lock JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2318 of 2490

Installation

1.

Position motor in housing and fi t and tighten securing nuts and

bolts.

2. Apply suitable lubricant to bore of new spindle inner seal and

fit seal over motor spindle.

3. Holding the capillary and purge valve clear, position

motor/housing assembly on bulkhead.

4. Seat motor spindle seal correctly in upper plenum aperture and

ensure that housing lo cates on lower studs.

5. Fit and tighten the housin g upper securing bolts.

6. Fit and tighten the housing lower securing screws and slide

locking clips inwards.

7. Position throttle cable adjustment bracket on throttle body and

fit and tighten securing bolts.

8. Position purge valve bracket at bulkhead and fit and tighten

securing bolt and nuts.

9. Position engine harness multiplu g on mounting bracket and fit

and tighten securing nut.

10. Connect motor harness multiplug and locate in retaining clip.

11. Apply suitable lubricant to bore of new outer seal and fit with

washer to motor spindle.

12. Fit and fully tighten collar nut on motor spindle.

13. Fit plenum cover. Refer to 76.10.01.

14. Fit wiper arm and blade. Refer to 84.15.44.90.

15. Fit top covers to LH and RH bulkheads and rear of engine

compartment. refer to 76.11.33 and 76.11.35.

16. Fit ground cable to battery te rminal and cover to battery.

Refer to 86.15.15.

Page 2320 of 2490

Installation

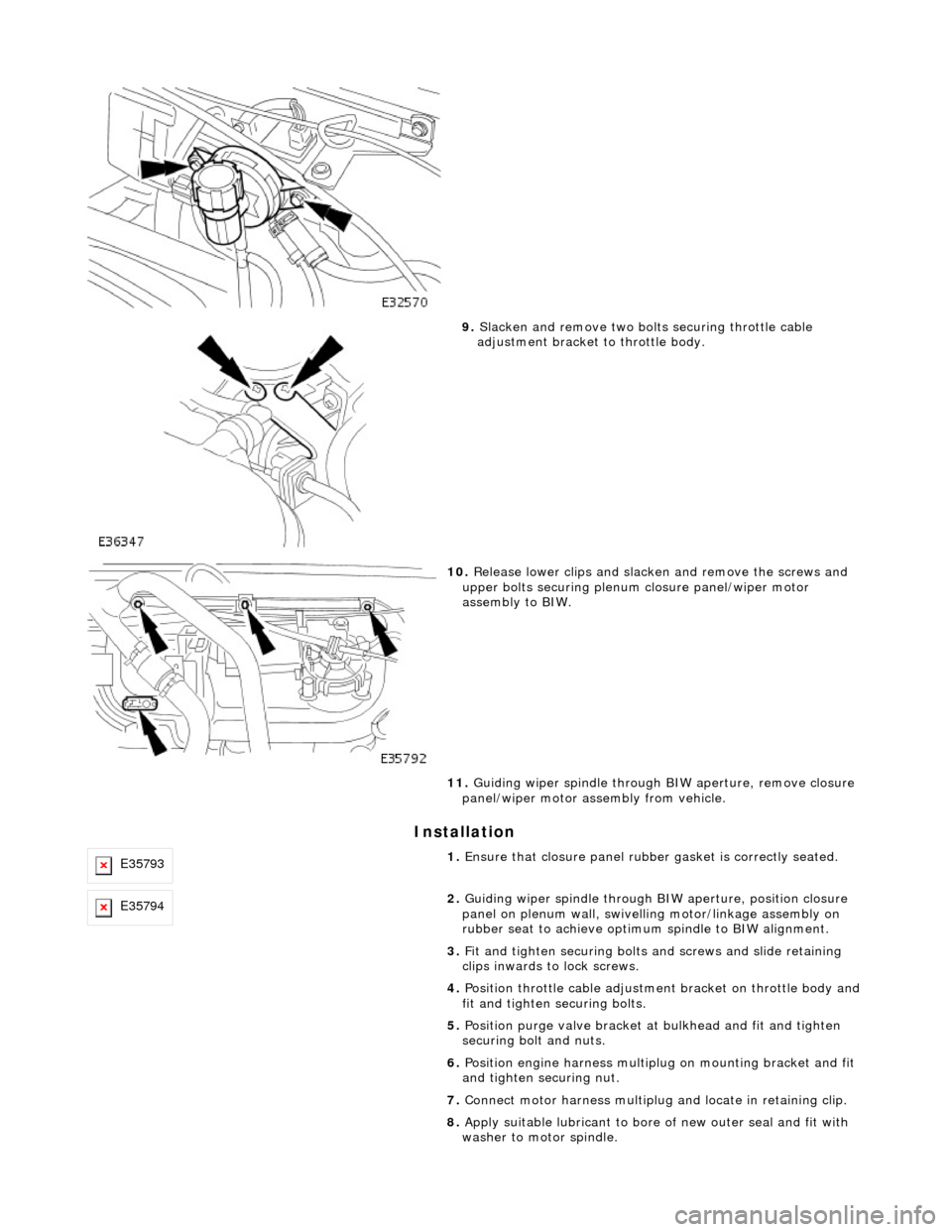

9. Slacken and remove two bolts securing throttle cable

adjustment bracket to throttle body.

10. Release lower clips and slacken and remove the screws and

upper bolts securing plenum closure panel/wiper motor

assembly to BIW.

11. Guiding wiper spindle through BIW aperture, remove closure

panel/wiper motor assembly from vehicle.

E357931. Ensure that closure panel rubbe r gasket is correctly seated.

E357942. Guiding wiper spindle through BI W aperture, position closure

panel on plenum wall, swivelling motor/linkage assembly on

rubber seat to achieve optimu m spindle to BIW alignment.

3. Fit and tighten securing bolts and screws and slide retaining

clips inwards to lock screws.

4. Position throttle cable adjustment bracket on throttle body and

fit and tighten securing bolts.

5. Position purge valve bracket at bulkhead and fit and tighten

securing bolt and nuts.

6. Position engine harness multiplu g on mounting bracket and fit

and tighten securing nut.

7. Connect motor harness multiplug and locate in retaining clip.

8. Apply suitable lubricant to bore of new outer seal and fit with

washer to motor spindle.

Page 2323 of 2490

10. Disconnect key interlock solenoid harness multiplug.

11. Release flasher/lamp/trip swit ch harness multiplugs from

retaining bracket and di sconnect multiplugs.

12. Disconnect cancellation module harness multiplugs.

13. Slacken and remove bolts securing switch

assemblies/cancellation module to column.

Page 2326 of 2490

8. Conne

ct key interlock solenoid harness multiplug.

9. Connect key t

ransponder exciter

coil multiplug and using new

tie straps, secure mu ltiplug to harness.

10 . Conne

ct wiper/washer switch mu

ltiplug, and fit multiplug onto

retaining bracket.

11. Fit driver side underscu ttle. Refer to 76.46.11.

12. Fit steering column uppe r cowl. Refer to 76.46.02.

13. Fit steering column lower cowl. Refer to 76.46.03

14. Fit steering wheel.

15. Fit driver airbag module. Refer to 76.73.39.

16. Fit groun

d cable to battery te

rminal and fit battery cover.

Refer to 86.15.15.

Page 2328 of 2490

Roof Opening Panel - Roof Opening Panel

Description and Operation

General Description

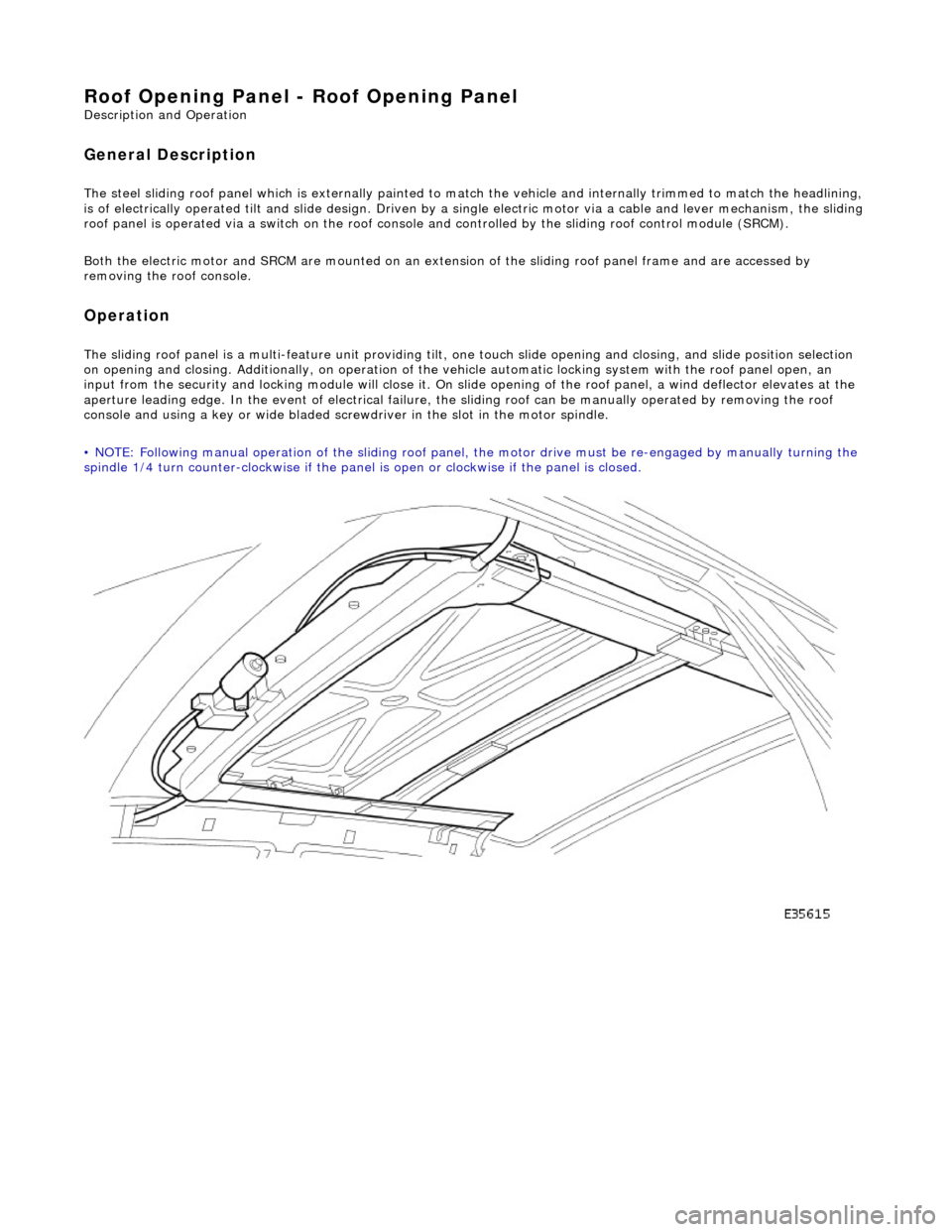

The steel sliding roof panel which is externally painted to ma tch the vehicle and internally trimmed to match the headlining,

is of electrically operated tilt and slide design. Driven by a single electric motor via a cable and lever mechanism, the slidi ng

roof panel is operated via a switch on the roof console and controlled by the sliding roof control module (SRCM).

Both the electric motor and SRCM are mounted on an extens ion of the sliding roof panel frame and are accessed by

removing the roof console.

Operation

The sliding roof panel is a multi-feature unit providing tilt, one touch slide opening and closing, and slide position selectio n

on opening and closing. Additi onally, on operation of the vehicle automatic locking system with the roof panel open, an

input from the security and lockin g module will close it. On slide opening of the roof panel, a wind deflector elevates at the

aperture leading edge. In the event of electrical failure, the sliding roof can be manually operated by removing the roof

console and using a key or wide bladed scre wdriver in the slot in the motor spindle.

• NOTE: Following manual operation of the sliding roof panel, the motor drive must be re-engaged by manually turning the

spindle 1/4 turn counter-clockwise if the panel is open or clockwise if the panel is closed.

Page 2329 of 2490

Roof Opening Panel - Motor Synchronization

General Procedures

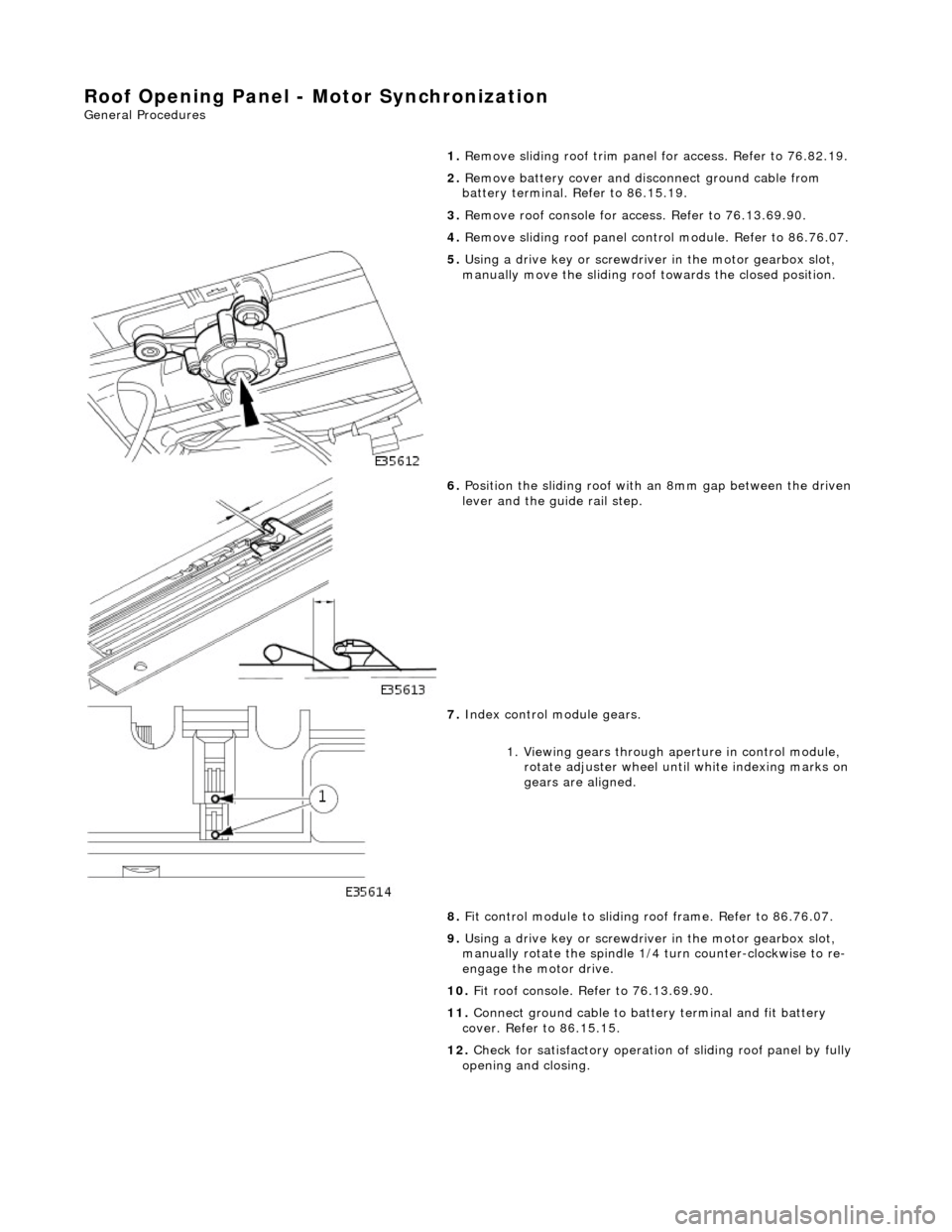

1.

Remove sliding roof trim panel for access. Refer to 76.82.19.

2. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

3. Remove roof console for ac cess. Refer to 76.13.69.90.

4. Remove sliding roof panel cont rol module. Refer to 86.76.07.

5. Using a drive key or screwdriver in the motor gearbox slot,

manually move the sliding roof towards the closed position.

6. Position the sliding roof with an 8mm gap between the driven

lever and the guide rail step.

7. Index control module gears.

1. Viewing gears through aperture in control module, rotate adjuster wheel until white indexing marks on

gears are aligned.

8. Fit control module to sliding r oof frame. Refer to 86.76.07.

9. Using a drive key or screwdriver in the motor gearbox slot,

manually rotate the spindle 1/4 turn counter-clockwise to re-

engage the motor drive.

10. Fit roof console. Refer to 76.13.69.90.

11. Connect ground cable to batt ery terminal and fit battery

cover. Refer to 86.15.15.

12. Check for satisfactory operation of sliding roof panel by fully

opening and closing.

Page 2336 of 2490

Installation

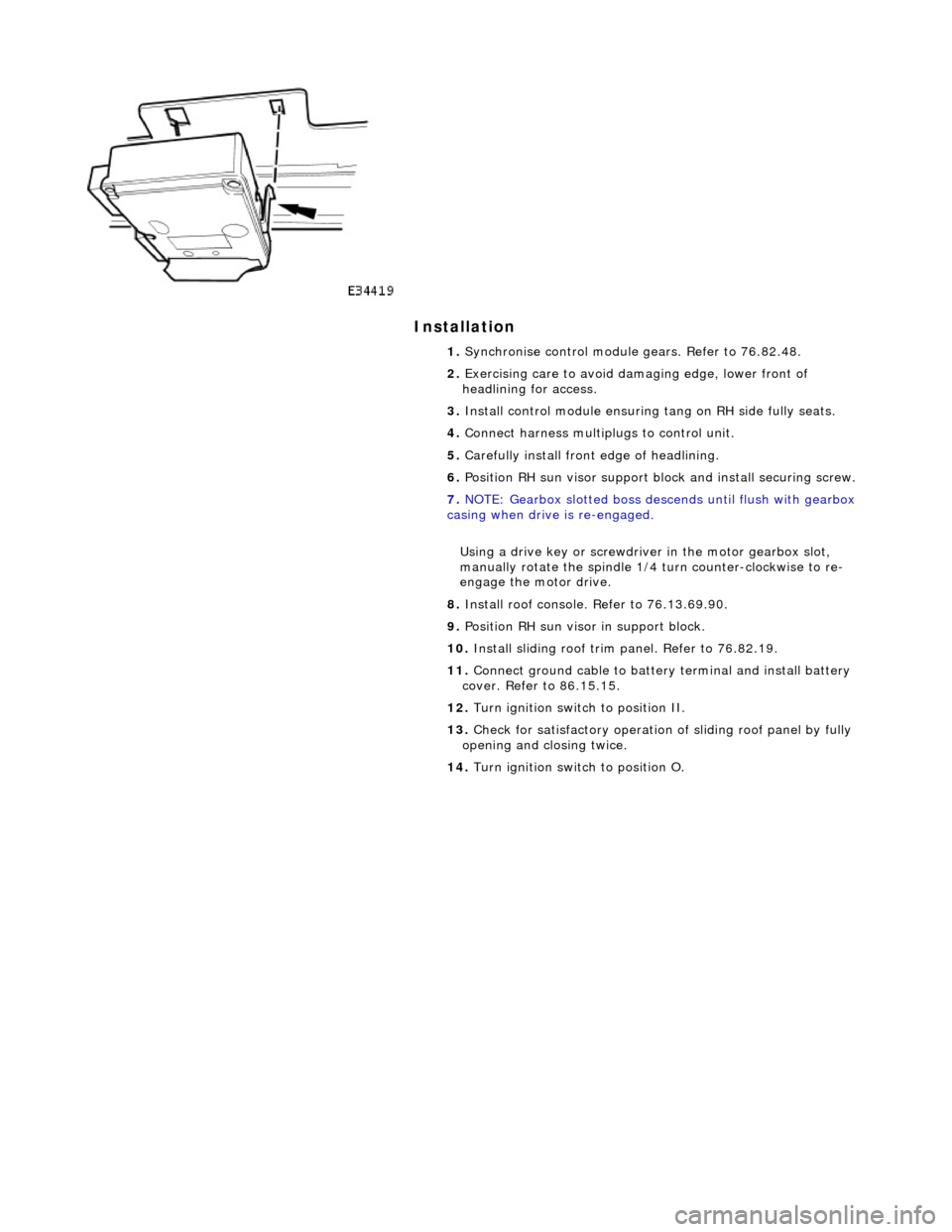

1. Synchronise control module gears. Refer to 76.82.48.

2. Exercising care to avoid da maging edge, lower front of

headlining for access.

3. Install control module ensuring tang on RH side fully seats.

4. Connect harness multiplugs to control unit.

5. Carefully install front edge of headlining.

6. Position RH sun visor support bl ock and install securing screw.

7. NOTE: Gearbox slotted boss descends until flush with gearbox

casing when drive is re-engaged.

Using a drive key or screwdriver in the motor gearbox slot,

manually rotate the spindle 1/4 turn counter-clockwise to re-

engage the motor drive.

8. Install roof console. Refer to 76.13.69.90.

9. Position RH sun visor in support block.

10. Install sliding roof trim panel. Refer to 76.82.19.

11. Connect ground cable to batter y terminal and install battery

cover. Refer to 86.15.15.

12. Turn ignition switch to position II.

13. Check for satisfactory operation of sliding roof panel by fully

opening and closing twice.

14. Turn ignition switch to position O.

Page 2338 of 2490

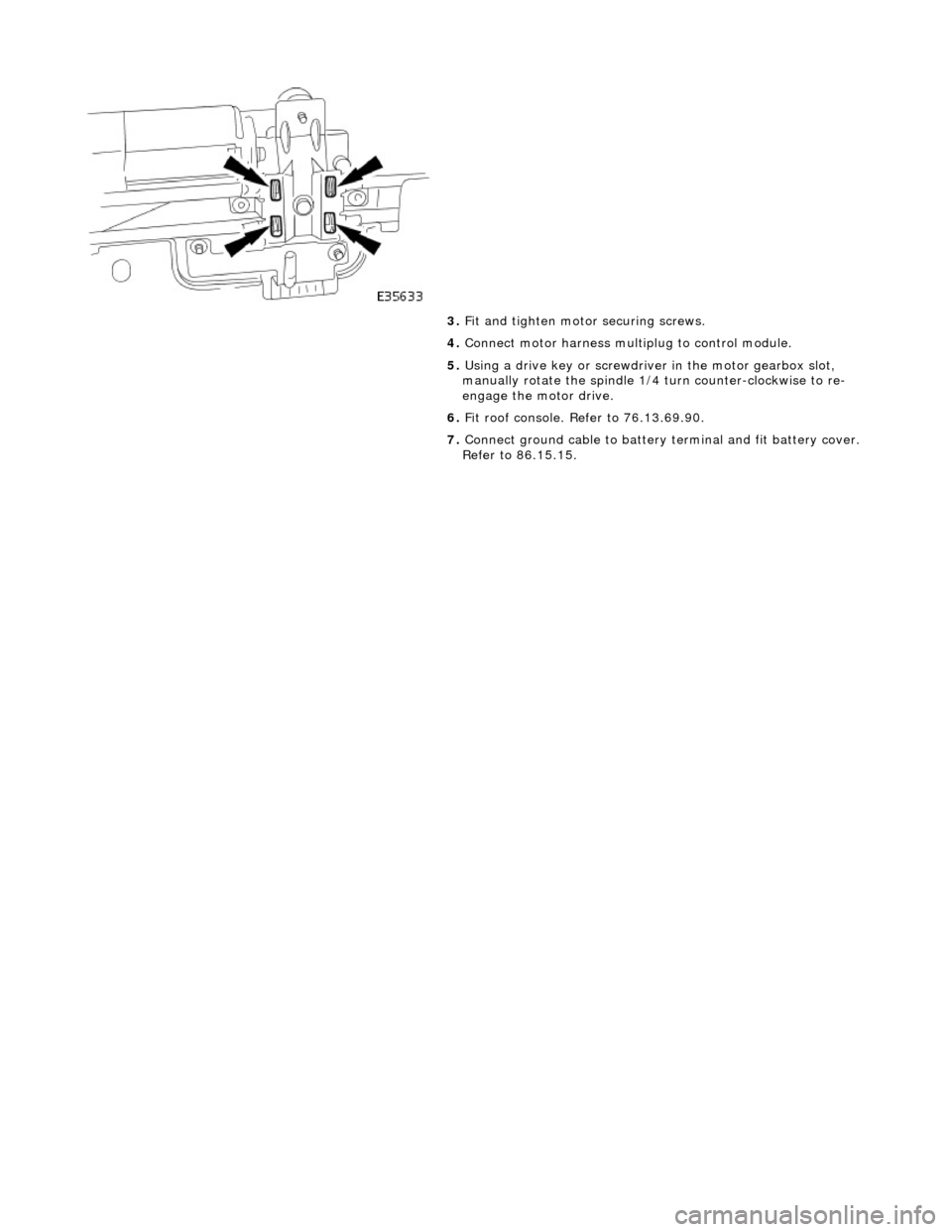

3. Fit and tighten motor securing screws.

4. Connect motor harness multiplug to control module.

5. Using a drive key or screwdriver in the motor gearbox slot,

manually rotate the spindle 1/4 turn counter-clockwise to re-

engage the motor drive.

6. Fit roof console. Refer to 76.13.69.90.

7. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.

Page 2344 of 2490

Bumpers - Front Bumper

Removal and Installation

Removal

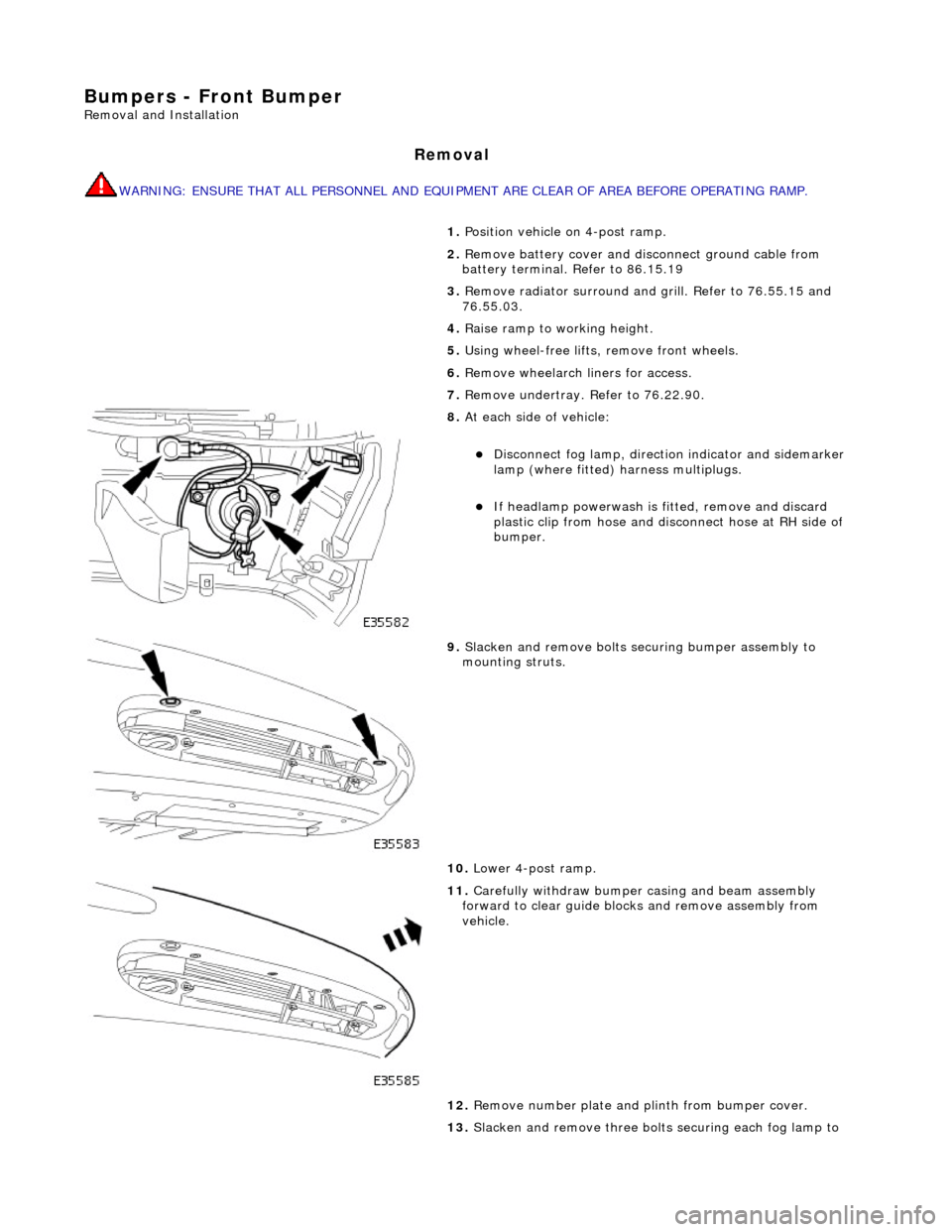

WARNING: ENSURE THAT ALL PERSONNEL AND EQUIPMENT ARE CLEAR OF AREA BEFORE OPERATING RAMP.

1. Position vehicle on 4-post ramp.

2. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19

3. Remove radiator surround and grill. Refer to 76.55.15 and

76.55.03.

4. Raise ramp to working height.

5. Using wheel-free lifts, remove front wheels.

6. Remove wheelarch liners for access.

7. Remove undertray. Refer to 76.22.90.

8. At each side of vehicle:

Disconnect fog lamp, directio n indicator and sidemarker

lamp (where fitted) harness multiplugs.

If headlamp powerwash is fitted, remove and discard

plastic clip from hose and disconnect hose at RH side of

bumper.

9. Slacken and remove bolts securing bumper assembly to

mounting struts.

10. Lower 4-post ramp.

11. Carefully withdraw bumper casing and beam assembly

forward to clear guide blocks and remove assembly from

vehicle.

12. Remove number plate and plinth from bumper cover.

13. Slacken and remove three bolts securing each fog lamp to

Page 2345 of 2490

bumper cover and remove both lamps from cover.

14. Release sidemarker lamp/refle ctor clips and remove both

lamps/reflectors from bumper cover.

15. Remove direction indicators fr om bumper assembly. Refer to

Section 417.01.

16. Remove powerwash jet assemb lies and hoses from top of

bumper assembly. Refer to Section 501-16.

17. Remove bumper blades.

1. Slacken and remove three screws securing each blade

to bumper cover.

2. Slide each blade forward to release two side tangs from cover and remove blade from bumper.

18. Rotate three splitter vane fasteners 1/4 turn counter-

clockwise and remove splitter vane from air intake.

19. Release tangs securing brake cooling ducts to cover and

remove ducts from bumper.