engine JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1243 of 2490

Drive Cycle for 40 thou leak test

Drive Cycle for 20 thou leak test (2001 my on only)

1. Make sure the "conditions

for ad

aptation" detailed at the start

of this section are met.

1. Avoiding high engine load s, drive the vehicle steadily

between 48 and 89 kph (30 and 55 mph) for 15 to 20

minutes after starting the engine. (Depending on the

amount of fuel vapor gene rated, the test may take

longer than this).

2. Where possible, avoid body roll to minimise fuel movement.

3. If the scan tool being used is able to read TIDs, check

TID 08 in mode 6. If the test has not completed, this

TID will display "0". Any other value indicates that

the test has successfully completed.

4. If the test has not completed, the drive cycle must be repeated.

5. If the scan tool being used is not able to read TIDs, the only way to confirm that the test has run is to

check for P1111 after running the 20 thou test, where

applicable.

1. This test needs to be completed within 50 minutes of starting

the engine from cold. It should be run following the 40 thou

test.

1. Continue driving the vehi cle steadily between 48 and

89 kph, (30 and 55 mph) avoiding high engine loads

for a further 15 minutes.

2. Avoiding excessive fuel movement, bring the vehicle to rest.

3. Allow to idle for two minutes.

4. Provided the vapor conditions are suitable, the test will complete.

5. If the scan tool being used is able to read TIDs, check

TID 06 in mode 6. If the test has not completed, this

TID will display "0". Any other value indicates that

the test has successfully completed.

6. If the test has not completed, the drive cycle must be repeated.

7. Check for DTCs. P1111 will be flagged if all monitors have run.

8. Leak check drive cycles will only normally be necessary if an Evaporative Emissions related DTC is

flagged.

9. Unless P1111 is required for the State inspection, fuelling adaptations will normally be all that is

required for the vehicle to adapt itself and complete

Page 1245 of 2490

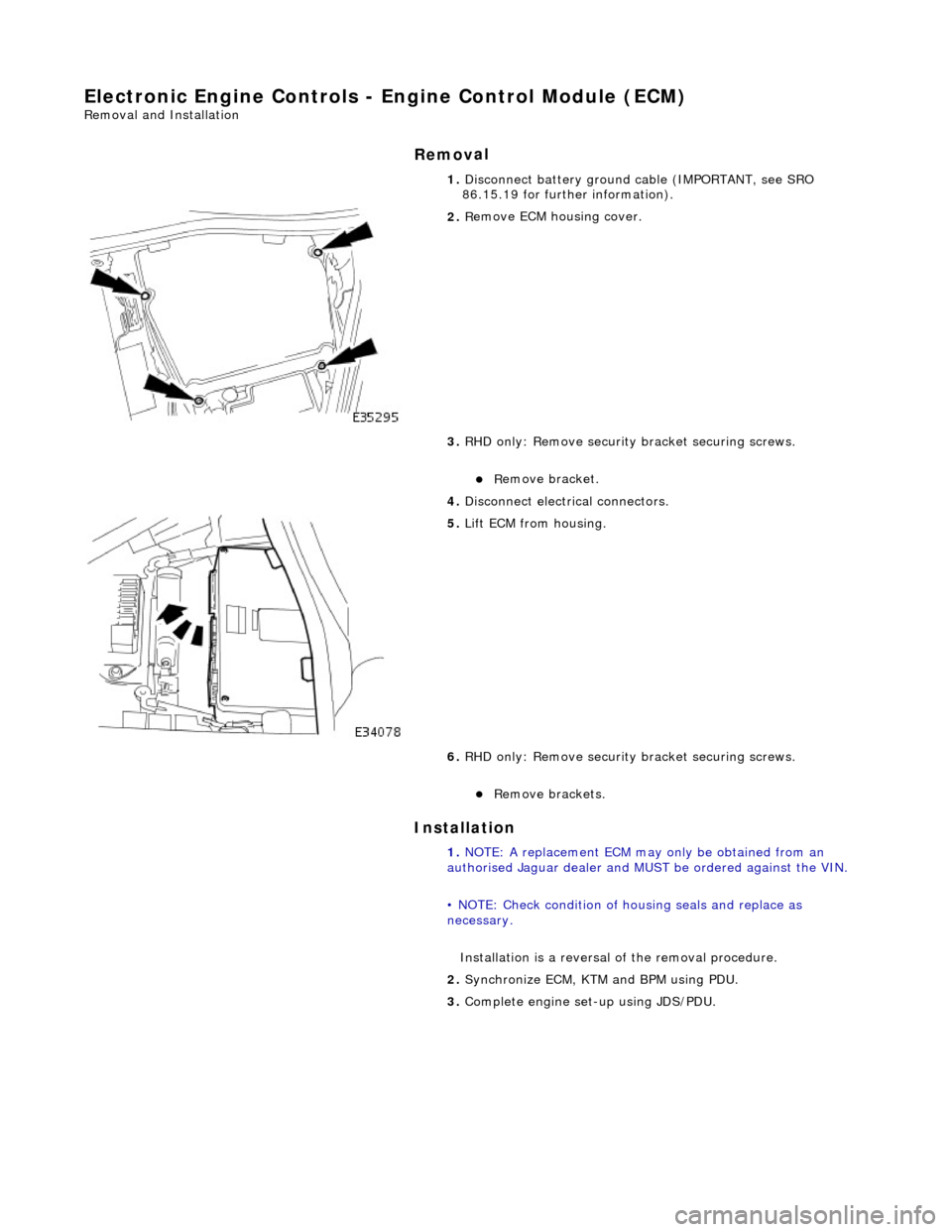

E

lectronic Engine Controls - Engine Control Module (ECM)

Re

moval and Installation

Remov

al

Installation

1.

Disc

onnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. R

emove ECM housing cover.

3. RHD only: Remove security bracket securing screws.

пЃ¬R

emove bracket.

4. Disconnect electrical connectors.

5. Li

ft ECM from housing.

6. RHD only: Remove security bracket securing screws.

пЃ¬R

emove brackets.

1. NOTE: A replacement ECM may only be obtained from an

authorised Jaguar dealer and MU ST be ordered against the VIN.

• NOTE: Check condition of ho using seals and replace as

necessary.

Installation is a reversal of the removal procedure.

2. Synchronize ECM, KTM and BPM using PDU.

3. Complete engine set- up using JDS/PDU.

Page 1246 of 2490

El

ectronic Engine Controls - En

gine Coolant Temperature (ECT)

Sensor4.0L NA V8 - AJ 27/3.2L NA V8 - AJ26

Remo

val and Installation

Remova

l

Installation

1. Op

en the engine compartment and fit paintwork protection

sheets.

2. Re

move the engine covers.

3. WA

RNING: ENSURE THAT THE ENGINE IS COLD BEFORE

COMMENCING WORK.

Slacken the coolant reservoir ca p to relieve coolant pressure

and re-tighten.

4. Remove t

he engine coolant temperature sensor.

1. Disconnect the harness plug from the sensor.

2. Remove the sensor and sealing washer.

1. Fitting is the reverse of the removal procedure, noting that a

new sealing washer should be us ed and tighten the sensor as

specified

Page 1248 of 2490

El

ectronic Engine Controls - En

gine Coolant Temperature (ECT)

Sensor4.0L SC V8 - AJ26

Re mo

val and Installation

Remova

l

Installation

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. WA

RNING: ENSURE THAT THE ENGINE IS COLD BEFORE

COMMENCING WORK.

Slacken the coolant reservoir ca p to relieve coolant pressure

and re-tighten.

3. Remove t

he engine coolant temperature sensor.

1. Disconnect the harness plug from the sensor.

2. Remove the sensor and sealing washer.

1. Fi

tting is the reverse of the removal procedure, noting that a

new sealing washer should be us ed and tighten the sensor as

specified

2. Check and adjust the cool ant level as required.

Page 1249 of 2490

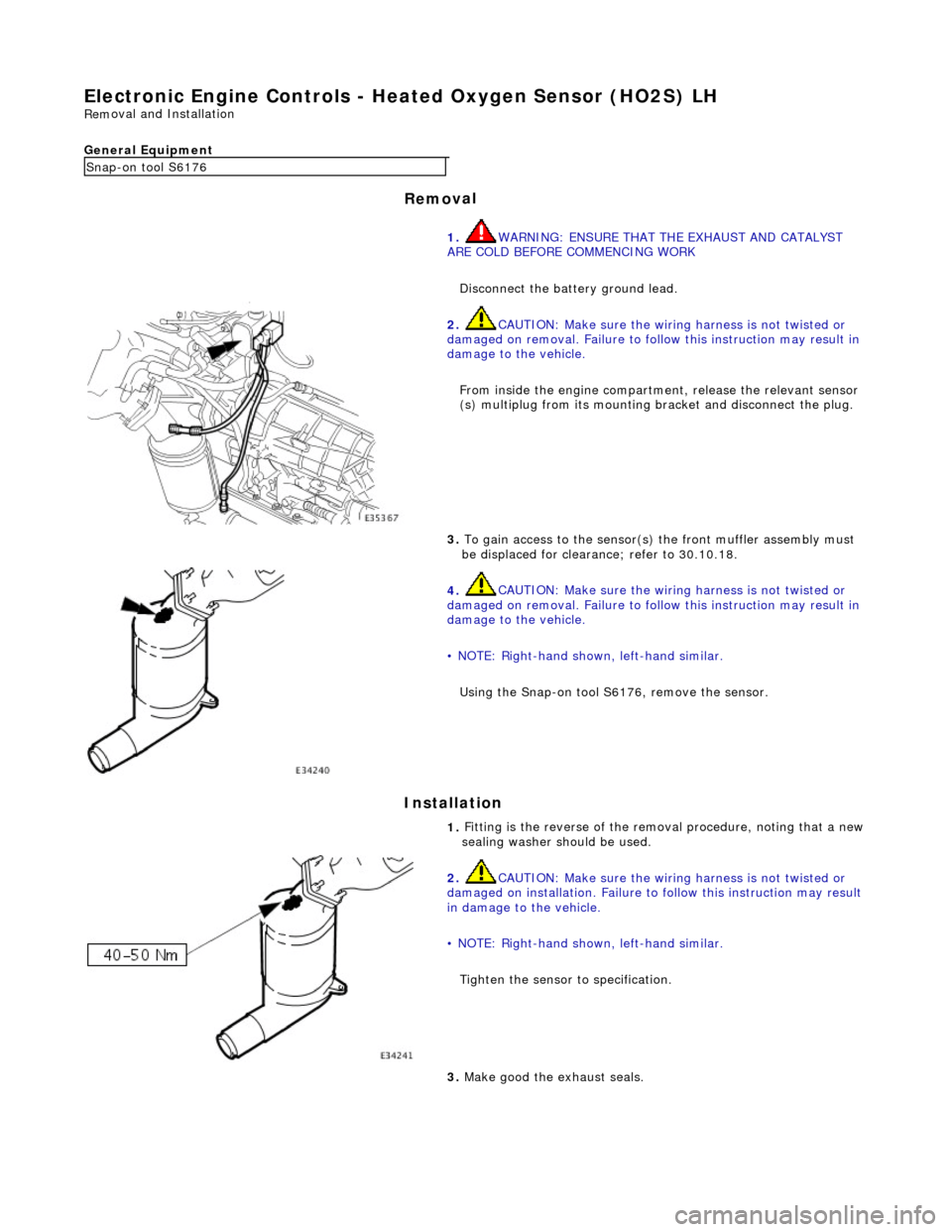

Electron

ic Engine Controls -

Heated Oxygen Sensor (HO2S) LH

Rem

oval and Installation

General Equipment

Remov

al

Installation

Snap

-on tool S6176

1. WARNING: ENSURE THAT TH E EXHAUST AND CATALYST

ARE COLD BEFORE COMMENCING WORK

Disconnect the battery ground lead.

2.

CAUTION: Make sure the wiring harness is not twisted or

damaged on removal. Failure to follow this instruction may result in

damage to the vehicle.

From inside the engine compartm ent, release the relevant sensor

(s) multiplug from its mounting bracket and disconnect the plug.

3.

To gain access to the sensor(s) the front muffler assembly must

be displaced for clearance; refer to 30.10.18.

4.

CAUTION: Make sure the wiring harness is not twisted or

damaged on removal. Failure to follow this instruction may result in

damage to the vehicle.

• NOTE: Right-hand shown, left-hand similar.

Using the Snap-on tool S6176, remove the sensor.

1.

Fitting is the reverse of the remo val procedure, noting that a new

sealing washer should be used.

2.

CAUTION: Make sure the wiring harness is not twisted or

damaged on installation. Failure to follow this instruction may result

in damage to the vehicle.

• NOTE: Right-hand shown, left-hand similar.

Tighten the sensor to specification.

3.

Make good the exhaust seals.

Page 1250 of 2490

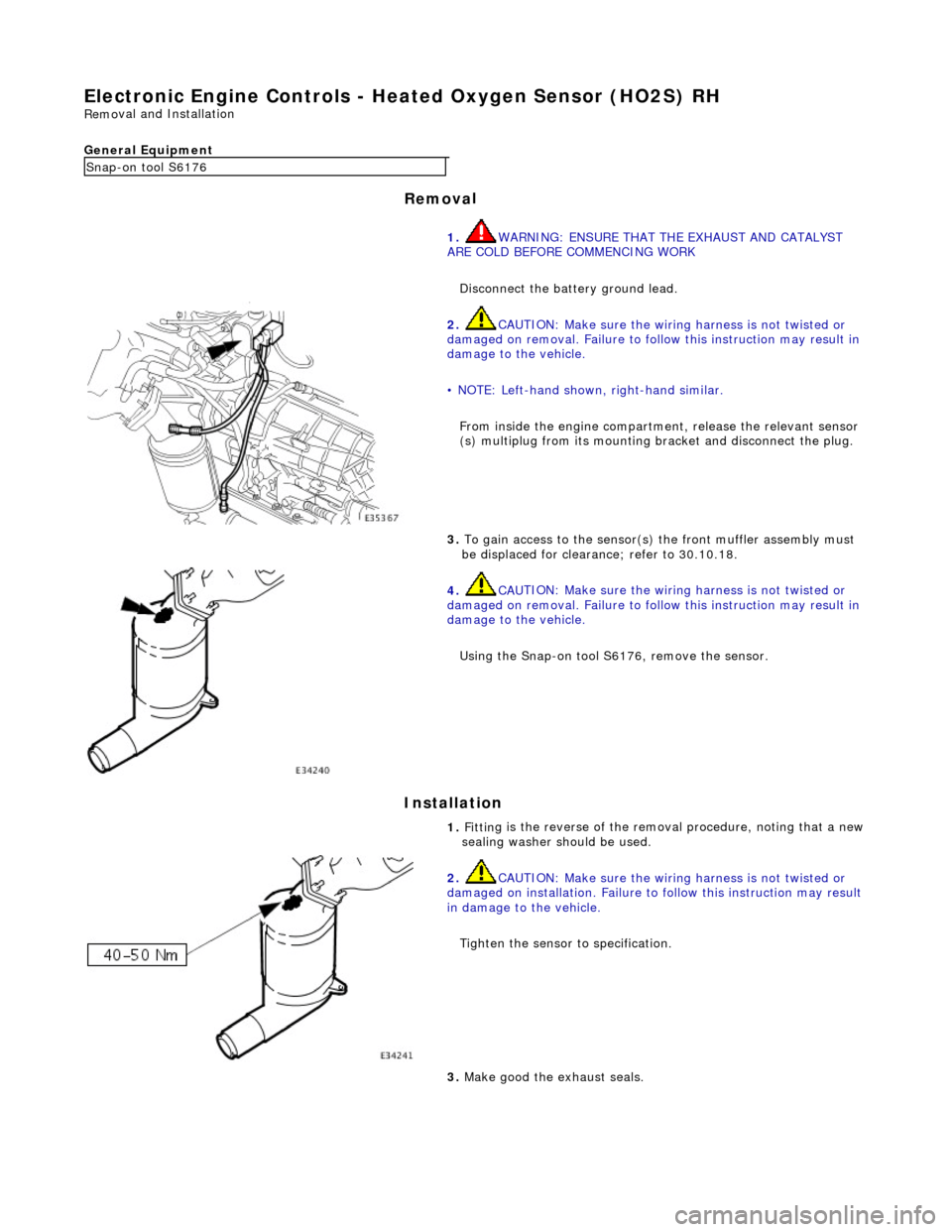

Electronic

Engine Controls -

Heated Oxygen Sensor (HO2S) RH

Remo

val and Installation

General Equipment

Remov a

l

Installation

Snap -on to

ol S6176

1. WARNING: ENSURE THAT TH E EXHAUST AND CATALYST

ARE COLD BEFORE COMMENCING WORK

Disconnect the battery ground lead.

2. CAU

TION: Make sure the wiring harness is not twisted or

damaged on removal. Failure to follow this instruction may result in

damage to the vehicle.

• NOTE: Left-hand shown, right-hand similar.

From inside the engine compartm ent, release the relevant sensor

(s) multiplug from its mounting bracket and disconnect the plug.

3. To

gain access to the sensor(s)

the front muffler assembly must

be displaced for clearance; refer to 30.10.18.

4. CAU

TION: Make sure the wiring harness is not twisted or

damaged on removal. Failure to follow this instruction may result in

damage to the vehicle.

Using the Snap-on tool S6176, remove the sensor.

1. Fittin

g is the reverse of the remo

val procedure, noting that a new

sealing washer should be used.

2. CAU

TION: Make sure the wiring harness is not twisted or

damaged on installation. Failure to follow this instruction may result

in damage to the vehicle.

Tighten the sensor to specification.

3. M

ake good the exhaust seals.

Page 1251 of 2490

E

lectronic Engine Controls - Inta

ke Air Temperature (IAT) Sensor

Re

moval and Installation

Remov

al

Installation

1.

Di

sconnect sensor connector at

rear of bank 1 charge air

cooler.

2. Re

move sensor.

пЃ¬Re

move sensor using a deep socket.

пЃ¬Discard sealin

g washer.

1. Installation is a reversal of the removal procedure.

Page 1252 of 2490

El

ectronic Engine Controls - Knock Se

nsor (KS) LH4.0L NA V8 - AJ27/3.2L

NA V8 - AJ26

Re mo

val and Installation

Remova

l

Installation

1.

Disc onne

ct battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Remove for access, appropriat e engine cover; refer to

12.30.06.

3. NO TE

: Bank 1 shown.

Disconnect knock sensor conne ctor from mounting bracket.

4. Disc

onnect connector.

5. NO TE

: Bank 1 shown.

Using special tools, crowfoot and extension, remove knock

sensor.

1. Installation is a reversal of the removal procedure.

2. Tighten sensor to 31 - 41 Nm.

Page 1253 of 2490

E

lectronic Engine Controls - Knock

Sensor (KS) LH4.0L SC V8 - AJ26

Re

moval and Installation

Remov

al

Installation

1.

R

emove supercharger; refer to 18.50.15.

2. Remove knock sensor from engine.

пЃ¬De

tach connector and disconnect.

пЃ¬R

emove knock sensor.

1. Installation is a reversal of the removal procedure.

2. Tighten sensor to 31 - 41 Nm.

Page 1254 of 2490

El

ectronic Engine Controls - Knock Se

nsor (KS) RH4.0L NA V8 - AJ27/3.2L

NA V8 - AJ26

Re mo

val and Installation

Remova

l

Installation

1.

Disc onne

ct battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Remove for access, appropriat e engine cover; refer to

12.30.06.

3. Disc onne

ct knock sensor conne

ctor from mounting bracket.

4. Disc

onnect connector.

5. Using speci a

l tools, crowfoot

and extension, remove knock

sensor.

1. Installation is a reversal of the removal procedure.

2. Tighten sensor to 31 - 41 Nm.