fuel injector JAGUAR X308 1998 2.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1078 of 2490

• NO

TE: When performing electrical voltag

e or resistance tests, always use a digital multimeter (DMM) accurate to 3

decimal places, and with an up-t o-date calibration certificate. When testing resistance, always take the resistance of the

DMM leads into account.

• NOTE: Check and rectify basic faults before beginning diagnostic ro utines involving pinpoint tests.

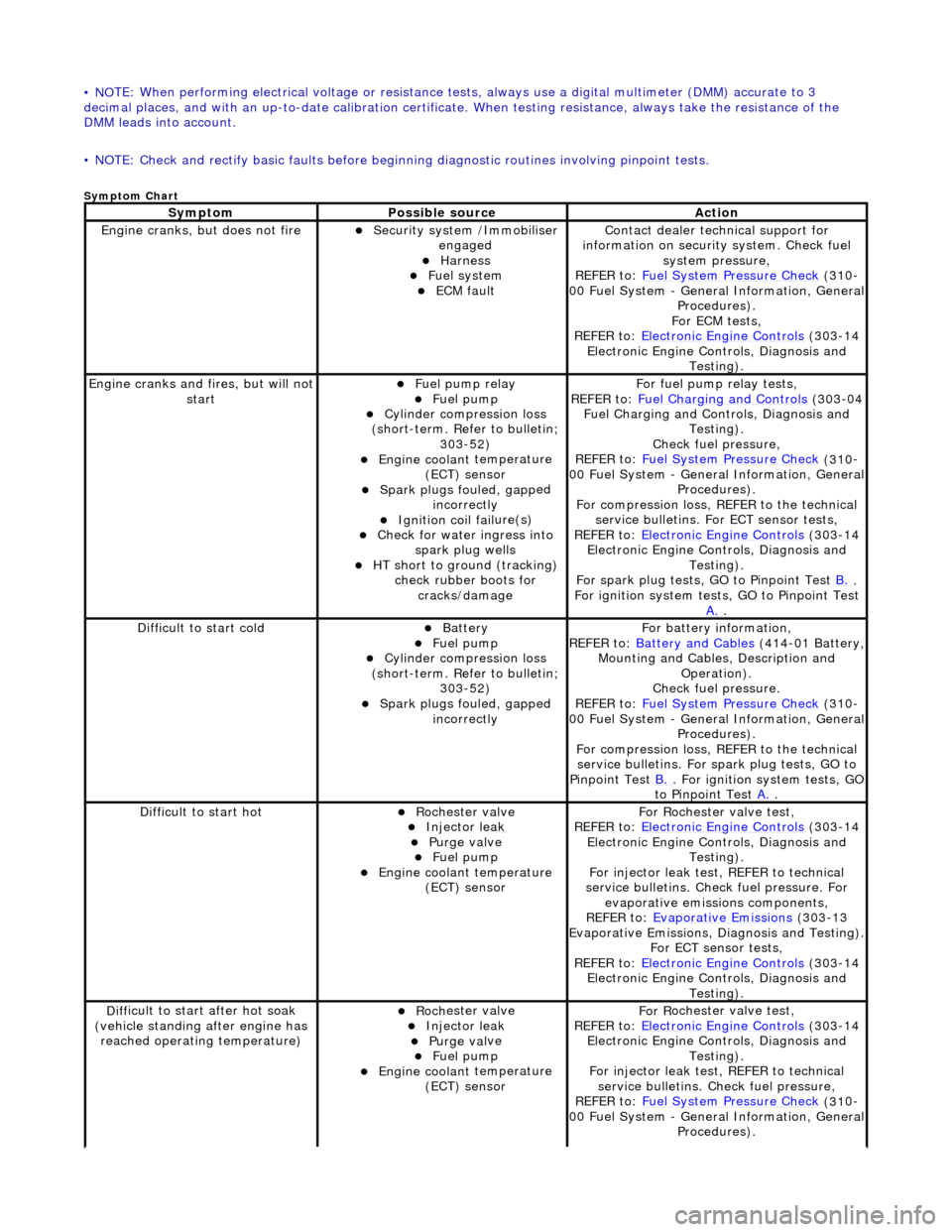

Sym

ptom Chart

Sy

m

ptom

Possib

l

e source

Acti

o

n

Engine

cranks, but does

not fire

Secu

rit

y system /Immobiliser

engaged

Harness Fue l

system

ECM fault

Contact deal er techni

cal support for

information on security system. Check fuel

system pressure,

REFER to: Fuel System Pressure Check

(310

-

00 Fuel System - Genera l Information, General

Procedures).

For ECM tests,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

Engine cranks and

fi

res, but will not

start

Fu

el pump relay

Fuel

pump

Cyl

i

nder compression loss

(short-term. Refer to bulletin; 303-52)

Engine coolan t

temperature

(ECT) sensor

Spark plugs fouled, gapp

ed

incorrectly

Ignition coil fail

ure(s)

Check f

o

r water ingress into

spark plug wells

HT sho rt to ground (tracking)

check rubber

boots for

cracks/damage

Fo

r fuel pump relay tests,

REFER to: Fuel Charging and Controls

(303

-04

Fuel Charging and Controls, Diagnosis and Testing).

Check fuel pressure,

REFER to: Fuel System Pressure Check

(310

-

00 Fuel System - Genera l Information, General

Procedures).

For compression loss, REFER to the technical service bulletins. For ECT sensor tests,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

For spark plug tests, GO to Pinpoint Test B.

.

For ign i

tion system tests, GO to Pinpoint Test

A.

.

Diff

icult to start cold

Batt

ery Fuel

pump

Cyl

i

nder compression loss

(short-term. Refer to bulletin; 303-52)

Spark plugs fouled, gapp

ed

incorrectly

F o

r battery information,

REFER to: Battery and Cables

(414

-01 Battery,

Mounting and Cables, Description and Operation).

Check fuel pressure.

REFER to: Fuel System Pressure Check

(310

-

00 Fuel System - Genera l Information, General

Procedures).

For compression loss, REFER to the technical service bulletins. For spark plug tests, GO to

Pinpoint Test B.

. For ig

nition system tests, GO

to Pinpoint Test A.

.

Diff

icult to start hot

Roc

h

ester valve

Injec

t

or leak

Purge

val

ve

Fue

l

pump

Engine coolan

t

temperature

(ECT) sensor

F or R

ochester

valve test,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

For injector leak test, REFER to technical

service bulletins. Check fuel pressure. For evaporative emissions components,

REFER to: Evaporative Emissions

(303

-13

Evaporative Emissions, Diagnosis and Testing).

For ECT sensor tests,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

D iff

icult to start after hot soak

(vehicle standing after engine has reached operating temperature)

Roc h

ester valve

Injec

t

or leak

Purge

val

ve

Fue

l

pump

Engine coolan

t

temperature

(ECT) sensor

F or R

ochester

valve test,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

For injector leak test, REFER to technical service bulletins. Check fuel pressure,

REFER to: Fuel System Pressure Check

(310

-

00 Fuel System - Genera l Information, General

Procedures).

Page 1083 of 2490

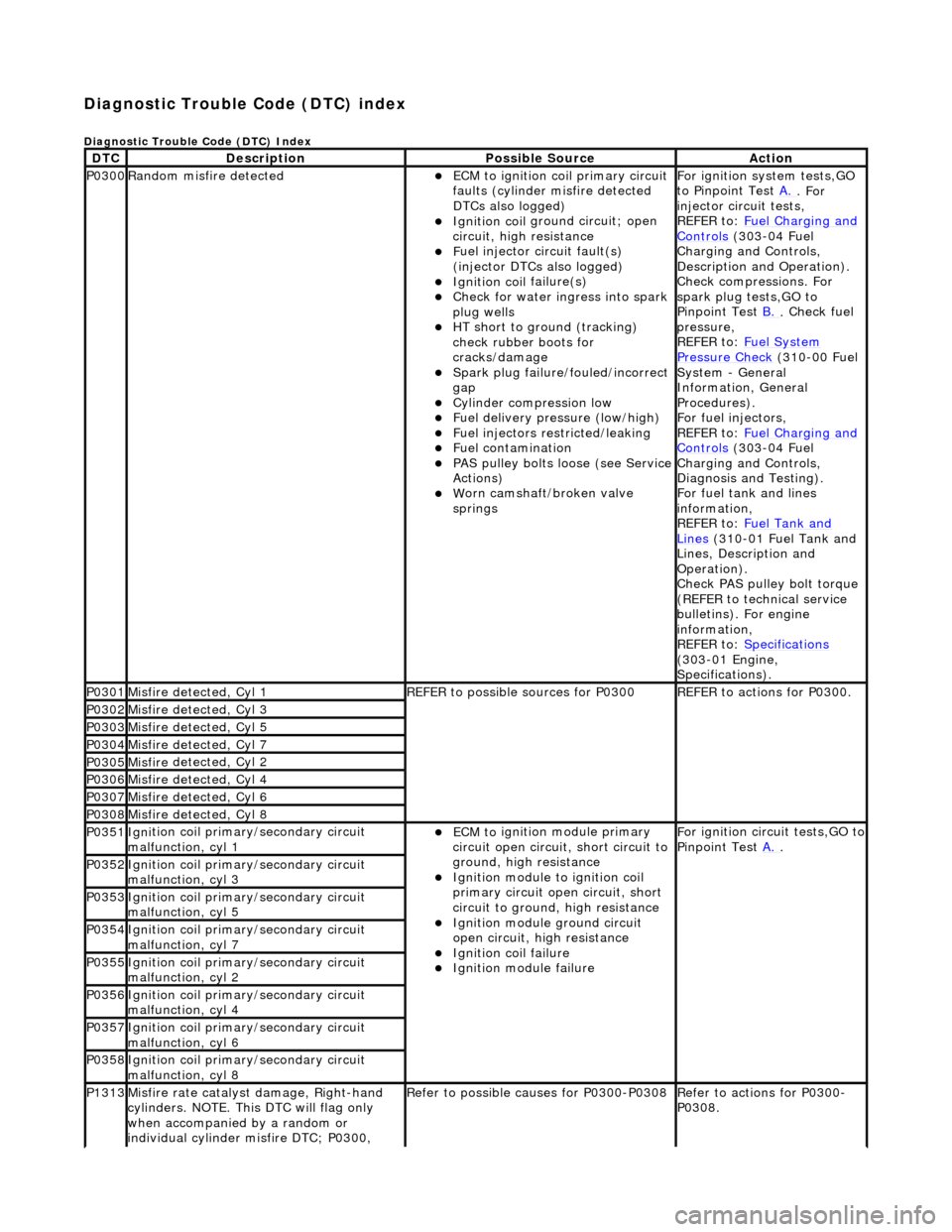

Diagnostic Trouble Code (D

TC) index

D

iagnostic Trouble Code (DTC) Index

DT

C

De

scription

Possib

le Source

Acti

on

P0300Ran

dom misfire detected

ECM t

o ignition coil primary circuit

faults (cylinder misfire detected

DTCs also logged)

Ignition coil

ground circuit; open

circuit, high resistance

F

uel injector circuit fault(s)

(injector DTCs also logged)

Ignition coil

failure(s)

Check f

or water ingress into spark

plug wells

HT sho

rt to ground (tracking)

check rubber boots for

cracks/damage

Spark plug

failure/fouled/incorrect

gap

Cy

linder compression low

F

uel delivery pressure (low/high)

F

uel injectors restricted/leaking

Fuel contamination

P

AS pulley bolts loose (see Service

Actions)

W

orn camshaft/broken valve

springs

For ign

ition system tests,GO

to Pinpoint Test A.

. For

inje

ctor circuit tests,

REFER to: Fuel Charging and

Controls (30

3-04 Fuel

Charging and Controls,

Description and Operation).

Check compressions. For

spark plug tests,GO to

Pinpoint Test B.

.

Check fuel

pressure,

REFER to: Fuel System

Pressure Check (31

0-00 Fuel

System - General

Information, General

Procedures).

For fuel injectors,

REFER to: Fuel Charging and

Controls (30

3-04 Fuel

Charging and Controls,

Diagnosis and Testing).

For fuel tank and lines

information,

REFER to: Fuel Tank and

Lin

es

(310-01 Fuel Tank and

Lines, Description and

Operation).

Check PAS pulley bolt torque

(REFER to technical service

bulletins). For engine

information,

REFER to: Specifications

(3

03-01 Engine,

Specifications).

P0301Misfire

detected, Cyl 1

R

EFER to possible sources for P0300

R

EFER to actions for P0300.

P0302Misfire

detected, Cyl 3

P0303Misfire

detected, Cyl 5

P0304Misfire

detected, Cyl 7

P0305Misfire

detected, Cyl 2

P0306Misfire

detected, Cyl 4

P0307Misfire

detected, Cyl 6

P0308Misfire

detected, Cyl 8

P0351Igni

tion coil primary/secondary circuit

malfunction, cyl 1

ECM to

ignition module primary

circuit open circuit, short circuit to

ground, high resistance

Igni

tion module to ignition coil

primary circuit open circuit, short

circuit to ground, high resistance

Ignition modu

le ground circuit

open circuit, hi gh resistance

Ignition coil

failure

Ignition modul

e failure

F

or ignition circuit tests,GO to

Pinpoint Test A.

.

P0352Igni

tion coil primary/secondary circuit

malfunction, cyl 3

P0353Igni

tion coil primary/secondary circuit

malfunction, cyl 5

P0354Igni

tion coil primary/secondary circuit

malfunction, cyl 7

P0355Igni

tion coil primary/secondary circuit

malfunction, cyl 2

P0356Igni

tion coil primary/secondary circuit

malfunction, cyl 4

P0357Igni

tion coil primary/secondary circuit

malfunction, cyl 6

P0358Igni

tion coil primary/secondary circuit

malfunction, cyl 8

P1313Misfire rate

catalyst damage, Right-hand

cylinders. NOTE. This DTC will flag only

when accompanied by a random or

individual cylinder misfire DTC; P0300,

R

efer to possible causes for P0300-P0308

R

efer to actions for P0300-

P0308.

Page 1138 of 2490

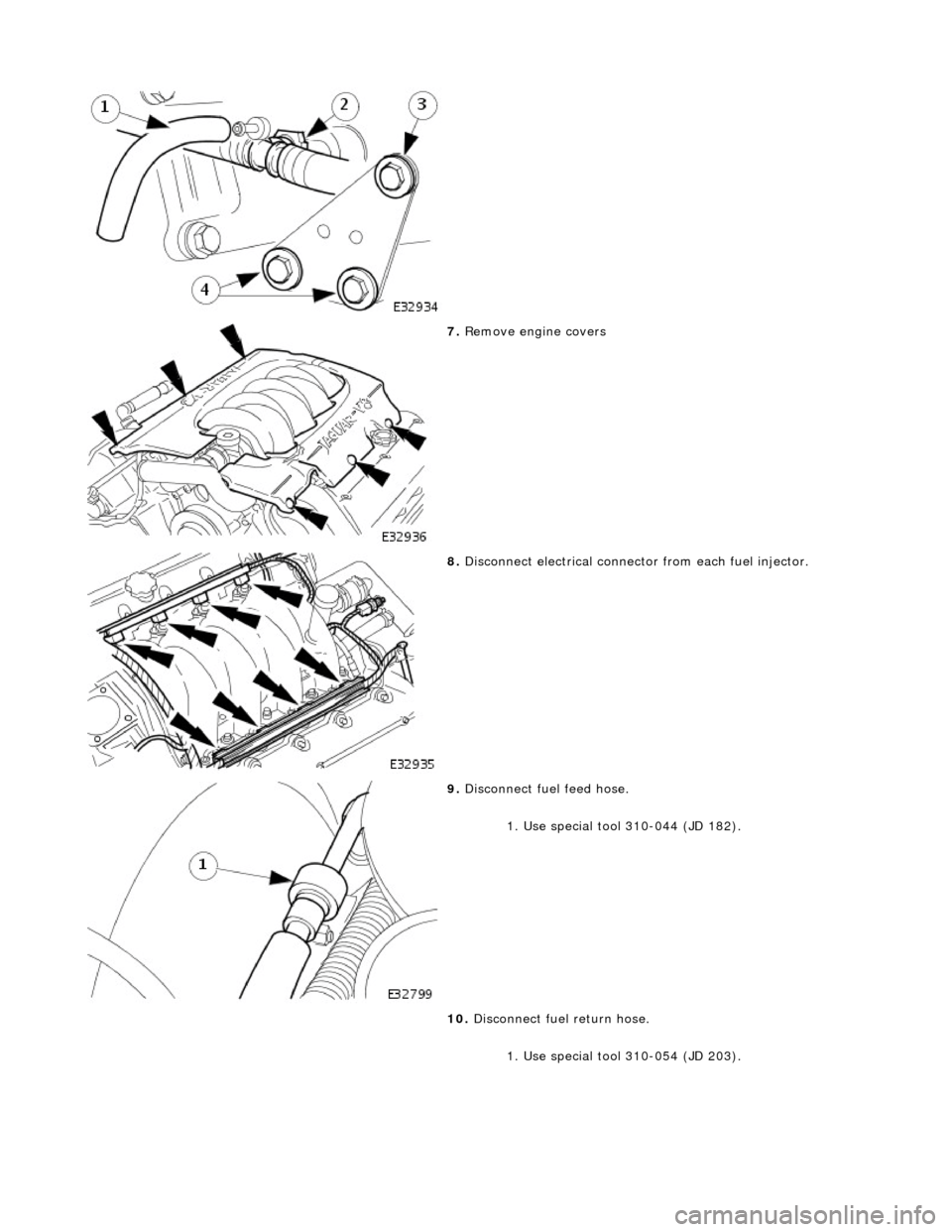

7. Re

move engine covers

8. Disc onne

ct electrical connector from each fuel injector.

9. Disc

onnect fuel feed hose.

1. Use special tool 310-044 (JD 182).

10. Disconnect fuel return hose.

1. Use special tool 310-054 (JD 203).

Page 1140 of 2490

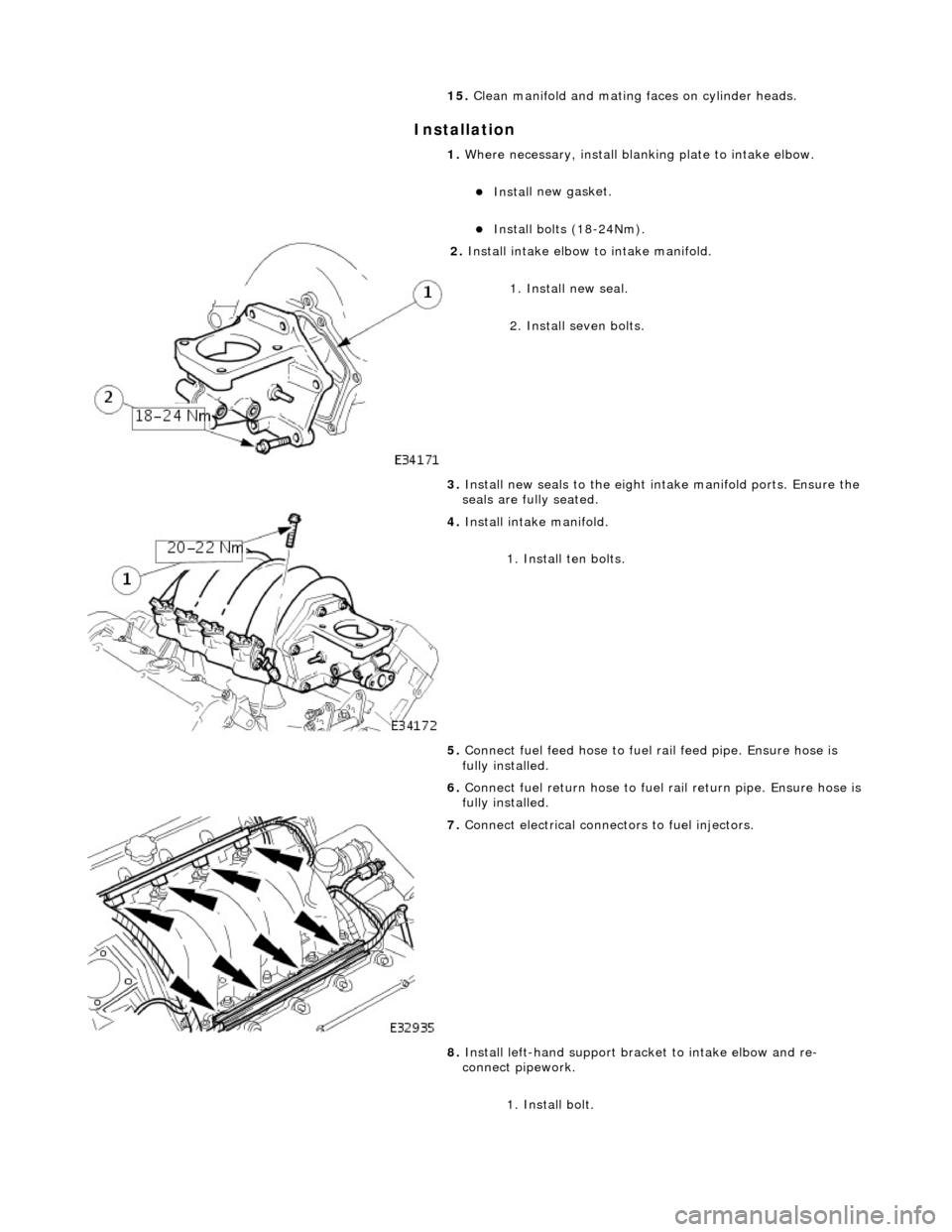

In

stallation

15.

Cle

an manifold and mating faces on cylinder heads.

1. Where necessary, install blanking plate to intake elbow.

Inst al

l new gasket.

Inst

al

l bolts (18-24Nm).

2. Inst al

l intake elbow to intake manifold.

1. Install new seal.

2. Install seven bolts.

3. Install new seals to the eight intake manifold ports. Ensure the

seals are fully seated.

4. Inst al

l intake manifold.

1. Install ten bolts.

5. Connect fuel feed hose to fuel rail feed pipe. Ensure hose is

fully installed.

6. Connect fuel return hose to fuel rail return pipe. Ensure hose is

fully installed.

7. Con n

ect electrical connectors to fuel injectors.

8. Install left-hand support brac ket to intake elbow and re-

connect pipework.

1. Install bolt.

Page 1149 of 2490

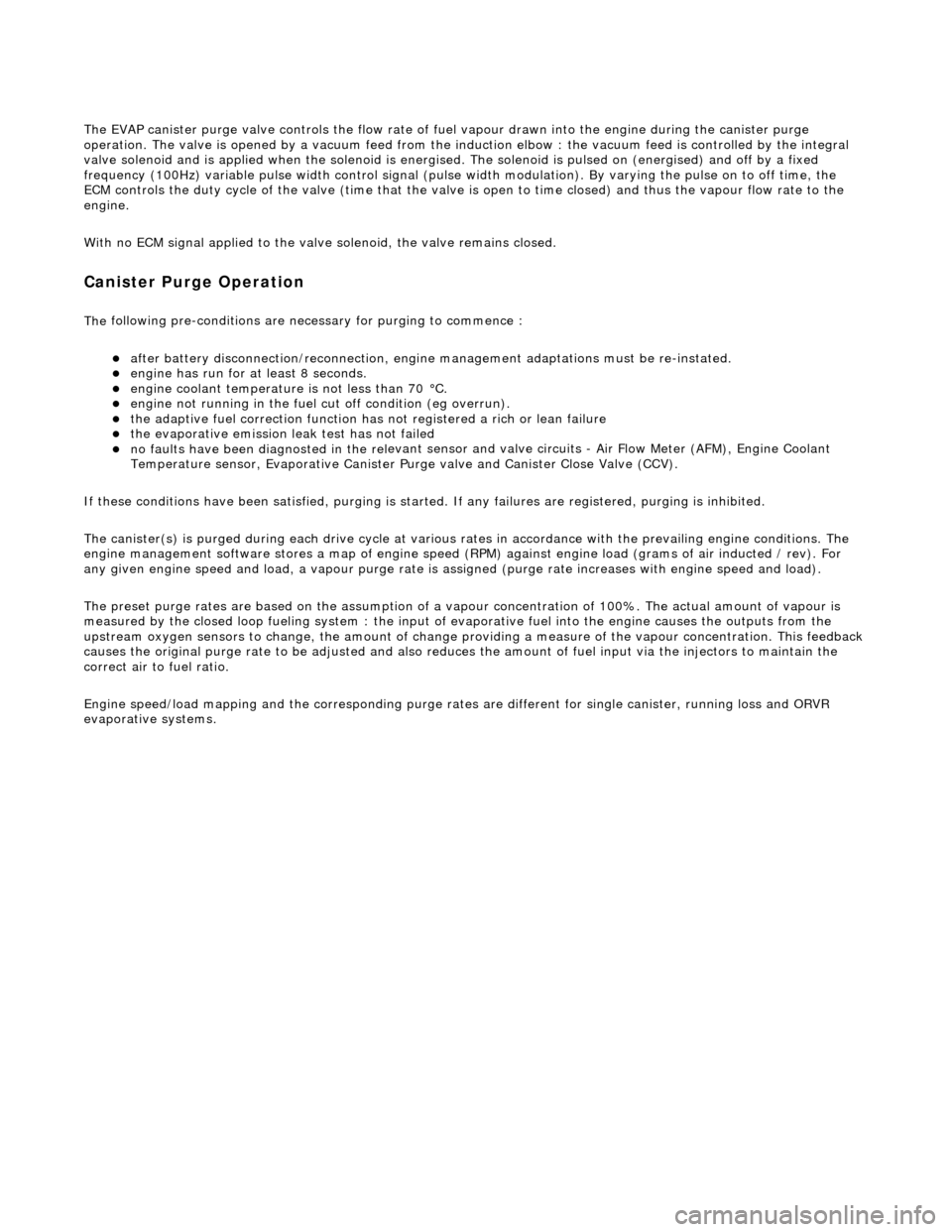

The E

VAP canister purge valve controls th

e flow rate of fuel vapour drawn into the engine during the canister purge

operation. The valve is opened by a vacu um feed from the induction elbow : the vacu um feed is controlled by the integral

valve solenoid and is applied when the so lenoid is energised. The solenoid is pulsed on (energised) and off by a fixed

frequency (100Hz) variable pulse width control signal (pulse width modulation). By varying the pulse on to off time, the

ECM controls the duty cycle of the valve (time that the valve is open to time closed) and thus the vapour flow rate to the

engine.

With no ECM signal applied to the va lve solenoid, the valve remains closed.

Can

ister Purge Operation

The

following pre-conditions are ne

cessary for purging to commence :

aft

er battery disconnection/reconnection, engine

management adaptations must be re-instated.

engine has run for

at least 8 seconds.

engi

ne coolant temperature is not less than 70 °C.

engine

not running in the fuel

cut off condition (eg overrun).

t

he adaptive fuel correction

function has not registered a rich or lean failure

t

he evaporative emission leak test has not failed

no faults have been diagnosted in th

e rel

evant sensor and valve circuits -

Air Flow Meter (AFM), Engine Coolant

Temperature sensor, Evaporativ e Canister Purge valve and Canister Close Valve (CCV).

If these conditions have been satisfied, purging is started. If any failures are registered, purging is inhibited.

The canister(s) is purged during each driv e cycle at various rates in accordance with the prevailing engine conditions. The

engine management software st ores a map of engine speed (RPM) against engine load (grams of air inducted / rev). For

any given engine speed and load, a vapour purge rate is assigned (purge rate increases with engine speed and load).

The preset purge rates are base d on the assumption of a vapour concentratio n of 100%. The actual amount of vapour is

measured by the closed loop fueling system : the input of evaporative fuel into the engine causes the outputs from the

upstream oxygen sensors to change, the am ount of change providing a measure of the vapour concentration. This feedback

causes the original purge rate to be adju sted and also reduces the amount of fuel input via the injectors to maintain the

correct air to fuel ratio.

Engine speed/load mapping and the corresp onding purge rates are different for single canister, running loss and ORVR

evaporative systems.

Page 1191 of 2490

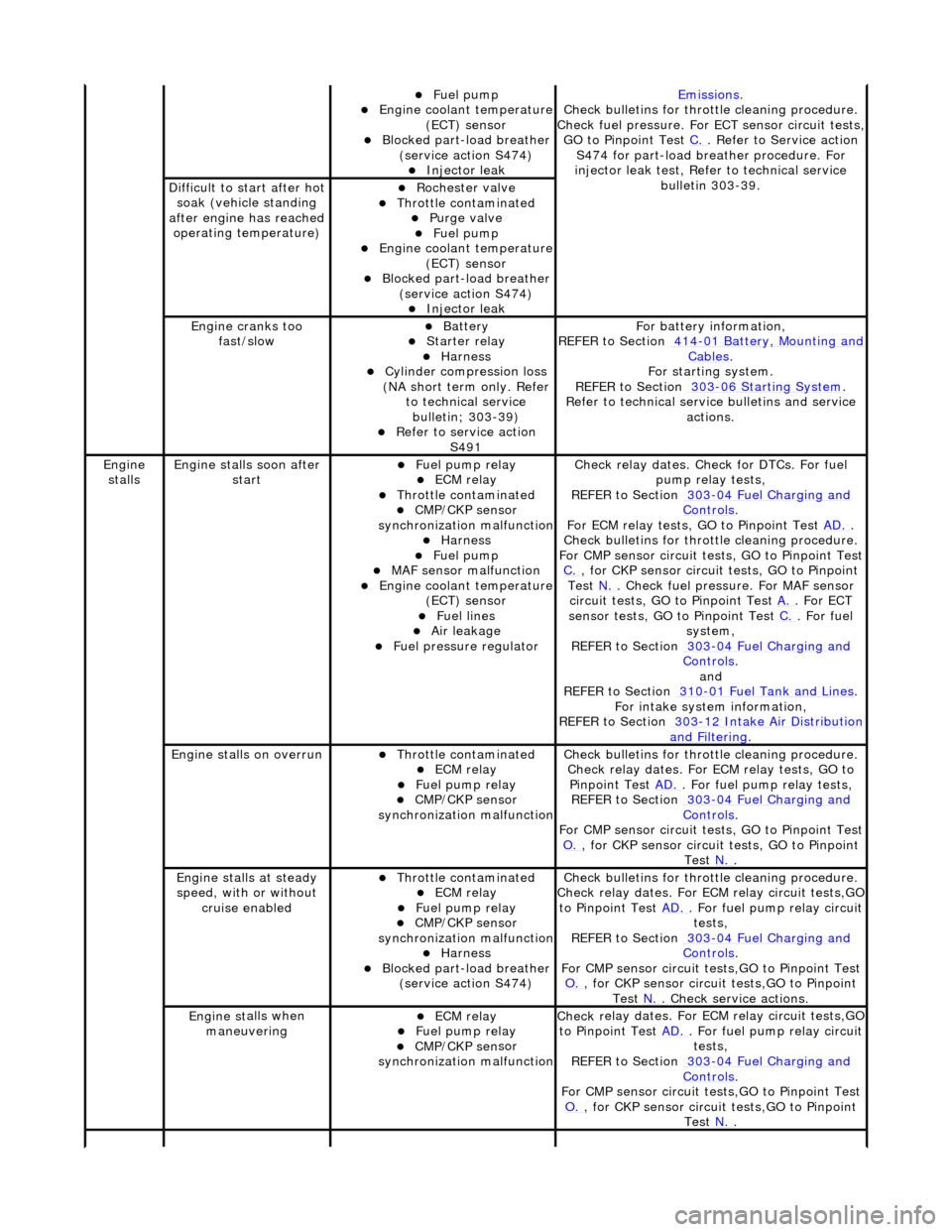

Fue

l pump

Engine coolan

t temperature

(ECT) sensor

Blocked part-load breather (

service action S474)

Injec

tor leak

Emiss

ions

.

Check bull

etins for throttle cleaning procedure.

Check fuel pressure. For ECT sensor circuit tests,

GO to Pinpoint Test C.

. Refer to Servi

ce action

S474 for part-load breather procedure. For

injector leak test, Refer to technical service bulletin 303-39.

D

ifficult to start after hot

soak (vehicle standing

after engine has reached operating temperature)

Roc

hester valve

Thr

ottle contaminated

Purge

valve

Fue

l pump

Engine coolan

t temperature

(ECT) sensor

Blocked part-load breather (

service action S474)

Injec

tor leak

Engine cranks too

fa

st/slow

Batt

ery

Starter relay Harness Cyl

inder compression loss

(NA short term only. Refer to technical service bulletin; 303-39)

R

efer to service action

S491

F

or battery information,

REFER to Section 414

-0

1 Battery, Mounting and

Cables.

F

or starting system.

REFER to Section 303

-06 Sta

rting System

.

R

efer to technical servic

e bulletins and service

actions.

Engine

stalls

Engine st

alls soon after

start

F

uel pump relay

ECM relay Thr

ottle contaminated

CMP/CKP sen

sor

synchronization malfunction

Harness Fue

l pump

MAF

sensor malfunction

Engine coolan

t temperature

(ECT) sensor

Fue

l lines

Air leakage

F

uel pressure regulator

Check r

elay dates. Chec

k for DTCs. For fuel

pump relay tests,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

F

or ECM relay tests, GO to Pinpoint Test

AD.

.

Check bull

etins for throttle cleaning procedure.

For CMP sensor circuit test s, GO to Pinpoint Test

C.

, for

CKP sensor circuit tests, GO to Pinpoint

Test N.

. Check fuel

pressure. For MAF sensor

circuit tests, GO to Pinpoint Test A.

. For EC

T

sensor tests, GO to Pinpoint Test C.

. F

or fuel

system,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

and

REF

ER to Section 310

-0

1 Fuel Tank and Lines

. F

or intake system information,

REFER to Section 303

-1

2 Intake Air Distribution

and F

iltering

.

Engine

stalls on overrun

Thr

ottle contaminated

ECM relay F

uel pump relay

CMP/CKP sen

sor

synchronization malfunction

Check bull

etins for throttle cleaning procedure.

Check relay dates. For ECM relay tests, GO to Pinpoint Test AD.

. F

or fuel pump relay tests,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

F

or CMP sensor circuit test

s, GO to Pinpoint Test

O.

, for

CKP sensor circuit tests, GO to Pinpoint

Test N.

.

E

ngine stalls at steady

speed, with or without cruise enabled

Thr

ottle contaminated

ECM relay F

uel pump relay

CMP/CKP sen

sor

synchronization malfunction

Harness Blocked part-load breather

(

service action S474)

Check bull

etins for throttle cleaning procedure.

Check relay dates. For EC M relay circuit tests,GO

to Pinpoint Test AD.

. F

or fuel pump relay circuit

tests,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

F

or CMP sensor circuit test

s,GO to Pinpoint Test

O.

, for

CKP sensor circuit tests,GO to Pinpoint

Test N.

. Che

ck service actions.

Engine st

alls when

maneuvering

ECM relay F

uel pump relay

CMP/CKP sen

sor

synchronization malfunction

Check r

elay dates. For EC

M relay circuit tests,GO

to Pinpoint Test AD.

. F

or fuel pump relay circuit

tests,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

F

or CMP sensor circuit test

s,GO to Pinpoint Test

O.

, for

CKP sensor circuit tests,GO to Pinpoint

Test N.

.

Page 1196 of 2490

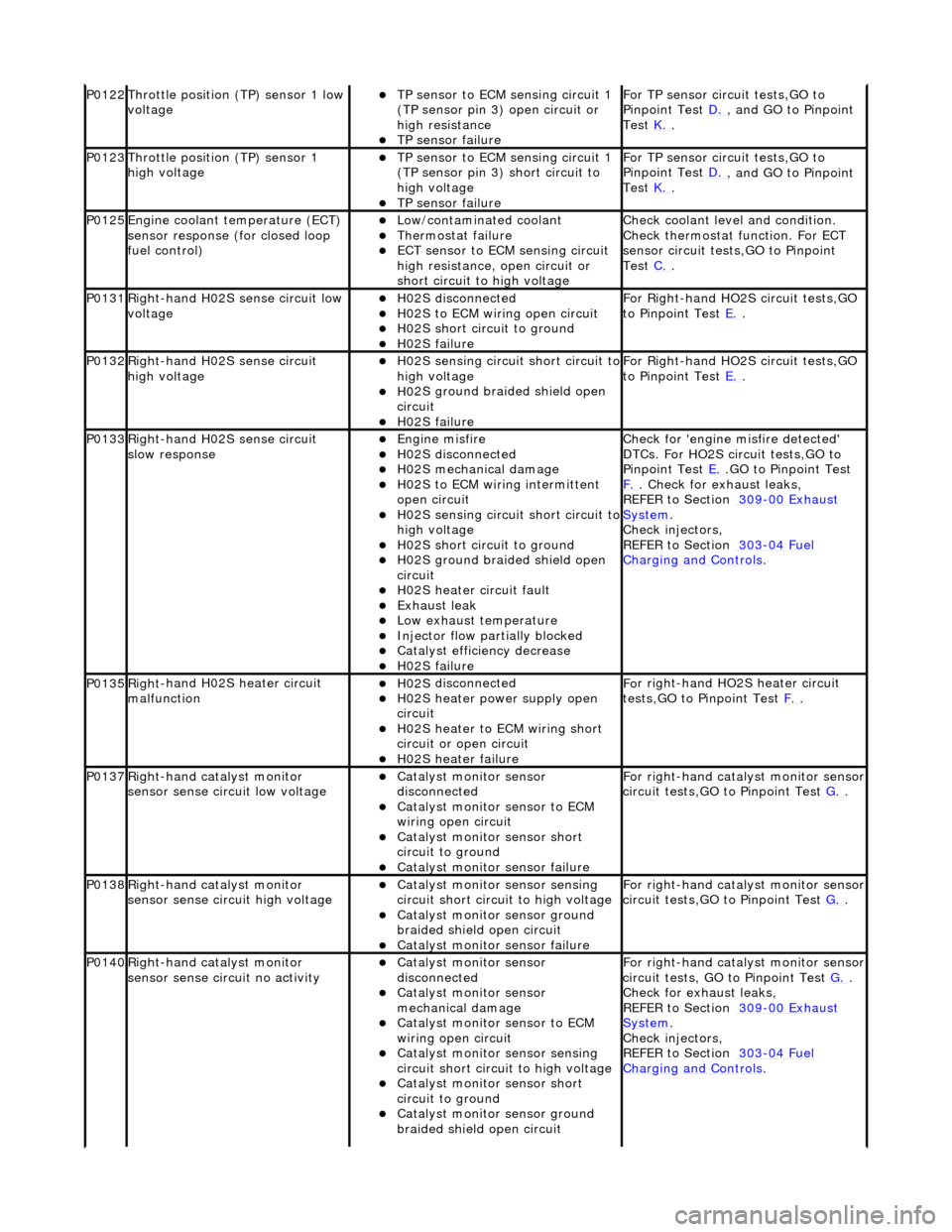

P0122Throttle

position (TP) sensor 1 low

voltage

TP se ns

or to ECM sensing circuit 1

(TP sensor pin 3) open circuit or

high resistance

TP sensor fail

ure

F

o

r TP sensor circ

uit tests,GO to

Pinpoint Test D.

, and GO

to Pinpoint

Test K.

.

P0123Throttl e

position (TP) sensor 1

high voltage

TP se ns

or to ECM sensing circuit 1

(TP sensor pin 3) short circuit to

high voltage

TP sensor fail

ure

F

o

r TP sensor circ

uit tests,GO to

Pinpoint Test D.

, and GO

to Pinpoint

Test K.

.

P0125En

gine coolant temperature (ECT)

sensor response (for closed loop

fuel control)

Low/contaminated coolant Therm o

stat failure

ECT se

ns

or to ECM sensing circuit

high resistance, open circuit or

short circuit to high voltage

Che c

k coolant level and condition.

Check thermostat function. For ECT

sensor circuit tests,GO to Pinpoint

Test C.

.

P0131Right -

hand H02S sense circuit low

voltage

H02 S

disconnected

H0

2S to

ECM wiring open circuit

H0

2S short ci

rcuit to ground

H0

2S fail

ure

F

or R

ight-hand HO2S circuit tests,GO

to Pinpoint Test E.

.

P0132Right-

hand H02S sense circuit

high voltage

H02 S

sensing circuit short circuit to

high voltage

H0 2S groun

d braided shield open

circuit

H0 2S fail

ure

F

or R

ight-hand HO2S circuit tests,GO

to Pinpoint Test E.

.

P0133Right-

hand H02S sense circuit

slow response

Engine m

isfire

H02

S

disconnected

H0

2S mechanical damage

H0

2S to

ECM wiring intermittent

open circuit

H02 S

sensing circuit short circuit to

high voltage

H02S short ci

rcuit to ground

H02S groun

d braided shield open

circuit

H0 2S heater circuit faul

t

Exhaus

t leak

Low e

x

haust temperature

Injector fl

ow parti

ally blocked

Catal

y

st efficiency decrease

H0

2S fail

ure

Chec

k for 'en

gine misfire detected'

DTCs. For HO2S circuit tests,GO to

Pinpoint Test E.

.G

O to Pinpoint Test

F.

. Check for exhaust leaks,

REF

ER to Section 309

-00

Ex

haust

Sy

ste

m

.

Chec k inje

ctors,

REFER to Section 303

-04 Fu

el

Charging and Cont

rols

.

P0135Right

-

hand H02S heater circuit

malfunction

H02 S

disconnected

H0

2S h

eater power supply open

circuit

H0 2S heater to ECM wi

ring short

circuit or open circuit

H0 2S heater fai

lure

F

o

r right-hand HO2S heater circuit

tests,GO to Pinpoint Test F.

.

P0137Right-

hand catalyst monitor

sensor sense circuit low voltage

Catal y

st monitor sensor

disconnected

Catal y

st monitor sensor to ECM

wiring open circuit

Catal y

st monitor sensor short

circuit to ground

Cat a

lyst monitor sensor failure

F

or ri

ght-hand catalyst monitor sensor

circuit tests,GO to Pinpoint Test G.

.

P0138Right -

hand catalyst monitor

sensor sense circuit high voltage

Catal y

st monitor sensor sensing

circuit short circuit to high voltage

Catalyst

monitor sensor ground

braided shield open circuit

Cata

lyst monitor sensor failure

F

or ri

ght-hand catalyst monitor sensor

circuit tests,GO to Pinpoint Test G.

.

P0140Right -

hand catalyst monitor

sensor sense circuit no activity

Catal y

st monitor sensor

disconnected

Catal y

st monitor sensor

mechanical damage

Catal y

st monitor sensor to ECM

wiring open circuit

Catal y

st monitor sensor sensing

circuit short circuit to high voltage

Cataly

st monitor sensor short

circuit to ground

Catalyst

monitor sensor ground

braided shield open circuit

F or ri

ght-hand catalyst monitor sensor

circuit tests, GO to Pinpoint Test G.

.

Check f o

r exhaust leaks,

REFER to Section 309

-00 Ex

haust

Sy

ste

m

.

Chec k inje

ctors,

REFER to Section 303

-04 Fu

el

Charging and Con

t

rols

.

Page 1197 of 2490

Exhaus

t leak

Low e

xhaust temperature

Cat

alyst monitor sensor failure

P0151Le

ft-hand H02S sense circuit low

voltage

H02

S disconnected

H0

2S to ECM wiring open circuit

H0

2S short circuit to ground

H0

2S failure

F

or left-hand HO2S circuit tests, GO

to Pinpoint Test H.

.

P0152Le

ft-hand H02S sense circuit high

voltage

H02

S sensing circuit short circuit to

high voltage

H0

2S ground braided shield open

circuit

H0

2S failure

F

or left-hand HO2S circuit tests,GO to

Pinpoint Test H.

.

P0153Le

ft-hand H02S sense circuit slow

response

Engine

misfire

H02

S disconnected

H0

2S mechanical damage

H0

2S to ECM wiring intermittent

open circuit

H02

S sensing circuit short circuit to

high voltage

H0

2S short circuit to ground

H0

2S ground braided shield open

circuit

H0

2S heater circuit fault

Exhaus

t leak

Low e

xhaust temperature

Injector fl

ow partially blocked

Catal

yst efficiency decrease

H0

2S failure

Chec

k for 'engine misfire detected'

DTCs. For HO2S circ uit tests, GO to

Pinpoint Test H.

. Check for exhaust

leak

s,

REFER to Section 309

-00

Exhaust

Sy

stem

.

Chec

k injectors,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0155Left-hand H02S heater

circuit

malfunction

H02

S disconnected

H0

2S heater power supply open

circuit

H0

2S heater to ECM wiring short

circuit or open circuit

H0

2S heater failure

F

or left-hand HO2S heater circuit

tests,GO to Pinpoint Test I.

.

P0157Le

ft-hand catalyst monitor sensor

sense circuit low voltage

Catal

yst monitor sensor

disconnected

Catal

yst monitor sensor to ECM

wiring open circuit

Catal

yst monitor sensor short

circuit to ground

Cat

alyst monitor sensor failure

F

or left-hand catalyst monitor sensor

circuit tests,GO to Pinpoint Test J.

.

P0158Le

ft-hand catalyst monitor sensor

sense circuit high voltage

Catal

yst monitor sensor sensing

circuit short circuit to high voltage

Catalyst

monitor sensor ground

braided shield open circuit

Cat

alyst monitor sensor failure

F

or left-hand catalyst monitor sensor

circuit tests,GO to Pinpoint Test J.

.

P0160Le

ft-hand catalyst monitor sensor

sense circuit no activity

Catal

yst monitor sensor

disconnected

Catal

yst monitor sensor

mechanical damage

Catal

yst monitor sensor to ECM

wiring open circuit

Catal

yst monitor sensor sensing

circuit short circuit to high voltage

Catal

yst monitor sensor short

circuit to ground

Catalyst

monitor sensor ground

braided shield open circuit

Exhaus

t leak

Low e

xhaust temperature

Cat

alyst monitor sensor failure

F

or left-hand catalyst monitor sensor

circuit tests,GO to Pinpoint Test J.

.

Check f

or exhaust leaks,

REFER to Section 309

-00

Exhaust

Sy

stem

.

P0171Right

-hand cylinders combustion

too lean

Air

intake leak between MAF senso

r and th

rottle

F

uel filter system blockage

F

uel injector blockage

F

uel pressure regulator failure (low

fuel pressure)

Low f

uel pump output

Check ai

r intake system for leaks,

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Check the fuel fi

lter,

REFER to Section 310

-01

Fuel Tank

and Lines.

Chec

k the fuel injectors and fuel

Page 1198 of 2490

H02S harness wiri

ng fault

E

x

haust leak (before catalyst)

ECM receivi

n

g incorrect signal from

one or more of the following

sensors - ECT, MAF, IAT, TP

pr essure regulator,

REF

ER to Section 303

-04

Fu

el

Charging and Con

t

rols

.

Chec k the

fuel pressure. Check the

exhaust system for leaks,

REFER to Section 309

-00 Ex

haust

Sy

ste

m

.

R e

fer to pinpoint tests for sensors

listed.

P0172Right -

hand cylinders combustion

too rich

Engine m

isfire

Bl

ocked air

filter

F

u

el system return blockage

Leak

i

ng fuel injector(s)

F

u

el pressure regulator failure

(high fuel pressure)

ECM receivi n

g incorrect signal from

one or more of the following

sensors - ECT, MAF, IAT, TP

Chec k for 'en

gine misfire detected'

DTCs. Check the air filter element,

REFER to Section 303

-1 2

Intake Air

Distribu

tion and Filterin

g

.

Chec k the

fuel lines,

REFER to Section 310

-01 Fu

el Tank

and Lines.

Chec k the

fuel injectors and fuel

pressure regulator,

REFER to Section 303

-04 Fu

el

Charging and Con

t

rols

.

R e

fer to pinpoint tests for sensors

listed.

P0174L e

ft-hand cylinders combustion

too lean

Air in

take leak between MAF senso

r and th

ro

ttle

F

u

el filter system blockage

F

u

el injector blockage

F

u

el pressure regulator failure (low

fuel pressure)

Low fu

el pump output

H0

2S harness wiri

ng fault

E

x

haust leak (before catalyst)

ECM receivi

n

g incorrect signal from

one or more of the following

sensors - ECT, MAF, IAT, TP

Check the ai r intak

e system for leaks,

REFER to Section 303

-1 2

Intake Air

Distribu

tion and Filterin

g

.

Check the fuel fi lter,

REF

ER to Section 310

-01

Fu

el Tank

and Lines.

Chec k the

fuel injectors and fuel

pressure regulator,

REFER to Section 303

-04 Fu

el

Charging and Con

t

rols

.

Chec k the

fuel pressure. For HO2S

circuit tests,GO to Pinpoint Test H.

,

a n

dGO to Pinpoint Test

I.

. Check

the

exhaust system for leaks,

REFER to Section 309

-00 Ex

haust

Sy

ste

m

.

R e

fer to pinpoint tests for sensors

listed.

P0175L e

ft-hand cylinders combustion

too rich

Engine m

isfire

Bl

ocked air

filter

F

u

el system return blockage

Leak

i

ng fuel injector(s)

F

u

el pressure regulator failure

(high fuel pressure)

ECM receivi n

g incorrect signal from

one or more of the following

sensors - ECT, MAF, IAT, TP

Chec k for 'en

gine misfire detected'

DTCs. Check air filter element,

REFER to Section 303

-1 2

Intake Air

Distribu

tion and Filterin

g

.

Chec k the

fuel lines,

REFER to Section 310

-01 Fu

el Tank

and Lines.

Chec k the

fuel injectors and fuel

pressure regulator,

REFER to Section 303

-04 Fu

el

Charging and Cont

rols

.

Re

fer to pinpoint tests for sensors

listed.

P0201 Fu

el injector circuit malfunction,

cyl 1

Injector discon n

ected

Inject

or wir

ing open or short circuit

Injector fail

ure

F

o

r fuel injector

circuit tests,

REFER to Section 303

-04 Fu

el

Charging and Con

t

rols

. P0202F

u

el injector circuit malfunction,

cyl 3

P0203F u

el injector circuit malfunction,

cyl 5

P0204F u

el injector circuit malfunction,

cyl 7

P0205F u

el injector circuit malfunction,

cyl 2

P0206F u

el injector circuit malfunction,

cyl 4

P0207F u

el injector circuit malfunction,

cyl 6

P0208F u

el injector circuit malfunction,

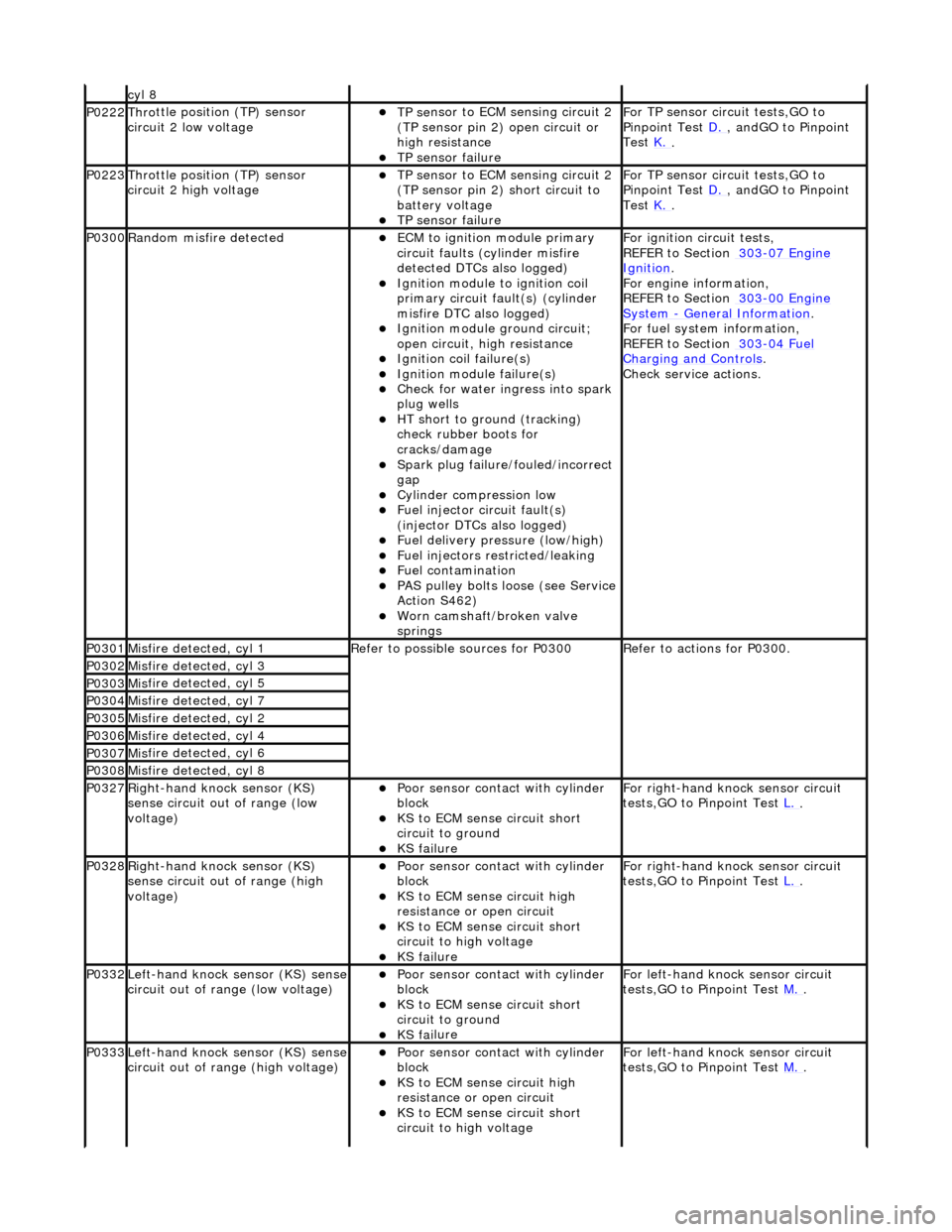

Page 1199 of 2490

cyl 8

P0222Thro

ttle position (TP) sensor

circuit 2 low voltage

TP se

nsor to ECM sensing circuit 2

(TP sensor pin 2) open circuit or

high resistance

TP sensor

failure

F

or TP sensor circ

uit tests,GO to

Pinpoint Test D.

, andG

O to Pinpoint

Test K.

.

P0223Thro

ttle position (TP) sensor

circuit 2 high voltage

TP se

nsor to ECM sensing circuit 2

(TP sensor pin 2) short circuit to

battery voltage

TP sensor

failure

F

or TP sensor circ

uit tests,GO to

Pinpoint Test D.

, andG

O to Pinpoint

Test K.

.

P0300Ran

dom misfire detected

ECM to

ignition module primary

circuit faults (cylinder misfire

detected DTCs also logged)

Igni

tion module to ignition coil

primary circuit fault(s) (cylinder

misfire DTC also logged)

Ignition modu

le ground circuit;

open circuit, hi gh resistance

Ignition coil

failure(s)

Ignition modul

e failure(s)

Check f

or water ingress into spark

plug wells

HT sho

rt to ground (tracking)

check rubber boots for

cracks/damage

Spark plug

failure/fouled/incorrect

gap

Cy

linder compression low

F

uel injector circuit fault(s)

(injector DTCs also logged)

F

uel delivery pressure (low/high)

F

uel injectors restricted/leaking

Fuel contamination

P

AS pulley bolts loose (see Service

Action S462)

W

orn camshaft/broken valve

springs

F

or ignition circuit tests,

REFER to Section 303

-07

Engine

Ignition.

F

or engine information,

REFER to Section 303

-00

Engine

Sy

stem

- General

Information

.

F

or fuel system information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

Check service

actions.

P0301Mis

fire detected, cyl 1

R

efer to possible sources for P0300

R

efer to actions for P0300.

P0302Mis

fire detected, cyl 3

P0303Mis

fire detected, cyl 5

P0304Mis

fire detected, cyl 7

P0305Mis

fire detected, cyl 2

P0306Mis

fire detected, cyl 4

P0307Mis

fire detected, cyl 6

P0308Mis

fire detected, cyl 8

P0327Right

-hand knock sensor (KS)

sense circuit out of range (low

voltage)

Poor sensor cont

act with cylinder

block

KS to

ECM sense circuit short

circuit to ground

KS fai

lure

F

or right-hand knock sensor circuit

tests,GO to Pinpoint Test L.

.

P0328Right

-hand knock sensor (KS)

sense circuit out of range (high

voltage)

Poor sensor cont

act with cylinder

block

KS to EC

M sense circuit high

resistance or open circuit

KS to

ECM sense circuit short

circuit to high voltage

KS fai

lure

F

or right-hand knock sensor circuit

tests,GO to Pinpoint Test L.

.

P0332Left-hand knock sens

or (KS) sense

circuit out of range (low voltage)

Poor sensor cont

act with cylinder

block

KS to

ECM sense circuit short

circuit to ground

KS fai

lure

F

or left-hand knoc

k sensor circuit

tests,GO to Pinpoint Test M.

.

P0333Left-hand knock sens

or (KS) sense

circuit out of range (high voltage)

Poor sensor cont

act with cylinder

block

KS to EC

M sense circuit high

resistance or open circuit

KS to

ECM sense circuit short

circuit to high voltage

F

or left-hand knoc

k sensor circuit

tests,GO to Pinpoint Test M.

.