engine JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1394 of 2490

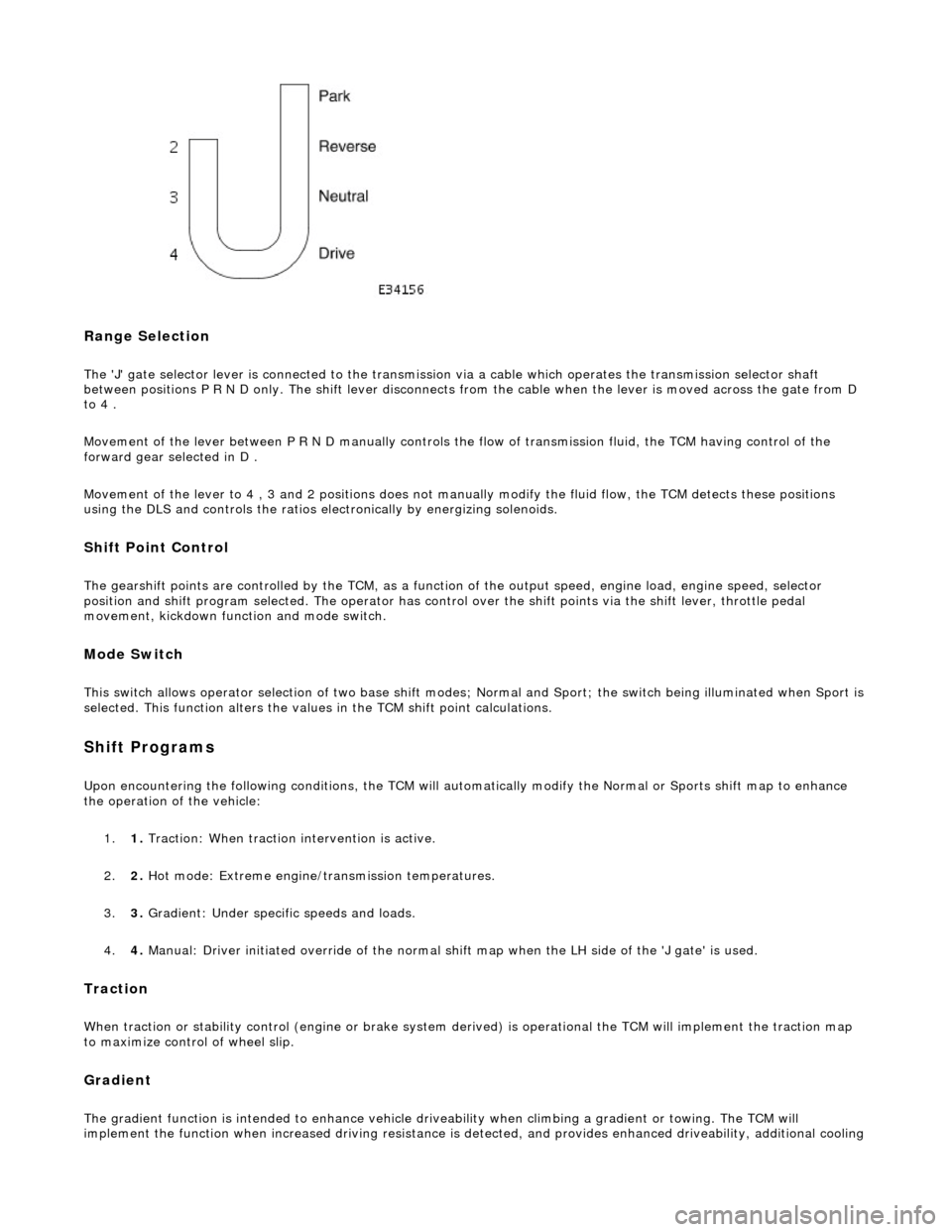

Range Selection

The 'J' gate selector lever is connected to the transmission via a cable which operates the transmission selector shaft

between positions P R N D only. The shift lever disconnects from the cable when the lever is moved across the gate from D

to 4 .

Movement of the lever between P R N D manu ally controls the flow of transmission fluid, the TCM having control of the

forward gear selected in D .

Movement of the lever to 4 , 3 and 2 positions does not manu ally modify the fluid flow, the TCM detects these positions

using the DLS and controls the ratios electronically by energizing solenoids.

Shift Point Control

The gearshift points are controlled by the TCM, as a function of the output speed, engine load, engine speed, selector

position and shift program selected. The operator has control over the shift points via the shift lever, throttle pedal

movement, kickdown function and mode switch.

Mode Switch

This switch allows operator selection of two base shift modes; Normal and Sport; th e switch being illuminated when Sport is

selected. This function alters the values in the TCM shift point calculations.

Shift Programs

Upon encountering the following conditions, the TCM will auto matically modify the Normal or Sports shift map to enhance

the operation of the vehicle:

1. 1. Traction: When traction intervention is active.

2. 2. Hot mode: Extreme engine/transmission temperatures.

3. 3. Gradient: Under specific speeds and loads.

4. 4. Manual: Driver initiated override of the normal shif t map when the LH side of the 'J gate' is used.

Traction

When traction or stability control (engine or brake system de rived) is operational the TCM will implement the traction map

to maximize control of wheel slip.

Gradient

The gradient function is intended to enhance vehicle drivea bility when climbing a gradient or towing. The TCM will

implement the function when increased driving resistance is de tected, and provides enhanced driveability, additional cooling

Page 1396 of 2490

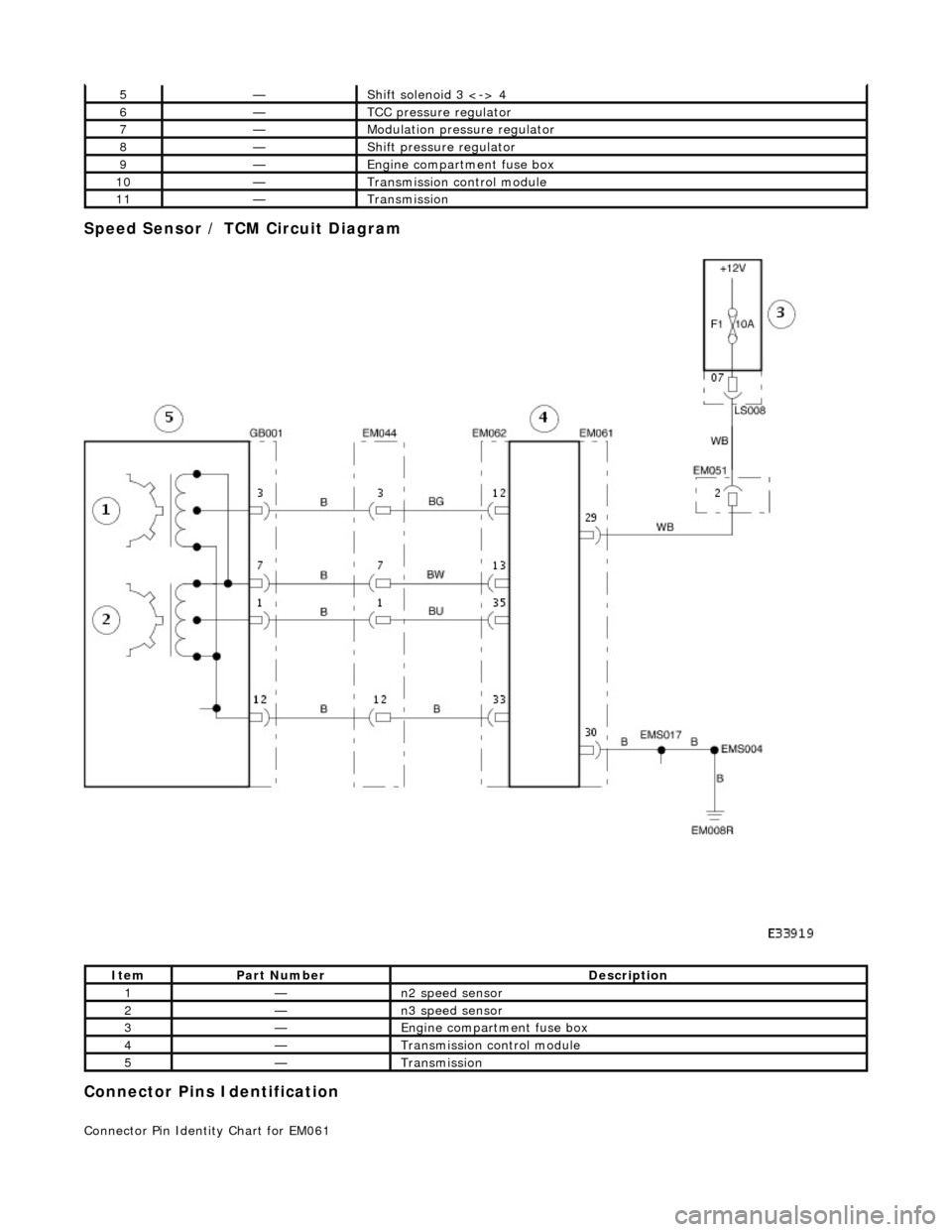

Speed Sensor / TCM Circuit Diagram

Connector Pins Identification

Connector Pin Identity Chart for EM061

5—Shift solenoid 3 <-> 4

6—TCC pressure regulator

7—Modulation pressure regulator

8—Shift pressure regulator

9—Engine compartment fuse box

10—Transmission control module

11—Transmission

ItemPart NumberDescription

1—n2 speed sensor

2—n3 speed sensor

3—Engine compartment fuse box

4—Transmission control module

5—Transmission

Page 1405 of 2490

Pinpoint test C: P0702, P0753, P0758, P0763

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to B2

B2: RENEW TORQUE CONVERTER

Renew the torque converter 1

Has the torque converter been renewed?

Yes GO to B3

B3: END

Drive the vehicle for a period from cold to include idle, brisk

acceleration and steady state cruising up to and including

normal engine temperature. Check for the presence of DTC 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST C : P0702, P0753, P0758, P0763

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

C1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to C2

C2: CHECK HARNESS +VE CONTINUITY

Page 1412 of 2490

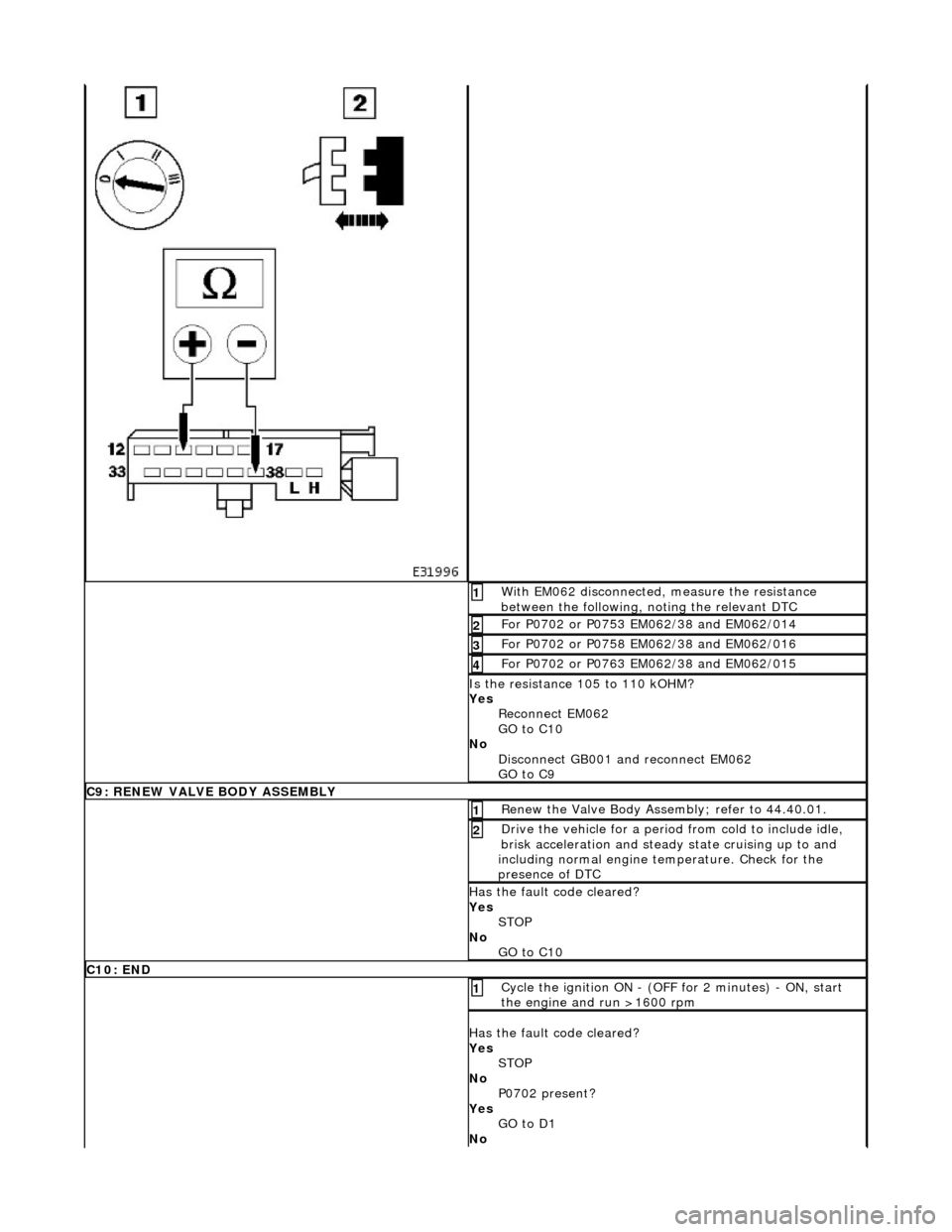

With EM062 disconnected, measure the resistance

between the following, noting the relevant DTC 1

For P0702 or P0753 EM062/38 and EM062/014 2

For P0702 or P0758 EM062/38 and EM062/016 3

For P0702 or P0763 EM062/38 and EM062/015 4

Is the resistance 105 to 110 kOHM?

Yes Reconnect EM062

GO to C10

No Disconnect GB001 and reconnect EM062

GO to C9

C9: RENEW VALVE BODY ASSEMBLY

Renew the Valve Body Assembly; refer to 44.40.01. 1

Drive the vehicle for a period from cold to include idle,

brisk acceleration and steady state cruising up to and

including normal engine temperature. Check for the

presence of DTC 2

Has the fault code cleared?

Yes STOP

No GO to C10

C10: END

Cycle the ignition ON - (OFF for 2 minutes) - ON, start

the engine and run >1600 rpm 1

Has the fault code cleared?

Yes STOP

No P0702 present?

Yes GO to D1

No

Page 1419 of 2490

Pinpoint test E: P0702

With EM062 disconnected, measure the resistance

between the following, noting the relevant DTC 1

For P0702 or P0748 EM062/38 and EM062/036 2

For P0702 or P1748 EM062/38 and EM062/037 3

Is the resistance 16 to 18 kOHM?

Yes Reconnect EM062

GO to D9

No Renew the Valve Body Assembly; refer to 44.40.01.

Drive the vehicle for a period from cold to include idle,

brisk acceleration and steady state cruising up to and

including normal engine temperature.

GO to D9

D9: END

Cycle the ignition ON - (OFF for 2 minutes) - ON, start

the engine and run >1600 rpm 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST E : P0702

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

E1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1427 of 2490

Pinpoint test H: P0730, P0780

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to G2

G2: RENEW TCM

Renew the TCM 1

Has the TCM been renewed?

Yes GO to G3

G3: END

• NOTE: The following step must be carried out in order that sy stem adaptions can take place.

Drive the vehicle for a period from cold to include idle, brisk

acceleration and steady state cruising up to and including

normal engine temperature. Check for the presence of DTC 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST H : P0730, P0780

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

H1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to H2

H2: RENEW VALVE BODY ASSEMBLY

Renew the valve body assembly 1

Drive the vehicle for a period from cold to include idle, brisk

acceleration and steady state cruising up to and including

normal engine temperature. Check for the presence of DTC 2

Has the fault code cleared?

Page 1430 of 2490

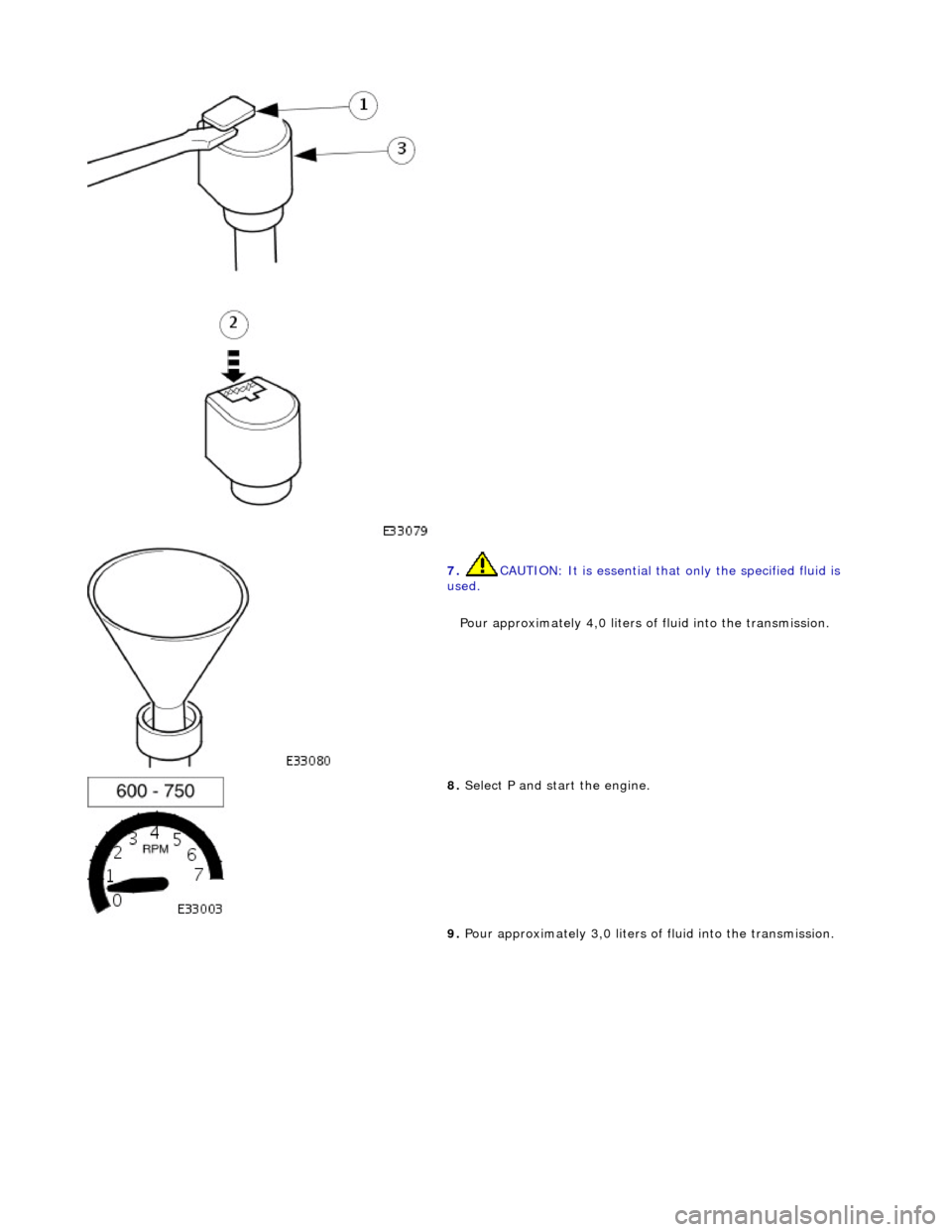

7. CAUTION: It is essential that only the specified fluid is

used.

Pour approximately 4,0 liters of fluid into the transmission.

8. Select P and start the engine.

9. Pour approximately 3,0 liters of fluid into the transmission.

Page 1431 of 2490

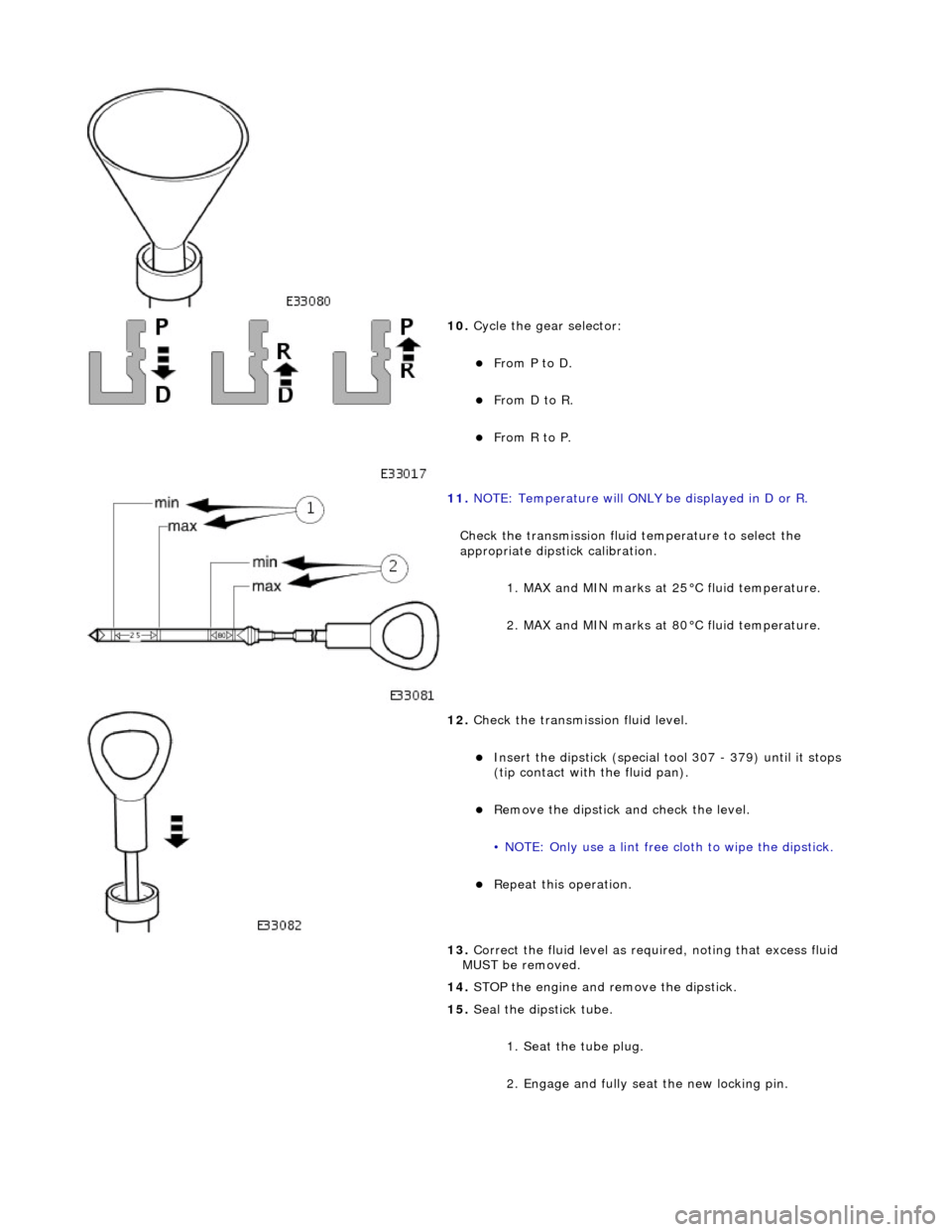

10. Cycle the gear selector:

пЃ¬From P to D.

пЃ¬From D to R.

пЃ¬From R to P.

11. NOTE: Temperature will ONLY be displayed in D or R.

Check the transmission fluid temperature to select the

appropriate dipstick calibration. 1. MAX and MIN marks at 25В°C fluid temperature.

2. MAX and MIN marks at 80В°C fluid temperature.

12. Check the transmission fluid level.

пЃ¬Insert the dipstick (special tool 307 - 379) until it stops

(tip contact with the fluid pan).

пЃ¬Remove the dipstick an d check the level.

• NOTE: Only use a lint free cloth to wipe the dipstick.

пЃ¬Repeat this operation.

13. Correct the fluid leve l as required, noting that excess fluid

MUST be removed.

14. STOP the engine and remove the dipstick.

15. Seal the dipstick tube.

1. Seat the tube plug.

2. Engage and fully seat the new locking pin.

Page 1433 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Extension

Housing Seal

In-vehicle Repair

Removal

Special Tool(s)

Oil seal replacer

307-378

Driveshaft wrench

205-053

1. Disconnect the battery ground lead.

2. Select N and choc the road wheels.

3. Remove the front muffler, re fer to Operation 30.10.18.

4. Remove the engine rear mounting bracket.

1. Support the transmission.

2. Remove the bolt, engine rear mounting to transmission.

3. Remove the four bolts which secure the mounting

cross member to the body.

5. Detach the driveshaft from th e transmission drive flange.

1. If the transmission is to be refitted, mark the position of the coupling relative to the drive flange.

5. CAUTION: Under no circ umstances remove the

driveshaft to flexible coupling fixings.

2. Remove the three bolts, tr ansmission drive flange to

flexible coupling.

6. Secure the driveshaft wrench 205 - 053 to the output shaft

flange.

Page 1443 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Transmission

Internal Wiring Harness Electr ical Connector O-Ring Seals

In-vehicle Repair

Removal

1. Disconnect the batt ery ground cable.

2. Open the engine compartment and fit paint protection sheets.

3. Raise the vehicle for access.

4. WARNING: TRANSMISSION FLUID MAY CAUSE SEVERE

BURNS, ENSURE THAT ALL SAFET Y PROCEDURES ARE OBSERVED

AND THAT THE RECEPTACLE FOR WASTE HAS SUFFICIENT

CAPACITY.

Drain the transmission fluid.

пЃ¬Carefully remove the drain pl ug and discard the sealing

washer.

5. Remove the harness heatshield lower fixing.

пЃ¬Remove the screw heatshield / fluid pan clamp.

6. Remove the harness heatshield.

пЃ¬Pull the heatshield from under the clip.

7. Disconnect the transmission link harness connector.

1. Release the locking lever on the guide bush and disconnect the harness connector.