bumper JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2388 of 2490

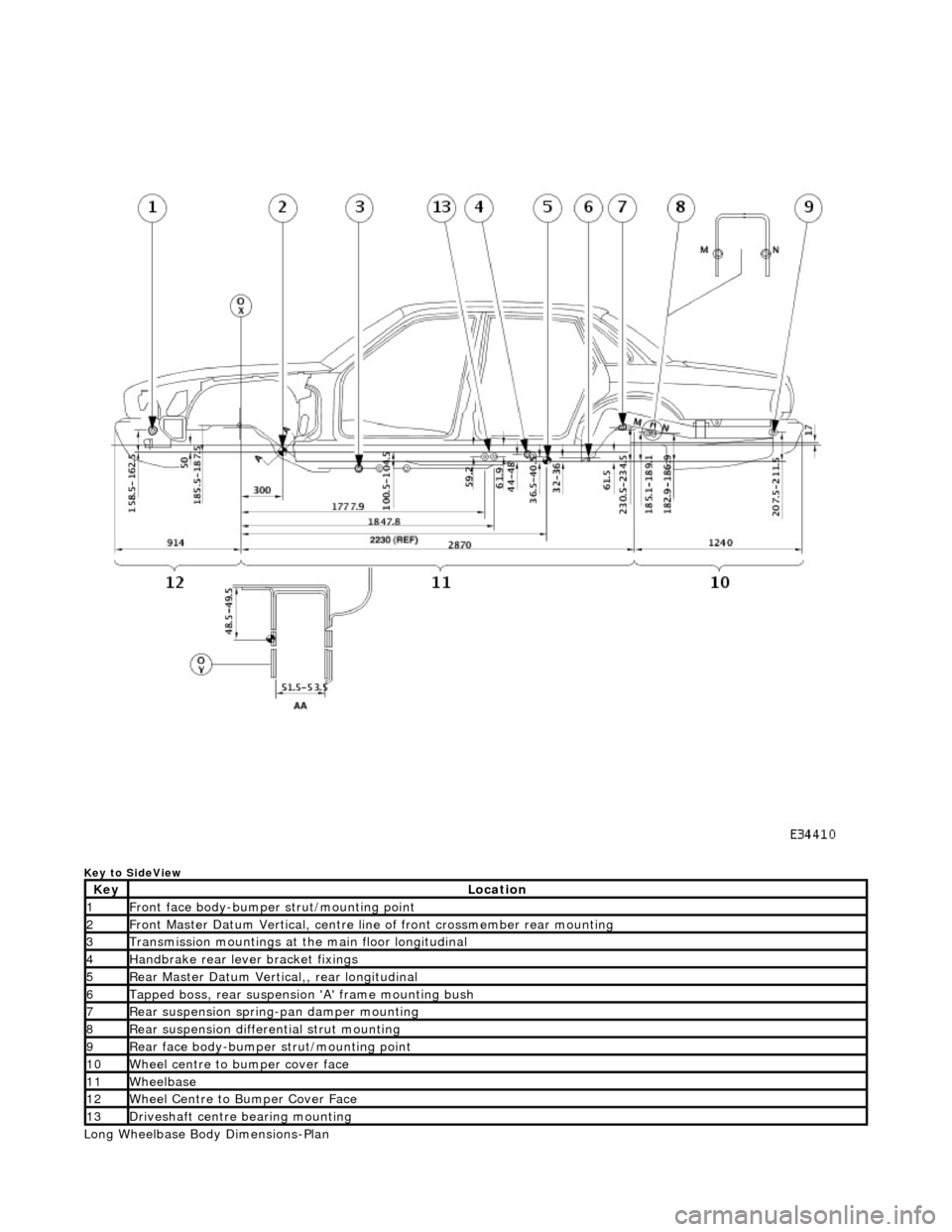

Key to SideView

Long Wheelbase Body Dimensions-Plan

KeyLocation

1Front face body-bumper strut/mounting point

2Front Master Datum Vertical, centre line of front crossmember rear mounting

3Transmission mountings at the main floor longitudinal

4Handbrake rear lever bracket fixings

5Rear Master Datum Vertical,, rear longitudinal

6Tapped boss, rear suspensi on 'A' frame mounting bush

7Rear suspension spring-pan damper mounting

8Rear suspension differential strut mounting

9Rear face body-bumper strut/mounting point

10Wheel centre to bumper cover face

11Wheelbase

12Wheel Centre to Bumper Cover Face

13Driveshaft centre bearing mounting

Page 2389 of 2490

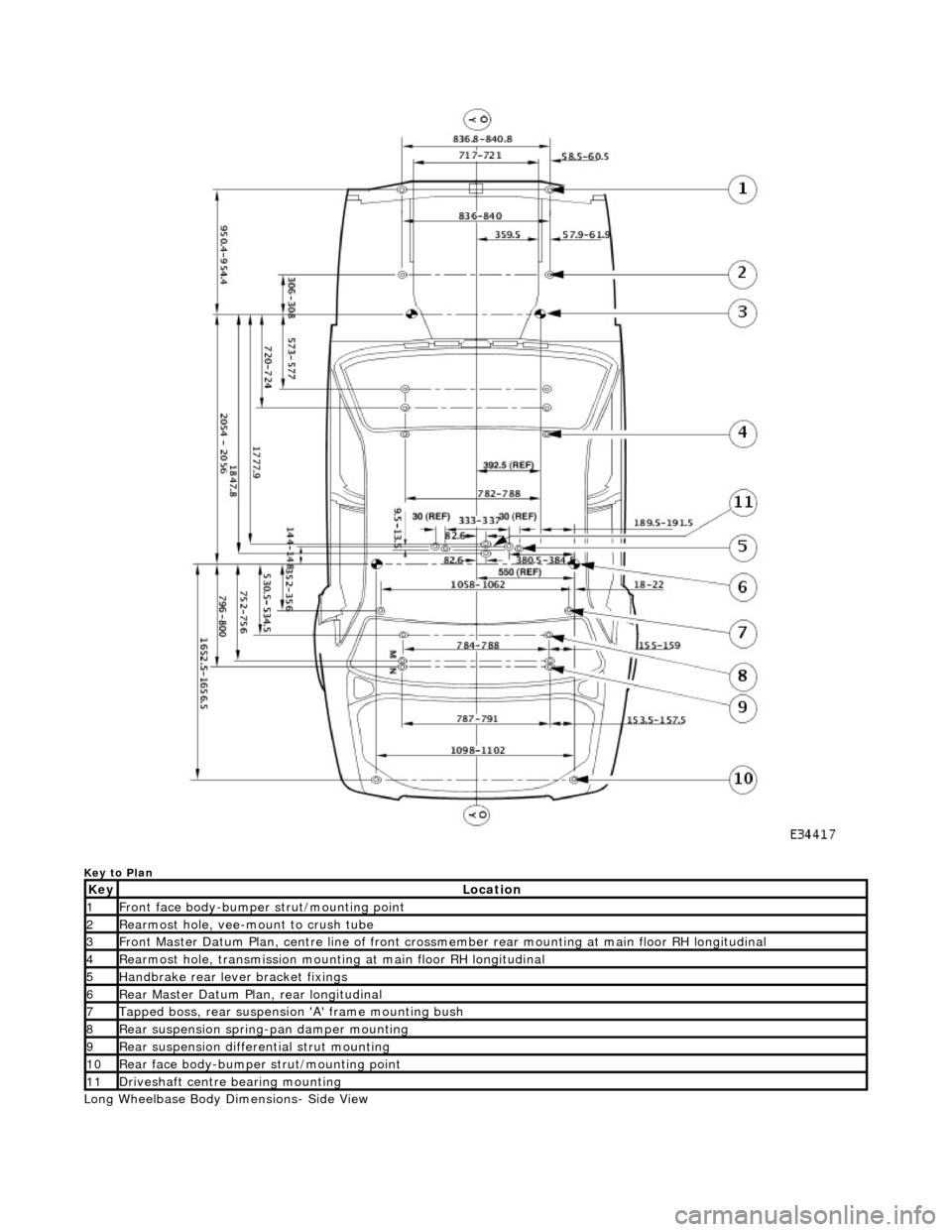

Key to Plan

Long Wheelbase Body Dimensions- Side View

KeyLocation

1Front face body-bumper strut/mounting point

2Rearmost hole, vee-mount to crush tube

3Front Master Datum Plan, centre line of front crossmember rear mount ing at main floor RH longitudinal

4Rearmost hole, transmission mounting at main floor RH longitudinal

5Handbrake rear lever bracket fixings

6Rear Master Datum Plan, rear longitudinal

7Tapped boss, rear suspension 'A' frame mounting bush

8Rear suspension spring-pan damper mounting

9Rear suspension differential strut mounting

10Rear face body-bumper strut/mounting point

11Driveshaft centre bearing mounting

Page 2390 of 2490

Key to SideView

KeyLocation

1Front face body-bumper strut/mounting point

2Front Master Datum Vertical, centre line of front crossmember rear mounting

3Transmission mountings at the main floor longitudinal

4Handbrake rear lever bracket fixings

5Rear Master Datum Vertical,, rear longitudinal

6Tapped boss, rear suspensi on 'A' frame mounting bush

7Rear suspension spring-pan damper mounting

8Rear suspension differential strut mounting

9Rear face body-bumper strut/mounting point

10Wheel centre to bumper cover face

11Wheelbase

12Wheel Centre to Bumper Cover Face

13Driveshaft centre bearing mounting

Page 2411 of 2490

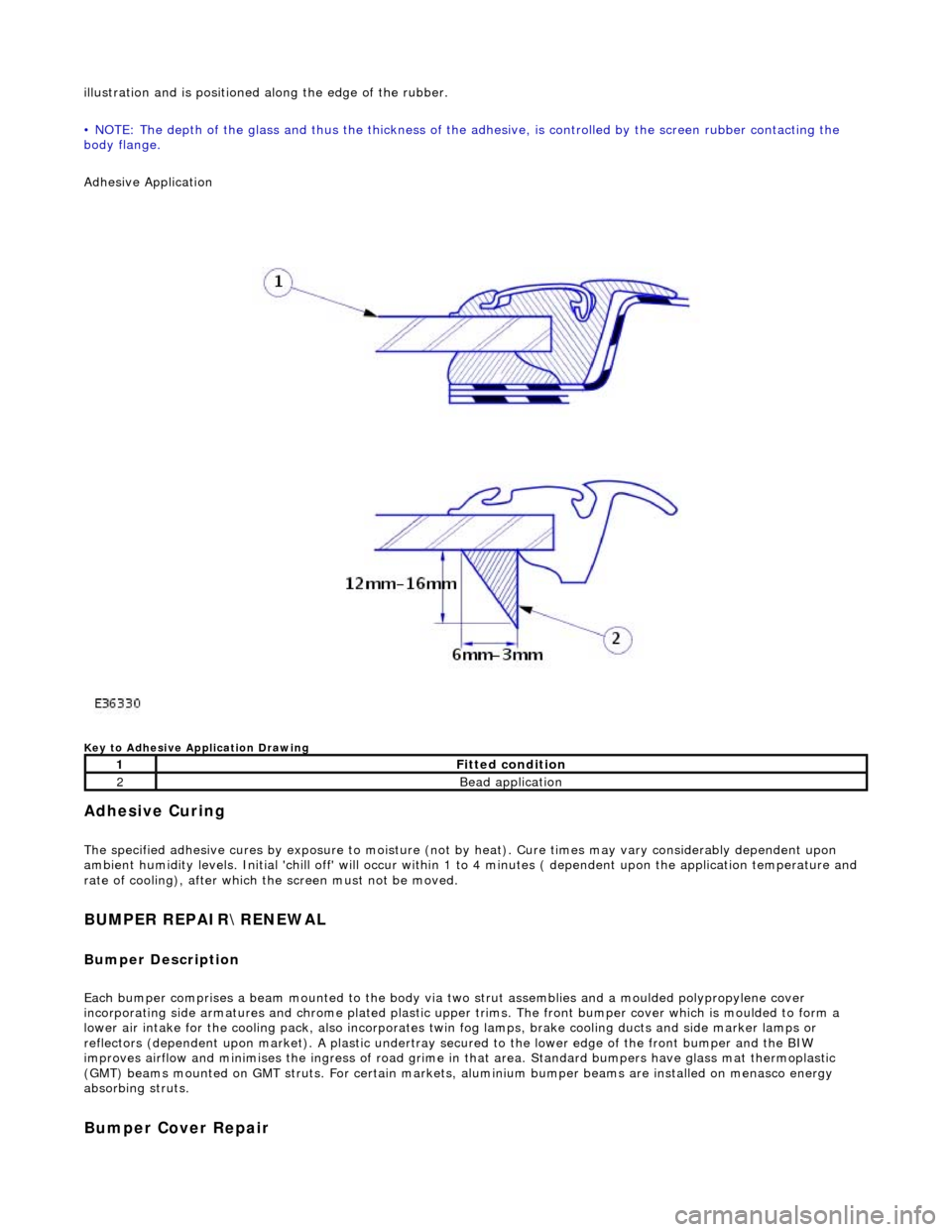

illustration and is positioned along the edge of the rubber.

• NOTE: The depth of the glass and thus the thickness of the ad hesive, is controlled by the screen rubber contacting the

body flange.

Adhesive Application

Key to Adhesive Application Drawing

Adhesive Curing

The specified adhesive cures by exposure to moisture (not by heat). Cure times may vary considerably dependent upon

ambient humidity levels. Initial 'chill off' will occur within 1 to 4 minutes ( dependent upon the application temperature and

rate of cooling), after which the screen must not be moved.

BUMPER REPAIR\RENEWAL

Bumper Description

Each bumper comprises a beam mounte d to the body via two strut assemblies and a moulded polypropylene cover

incorporating side armatures and chrome plated plastic upper trims. The front bumper cover which is moulded to form a

lower air intake for the cooling pack, also incorporates twin fog lamps, brake cooling ducts and side marker lamps or

reflectors (dependent upon market). A plastic undertray secured to the lower edge of the front bumper and the BIW

improves airflow and minimises the ingres s of road grime in that area. Standard bumpers have glass mat thermoplastic

(GMT) beams mounted on GMT struts. For certain markets, aluminium bumper beams are installed on menasco energy

absorbing struts.

Bumper Cover Repair

1Fitted condition

2Bead application

Page 2412 of 2490

Prior to commencing any work, bumper damage should be assessed for repairability and categorized in accordance with the

following guidelines. Bumper covers that are torn or holed are not repairable and must be discarded.

CAUTION: Cosmetic appearance must no t jeopardise safety. No attempt must be made to repair bumper covers

damaged beyond category three. Damage of this extent will compromise the protective performance of the cover and it

must be renewed. The thermo-s etting nature of the cover material, preclude s the repair of splits by heat or welding

techniques.

Repair Materials

Repair of accepted damage for categories 2 and 3 may be carried out using 3M '5900 FPRM' (Flexible part repair material)

or Kent Industries 'Urepatch'. Repair product manufacturers' recommendations an d procedures must always be strictly

followed.

Bumper Cover Refinishing

The paint refinishing system must be approved by Jaguar Cars Ltd., and be appropriate for polyurethane substrate

application. It is essential that the fini shing clear lacquer includes a plasticising ingredient (mixed to the manufacturer's

recommendation) that will achieve the 'semi-fl ex' condition of the factory finished item.

Bumper Cover Support

Exposure to heat decreases bumper cover rigidity. Covers removed for repair mu st therefore be supported to prevent

distortion and sagging during the paint curing process. Where the original bumper cover has been repaired, the beam will

provide sufficient support for the centre section. It is recommended that the side armatu res are supported as they would be

on the vehicle. If a new cover is required, the beam may be temporarily fitted to provide the necessary support during

refinishing.

CAUTION: During heat cure, the effective panel temperature must not exceed 95°C.

Simple Jig Constr uction for Bumper Cover Support

CategoryDamage

CosmeticAbrasion to surface paint finish only

Substrate surfaceDeep scratches, gouges or lo calized radial stress cracks.

Substrate

penetrationSplits not exceeding 100mm. Splits radiating fr om a gouge and accompanied by localized stress

cracks.

Page 2413 of 2490

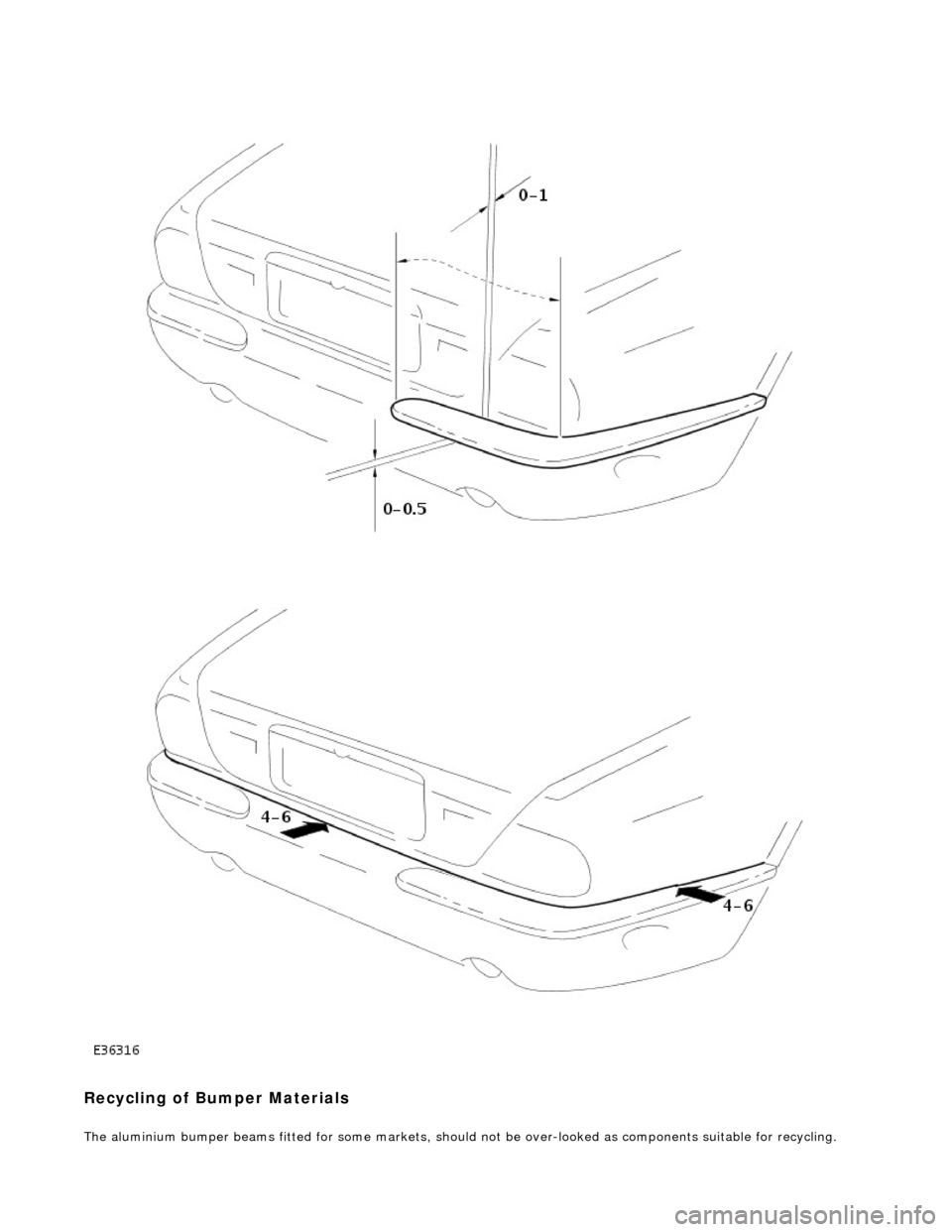

Replacement Bumper Covers

Replacement covers are supplied in a primed condition and must be finished to match the vehicle in accordance with the

procedures included in this section..

New bumper covers and replacem ent fixings such as bumper beam adjusters an d guide blocks must be fitted and adjusted

as detailed in the Bumper Setting Dimensions drawings.

Front Bumper Setting Dimensions

Page 2414 of 2490

Rear Bumper Setting Dimensions

Page 2415 of 2490

Recycling of Bumper Materials

The aluminium bumper beams fitted for some markets, should not be over-looked as components suitable for recycling.

Page 2416 of 2490

Replacement bumper cover assemblies includer side armatures, which should be removed from discarded bumper

assemblies and rout ed for recycling.

BODY SIDE MOULDINGS

Description

Two types of moulding are fitted to the standard wheelbase sedan. The lower mouldings are positioned on the body / door

lower feature lines. Where applicable, the upper mouldings are positioned using the lower mouldings as data. Replacement

lower mouldings are supplied in a primed condition and must be finished as detailed in this section.

Side Moulding Positions

Body Closures

Clearances and Alignments

When any panel, closure or body component is renewed, refitted or reset, the specified clearances and alignments must be

restored. This ensures that vehicle appearance and operation fully satisfy design intent and the customer.

Clearances

Gaps should be uniform around body panel contours and must be parallel to within 1mm in a 400mm linear measurement.

LocationFinishApplicationFixing method

UpperPolished stainless steelDaimler / VDPSelf adhesive

LowerBody colorAll modelsSelf adhesive

1Adhesive tape

2Moulding, Daimler/VDP

3Moulding all models

Page 2417 of 2490

Panels centered between two adjacent panels must have equal gaps on either side. For exceptions to this, refer to the

appropriate specification. Gaps between ad jacent panels or components must not expose harnesses, labels, brackets or

visually poor joint or assembly conditions.

• NOTE: Sliding roof panel clearances are specified without the edge seal installed.

Areas of particular concern are, fuel filler flap, trunk lid to fenders and saddle panels, hood to fenders, grill and headlamps,

sliding roof to main roof panel, door gaps at fenders, B\C posts, roof drip rail an d rocker panel, and bumper cover to fenders

and cross car assemblies

Alignment

Panels must be correctly profiled to maintain cosmetic appearance, and ensure co rrect seating of seals with minimal wind

noise. Areas of particular concern are hood to fenders, trunk lid to fenders and saddle panels, doors to apertures, doors to

fenders and adjacent doors and relationship of the sliding roof panel leading and trailing edges to the main roof panel.

Exterior Fitments

Bezels, trims and lamps must be concentric with apertu res and have equal clearances with adjacent panels.

Areas of particular concern are headlamp to hood, fender and trim panel, exhaust tailpipe trim to bumper cover cut-out,

rear lamp assembly to trunk lid, fender and bumper cover trim, and side feature lines including body side mouldings, fender

to door and door to door.

Exterior Clearances and Alignments-Front