lock JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2346 of 2490

In

stallation

20

. Remove an

d discard four scrive

ts securing upper section of

air intake to beam.

21 . D

rill out rivets securing uppe

r section of cover to bumper

beam.

22. Withdraw bumper beam from cover.

1. Position beam in cover, ensuring that tangs locate correctly in

beam slots.

2. Using new fir tree fast eners, scrivets and rivets, secure beam

to bumper cover.

3. Install fog lights, direction indicators, and side marker

lamps/reflectors in bumper cover.

4. Fit chrome blades to top of casing locating tangs in slots and fit

and tighten securing screws.

5. Fit powerwash jet assemblies to bumper cover. Refer to

Section 501.16.

6. Fit bumper assembly to vehicle. Refer to operations in this

section.

7. Position splitter vane in air intake and secure by rotating

fasteners 1/4 turn clockwise.

8. Fit number plate and plinth.

9. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.

Page 2347 of 2490

Bumpers - Front Bumper and Bumper Cover

Removal and Installation

Removal

WARNING: ENSURE THAT ALL PERSONNEL AND EQUIPMENT ARE CLEAR OF AREA BEFORE OPERATING RAMP.

Installation

1. Position vehicle on 4-post ramp.

2. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

3. Remove radiator surround and grill. Refer to 76.55.15 and

76.55.03.

4. Raise ramp to working height.

5. Using wheel-free lifts, remove front wheels.

6. Remove wheelarch liners for access.

7. Remove undertray. Refer to 76.22.90.

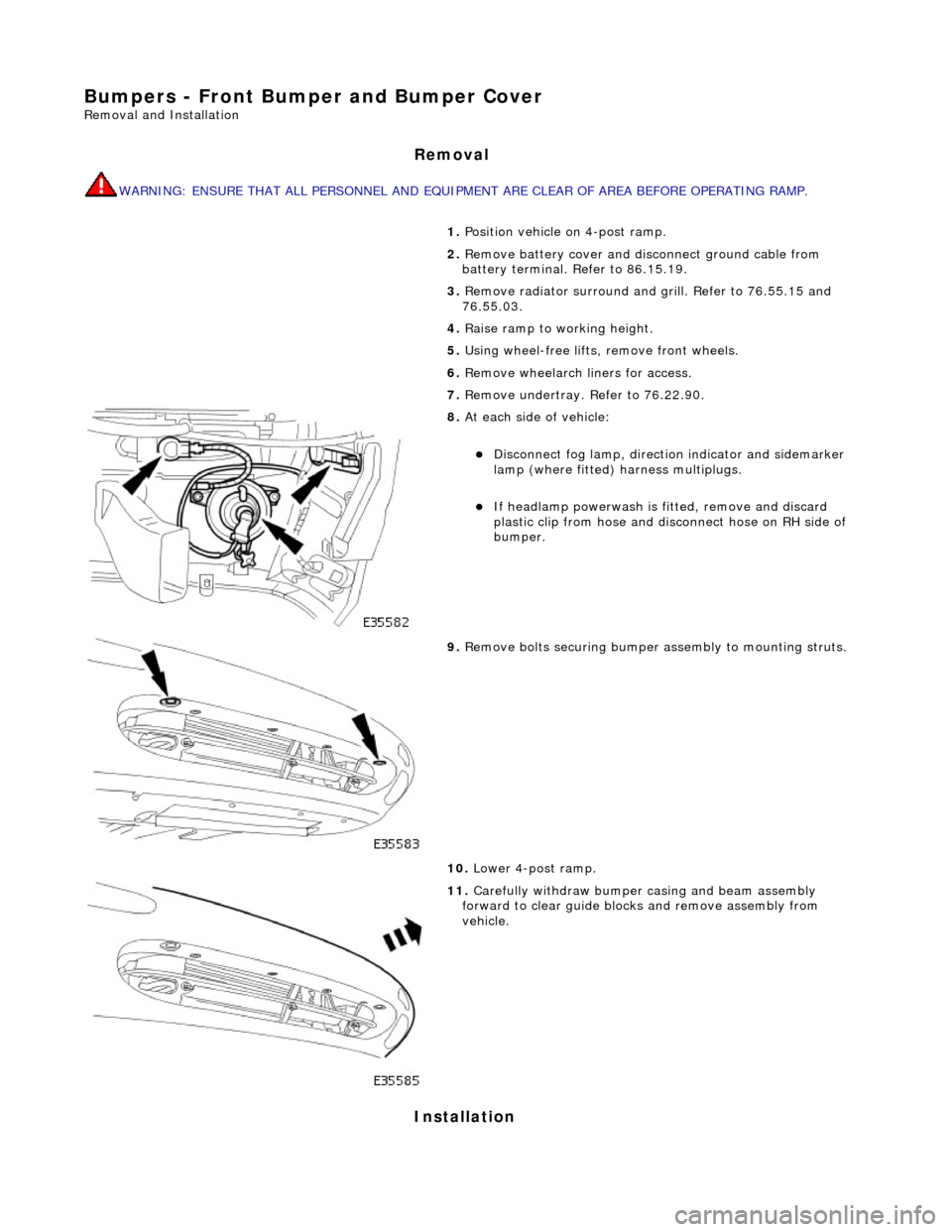

8. At each side of vehicle:

Disconnect fog lamp, directio n indicator and sidemarker

lamp (where fitted) harness multiplugs.

If headlamp powerwash is fitted, remove and discard

plastic clip from hose and disconnect hose on RH side of

bumper.

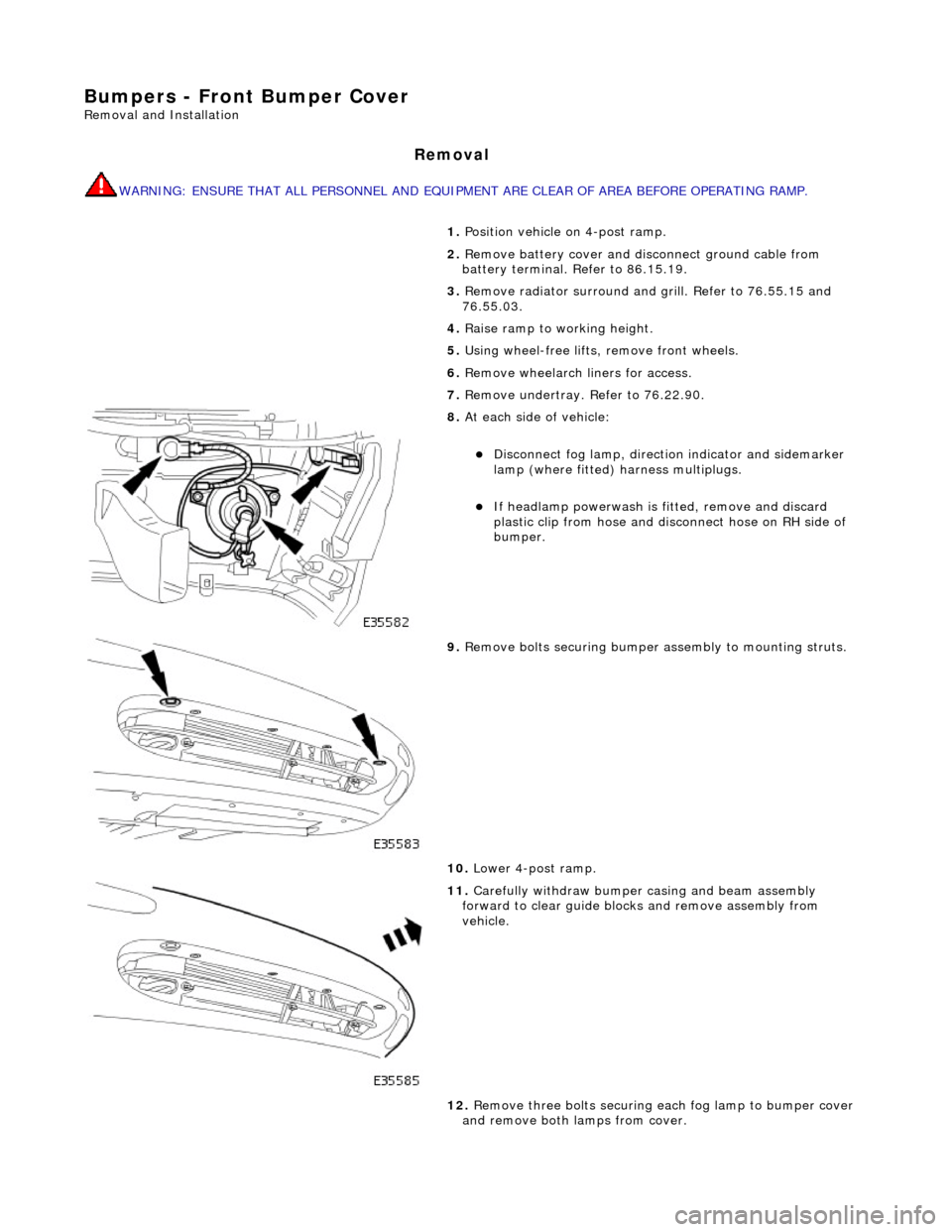

9. Remove bolts securing bumper assembly to mounting struts.

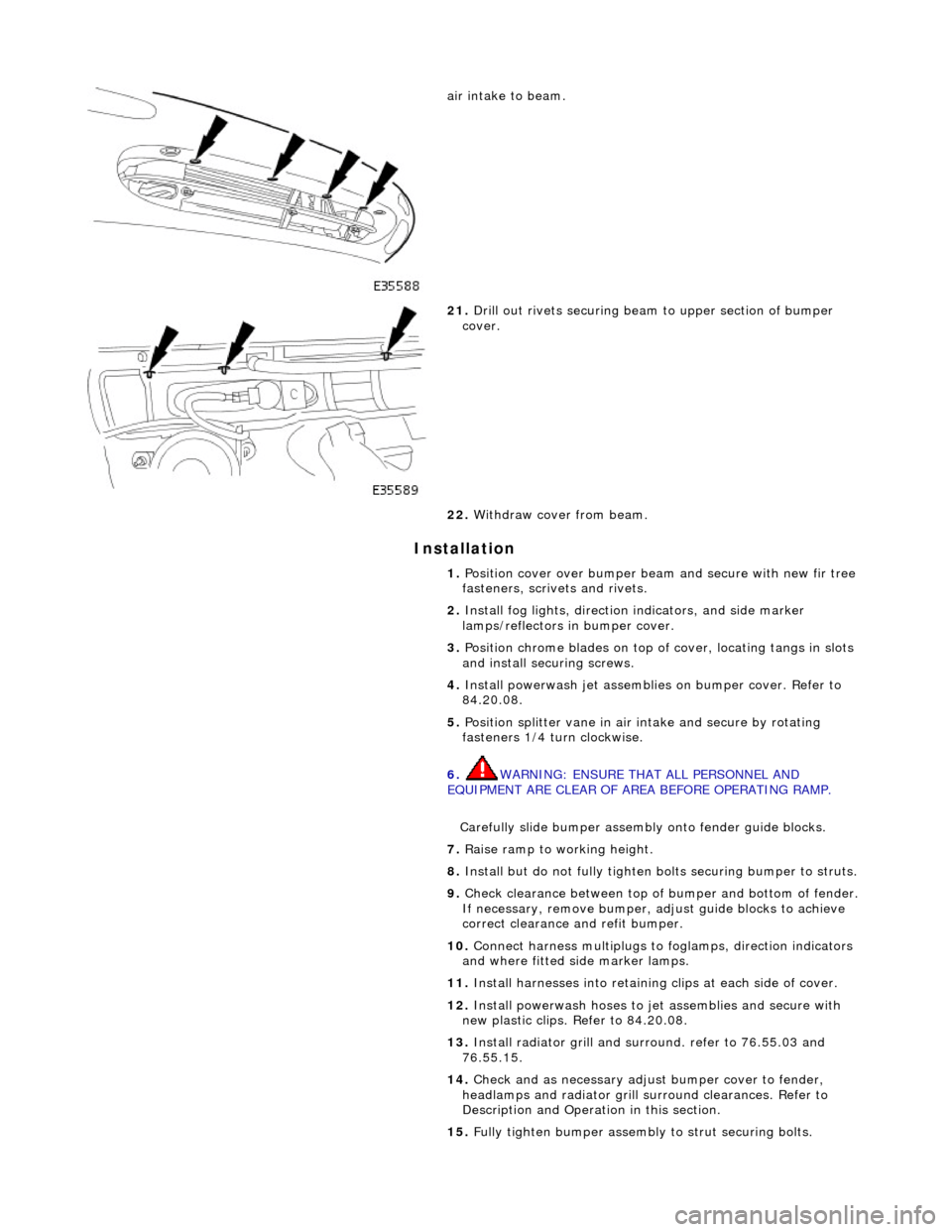

10. Lower 4-post ramp.

11. Carefully withdraw bumper casing and beam assembly

forward to clear guide blocks and remove assembly from

vehicle.

Page 2348 of 2490

1.

WARNING: ENSURE THAT ALL PERSONNEL AND

EQUIPMENT ARE CLEAR OF AREA BEFORE OPERATING RAMP.

Carefully slide bumper assembly onto fender guide blocks.

2. Raise ramp to working height.

3. Install but do not fully tighten bo lts securing bumper to struts.

4. Check clearance between top of bumper and bottom of fender.

If necessary, remove bumper, adjust guide blocks to achieve

correct clearance and refit bumper.

5. Connect harness multiplugs to foglamps, direction indicators

and where fitted side marker lamps.

6. Install harnesses in retaining clips at each side of cover.

7. Install powerwash hoses to jet assemblies and secure with new

plastic clips. Refer to Section 501.16.

8. Install radiator grill and su rround. refer to 76.55.03 and

76.55.15.

9. Check and as necessary adjust bumper cover to fender,

headlamps and radiator grill surround clearances. Refer to

Description and Operation in this section.

10. Fully tighten bumper assembly to strut securing bolts.

11. Install wheelarch liners.

12. Install undertray. Refer to 76.22.90.

13. Lower 4-post ramp.

14. Install road wheels and lower wheel-free lifts.

Page 2349 of 2490

Bumpers - Front Bumper Cover

Removal and Installation

Removal

WARNING: ENSURE THAT ALL PERSONNEL AND EQUIPMENT ARE CLEAR OF AREA BEFORE OPERATING RAMP.

1. Position vehicle on 4-post ramp.

2. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

3. Remove radiator surround and grill. Refer to 76.55.15 and

76.55.03.

4. Raise ramp to working height.

5. Using wheel-free lifts, remove front wheels.

6. Remove wheelarch liners for access.

7. Remove undertray. Refer to 76.22.90.

8. At each side of vehicle:

Disconnect fog lamp, directio n indicator and sidemarker

lamp (where fitted) harness multiplugs.

If headlamp powerwash is fitted, remove and discard

plastic clip from hose and disconnect hose on RH side of

bumper.

9. Remove bolts securing bumper assembly to mounting struts.

10. Lower 4-post ramp.

11. Carefully withdraw bumper casing and beam assembly

forward to clear guide blocks and remove assembly from

vehicle.

12. Remove three bolts securing each fog lamp to bumper cover

and remove both lamps from cover.

Page 2350 of 2490

13. Release sidemarker lamp/refle ctor clips and remove both

lamps/reflectors from bumper cover.

14. Remove direction indicators fr om bumper assembly. Refer to

Section 417.

15. Release tangs securing brake cooling ducts to bumper cover

and remove ducts.

16. Remove powerwash jet assemb lies and hoses from top of

bumper assembly. Refer to 84.20.08.

17. Remove bumper blades.

1. Remove three screws secu ring each blade to bumper

cover.

2. Slide each blade forward to release two side tangs from cover and remove blades from bumper.

18. Rotate three splitter vane fasteners 1/4 turn counter-

clockwise and remove splitter vane from air intake.

19. Remove number plate and plinth.

20. Remove and discard four scrive ts securing upper section of

Page 2351 of 2490

Installation

air intake to beam.

21. Drill out rivets securing beam to upper section of bumper

cover.

22. Withdraw cover from beam.

1. Position cover over bumper beam and secure with new fir tree

fasteners, scrivets and rivets.

2. Install fog lights, direction indicators, and side marker

lamps/reflectors in bumper cover.

3. Position chrome blades on top of cover, locating tangs in slots

and install securing screws.

4. Install powerwash jet assemblies on bumper cover. Refer to

84.20.08.

5. Position splitter vane in air intake and secure by rotating

fasteners 1/4 turn clockwise.

6. WARNING: ENSURE THAT ALL PERSONNEL AND

EQUIPMENT ARE CLEAR OF AREA BEFORE OPERATING RAMP.

Carefully slide bumper assembly onto fender guide blocks.

7. Raise ramp to working height.

8. Install but do not fully tighten bo lts securing bumper to struts.

9. Check clearance between top of bumper and bottom of fender.

If necessary, remove bumper, adjust guide blocks to achieve

correct clearance and refit bumper.

10. Connect harness multiplugs to foglamps, direction indicators

and where fitted side marker lamps.

11. Install harnesses into retaining clips at each side of cover.

12. Install powerwash hoses to jet assemblies and secure with

new plastic clips. Refer to 84.20.08.

13. Install radiator grill and su rround. refer to 76.55.03 and

76.55.15.

14. Check and as necessary adjust bumper cover to fender,

headlamps and radiator grill surround clearances. Refer to

Description and Operation in this section.

15. Fully tighten bumper assembly to strut securing bolts.

Page 2354 of 2490

Bumpers - Rear Bumper

Removal and Installation

Removal

1. Position vehicle on 4-post lift.

2. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

3. WARNING: THE REAR BUMPER IS CLOSE TO THE

EXHAUST PIPES WHICH MAY BE HOT. CARE MUST THEREFORE BE

EXERCISED WHEN WORKING IN THIS VICINITY.

Raise vehicle to working height.

4. Disconnect sidemarker lamp ha rness multiplugs and position

clear of armatures.

5. Slacken and remove bumper to strut securing bolts.

6. With assistance, carefully slide bumper clear of guide blocks

and remove from vehicle.

7. Release retaining clips and remo ve sidemarker lamps/reflectors from bumper.

8. Remove bumper blades.

1. Slacken and remove three screws securing each blade

to bumper cover.

Page 2356 of 2490

Bumpers - Rear Bumper Cover

Removal and Installation

Removal

Installation

1. Position vehicle on 4-post lift.

2. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

3. WARNING: THE REAR BUMPER IS CLOSE TO THE

EXHAUST PIPES WHICH MAY BE HOT. CARE MUST THEREFORE BE

EXERCISED WHEN WORKING IN THIS VICINITY.

Raise vehicle to working height.

4. If fitted, disconnect sidemarker lamp harness multiplugs and

position clear of armatures.

5. Slacken and remove bumper to strut securing bolts.

6. With assistance, carefully slide bumper clear of guide blocks

and remove from vehicle.

1. Release retaining clips and remo ve sidemarker lamps/reflectors from bumper.

2. Remove bumper blades.

1. Slacken and remove three screws securing each blade

Page 2359 of 2490

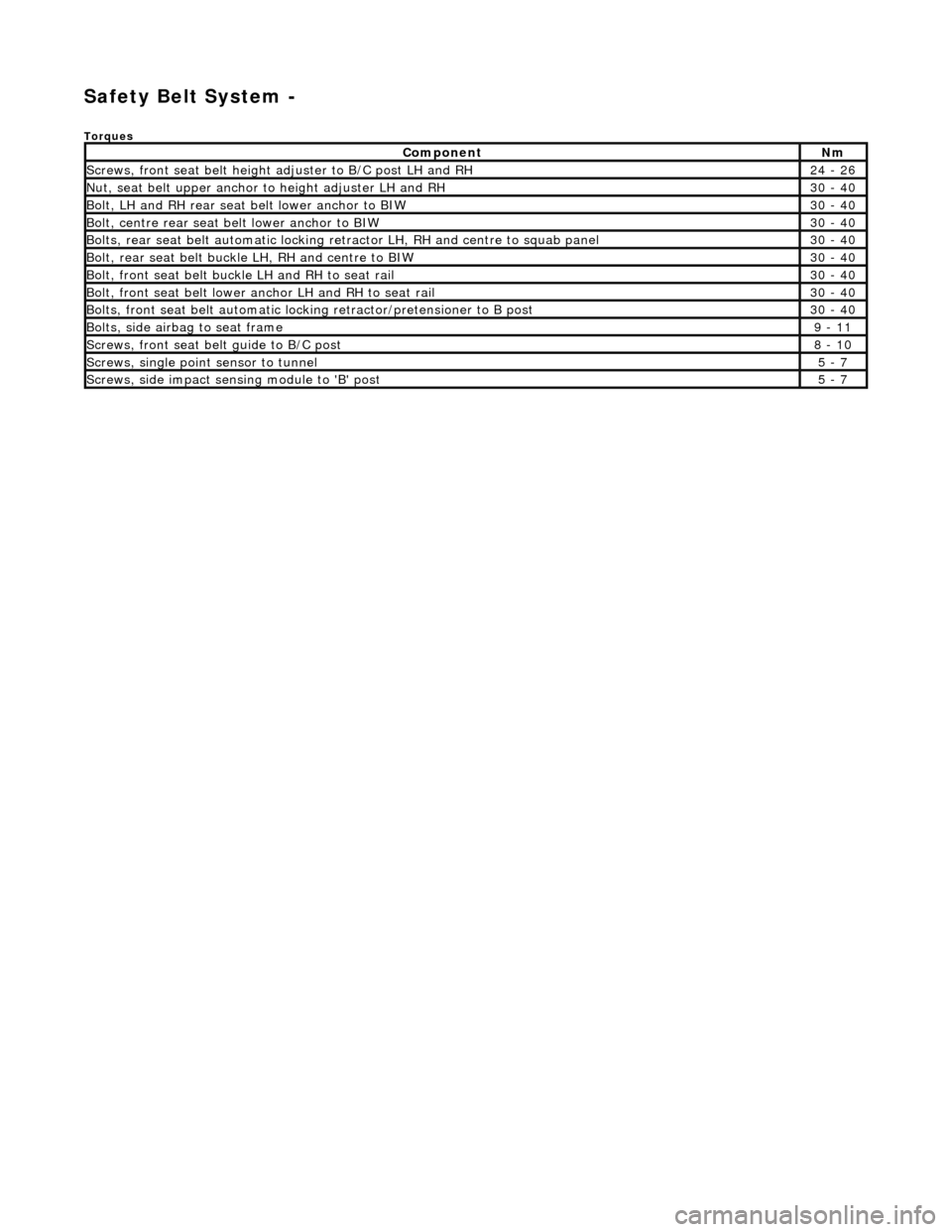

Safety Belt System -

Torques

ComponentNm

Screws, front seat belt height adjuster to B/C post LH and RH24 - 26

Nut, seat belt upper anchor to height adjuster LH and RH30 - 40

Bolt, LH and RH rear seat belt lower anchor to BIW30 - 40

Bolt, centre rear seat belt lower anchor to BIW30 - 40

Bolts, rear seat belt automatic locking re tractor LH, RH and centre to squab panel30 - 40

Bolt, rear seat belt buckle LH, RH and centre to BIW30 - 40

Bolt, front seat belt buckle LH and RH to seat rail30 - 40

Bolt, front seat belt lower an chor LH and RH to seat rail30 - 40

Bolts, front seat belt automatic lock ing retractor/pretensioner to B post30 - 40

Bolts, side airbag to seat frame9 - 11

Screws, front seat belt guide to B/C post8 - 10

Screws, single point sensor to tunnel5 - 7

Screws, side impact sens ing module to 'B' post5 - 7

Page 2361 of 2490

A pyrotechnic front seat belt pre-tensioning device with independent el ectronic sensing and retractor unit is installed at the

base of each 'B' post. In the event of se vere frontal impact, this provides additional front occupant protection by removing

any excess slack from the seat be lt. Seat belt pre-tensioning activates when a frontal impact of sufficient force occurs within

30 degrees of vehicle center line. Under such an impact, el ectronic sensors in the retractor unit fire, igniting the pre-

tensioner gas generator. The ga s generator initiates a chemical reaction, producing gases under pressure. Gas pressure

drives the piston/cable up a tube, rotating the retractor sp indle and removing excess slack from the seat belt. When the

pre-tensioner unit has been activated, the seat belt will lock and cannot be retracted or pulled from the reel.If a seat belt

pre-tensioner activates, a small quantity (less than 1 liter) of gas is produced containing nitrogen, oxygen and water vapor.