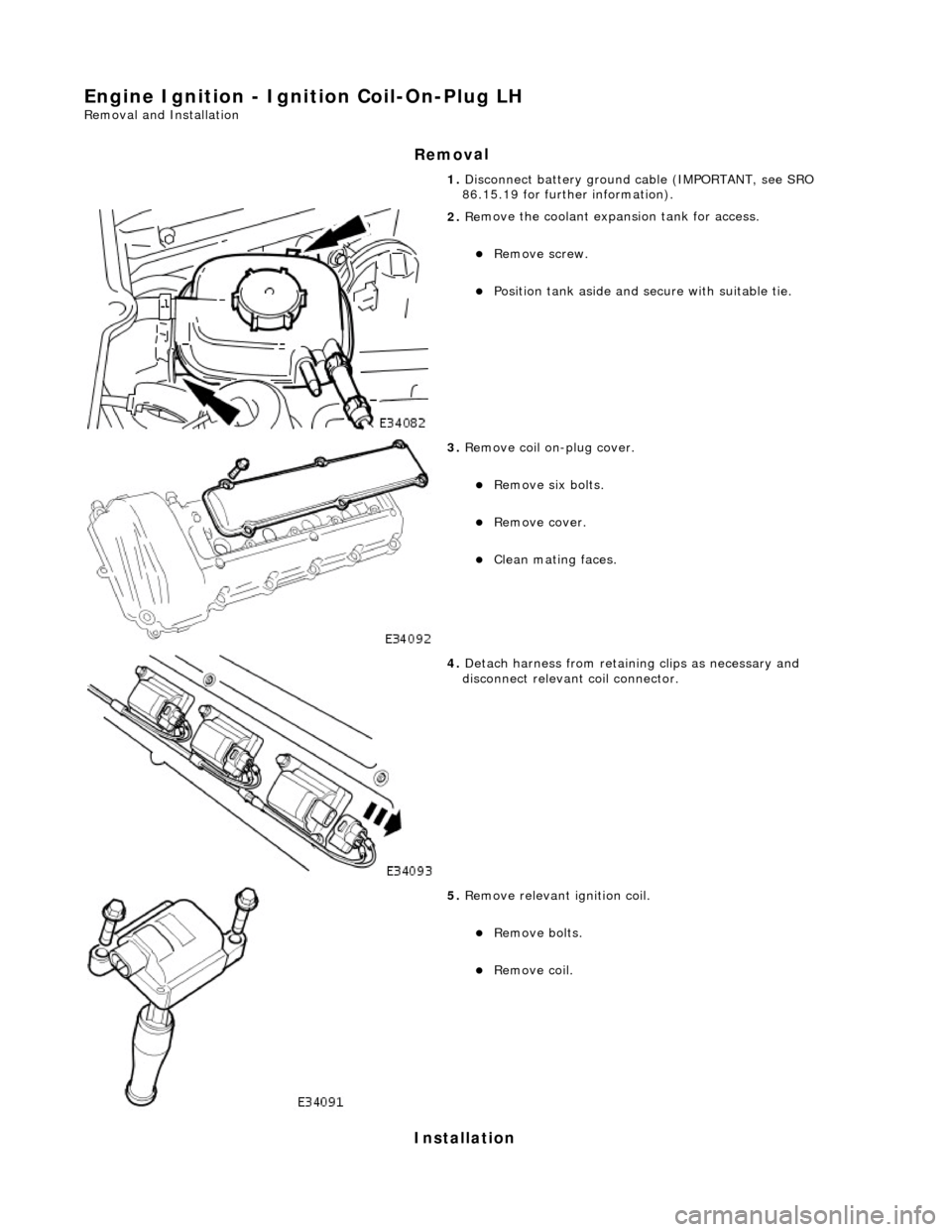

Engine Igni

tion - Ignition Coil-On-Plug LH

Re

moval and Installation

Remov

al

Installation

1. Disc

onnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Re

move the coolant expansion tank for access.

пЃ¬R

emove screw.

пЃ¬Position tank aside an

d secu

re with suitable tie.

3. Re

move coil on-plug cover.

пЃ¬R

emove six bolts.

пЃ¬R

emove cover.

пЃ¬Cle

an mating faces.

4. D

etach harness from retain

ing clips as necessary and

disconnect relevant coil connector.

5. R

emove relevant ignition coil.

пЃ¬Re

move bolts.

пЃ¬Re

move coil.

Page 1089 of 2490

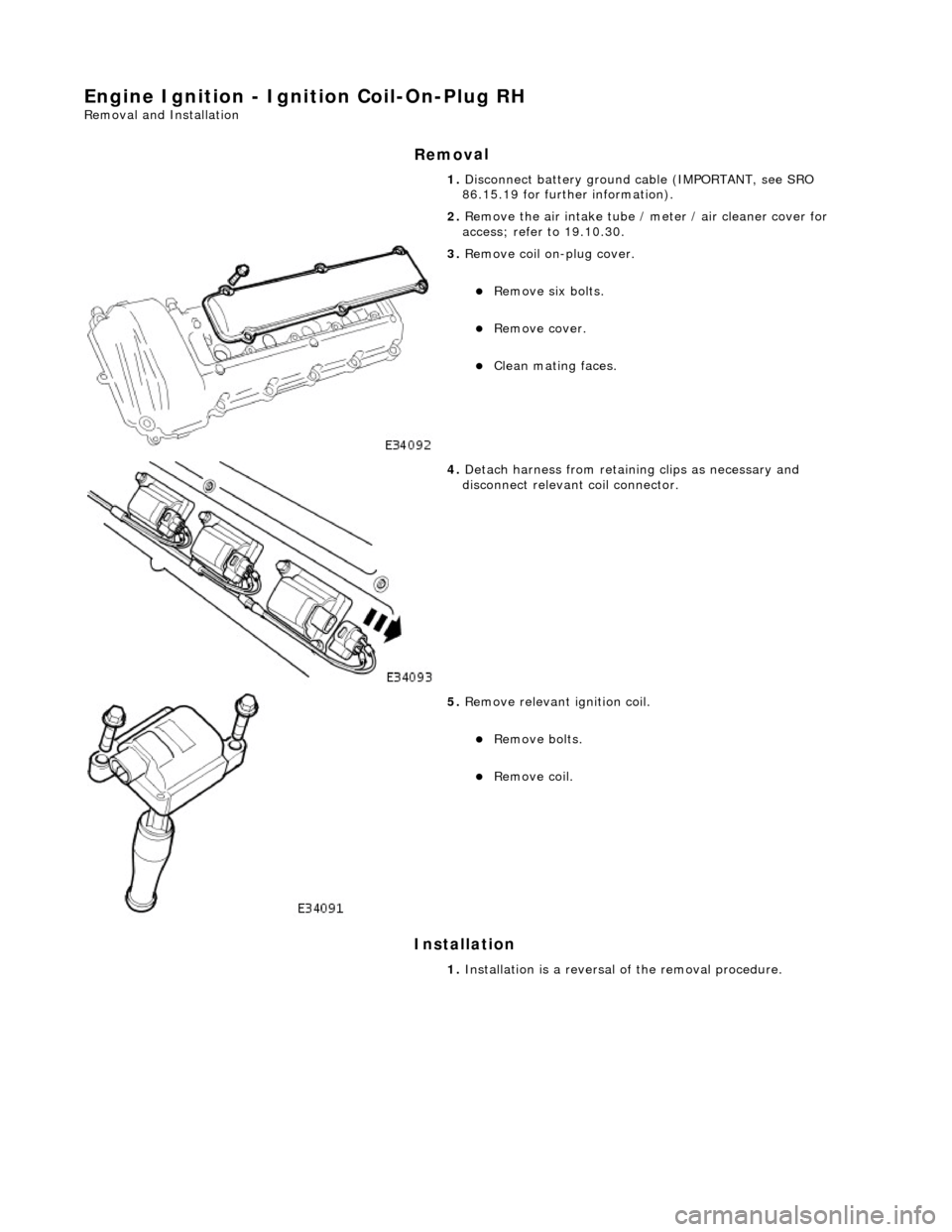

Engine Igni

tion - Ignition Coil-On-Plug RH

Re

moval and Installation

Remov

al

Installation

1. Disc

onnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Remove the air intake tube / meter / air cleaner cover for

access; refer to 19.10.30.

3. Re

move coil on-plug cover.

пЃ¬R

emove six bolts.

пЃ¬R

emove cover.

пЃ¬Cle

an mating faces.

4. D

etach harness from retain

ing clips as necessary and

disconnect relevant coil connector.

5. R

emove relevant ignition coil.

пЃ¬Re

move bolts.

пЃ¬Re

move coil.

1. Installation is a reversal of the removal procedure.

Page 1091 of 2490

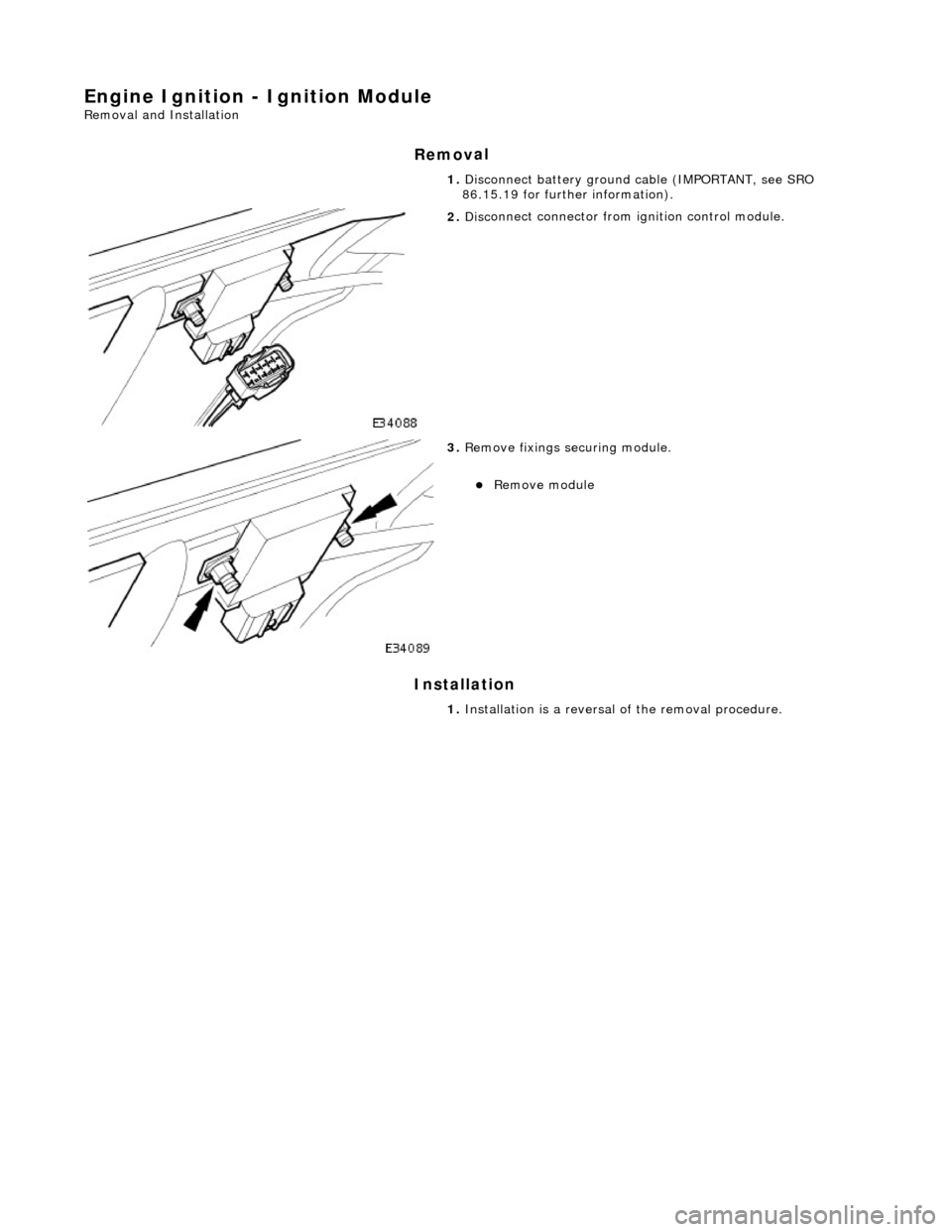

Engine Igni

tion - Ignition Module

Re

moval and Installation

Remov

al

Installation

1.

Disc

onnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Disc

onnect connector from ignition control module.

3. Re

move fixings securing module.

пЃ¬Re

move module

1. Installation is a reversal of the removal procedure.

Page 1092 of 2490

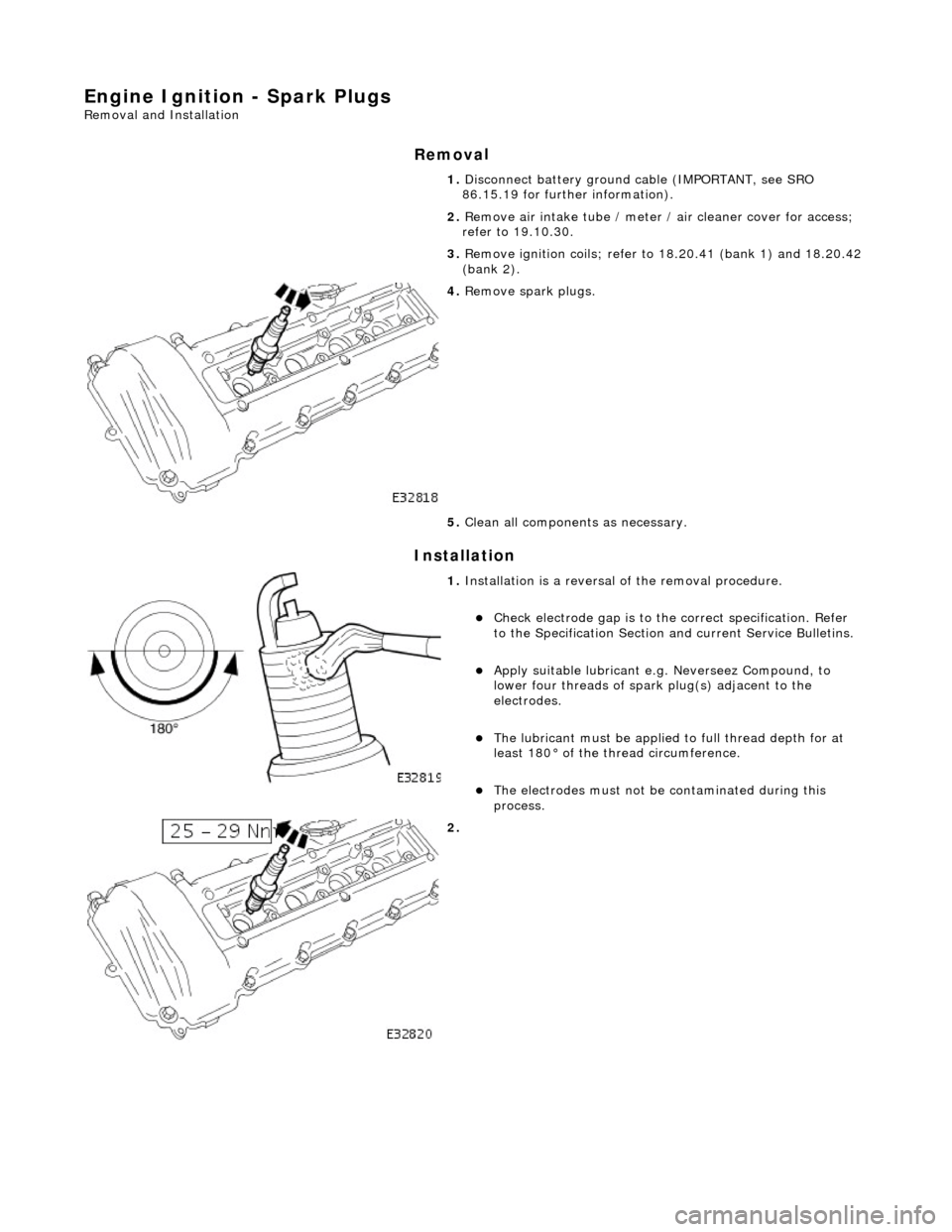

Engine Ignition - Spark

Plugs

Re

mo

val and Installation

Remov

a

l

Installation

1.

Disc onne

ct battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Remove air intake tube / meter / air cleaner cover for access;

refer to 19.10.30.

3. Remove ignition coils; refer to 18.20.41 (bank 1) and 18.20.42

(bank 2).

4. Re

move spark plugs.

5. Clean all components as necessary.

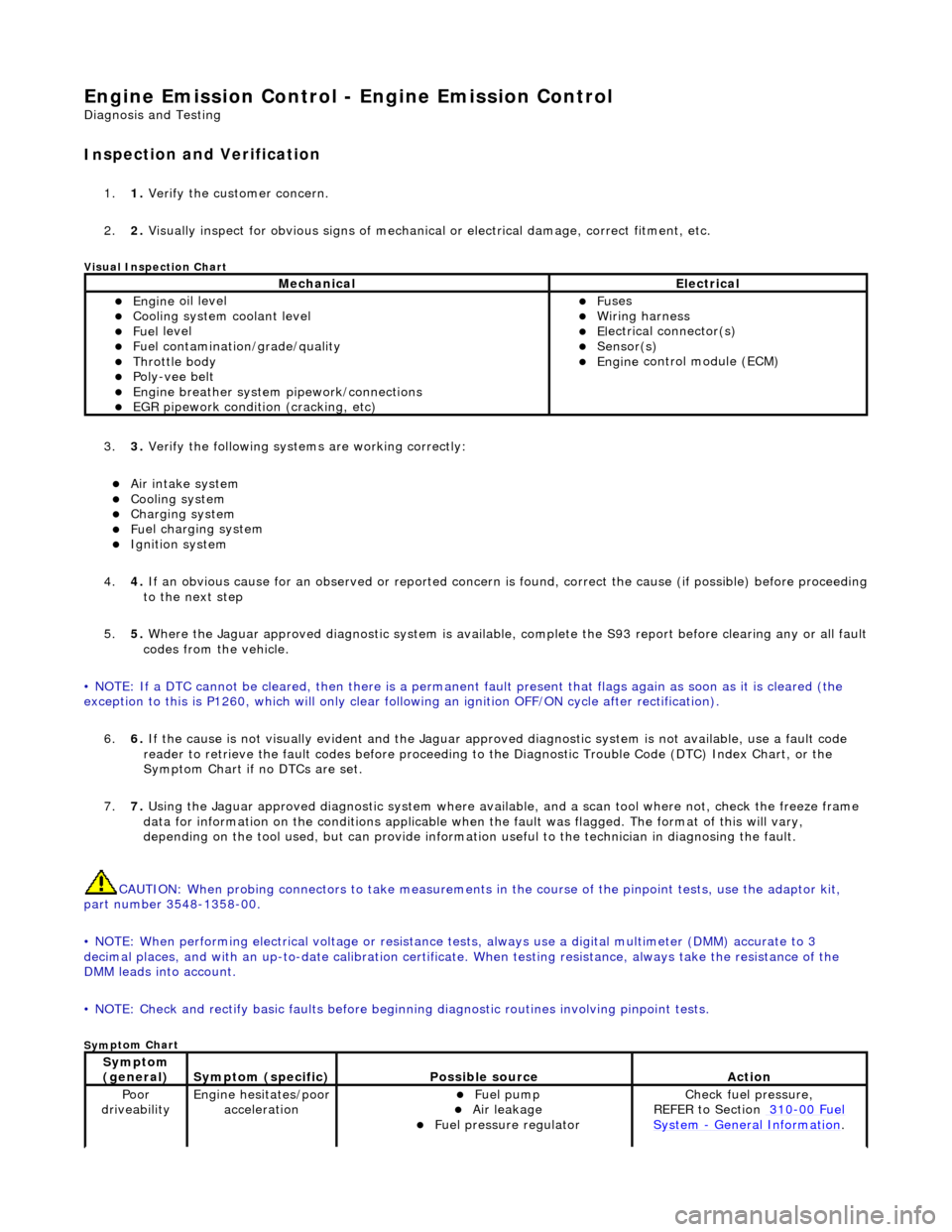

1. Installation

is a reversal

of the removal procedure.

пЃ¬Check ele

ctrode gap is to the

correct specification. Refer

to the Specification Section and current Service Bulletins.

пЃ¬Apply su

itable lubricant e.

g. Neverseez Compound, to

lower four threads of spark plug(s) adjacent to the

electrodes.

пЃ¬The lubrican t must be applied

to full thread depth for at

least 180В° of the thread circumference.

пЃ¬T h

e electrodes must not be

contaminated during this

process.

2.

Page 1094 of 2490

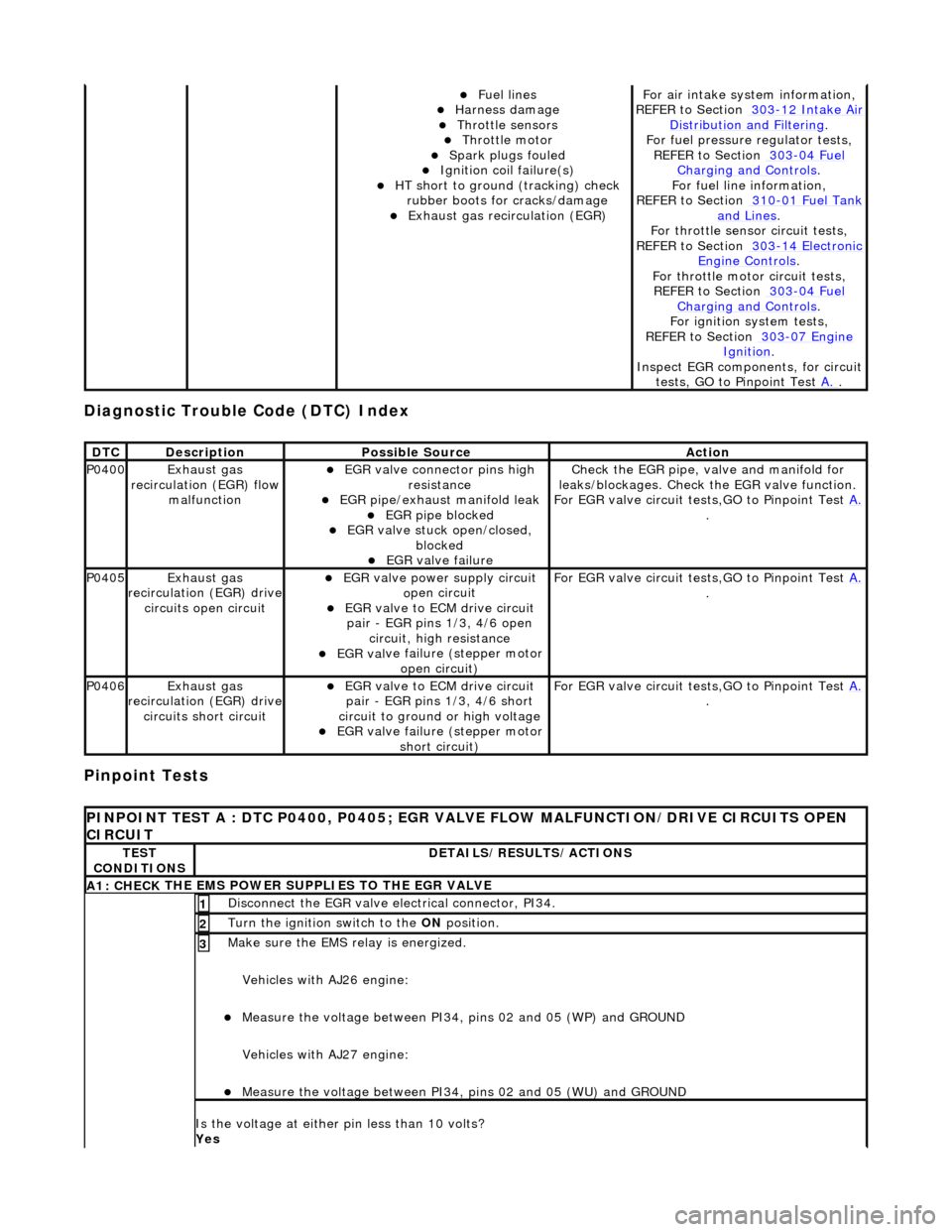

Engine Emission

Control - Engine Emission Control

D

iagn

osis and Testing

I

n

spection and Verification

1.

1. Veri fy the customer concern.

2. 2. Vis

ually inspect for obvious signs of mechanical

or electrical damage, correct fitment, etc.

Vi

sual Inspection Chart

3.

3. Veri fy the foll

owing syst

ems are working correctly:

пЃ¬Air intake

system

пЃ¬Coo

ling system

пЃ¬Charging system

пЃ¬Fu

el charging system

пЃ¬Ignition sys

t

em

4. 4. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding

to the next step

5. 5. Where the Jaguar approved diagnostic sy stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared (the

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

6. 6. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

7. 7. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

depending on the tool used, but can pr ovide information useful to the technician in diagnosing the fault.

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit,

part number 3548-1358-00.

• NOTE: When performing electrical voltag e or resistance tests, always use a digital multimeter (DMM) accurate to 3

decimal places, and with an up-t o-date calibration certificate. When testing resistance, always take the resistance of the

DMM leads into account.

• NOTE: Check and rectify basic faults before beginning diagnostic ro utines involving pinpoint tests.

Sym

ptom Chart

MechanicalElectrical

пЃ¬Engi

ne

oil level

пЃ¬Coo

ling system coolant level

пЃ¬Fue

l

level

пЃ¬Fuel contaminatio

n

/

grade/quality

пЃ¬Throttle body пЃ¬Poly

-ve

e belt

пЃ¬Engine breath

er

system

pipework/connections

пЃ¬EGR pipework

condition (cracking, etc)

пЃ¬F

u

ses

пЃ¬W

i

ring harness

пЃ¬E

l

ectrical connector(s)

пЃ¬Sens

o

r(s)

пЃ¬Engine

control module (E

CM)

Sy

m

ptom

(general)

S y

mptom (specific)

Possib

l

e source

Acti

o

n

Poor

dr iveabilityEngine h e

sitates/poor

acceleration

пЃ¬Fue l

pump

пЃ¬Air leakage пЃ¬F

u

el pressure regulator

Chec

k fu

el pressure,

REFER to Section 310

-00 Fu

el

Sy

ste

m

- General Informati

on.

Page 1095 of 2490

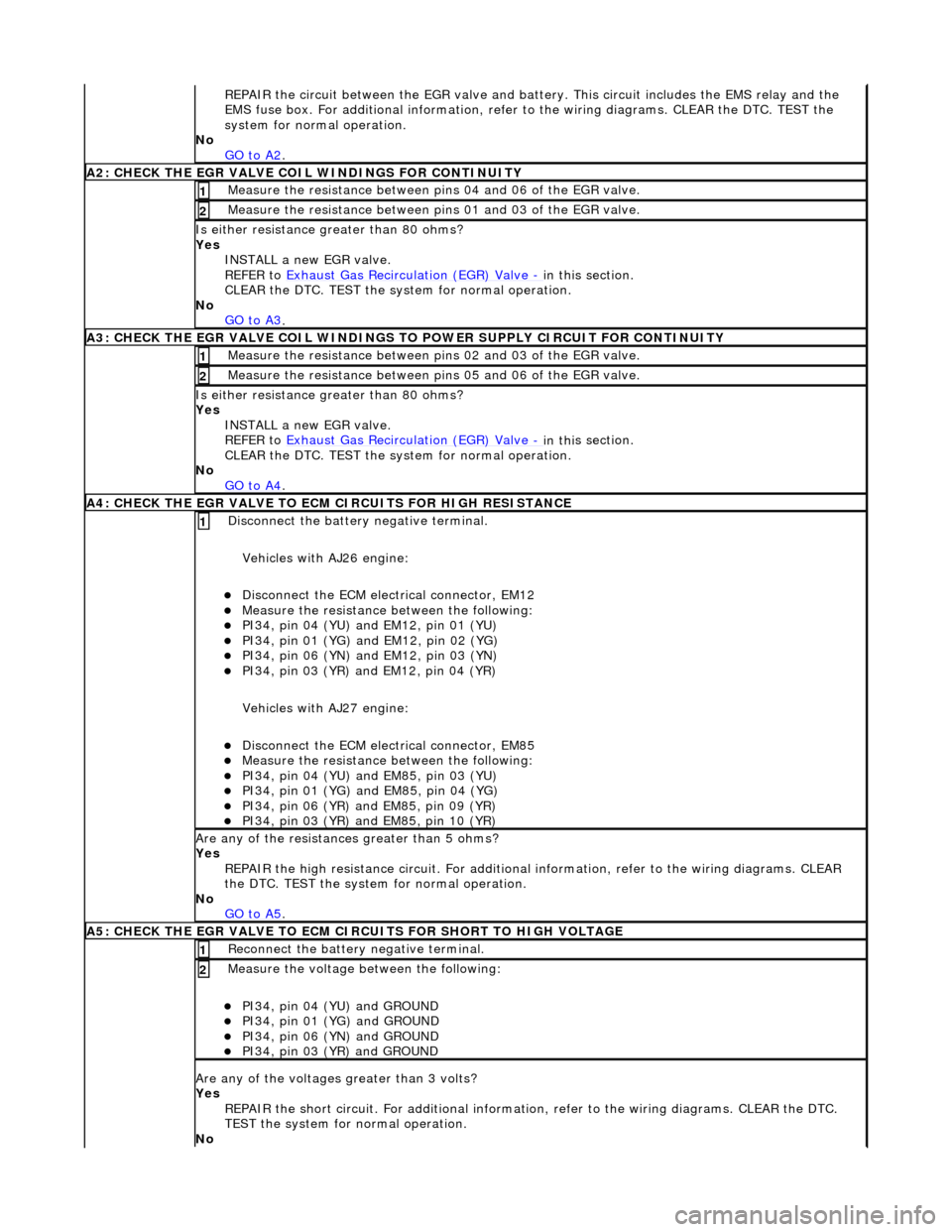

Diagnostic Trouble Code (D

TC) Index

Pinpoint Tests

пЃ¬Fue

l lines

пЃ¬Harness damage

пЃ¬Throttl

e sensors

пЃ¬Throttl

e motor

пЃ¬Spark plugs

fouled

пЃ¬Ignition coil

failure(s)

пЃ¬HT sho

rt to ground (tracking) check

rubber boots for cracks/damage

пЃ¬Exhaus

t gas recirculation (EGR)

F

or air intake syst

em information,

REFER to Section 303

-12

Intake Air

Distribu

tion and Filtering

.

F

or fuel pressure

regulator tests,

REF

ER to Section 303

-04

Fuel

Charging and Con

trols

.

F

or fuel line information,

REFER to Section 310

-01

Fuel Tank

and Lines.

F

or throttle sensor

circuit tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

Fo

r throttle motor

circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

For ign

ition system tests,

REFER to Section 303

-07

Engine

Ignition.

Inspe

ct EGR components, for circuit

tests, GO to Pinpoint Test A.

.

DT

C

De

scription

Possib

le Source

Acti

on

P0400Exhaus

t gas

recirculation (EGR) flow malfunction

пЃ¬EGR

valve connector pins high

resistance

пЃ¬EGR pipe/exhaust manifold leak пЃ¬EGR pipe block

ed

пЃ¬EGR val

ve stuck open/closed,

blocked

пЃ¬EGR

valve failure

Check the EGR pi

pe, valve and manifold for

leaks/blockages. Check the EGR valve function.

For EGR valve circuit tests,GO to Pinpoint Test A.

.

P0405Exhaus

t gas

recirculation (EGR) drive

circuits open circuit

пЃ¬EGR valve power supply circuit o

pen circuit

пЃ¬EGR valve t

o ECM drive circuit

pair - EGR pins 1/3, 4/6 open circuit, high resistance

пЃ¬EGR val

ve failure (stepper motor

open circuit)

F

or EGR valve circuit tests,GO to Pinpoint Test

A.

.

P0406Exhaus

t gas

recirculation (EGR) drive

circuits short circuit

пЃ¬EGR valve t

o ECM drive circuit

pair - EGR pins 1/3, 4/6 short

circuit to ground or high voltage

пЃ¬EGR val

ve failure (stepper motor

short circuit)

F

or EGR valve circuit tests,GO to Pinpoint Test

A.

.

P

INPOINT TEST A : DTC P0400, P0405; EGR VALV

E FLOW MALFUNCTION/DRIVE CIRCUITS OPEN

CIRCUIT

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1: CHECK

THE EMS POWER SU

PPLIES TO THE EGR VALVE

D

isconnect the EGR valve electrical connector, PI34.

1

Turn the ignition swi

tch to the ON

position.

2

Make sure the EMS re lay i

s energized.

Vehicles with AJ26 engine:

пЃ¬Me

asure the voltage between PI34, pins 02 and 05 (WP) and GROUND

Vehicles with AJ27 engine:

пЃ¬Me

asure the voltage between PI34, pins 02 and 05 (WU) and GROUND

3

Is th

e voltage at either pin less than 10 volts?

Yes

Page 1096 of 2490

RE

PAIR the circuit between the EGR valve and battery. This circuit includes the EMS relay and the

EMS fuse box. For additional info rmation, refer to the wiring diagrams. CLEAR the DTC. TEST the

system for normal operation.

No GO to A2

.

A2: CHECK THE EGR VALVE COIL WIND

INGS FOR CONTINUITY

Meas

ure t

he resistance between pins 04 and 06 of the EGR valve.

1

Meas

ure t

he resistance between pins 01 and 03 of the EGR valve.

2

Is either resi

stance

greater

than 80 ohms?

Yes INSTALL a new EGR valve.

REFER to Exhaust Gas Recirculation (EGR) Valve

- in thi

s section.

CLEAR the DTC. TEST the syst em for normal operation.

No GO to A3

.

A3: CHECK THE EGR VALVE COIL WINDINGS TO

POWER SUPPLY CIRCUIT FOR CONTINUITY

Meas

ure t

he resistance between pins 02 and 03 of the EGR valve.

1

Meas

ure t

he resistance between pins 05 and 06 of the EGR valve.

2

Is either resi

stance greater

than 80 ohms?

Yes INSTALL a new EGR valve.

REFER to Exhaust Gas Recirculation (EGR) Valve

- in thi

s section.

CLEAR the DTC. TEST the syst em for normal operation.

No GO to A4

.

A4: CHECK THE EGR VALVE T

O ECM

CIRCUITS FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

Vehicles with AJ26 engine:

пЃ¬D i

sconnect the ECM electrical connector, EM12

пЃ¬Meas

ure t

he resistance between the following:

пЃ¬PI34, pin

0

4 (YU) and EM12, pin 01 (YU)

пЃ¬PI34,

pi

n 01 (YG) and EM12, pin 02 (YG)

пЃ¬PI34, pin

0

6 (YN) and EM12, pin 03 (YN)

пЃ¬PI34,

pi

n 03 (YR) and EM12, pin 04 (YR)

Vehicles with AJ27 engine:

пЃ¬D i

sconnect the ECM electrical connector, EM85

пЃ¬Meas

ure t

he resistance between the following:

пЃ¬PI34, pin

0

4 (YU) and EM85, pin 03 (YU)

пЃ¬PI34, pi

n 01 (YG) and EM85, pin 04 (YG)

пЃ¬PI34, pi

n 06 (YR) and EM85, pin 09 (YR)

пЃ¬PI34, pi

n 03 (YR) and EM85, pin 10 (YR)

1

Are an

y of the resistances greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to A5

.

A5: CHECK THE EGR VALVE T

O ECM CIRCUITS FOR SHORT TO HIGH VOLTAGE

R

e

connect the battery negative terminal.

1

Meas

ure t

he voltage between the following:

пЃ¬PI34, pin

0

4 (YU) and GROUND

пЃ¬PI34, pin

0

1 (YG) and GROUND

пЃ¬PI34, pin

0

6 (YN) and GROUND

пЃ¬PI34, pin

0

3 (YR) and GROUND

2

Are any of th

e volt

ages greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No

Page 1098 of 2490

Engine Emission

Control - Exhaus

t Gas Recirculation (EGR) Valve

Remo

val and Installation

Remov

a

l

1.

Re

move the engine cover.

For additional informat ion, refer to Section 501

-05

Interior

Trim and Ornamen

t

ation

.

2. Disc

onnect the evaporative emission canister purge valve

electrical connector.

3. Detac

h and reposition the evaporative emission canister purge

valve.

4. NOTE : Cap the coolan

t hose

to minimize coolant loss.

Disconnect the coolant hose.

5. Disconnect the exhaust gas recirc ulation (EGR) valve electrical

connector.

Page 1102 of 2490

9.

Connect

the evaporative emission canister purge valve

electrical connector.

10. Check and if necessary to p up the cooling system.

11. Install the engine cover.

For additional informat ion, refer to Section 501

-05

Interior

Trim and Ornament

ation

.