engine JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1255 of 2490

E

lectronic Engine Controls - Knock

Sensor (KS) RH4.0L SC V8 - AJ26

Re

moval and Installation

Remov

al

Installation

1.

R

emove supercharger; refer to 18.50.15.

2. Remove knock sensor from engine.

пЃ¬De

tach connector and disconnect.

пЃ¬R

emove knock sensor.

1. Installation is a reversal of the removal procedure.

2. Tighten sensor to 31 - 41 Nm.

Page 1256 of 2490

El

ectronic Engine Controls -

Mass Air Flow (MAF) Sensor

Remo

val and Installation

Remov

a

l

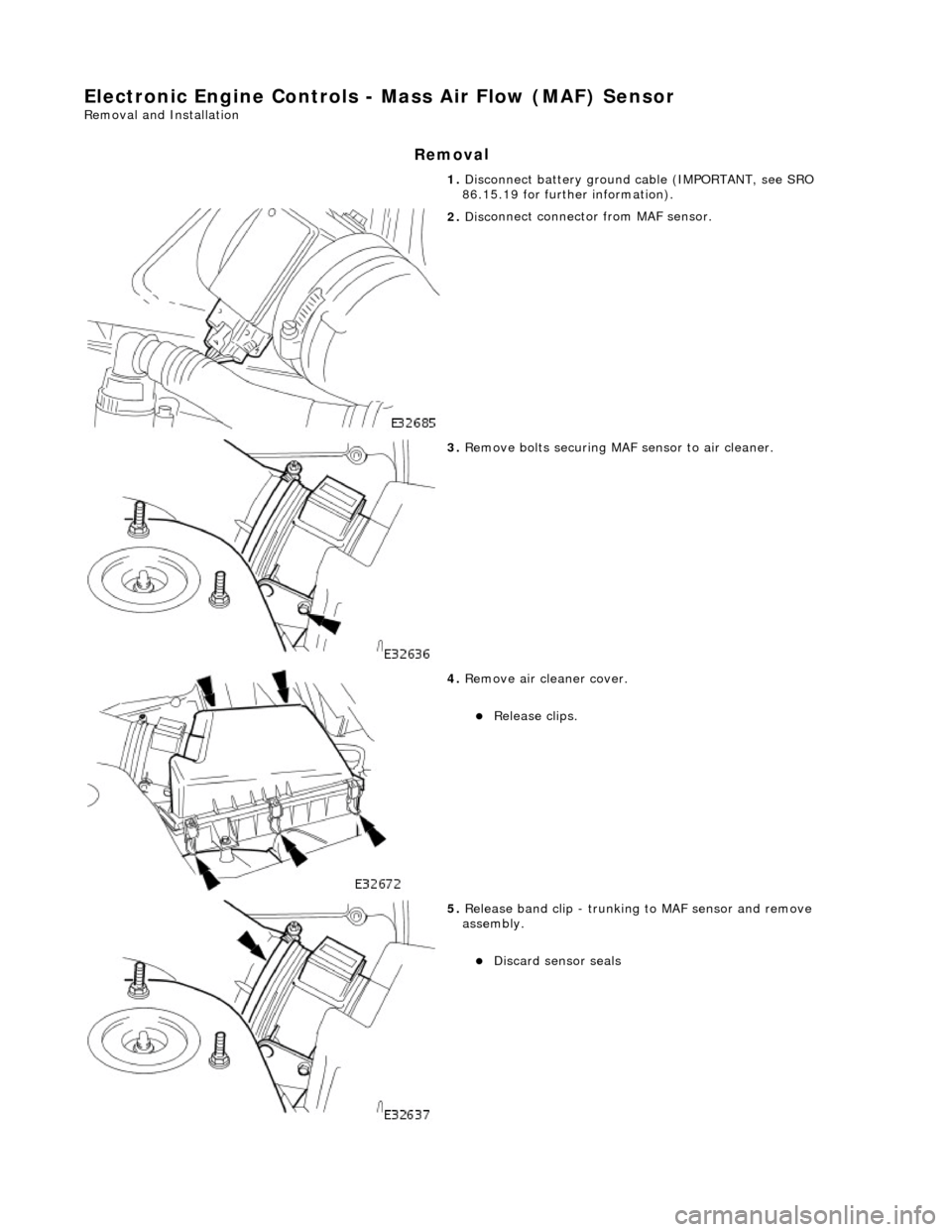

1.

Disc onne

ct battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Disc

onnect connector from MAF sensor.

3. Re

move bolts securing MAF sensor to air cleaner.

4. Re

move air cleaner cover.

пЃ¬Re

lea

se clips.

5. Re

lease band clip - trunking to MAF sensor and remove

assembly.

пЃ¬Di sc

ard sensor seals

Page 1258 of 2490

El

ectronic Engine Controls - Variable

Camshaft Timing (VCT) Oil Control

Solenoid

Re mo

val and Installation

Remova

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Disc

onnect the batt

ery ground cable.

пЃ¬Re

move the battery cover.

3. Disc

onnect the VVT solenoid connector.

4. Re

move the two bolts which secure the VVT solenoid to the

timing cover.

5. Pull the VVT solenoid clear and discard the O-ring.

Page 1260 of 2490

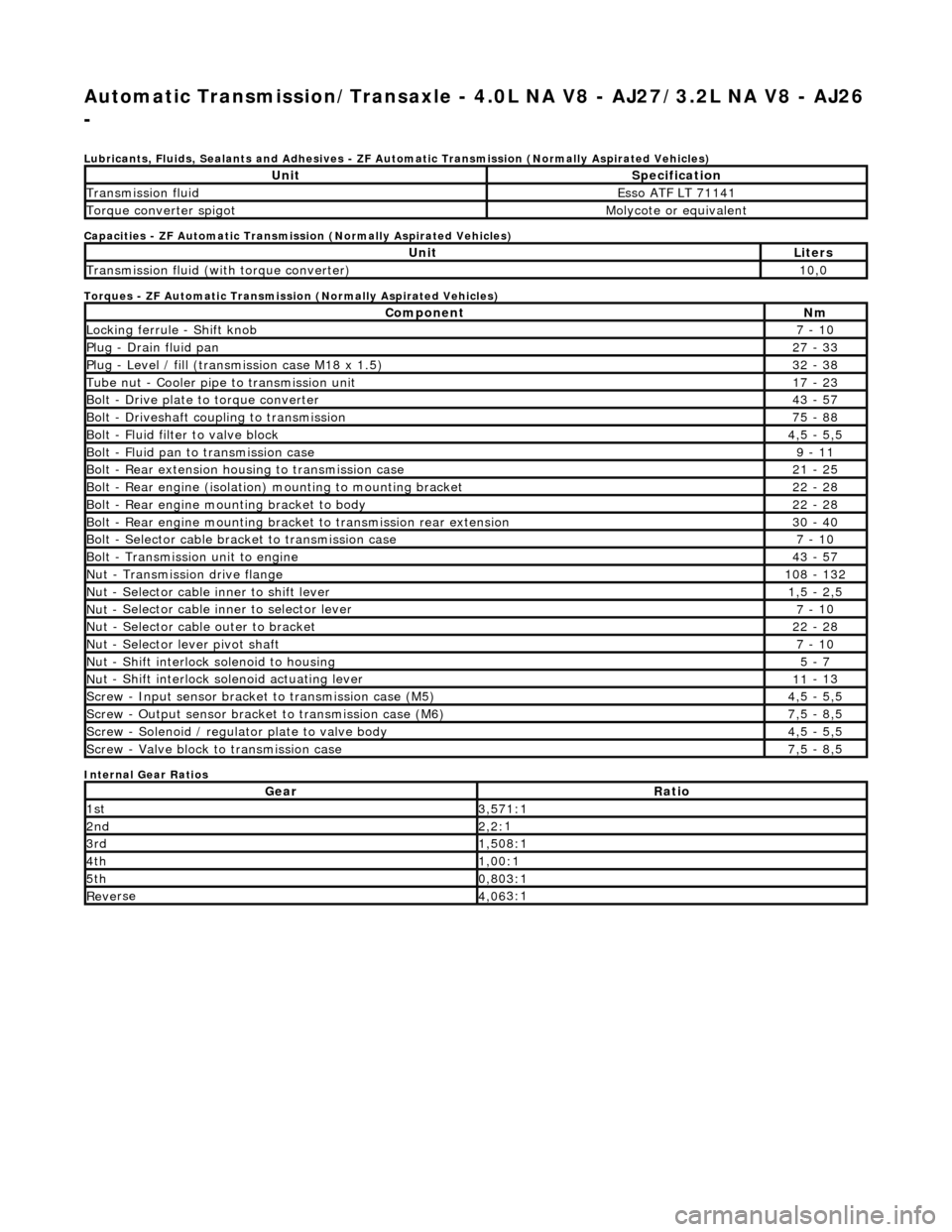

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

-

Lubri c

ants, Fluids, Sealants and Adhesives - ZF Au

tomatic Transmission (Normally Aspirated Vehicles)

Capacities - ZF Automatic Transmission (Normally Aspirated Vehicles)

Torques - ZF Automatic Transmission (Normally Aspirated Vehicles)

Internal Gear Ratios

UnitS p

ecification

Transmissi

on fluidEsso

ATF LT 71141

Torque converter spigotMolyc

o

te or equivalent

UnitLi

t

ers

Transmissi

on fluid (with

torque converter)

10

,0

Com p

onent

Nm

Locki

n

g ferrule - Shift knob

7 -

10

P

l

ug - Drain fluid pan

27

-

33

P

l

ug - Level / fill (transmission case M18 x 1.5)

32

-

38

Tu

be

nut - Cooler pipe to transmission unit

17

-

23

B

o

lt - Drive plate to torque converter

43

-

57

B

o

lt - Driveshaft coupling to transmission

75

-

88

Bo

lt

- Fluid filter to valve block

4,

5 -

5,5

Bolt

-

Fluid pan to transmission case

9 -

11

B

o

lt - Rear extension housing to transmission case

21

-

25

Bolt

-

Rear engine (isolation) mounting to mounting bracket

22

-

28

Bolt -

Rear engine moun

ting bracket to body

22

-

28

Bolt

-

Rear engine mounting bracke

t to transmission rear extension

30 -

40

B

o

lt - Selector cable bracket to transmission case

7 -

10

Bolt

-

Transmission unit to engine

43

-

57

Nu

t -

Transmission drive flange

1

08 -

132

Nu

t -

Selector cable inner to shift lever

1,

5 -

2,5

Nu

t -

Selector cable inner to selector lever

7 -

10

Nu

t -

Selector cable outer to bracket

22

-

28

Nu

t

- Selector lever pivot shaft

7 -

10

Nu

t -

Shift interlock solenoid to housing

5 -

7

Nut -

Shift interlock solenoid actuating lever

11

-

13

Sc

re

w - Input sensor bracket to transmission case (M5)

4,

5 -

5,5

Screw

-

Output sensor bracket to transmission case (M6)

7,

5 -

8,5

Screw

-

Solenoid / regulator plate to valve body

4,

5 -

5,5

Sc

re

w - Valve block to transmission case

7,

5 -

8,5

GearRatio

1s

t3,57

1:1

2n

d2,2:

1

3r

d1,50

8:1

4t

h1,00

:1

5t

h0,80

3:1

Re

ve

rse

4,

06

3:1

Page 1261 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Transmission Descriptio

n

Description an

d Operation

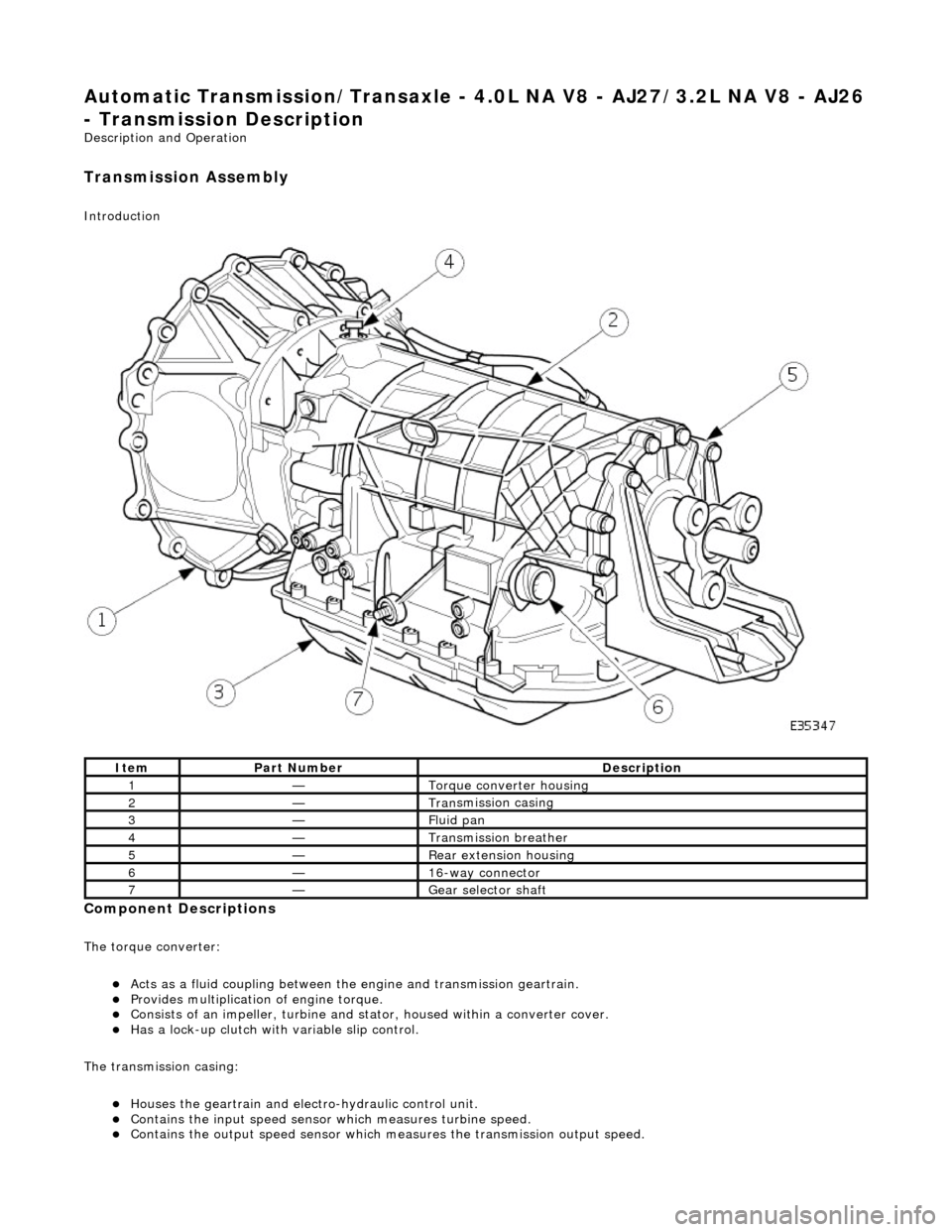

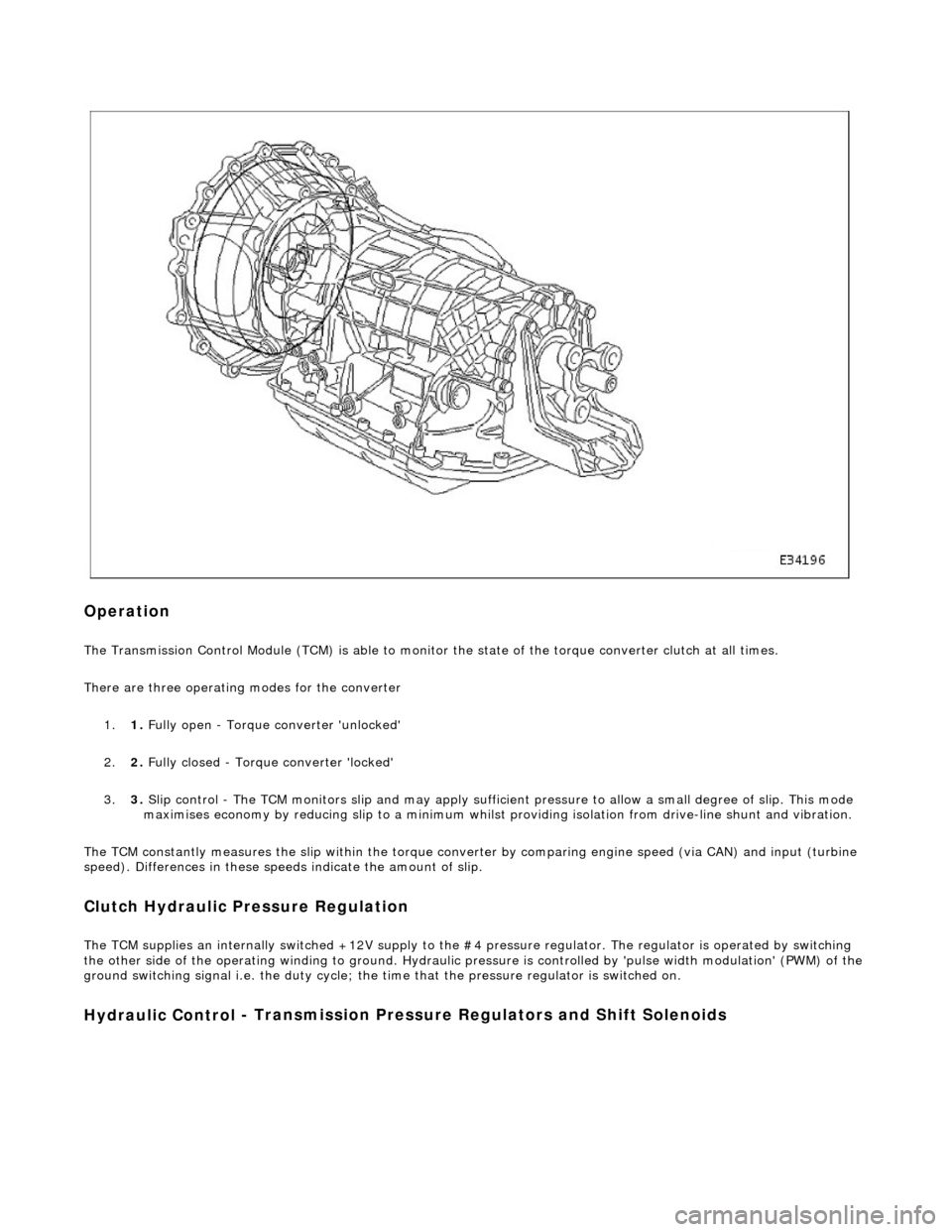

Transmission As

sembly

Int

roduction

Compon

ent Descriptions

The t

orque converter:

пЃ¬Acts as a fluid

coupling between the

engine and transmission geartrain.

пЃ¬P

rovides multiplication of engine torque.

пЃ¬Cons

ists of an impeller, turbine and stat

or, housed within a converter cover.

пЃ¬Has a l

ock-up clutch with variable slip control.

The transmission casing:

пЃ¬Houses the geartrain and elec t

ro-hydraulic control unit.

пЃ¬Contains

the input speed sensor which measures turbine speed.

пЃ¬Contai

ns the output speed sensor which measures the transmission output speed.

It

em

Par

t Number

De

scription

1—Torque c

onverter housing

2—Tran

smission casing

3—Fluid pan

4—Transmission bre

ather

5—Re

ar extension housing

6—16

-way connector

7—Gear s

elector shaft

Page 1262 of 2490

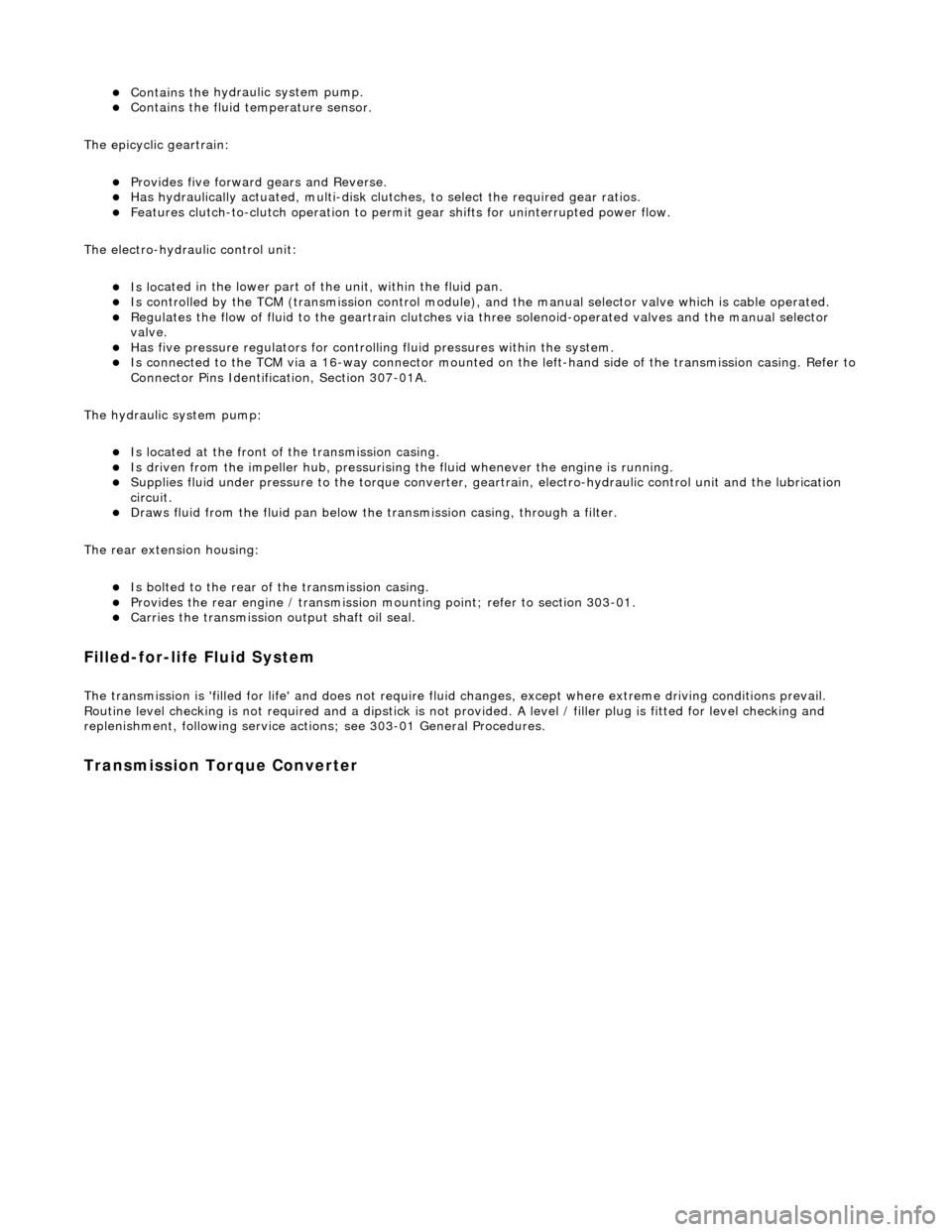

пЃ¬Contains th

e hydraulic system pump.

пЃ¬Contains

th

e fluid temperature sensor.

The epicyclic geartrain:

пЃ¬Provi des fi

ve forward gears and Reverse.

пЃ¬Has

h

ydraulically actuated, multi-disk clutches, to select the required gear ratios.

пЃ¬Feature

s clutch-to-clutch operation to permit

gear shifts for uninterrupted power flow.

The electro-hydraulic control unit:

пЃ¬Is lo c

ated in the lower part of

the unit, within the fluid pan.

пЃ¬Is controlled

by the TCM (transmissio

n control module), and the manual selector valve which is cable operated.

пЃ¬Re

gulates the flow of fluid to the ge

artrain clutches via three solenoid-operated valv es and the manual selector

valve.

пЃ¬Has fi ve pressure

regulators for controll

ing fluid pressures within the system.

пЃ¬Is con

nected to the TCM via a 16-way connector mounted on

the left-hand side of the transmission casing. Refer to

Connector Pins Identification, Section 307-01A.

The hydraulic system pump:

пЃ¬Is l o

cated at the front of the transmission casing.

пЃ¬Is dri

v

en from the impeller hub,

pressurising the fluid whenever the engine is running.

пЃ¬Supplie

s fluid under pressure to the torq

ue converter, geartrain, electro-hydr aulic control unit and the lubrication

circuit.

пЃ¬D r

aws fluid from the fluid pa

n below the transmission casing, through a filter.

The rear extension housing:

пЃ¬Is bolt

ed to the rear of the transmission casing.

пЃ¬Provides the rear engine / transmi

ssion mo

unting point; refer to section 303-01.

пЃ¬Carrie

s the transmission output shaft oil seal.

Filled-for-l

i

fe Fluid System

The

transm

ission is 'filled for life' and

does not require fluid changes, except where extreme driving conditions prevail.

Routine level checking is not required and a dipstick is not pr ovided. A level / filler plug is fitted for level checking and

replenishment, following service actions; see 303-01 General Procedures.

Transmission Torque Converter

Page 1263 of 2490

Op

eration

The T

ransmission Control Module (TCM) is

able to monitor the state of the torque converter clut ch at all times.

There are three operating modes for the converter

1. 1. Fully open - Torque converter 'unlocked'

2. 2. Fully closed - Torque converter 'locked'

3. 3. Slip control - The TCM monitors slip and may apply sufficie nt pressure to allow a small degree of slip. This mode

maximises economy by reducing slip to a minimum whilst providing isolation from drive-line shunt and vibration.

The TCM constantly measures the slip within the torque conver ter by comparing engine speed (via CAN) and input (turbine

speed). Differences in these speeds indicate the amount of slip.

Clutch Hydraulic Pressure Regulation

The T

CM supplies an internally switched +1

2V supply to the #4 pressure regulator. The regulator is operated by switching

the other side of the operating winding to ground. Hydraulic pressure is controlled by 'pulse width modulation' (PWM) of the

ground switching signal i.e. the duty cycle; the time that the pressure regulator is switched on.

Hydraulic Control

- Transmission Pre

ssure Regulators an d Shift Solenoids

Page 1266 of 2490

Operation

The transmission fluid temperature sensor is integrated into the internal harness within the fluid pan.

It should be noted that this component is not serviceable, ne cessitating the renewal of the internal harness should a fault

occur.

Following engine start-up, if the fluid temperature is < 20 В°C and does not increase by 10 В°C after 180 seconds, a failure

judgement is made. A similar judgement is made should the temperature change by more than 5 В°C in <100 milliseconds.

The MIL is illuminated if the failure judgement is made on two successive trips.

Sensor output is continuously monitored for out of range values. If a sustained high, or low inpu t is sensed, indicating a

harness or connector fault, a failure judgement is made.

Location of Sensor Within The Harness

Temperature / Resistance Relationship Chart

Page 1268 of 2490

Input speed is monitored by the TCM with a rationality check being made against output speed. A fault will be flagged if the

indicated input speed exceeds 7400 rpm. Additionally, a failure judgement will be made if the indicated input speed is <160

rpm with engine speed >608 rpm and output speed >224 rpm

The procedure is similar for the output sp eed diagnostic. A fault (non OBDII) will be flagged if the indicated input speed

exceeds 6712 rpm. Additionally a failure judgement will be ma de if the indicated output speed is <160 rpm and the average

road wheel speed exceeds 100 rpm.

Under normal circumstance s after the output speed diagnost ic fault code has been set, the TCM uses rear wheel speed

information to compute its calculations, this has no effect on transmission operation. However, should a second fault occur,

in the ABS system, thus making rear wheel speed information unavailable, an additional fault code will be logged.

Control Systems

Introduction

Gear selection is achieved by controlling the flow of transmission fluid to internal multi-disc clutches.

The three solenoid valves direct the transmission fluid flow to the selected clutches and the pressure regulators control the

fluid pressure to each component. One pr essure regulator serves as a master pressure control for the entire system and a

second is used exclusively for torque converter clutch lock-up operation.

The TCM controls the internal components thus determining gear selection and shift pattern.

In the event of an electronic system fault the basic function s Park, Reverse Neutral and Drive Fourth are retained by the

hydraulic system.

Transmission Control Module (TCM)

The TCM is located in the same housing as th e ECM and is accessed in the same manner.

The TCM performs several 'self check' procedur es to ensure correct operation. It is possible due to the nature of these faults

that the module will fail to communicate with other nodes. However, condemnation of the TCM should not take place until

any CAN or power supply related problems have been resolved.

There are three self check procedures for the TCM. 1. 1. Check on ROM by calculatin

g a checksum and comparing this with a known stored value.

Page 1269 of 2490

2.2. Check on non-volatile diagnostic memory by wr iting a test pattern and then reading it back.

3. 3. Internal 'watchdog' hardware to check whether the TCM has crashed.

Transmission Control Module Supply Voltage

The TCM monitors battery and igni tion switched supply voltages.

A permanent supply is used to maintain a battery backed 'memor y'. Should this supply be cut, due to battery disconnection

perhaps, the 'adaptive shift' valu es will be lost. This will result in a small reduction in shift quality for a period until th e

adaptions are 're-learned'

The TCM will adopt 'limp home' mode as a result of the supply voltage being >16V or <7V with an engine speed >1600

rpm.

Should the ignition supply be >7V but <9V the TCM will hold the gear that it has currently selected. If after 2.5 seconds,

with the engine speed >1600 rpm, the voltage remains at this level, 'limp home' mode will be adopted. The 2.5 second

delay is built in to prevent reaction to a momentary voltage fluctuation.

Operation

CAUTION: Disconnection of the TCM and / or the vehicle batt ery will cause system adaptions to be lost; this may be

apparent by shift quality degradation. Fo llowing reconnection, a period of 'varied' driving will reinstate adaptions and thus

normal operation. Please ensure that the customer is made aware that the adaption period is variable and may occur after

handover, as the transmission re-learns the prevailing driving style.

• NOTE: Should the TCM fail, please ensure that the control housing cooling fan is operating correctly. Failure of the cooling

fan MUST be rectified before renewing the TCM and details of a fan fa ilure should accompany the returned TCM.

The TCM processes information received in both analogue and digital form, such as:

пЃ¬Transmission input speed пЃ¬Transmission output speed пЃ¬Throttle position пЃ¬Pedal demand пЃ¬Gear selector position пЃ¬Engine torque пЃ¬Engine speed пЃ¬Transmission oil temperature пЃ¬Mode switch

This information is then used by the TC M to control shift energy management and decide which shift program to implement

and which gear to select.

The TCM uses the various sensors and inpu ts to monitor the correct operation of the system an d is programmed to take

default action and inform the operator when a fault occurs.

Safety Functions

The safety functions are designed to safeguard against inappr opriate actions by the operator as well as against system

malfunctions. The system prevents reve rse gear from being engaged at high forward speeds and prevents manual

downshifting at excessive engine speeds; these functions are not operational in mechanical limp-home mode.

The TCM constantly monitors the transmissi on for faults. In the event of a problem the TCM will adopt a 'limp home' mode

in which only P R N D - (selector in D but only fourth gear is enabled) are available. The operator will be made aware of

certain faults by an in strument panel warning.

The electrical and diagnostic system has been designed such that system integrity is protected at all times, the safety

concept being based on th e following three points: