vi number JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 364 of 2490

Rear Disc Brake -

Lubric

ants, Fluids, Sealants and Adhesives

CAUTI

O

N: Do not use brake fluid ITT Supe

r Dot 4 on 2006my vehicles onwards. Fa ilure to follow this instruction may

result in damage to the vehicle.

• NOTE: Brake fluid ITT Super Dot 4 has now been superseded by Shell ESL Super Dot 4 which is the Jaguar recommended

brake fluid. Shell ESL Super Dot 4 can be used on all model years.

Torques

- Brembo Brakes

Torques

Brake Tube, Hoses and Bracket Torques

CAUTIO

N: Replacement of

nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

UnitS p

ecification

Brake flu

i

d

ITT Supe

r Dot 4

Brake flui

d

Shell E

SL Supe

r Dot 4

Brem

bo Brake G

rease

Mol

i

kote Cu 7439

Com

p

onent

Nm

Bol

t

- anchor bracket to hub carrier

60

B

o

lt - caliper to anchor bracket

DO

N

OT REMOVE

Bleed n

i

pple

12

-16

Un

ion bolt - brake hose to caliper

22

-26

Com p

onent

Nm

Bol

t

- caliper carrier to hub carrier

60

Guide

Pi

n - caliper housing to caliper carrier

25

-30

Comp

onent

Nm

Bleed ni

pple - front

4-6

Bleed ni

pple - rear

8-11

Hose union to rear cal

i

per - union bolt

30

-40

Hose to fr ont cal

iper

10

-14

M1 0 h

ose locknut

15

-20

M10 brake

tube female-nut

13

-17

M10 brake

tube male-nut

13

-17

M12 brake

tube male-nut

15

-20

M18 bu

lkhead brake tube connector

22

-28

Brake tube clip retention -

bracket to body

4-

6

Page 365 of 2490

Rear

Disc Brake - Rear Disc Brake

Description an

d Operation

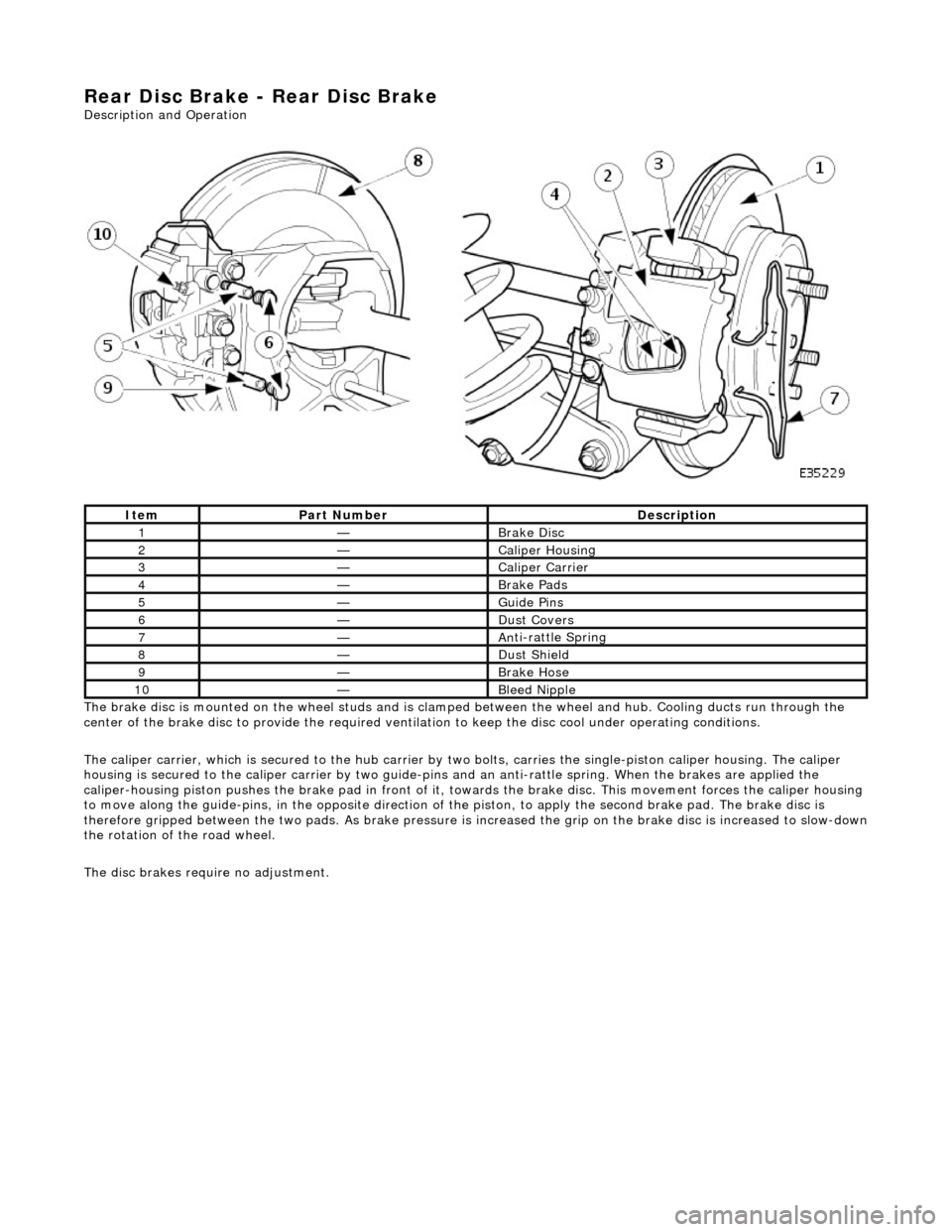

The brake disc is mounted on the wheel studs and is clamped between the wheel and hub. Cooling ducts run through the

center of the brake disc to provide the required ventilation to keep the disc cool under operating conditions.

The caliper carrier, which is se cured to the hub carrier by two bolts, carries the single-piston caliper housing. The caliper

housing is secured to the caliper carrier by two guide-pins and an anti-rattle spring. When the brakes are applied the

caliper-housing piston pushes th e brake pad in front of it, towards the brake di sc. This movement forces the caliper housing

to move along the guide-pins, in the oppo site direction of the piston, to apply the second brake pad. The brake disc is

therefore gripped between the two pads. As brake pressure is increased the grip on the brake disc is increased to slow-down

the rotation of the road wheel.

The disc brakes requ ire no adjustment.

It

em

Par

t Number

De

scription

1—B

rake Disc

2—Caliper Housin

g

3—Caliper Carrier

4—Brake Pad

s

5—Guide P

ins

6—Du

st Covers

7—An

ti-rattle Spring

8—Du

st Shield

9—Brake Hos

e

10—Bleed Nipp

le

Page 366 of 2490

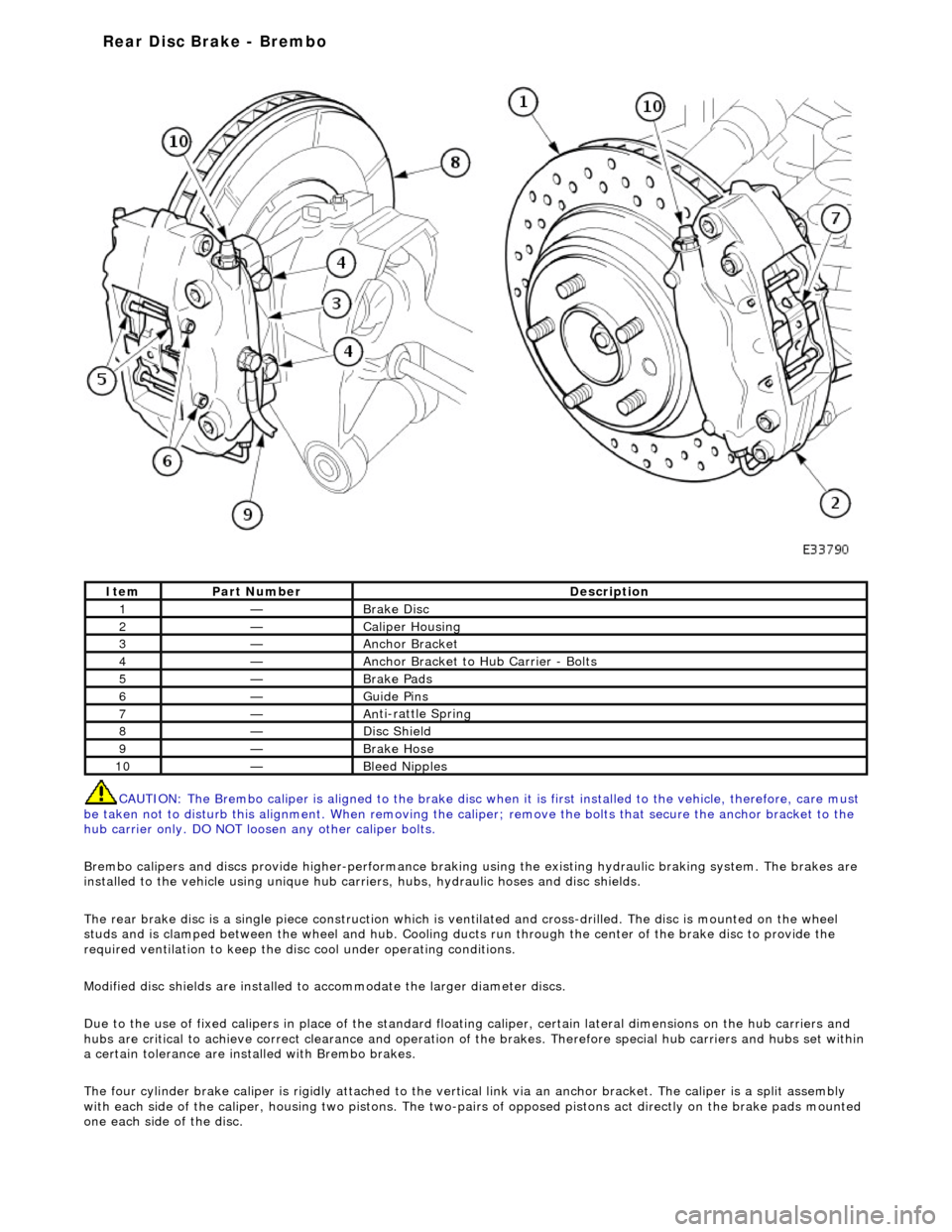

CAUTI O

N: The Brembo caliper is aligned to

the brake disc when it is first installed to the vehicle, therefore, care must

be taken not to disturb this alignment. When removing the ca liper; remove the bolts that secure the anchor bracket to the

hub carrier only. DO NOT loos en any other caliper bolts.

Brembo calipers and discs provide higher -performance braking using the existing hydraulic braking system. The brakes are

installed to the vehicle using unique hub carr iers, hubs, hydraulic hoses and disc shields.

The rear brake disc is a single piece co nstruction which is ventilated and cross-drilled. The disc is mounted on the wheel

studs and is clamped between the wheel and hub. Cooling ducts run through the ce nter of the brake disc to provide the

required ventilation to keep the disc cool under operating conditions.

Modified disc shields are installed to accommodate the larger diameter discs.

Due to the use of fixed calipers in place of the standard floating caliper, certain lateral dimensions on the hub carriers and

hubs are critical to achieve correct cleara nce and operation of the brakes. Therefore special hub carriers and hubs set within

a certain tolerance are inst alled with Brembo brakes.

The four cylinder brake caliper is rigidly attached to the vert ical link via an anchor bracket. The caliper is a split assembly

with each side of the caliper, housing two pistons. The two-pairs of opposed pistons act direct ly on the brake pads mounted

one each side of the disc.

It e

m

Par

t

Number

De

scr

iption

1—Brake D

i

sc

2—Caliper Housin

g

3—Anchor Bracke

t

4—Anchor Bracket to H

u

b Carrier - Bolts

5—Brake Pads

6—Guide Pi

ns

7—An

ti

-rattle Sprin

g

8—Di

sc

Shield

9—Brake Hos

e

10—Bleed Nipp

les

Rear Disc Brake - Brembo

Page 368 of 2490

Rear Disc Brake - Brake CaliperVehicles W

ith: Standard Brakes

Re

mo

val and Installation

Remov

a

l

WA

RNING: BRAKE DUST, IF INHALED CAN DAMAGE YOUR

HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

The brake pad adhesive backing must not be reused, therefore always install new brake pads, irrespective of the

condition of the original pads when replacing a brake caliper. Always replace brake pads as an axle set.

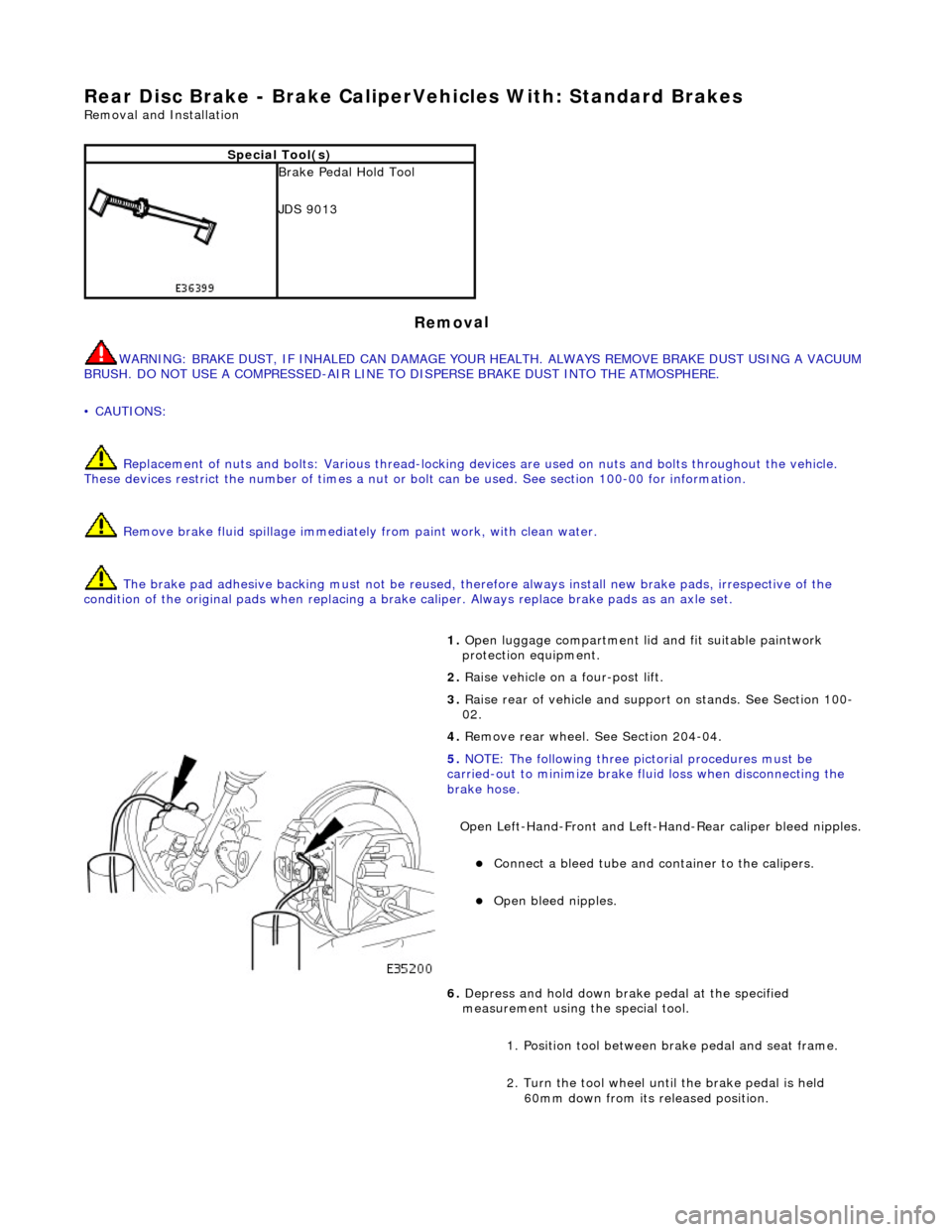

Sp

ecial Tool(s)

Brake Pedal

H

old Tool

JDS 9013

1. Op

en luggage compartment lid and fit suitable paintwork

protection equipment.

2. Raise vehicle on a four-post lift.

3. Raise rear of vehicl e and support on stan ds. See Section 100-

02.

4. Remove rear wheel. See Section 204-04.

5. NOTE

: Th

e following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake hose.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

Connect a

bleed tube and co

ntainer to the calipers.

Op

en bleed nipples.

6. Depress and hold down brak e pedal at the specified

measurement using the special tool.

1. Position tool between brake pedal and seat frame.

2. Turn the tool wheel unti l the brake pedal is held

60mm down from its released position.

Page 372 of 2490

Rear Disc Brake - Brake CaliperVehicles With: High Performance Brakes

Remo

val and Installation

Remov

a

l

S

p

ecial Tool(s)

Brake Pedal

H

old Tool

JDS 9013

1. WARNING: BRAKE DUST, IF INHALED CAN DAMAGE

YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRE SSED-AIR LINE TO DISPERSE

BRAKE DUST INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

See section 100-00 for information.

Remove brake fluid spillage immediately from paint work,

with clean water.

The Brembo caliper is aligned to the brake disc when it is

first installed to the vehicle, therefore, care must be taken not to

disturb this alignment. When removing the caliper; remove the

bolts that secure the anchor brac ket to the hub carrier only. DO

NOT loosen any other caliper bolts.

Open engine compartment and fit paint work protection covers

to fenders.

2. Raise

vehicle on a four-post lift.

3. Raise front of vehicle and support on stands. Refer to Section

100-02.

4. Remove front wheels. Refe r to operation 74.20.05.

5. NOTE : Th

e following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake hose.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

Connect a

bleed tube and co

ntainer to the calipers.

Op

en bleed nipples.

6. Depress and hold down brak e pedal at the specified

measurement using the special tool.

Page 376 of 2490

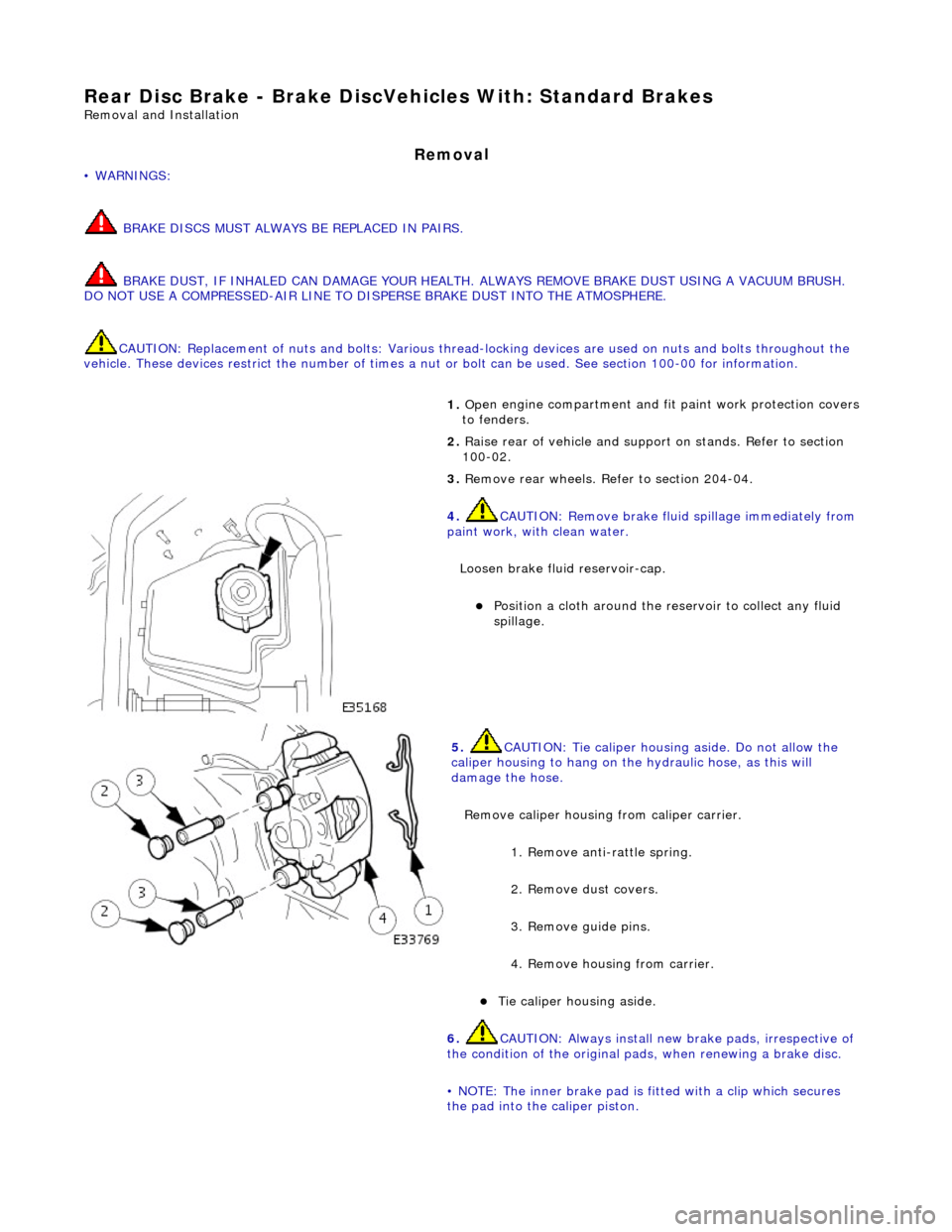

Rear Disc

Brake - Brake DiscVe

hicles With: Standard Brakes

Remo

val and Installation

Remov

a

l

• WAR

N

INGS:

BRAKE DISCS MUST ALWAYS BE REPLACED IN PAIRS.

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH.

DO NOT USE A COMPRESSED-AIR LINE TO DI SPERSE BRAKE DUST INTO THE ATMOSPHERE.

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

1. Op

en engine compartment and fit

paint work protection covers

to fenders.

2. Raise rear of vehicle and support on stands. Refer to section

100-02.

3. Remove rear wheels. Refer to section 204-04.

4. CAUTIO

N: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

Position a cloth around the reser

voir to collect any fluid

spillage.

5. CAUT

ION: Tie caliper housing aside. Do not allow the

caliper housing to hang on the hydraulic hose, as this will

damage the hose.

Remove caliper housing from caliper carrier.

1. Remove anti-rattle spring.

2. Remove dust covers.

3. Remove guide pins.

4. Remove housing from carrier.

Tie

caliper housing aside.

6.

CAUTIO

N: Always install new brake pads, irrespective of

the condition of the original pads, when renewing a brake disc.

• NOTE: The inner brake pad is fitted with a clip which secures

the pad into the caliper piston.

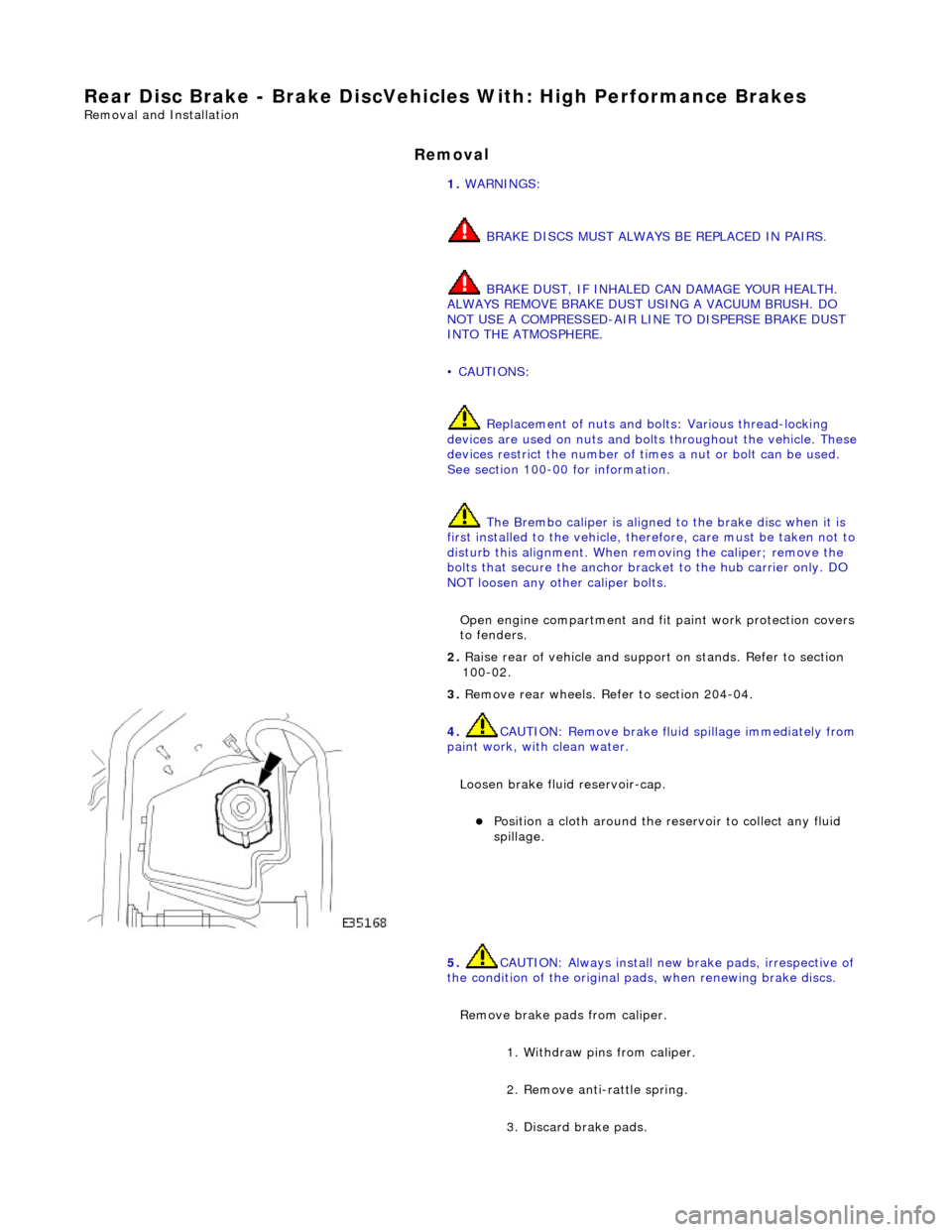

Page 380 of 2490

Rear Disc

Brake - Brake DiscVehicl

es With: High Performance Brakes

Remo

val and Installation

Remov

a

l

1.

WAR N

INGS:

BRAKE DISCS MUST ALWAYS BE REPLACED IN PAIRS.

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH.

ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH. DO

NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST

INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

See section 100-00 for information.

The Brembo caliper is aligned to the brake disc when it is

first installed to the vehicle, therefore, care must be taken not to

disturb this alignment. When removing the caliper; remove the

bolts that secure the anchor brac ket to the hub carrier only. DO

NOT loosen any other caliper bolts.

Open engine compartment and fit paint work protection covers

to fenders.

2. Ra

ise rear of vehicle and support

on stands. Refer to section

100-02.

3. Remove rear wheels. Refer to section 204-04.

4. CAUTIO

N: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

Position a cloth around the reser

voir to collect any fluid

spillage.

5. CAUTIO

N: Always install new brake pads, irrespective of

the condition of the original pads, when renewing brake discs.

Remove brake pads from caliper. 1. Withdraw pins from caliper.

2. Remove anti-rattle spring.

3. Discard brake pads.

Page 384 of 2490

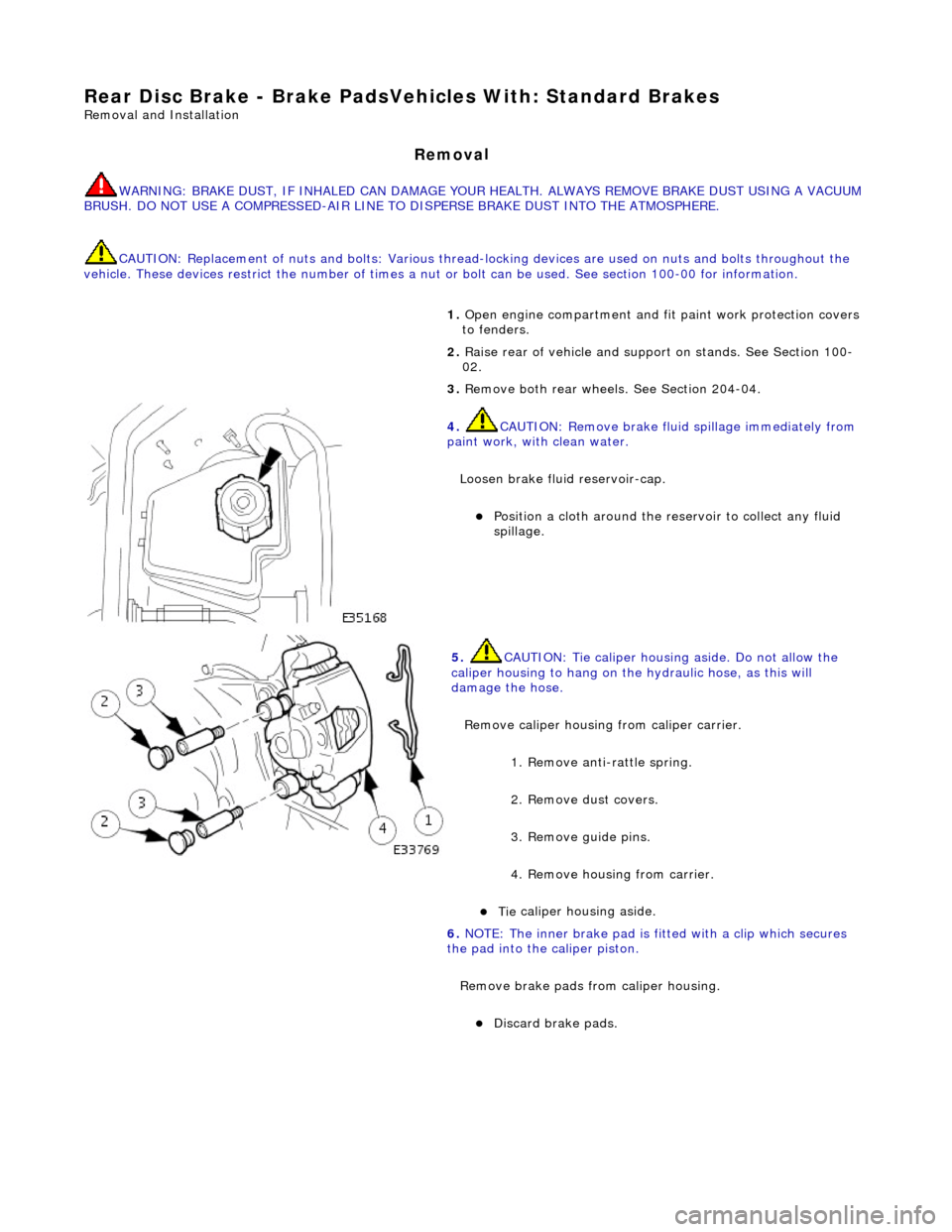

Rear Di

sc Brake - Brake PadsVe

hicles With: Standard Brakes

Remo

val and Installation

Remov

a

l

W

A

RNING: BRAKE DUST, IF INHALED CAN DAMAGE YOUR

HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST INTO THE ATMOSPHERE.

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

1. Op

en engine compartment and fit

paint work protection covers

to fenders.

2. Raise rear of vehicl e and support on stan ds. See Section 100-

02.

3. Remove both rear wheels. See Section 204-04.

4. CAUTIO

N: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

Position a cloth around the reser

voir to collect any fluid

spillage.

5. CAUT

ION: Tie caliper housing aside. Do not allow the

caliper housing to hang on the hydraulic hose, as this will

damage the hose.

Remove caliper housing from caliper carrier.

1. Remove anti-rattle spring.

2. Remove dust covers.

3. Remove guide pins.

4. Remove housing from carrier.

Tie

caliper housing aside.

6.

NO TE

: The inner brake pad is fitt

ed with a clip which secures

the pad into the caliper piston.

Remove brake pads from caliper housing.

Discard b

rake pads.

Page 387 of 2490

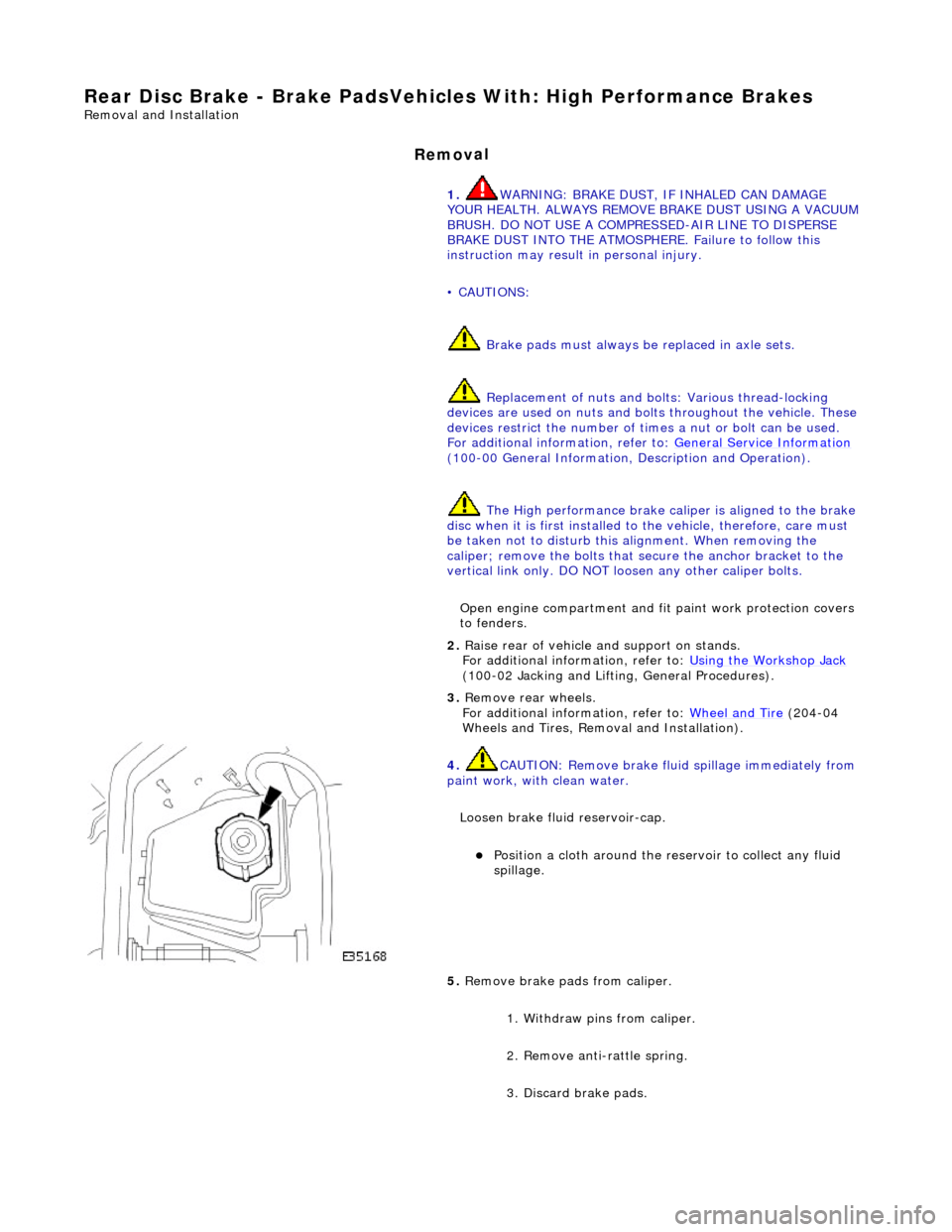

Rear Dis

c Brake - Brake PadsVehicl

es With: High Performance Brakes

Re

moval and Installation

Remov

al

1.

W

ARNING: BRAKE DUST, IF INHALED CAN DAMAGE

YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRE SSED-AIR LINE TO DISPERSE

BRAKE DUST INTO THE ATMOSPHERE. Failure to follow this

instruction may result in personal injury.

• CAUTIONS:

Brake pads must always be replaced in axle sets.

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

For additional information, refer to: General Service Information

(10

0-00 General Information,

Description and Operation).

The High performance brake caliper is aligned to the brake

disc when it is first installed to the vehicle, therefore, care must

be taken not to disturb this alignment. When removing the

caliper; remove the bolts that se cure the anchor bracket to the

vertical link only. DO NOT loosen any other caliper bolts.

Open engine compartment and fit paint work protection covers

to fenders.

2. R

aise rear of vehicle an

d support on stands.

For additional information, refer to: Using the Workshop Jack

(10

0-02 Jacking and Lifting, General Procedures).

3. Remove rear wheels.

For additional information, refer to: Wheel and Tire

(20

4-04

Wheels and Tires, Remo val and Installation).

4. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

Position a cloth around the

reservoir to collect any fluid

spillage.

5. Remove brake

pads from caliper.

1. Withdraw pins from caliper.

2. Remove anti-rattle spring.

3. Discard brake pads.

Page 390 of 2490

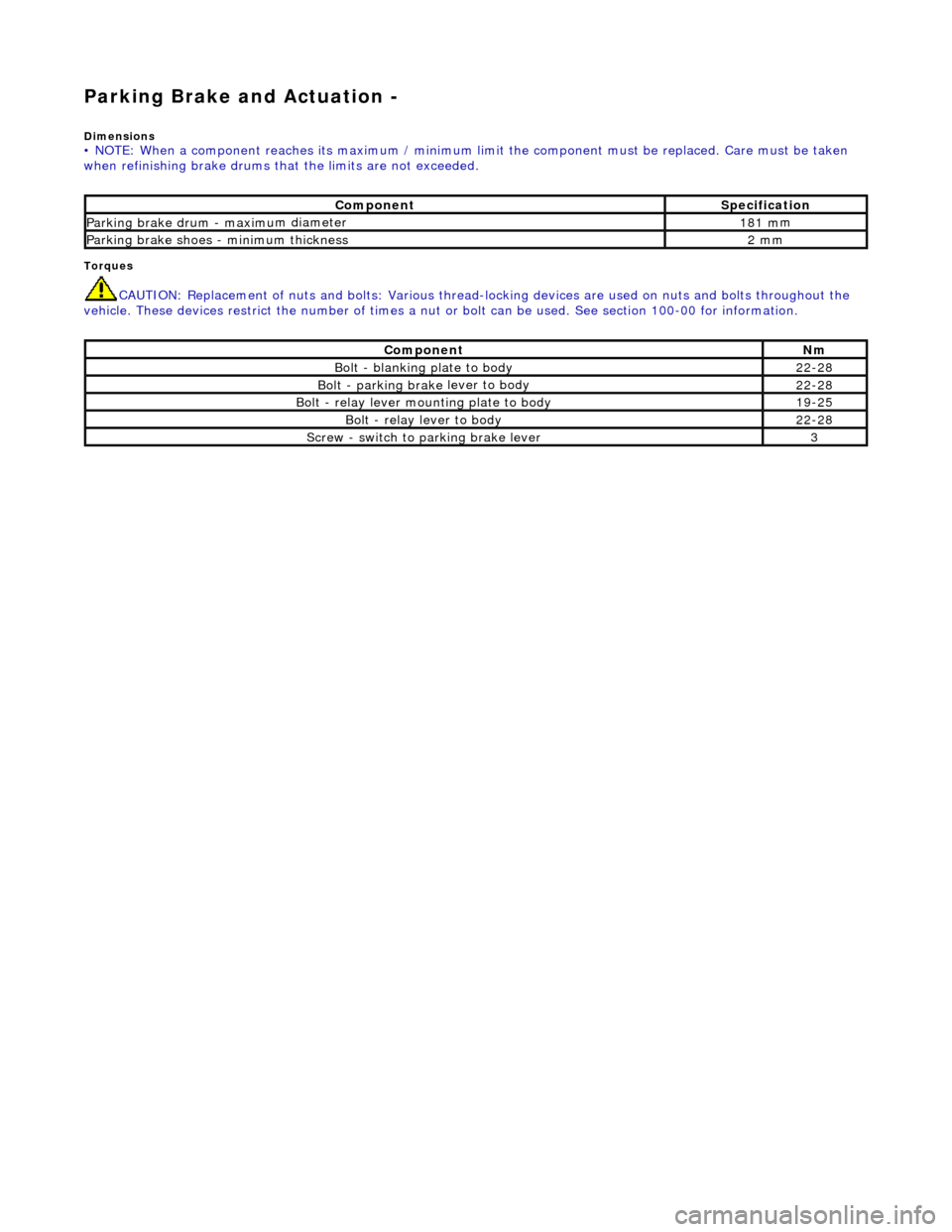

Parking Brake and Actuation -

Dim

ensions

• NO

TE: When a component reaches its maximum / minimum limit the component must be replaced. Care must be taken

when refinishing brake drums that the limits are not exceeded.

Torq ues

CAUTI

O

N: Replacement of

nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Com p

onent

S

p

ecification

Parkin

g brake drum - maximu

m diameter

1

81 m

m

Parkin

g brake sh

oes - minimum thickness

2 m

m

Com p

onent

Nm

Bolt - blan

k

ing plate to body

22

-28

Bolt - park ing brake

lever to body

22

-28

Bolt - r

elay lever mounting plate to body

19

-25

Bo lt

- relay lever to body

22

-28

Screw - switch to parking brake lever3