Connector JAGUAR X308 1998 2.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 435 of 2490

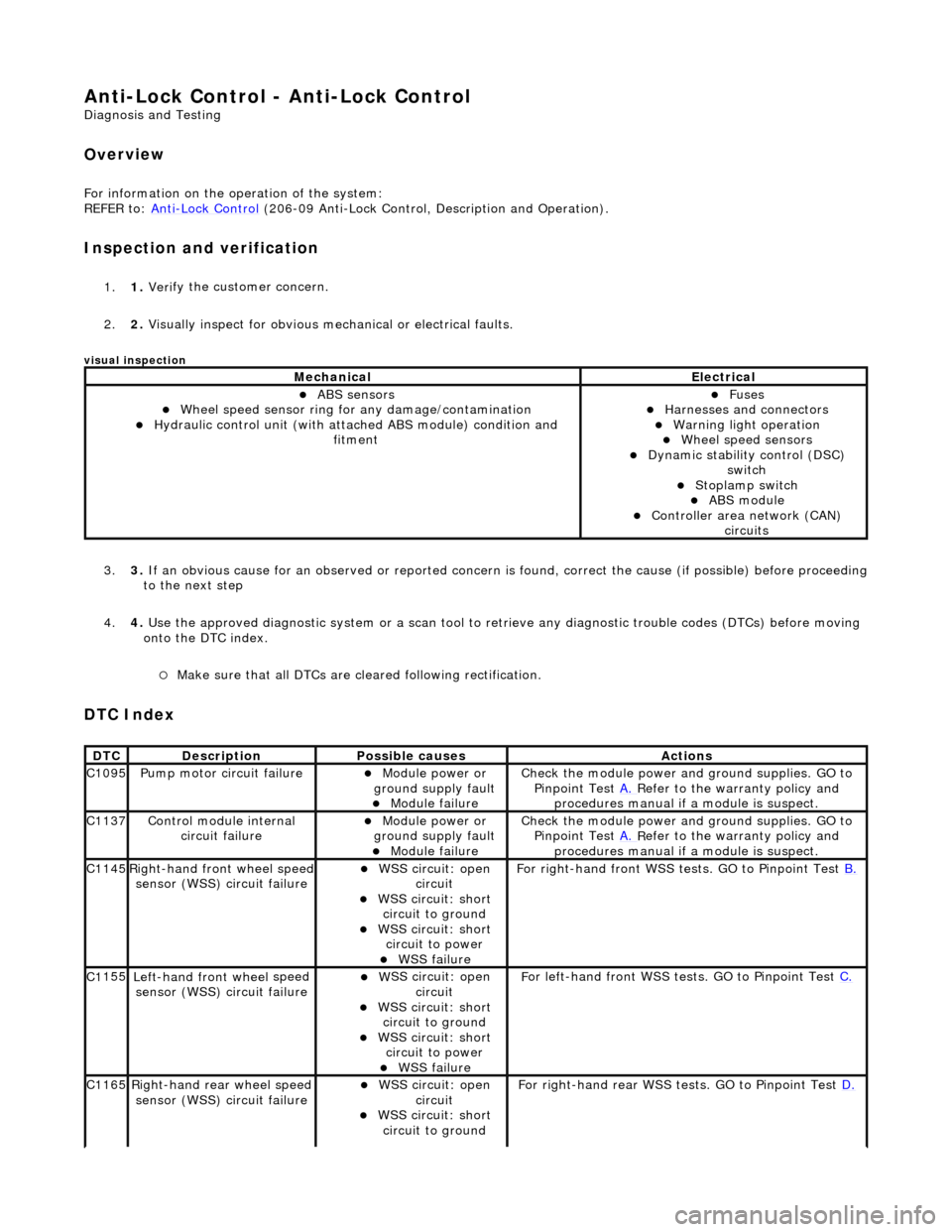

Anti-Lock Control - Anti-Lock Control

D

iagnosis and Testing

Ov

erview

Fo

r information on the operation of the system:

REFER to: Anti

-Lock Control

(206-09 Anti-Lock Control, Description and Operation).

I

nspection and verification

1.

1. Veri

fy the customer concern.

2. 2. Visually inspect for obvious mech anical or electrical faults.

visual insp

ection

3.

3. If

an obvious cause for an observed or

reported concern is found, correct th e cause (if possible) before proceeding

to the next step

4. 4. Use the approved diagnostic system or a scan tool to retrieve any diagnostic trouble codes (DTCs) before moving

onto the DTC index.

п‚ЎMake sure that

all DTCs are cleared following rectification.

DTC Index

MechanicalElectrical

пЃ¬ABS se

nsors

пЃ¬W

heel speed sensor ring for

any damage/contamination

пЃ¬Hydrauli

c control unit (with attached ABS module) condition and

fitment

пЃ¬F

uses

пЃ¬Harnes

ses and connectors

пЃ¬War

ning light operation

пЃ¬Wh

eel speed sensors

пЃ¬Dynam

ic stability control (DSC)

switch

пЃ¬Stoplamp switch

пЃ¬ABS module пЃ¬Con

troller area network (CAN)

circuits

DT

C

De

scription

Possib

le causes

Acti

ons

C1

095

Pump mo

tor circuit failure

пЃ¬Module power or

gr

ound supply fault

пЃ¬Module

failure

Check the modu

le power and

ground supplies. GO to

Pinpoint Test A.

R

efer to the warranty policy and

procedures manual if a module is suspect.

C1

137

Control modu

le internal

circuit failure

пЃ¬Module power or

gr

ound supply fault

пЃ¬Module

failure

Check the modu

le power and

ground supplies. GO to

Pinpoint Test A.

R

efer to the warranty policy and

procedures manual if a module is suspect.

C1

145

Right

-hand front wheel speed

sensor (WSS) circuit failure

пЃ¬W

SS circuit: open

circuit

пЃ¬W

SS circuit: short

circuit to ground

пЃ¬W

SS circuit: short

circuit to power

пЃ¬WSS

failure

F

or right-hand front WSS tests. GO to Pinpoint Test

B.

C1

155

Left-hand front wheel

speed

sensor (WSS) circuit failure

пЃ¬W

SS circuit: open

circuit

пЃ¬W

SS circuit: short

circuit to ground

пЃ¬W

SS circuit: short

circuit to power

пЃ¬WSS

failure

F

or left-hand front WSS tests. GO to Pinpoint Test

C.

C1

165

Ri

ght-hand rear wheel speed

sensor (WSS) circuit failure

пЃ¬W

SS circuit: open

circuit

пЃ¬W

SS circuit: short

circuit to ground

F

or right-hand rear WSS test

s. GO to Pinpoint Test D.

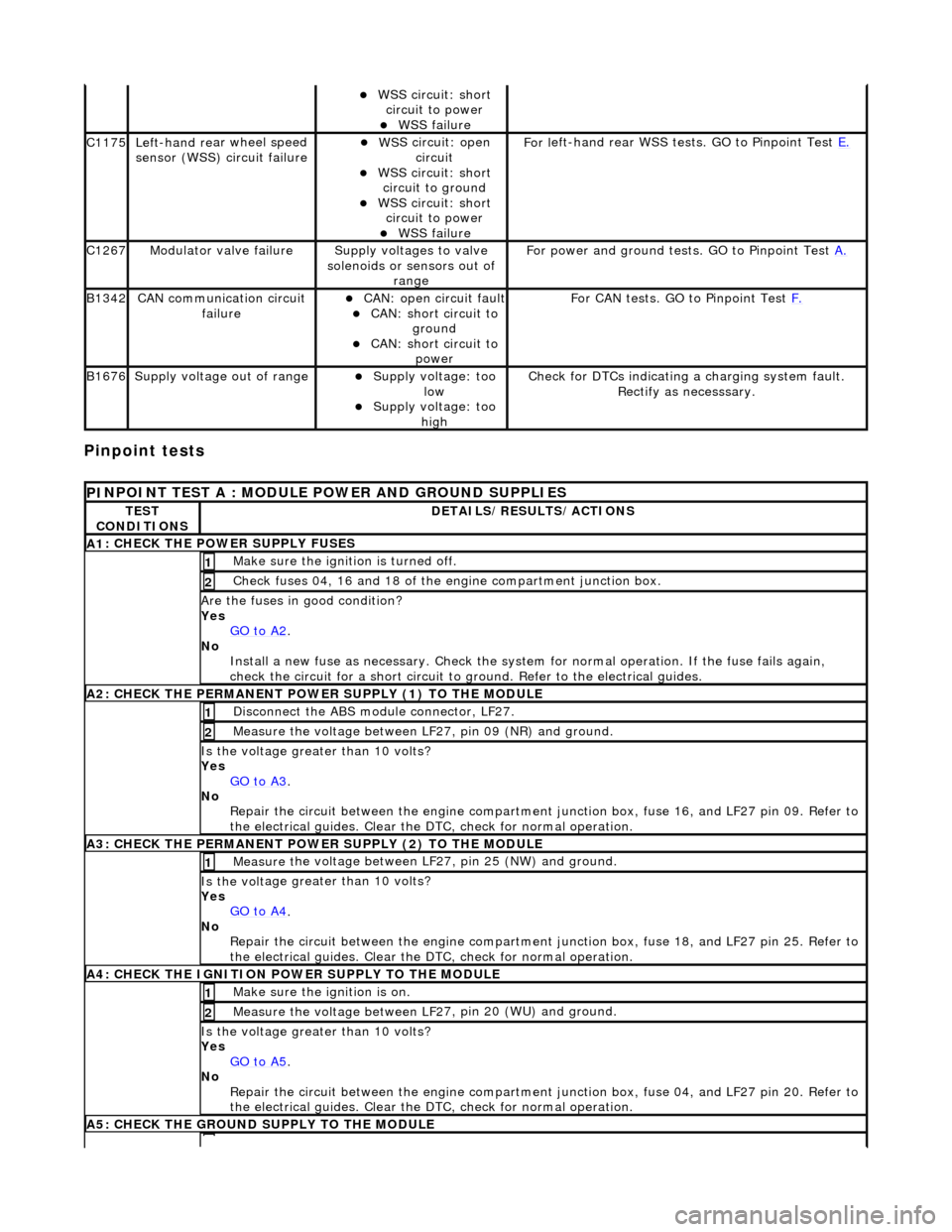

Page 436 of 2490

Pinpoint tests

пЃ¬W

S

S circuit: short

circuit to power

пЃ¬WSS f

ailure

C1

175Left -hand re

ar wheel speed

sensor (WSS) circuit failure

пЃ¬W S

S circuit: open

circuit

пЃ¬WS

S circuit: short

circuit to ground

пЃ¬W S

S circuit: short

circuit to power

пЃ¬WSS f

ailure

F

or l

eft-hand rear WSS test

s. GO to Pinpoint Test E.

C1267Modulat or valv

e failure

Supply volt

ages

to valve

solenoids or sensors out of range

Fo

r power and ground tests. GO to Pinpoint Test

A.

B1342CAN co

mmunication circuit

failure

пЃ¬CAN :

open circuit fault

пЃ¬CAN:

short circuit to

ground

пЃ¬CAN :

short circuit to

power

Fo

r CAN tests. GO to Pinpoint Test

F.

B1676Supply volt

age out of range

пЃ¬Supply voltage:

too

low

пЃ¬Supply volt age:

too

high

Check fo

r DTCs indicating a charging system fault.

Rectify as necesssary.

PI

NPOINT TEST A : MODULE

POWER AND GROUND SUPPLIES

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

A

1

: CHECK THE POWER SUPPLY FUSES

Make sure the igniti

on is turned off. 1

Chec

k fuses 04, 16 and 18 of the engine compartment junction box.

2

Are th

e fus

es in good condition?

Yes GO to A2

.

No

Install a new f

use as

necessary. Check the syst em for normal operation. If the fuse fails again,

check the circuit for a short circuit to ground. Refer to the electrical guides.

A2: CHECK THE PERMANENT

POWER SUPPLY (1) TO THE MODULE

Disc

onnect the ABS module connector, LF27.

1

Measure the voltage between LF

2

7, pin 09 (NR) and ground.

2

Is the vol

t

age greater than 10 volts?

Yes GO to A3

.

No Re

pair the circuit between the engine compartment

junction box, fuse 16, and LF27 pin 09. Refer to

the electrical guides. Clear the DTC, check for normal operation.

A3: CHECK THE PERMANENT

POWER SUPPLY (2) TO THE MODULE

Meas

ure t

he voltage between LF27, pin 25 (NW) and ground.

1

Is the vol

t

age greater than 10 volts?

Yes GO to A4

.

No

Re

pair the circuit between the engine compartment ju

nction box, fuse 18, and LF27 pin 25. Refer to

the electrical guides. Clear the DTC, check for normal operation.

A4: CHECK

THE IGNITION POWER SUPPLY TO THE MODULE

Make sure the ignition is on. 1

Measure the

voltage between LF 2

7, pin 20 (WU) and ground.

2

Is the vol

t

age greater than 10 volts?

Yes GO to A5

.

No Re

pair the circuit between the engine compartment ju

nction box, fuse 04, and LF27 pin 20. Refer to

the electrical guides. Clear the DTC, check for normal operation.

A5: CHECK

THE GROUND SUPPLY TO THE MODULE

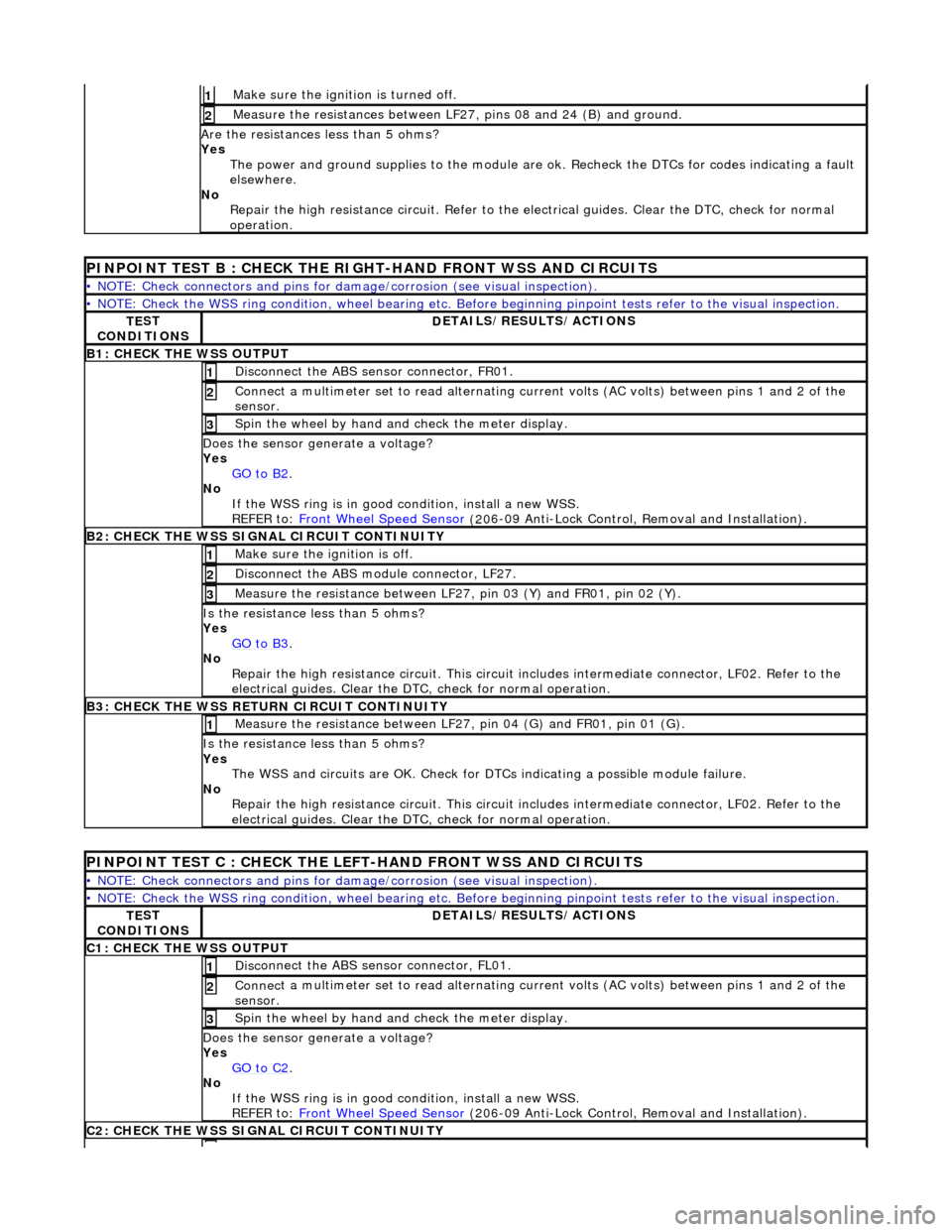

Page 437 of 2490

Make sure the ignition is turned off. 1

Meas

ure the resistances between LF27,

pins 08 and 24 (B) and ground.

2

Are

the resistances less than 5 ohms?

Yes The power and ground supplies to the module are ok . Recheck the DTCs for codes indicating a fault

elsewhere.

No Repair the high resistance circui t. Refer to the electrical guides. Clear the DTC, check for normal

operation.

PINPOINT TE

ST B : CHECK THE RIGHT-HAND FRONT WSS AND CIRCUITS

•

NOTE: Check connectors and pins for damage/corrosion

(see visual inspection).

•

NOTE: Check the WSS ring condition, whee

l bearing etc. Before beginning pinpoint test s refer to the visual inspection.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

B1: CHECK

THE WSS OUTPUT

Disc

onnect the ABS sensor connector, FR01.

1

Connec

t a multimeter set

to read alternating curr ent volts (AC volts) between pins 1 and 2 of the

sensor.

2

Spin

the wheel by hand and check the meter display.

3

Doe

s the sensor generate a voltage?

Yes GO to B2

.

No

If the WSS ring is in good condition, install a new WSS.

REFER to: Front Wheel Speed Sensor

(20

6-09 Anti-Lock Control, Removal and Installation).

B2:

CHECK THE WSS SIGNAL CIRCUIT CONTINUITY

Make sure the ignition is off. 1

Di

sconnect the ABS module connector, LF27.

2

Meas

ure the resistance between LF27

, pin 03 (Y) and FR01, pin 02 (Y).

3

I

s the resistance less than 5 ohms?

Yes GO to B3

.

No

Repair the high resistance circui t. This circuit includes intermediate connector, LF02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

B3:

CHECK THE WSS RETURN CIRCUIT CONTINUITY

Meas

ure the resistance between LF27

, pin 04 (G) and FR01, pin 01 (G).

1

I

s the resistance less than 5 ohms?

Yes The WSS and circuits are OK. Check for DTCs indicating a possible module failure.

No Repair the high resistance circui t. This circuit includes intermediate connector, LF02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

P

INPOINT TEST C : CHECK THE LEFT-HAND FRONT WSS AND CIRCUITS

•

NOTE: Check connectors and pins for damage/corrosion

(see visual inspection).

•

NOTE: Check the WSS ring condition, whee

l bearing etc. Before beginning pinpoint test s refer to the visual inspection.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

C1

: CHECK THE WSS OUTPUT

Disc

onnect the ABS sensor connector, FL01.

1

Connec

t a multimeter set

to read alternating curr ent volts (AC volts) between pins 1 and 2 of the

sensor.

2

Spin

the wheel by hand and check the meter display.

3

Doe

s the sensor generate a voltage?

Yes GO to C2

.

No

If the WSS ring is in good condition, install a new WSS.

REFER to: Front Wheel Speed Sensor

(20

6-09 Anti-Lock Control, Removal and Installation).

C2

: CHECK THE WSS SIGNAL CIRCUIT CONTINUITY

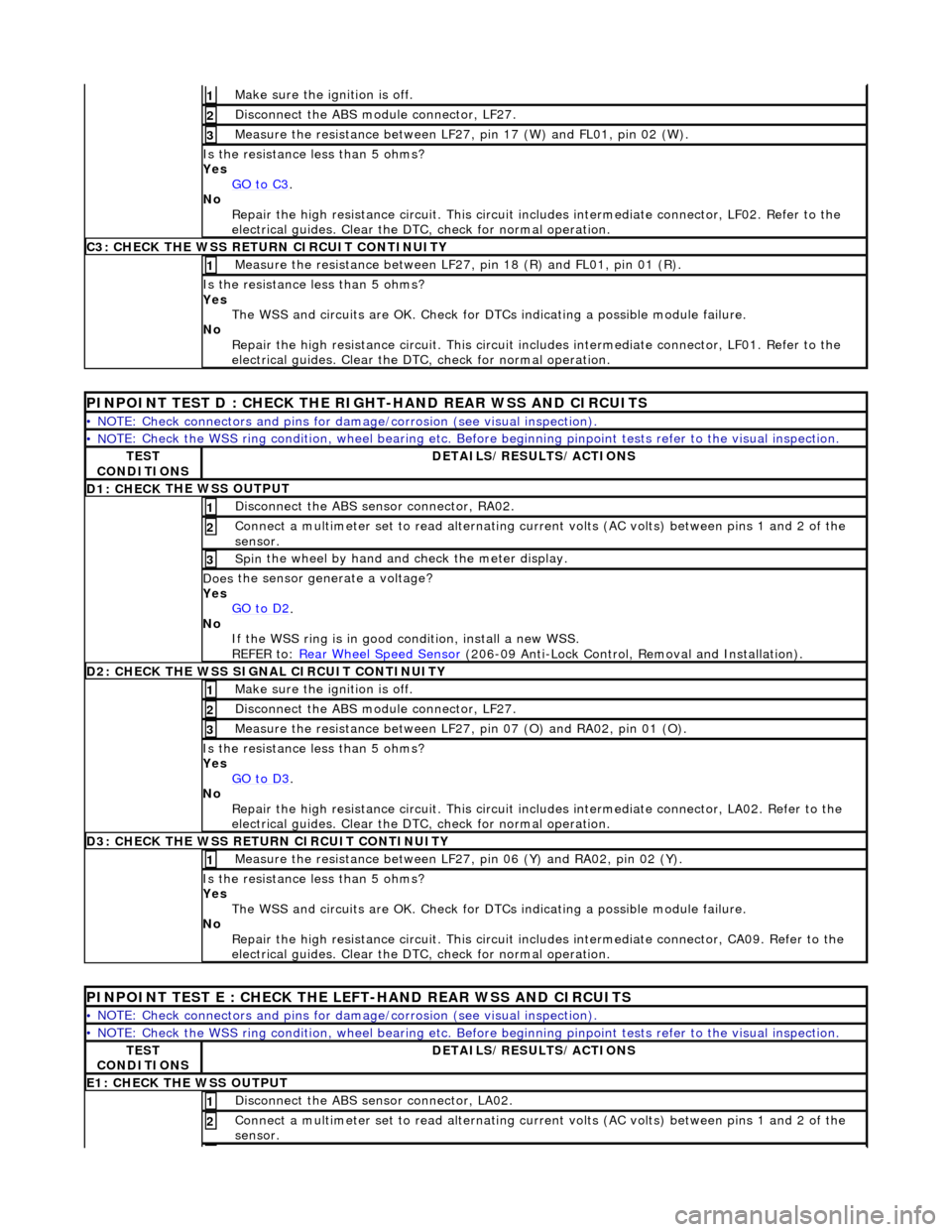

Page 438 of 2490

Make sure the ignition is off. 1

Disc

onnect the ABS module connector, LF27.

2

M

e

asure the resistance between LF27, pin 17 (W) and FL01, pin 02 (W).

3

I

s

the resistance less than 5 ohms?

Yes GO to C3

.

No

Re

pair the high resistance circui

t. This circuit includes intermed iate connector, LF02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

C3: CH

ECK THE WSS RETURN CIRCUIT CONTINUITY

Measure

the resistance between LF27, pin 18 (R) and FL01, pin 01 (R).

1

Is

the resistance less than 5 ohms?

Yes The WSS and circuits are OK. Check for DTCs indicating a possible module failure.

No Repair the high resistance circui t. This circuit includes intermediate connector, LF01. Refer to the

electrical guides. Clear the DTC, check for normal operation.

PI

NPOINT TEST D : CHECK THE RIGH

T-HAND REAR WSS AND CIRCUITS

•

NOTE: Check connectors and pins for damage/corrosion

(see visual inspection).

• NO

TE: Check the WSS ring condition, whee

l bearing etc. Before beginning pinpoint test s refer to the visual inspection.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

D1: CHECK

THE WSS OUTPUT

Disc

onne

ct the ABS sensor connector, RA02.

1

Connec

t

a multimeter set

to read alternating curr ent volts (AC volts) between pins 1 and 2 of the

sensor.

2

Spin

the wheel by hand and check the meter display.

3

Doe

s

the sensor generate a voltage?

Yes GO to D2

.

No

If

the WSS ring is in good condition, install a new WSS.

REFER to: Rear Wheel Speed Sensor

(206-0

9 Anti-Lock Control, Removal and Installation).

D

2

: CHECK THE WSS SIGNAL CIRCUIT CONTINUITY

Make sure the ignition is off. 1

Disc

onnect the ABS module connector, LF27.

2

Measure t

he resistance between LF27

, pin 07 (O) and RA02, pin 01 (O).

3

Is

the resistance less than 5 ohms?

Yes GO to D3

.

No Re

pair the high resistance circui

t. This circuit includes intermed iate connector, LA02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

D3:

CHECK THE WSS RETURN CIRCUIT CONTINUITY

Meas

ure t

he resistance between LF27

, pin 06 (Y) and RA02, pin 02 (Y).

1

Is

the resistance less than 5 ohms?

Yes The WSS and circuits are OK. Check for DTCs indicating a possible module failure.

No Repair the high resistance circui t. This circuit includes intermediate connector, CA09. Refer to the

electrical guides. Clear the DTC, check for normal operation.

PI

NPOINT TEST E : CHECK THE LEFT-HAND REAR WSS AND CIRCUITS

•

NOTE: Check connectors and pins for damage/corrosion

(see visual inspection).

• NO

TE: Check the WSS ring condition, whee

l bearing etc. Before beginning pinpoint test s refer to the visual inspection.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

E1

: CHECK THE W

SS OUTPUT

Disc

onne

ct the ABS sensor connector, LA02.

1

Connec

t

a multimeter set

to read alternating curr ent volts (AC volts) between pins 1 and 2 of the

sensor.

2

Page 439 of 2490

Spin

the wheel by hand and check the meter display.

3

Doe

s the sensor generate a voltage?

Yes GO to E2

.

No

If the WSS ring is in good condition, install a new WSS.

REFER to: Rear Wheel Speed Sensor

(20

6-09 Anti-Lock Control, Removal and Installation).

E2

: CHECK THE WSS SIGNAL CIRCUIT CONTINUITY

Make sure the ignition is off. 1

Di

sconnect the ABS module connector, LF27.

2

Meas

ure the resistance between LF27

, pin 21 (U) and LA02, pin 01 (U).

3

I

s the resistance less than 5 ohms?

Yes GO to E3

.

No

Repair the high resistance circui t. This circuit includes intermediate connector, LA02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

E3

: CHECK THE WSS RETURN CIRCUIT CONTINUITY

Meas

ure the resistance between LF27

, pin 22 (U) and LA02, pin 02 (U).

1

I

s the resistance less than 5 ohms?

Yes The WSS and circuits are OK. Check for DTCs indicating a possible module failure.

No Repair the high resistance circui t. This circuit includes intermediate connector, CA29. Refer to the

electrical guides. Clear the DTC, check for normal operation.

P

INPOINT TEST F : CONT

ROLLER AREA NETWORK (CAN) INTEGRITY TEST

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

F

1: CHECK THE NETWORK INTEGRITY

FROM THE DIAGNOSTIC SOCKET

M

easure the resistance between pins 06 (Y) and 14 (G) of the diagnostic socket.

1

I

s the resistance 60 ohms?

Yes The CAN system is OK. Check for DTCs indicating a fault elsewhere.

No Check the CAN system for open an d short circuits. Refer to the electrical guides. Clear the DTC,

check for normal operation.

Page 441 of 2490

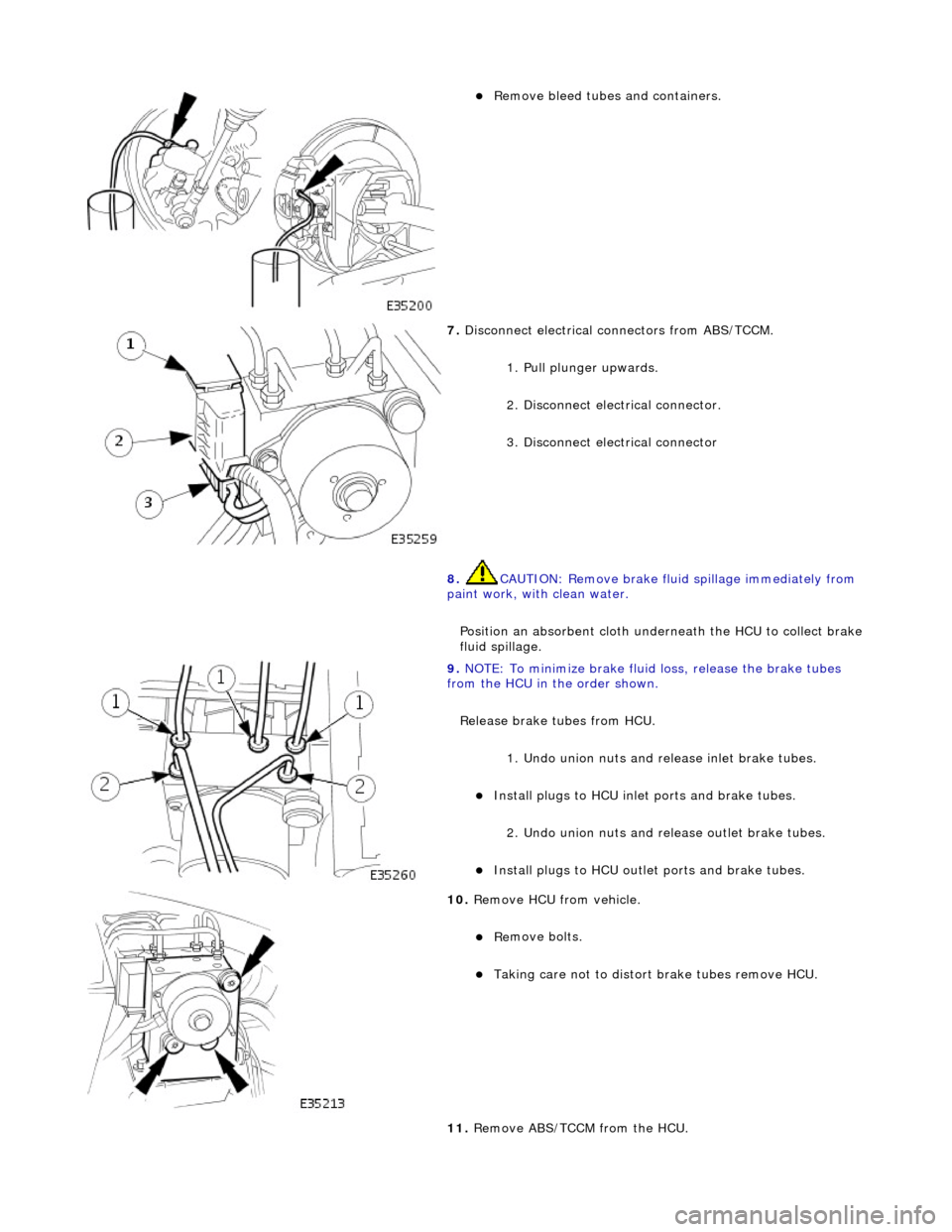

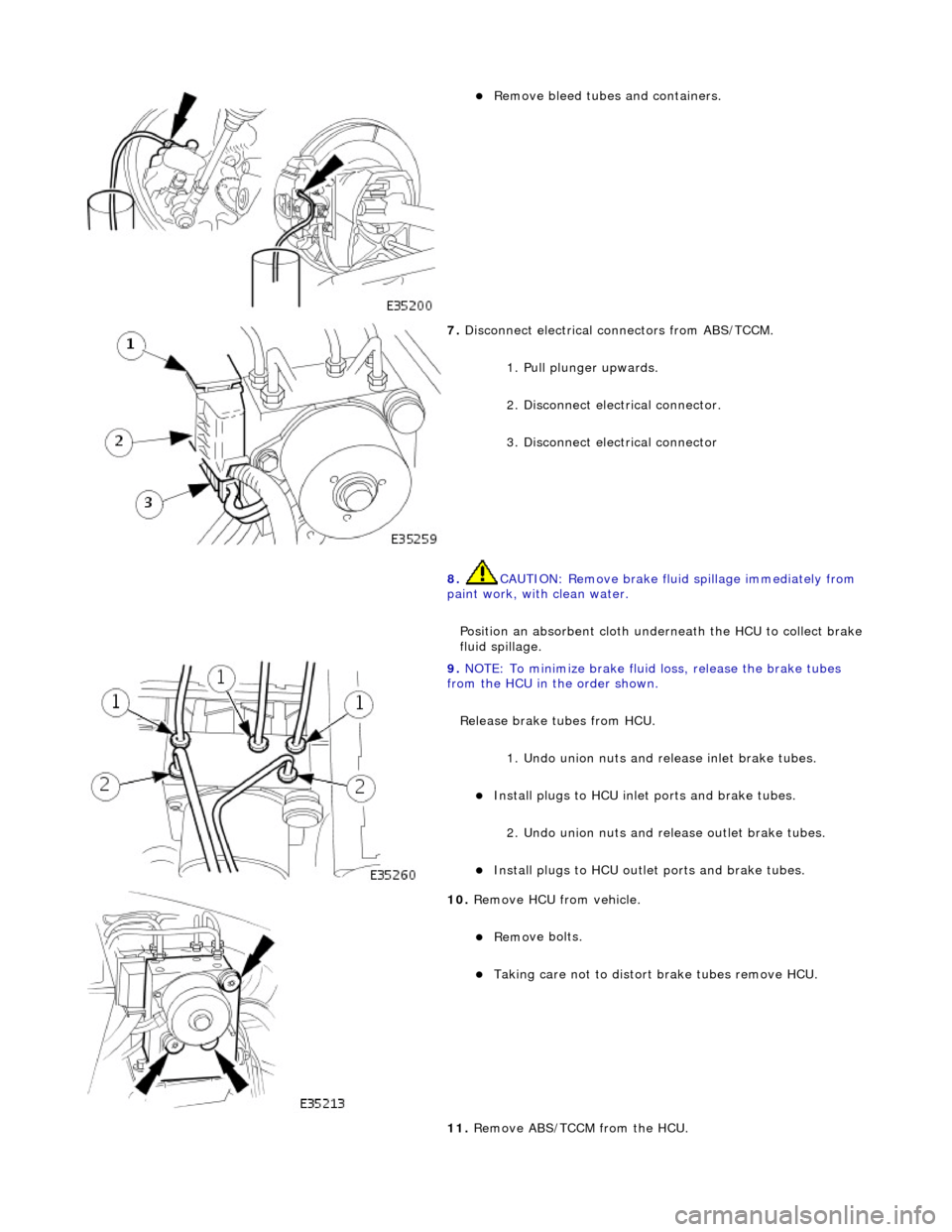

пЃ¬Remove bleed tub

es and containers.

7. Disc

onnect electrical connectors from ABS/TCCM.

1. Pull plunger upwards.

2. Disconnect electrical connector.

3. Disconnect electrical connector

8. CAUTION: Remove brake flui d spillage immediately from

paint work, with clean water.

Position an absorbent cloth under neath the HCU to collect brake

fluid spillage.

9. NOTE

: To minimize brake fluid

loss, release the brake tubes

from the HCU in the order shown.

Release brake tubes from HCU.

1. Undo union nuts and re lease inlet brake tubes.

пЃ¬Install plugs to HCU inlet por

ts and brake tubes.

2. Undo union nuts and re lease outlet brake tubes.

пЃ¬Inst

all plugs to HCU outlet

ports and brake tubes.

10

.

Remove HCU from vehicle.

пЃ¬Re

move bolts.

пЃ¬T

aking care not to distort

brake tubes remove HCU.

11. Remove ABS/TCCM from the HCU.

Page 442 of 2490

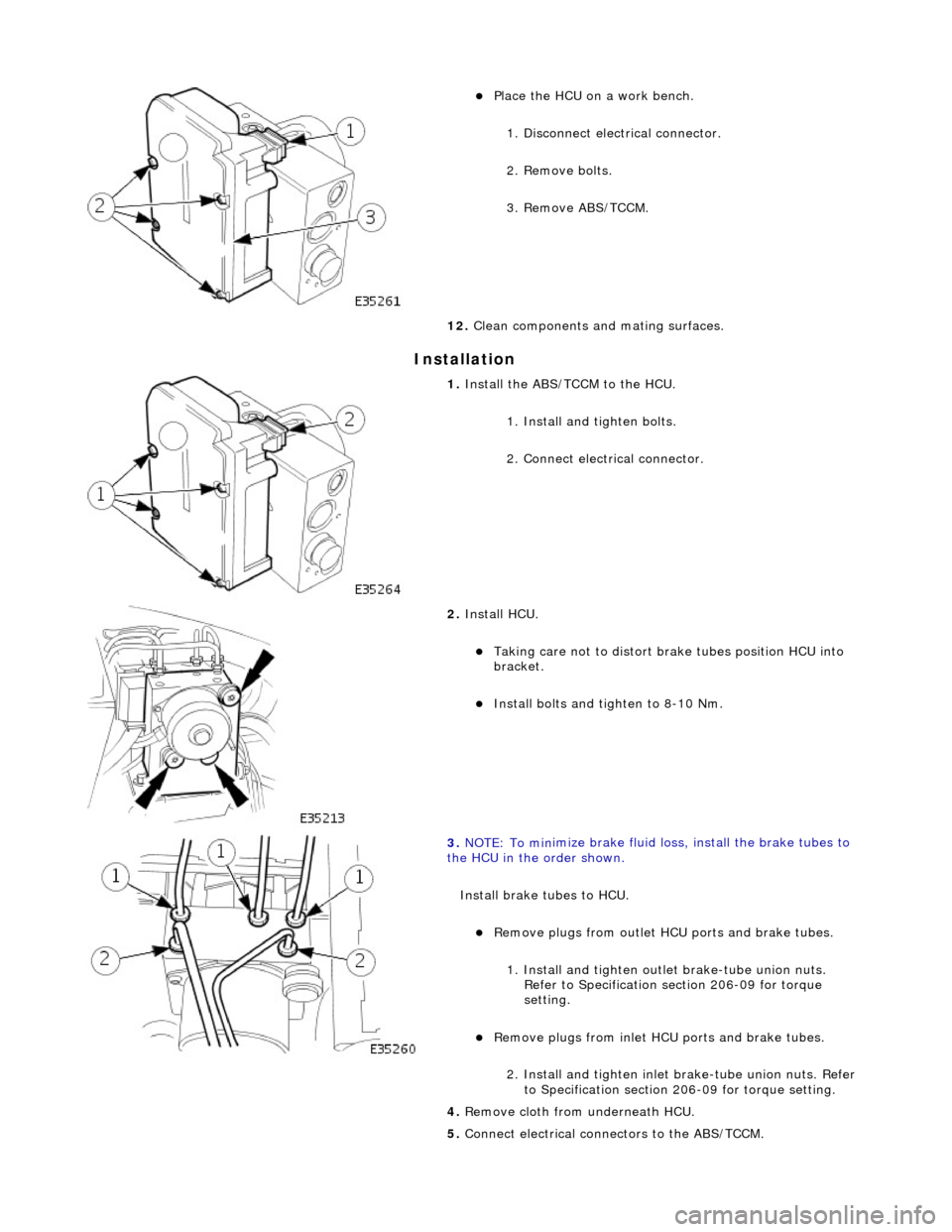

In

stallation

пЃ¬Pla

ce the HCU on a work bench.

1. Disconnect electrical connector.

2. Remove bolts.

3. Remove ABS/TCCM.

12. Clean components and mating surfaces.

1. Install th e AB

S/TCCM to the HCU.

1. Install and tighten bolts.

2. Connect electrical connector.

2. Install HCU.

пЃ¬Takin g

care not to distort brake tubes position HCU into

bracket.

пЃ¬Install bolts and tighten to 8-1

0 Nm.

3. NOTE : To min

imize brake fluid lo

ss, install the brake tubes to

the HCU in the order shown.

Install brake tubes to HCU.

пЃ¬Re

move plugs from outlet HC

U ports and brake tubes.

1. Install and tighten outl et brake-tube union nuts.

Refer to Specification section 206-09 for torque

setting.

пЃ¬Re mo

ve plugs from inlet HC

U ports and brake tubes.

2. Install and tighten inlet brake-tube union nuts. Refer to Specification section 206-09 for torque setting.

4. Remove cloth from underneath HCU.

5. Connect electrical connectors to the ABS/TCCM.

Page 443 of 2490

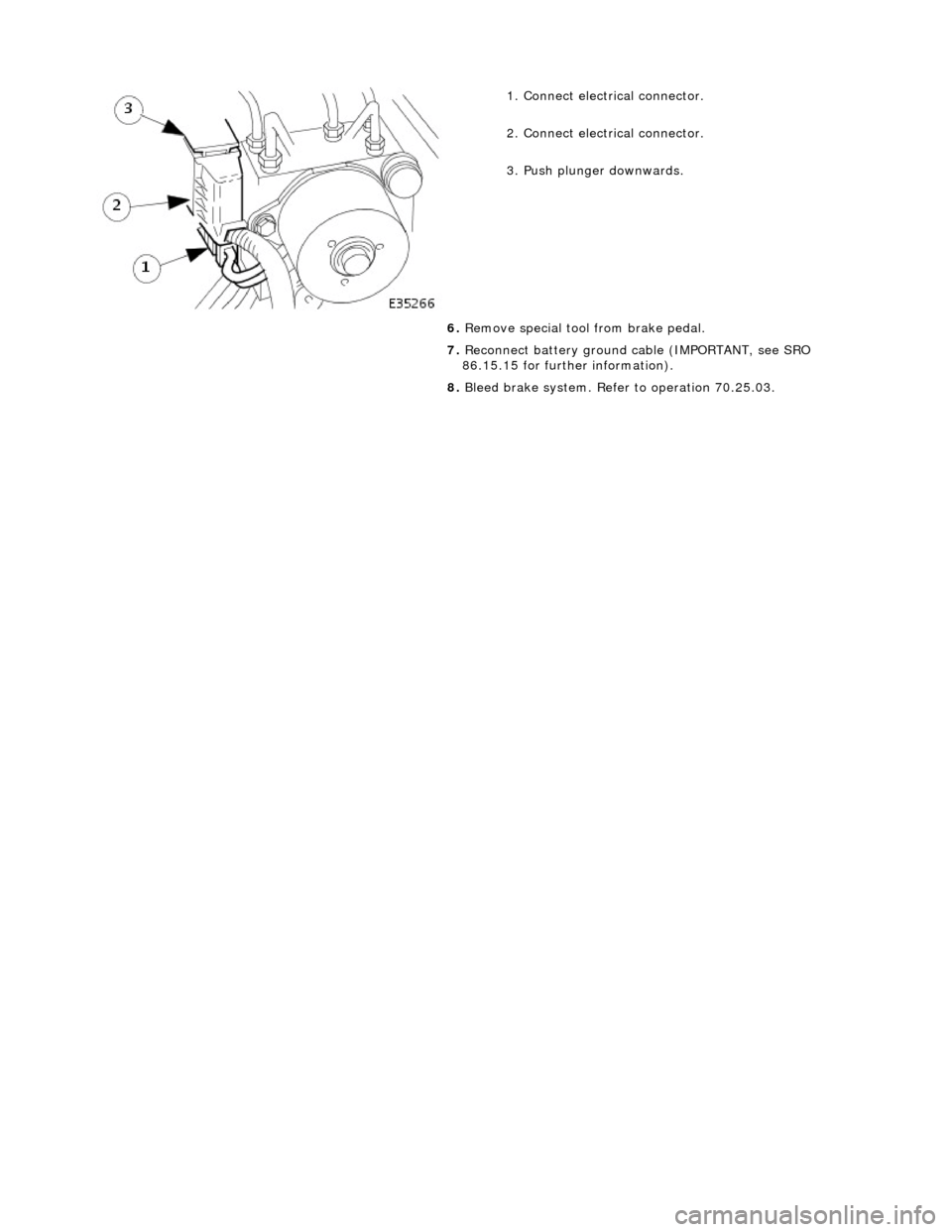

1.

Connect electrical connector.

2. Connect electrical connector.

3. Push plunger downwards.

6. Remove special tool from brake pedal.

7. Reconnect battery ground cable (IMPORTANT, see SRO

86.15.15 for further information).

8. Bleed brake system. Refer to operation 70.25.03.

Page 444 of 2490

Anti-Lock Control - Front Wheel Speed Sensor

Remo

val and Installation

Remov

a

l

Installation

1.

Ra

ise front of vehicle and support

on stands. Refer to section

100-02.

2. Remove wh

eel speed sensor.

пЃ¬Di

sc

onnect harness connector.

пЃ¬Re

mo

ve bolt.

3. Clean components and mating surfaces.

1. Inst al

l wheel speed sensor.

пЃ¬Posit

i

on sensor.

пЃ¬Install and tigh

ten bolt to 8-1

0 Nm.

пЃ¬Conne

ct

harness connector.

2. Remove stands an d lower vehicle.

Page 446 of 2490

пЃ¬Remove bleed tube

s and containers.

7. Disc onne

ct electrical connectors from ABS/TCCM.

1. Pull plunger upwards.

2. Disconnect electrical connector.

3. Disconnect electrical connector

8. CAUTION: Remove brake flui d spillage immediately from

paint work, with clean water.

Position an absorbent cloth under neath the HCU to collect brake

fluid spillage.

9. NOTE : To min

imize brake fluid loss, release the brake tubes

from the HCU in the order shown.

Release brake tubes from HCU.

1. Undo union nuts and re lease inlet brake tubes.

пЃ¬Install plugs to HCU inlet por t

s and brake tubes.

2. Undo union nuts and re lease outlet brake tubes.

пЃ¬Instal

l plugs to HCU outlet

ports and brake tubes.

10 . R

emove HCU from vehicle.

пЃ¬Re

mo

ve bolts.

пЃ¬T

a

king care not to distort

brake tubes remove HCU.

11. Remove ABS/TCCM from the HCU.