air condition JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1126 of 2490

Intake Air Distribution and Filtering - Charge Air Cooler Radiator

Remo

val and Installation

Remov

a

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Disconnect the battery.

1. Remove the battery cover.

2. Disconnect the battery ground cable.

3. Remove the engine radiator and air conditioning condensor

assembly. Refer to operation 26.40.01.

4. Remove the grill assembly fo r access. Refer to operation

76.55.15.

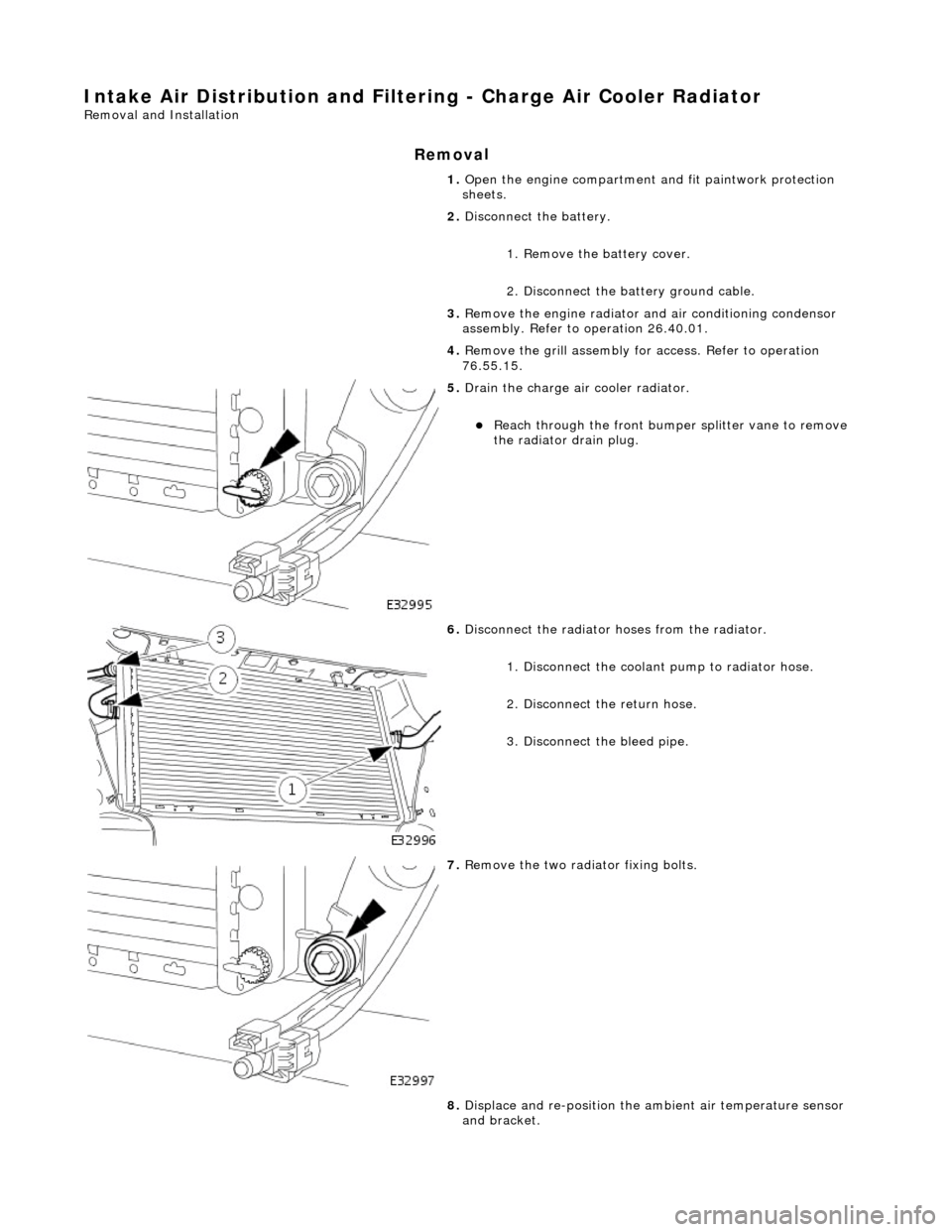

5. Drain th e charge air cooler radiator.

пЃ¬Reach t

hrough the front bumper

splitter vane to remove

the radiator drain plug.

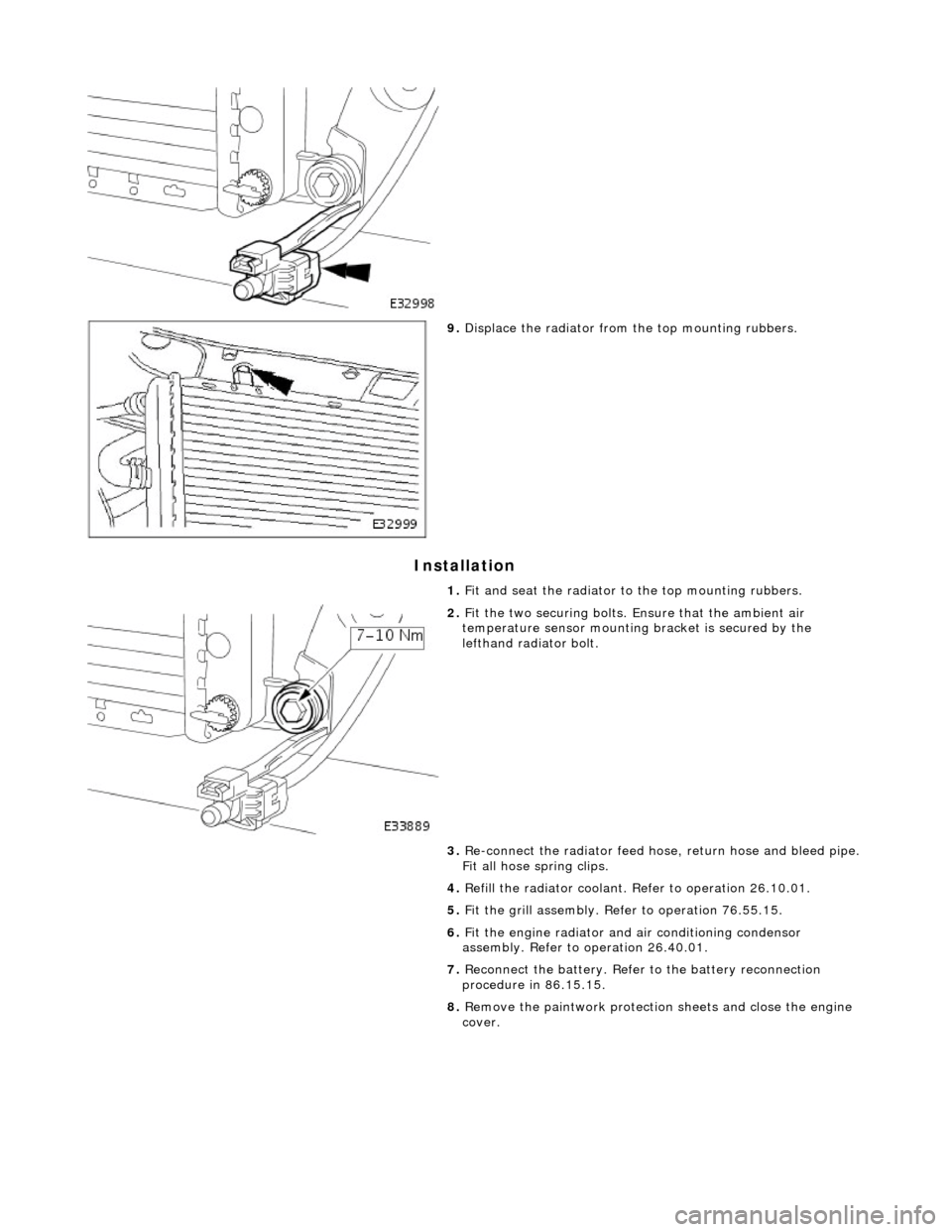

6. Disc

onnect the radiator

hoses from the radiator.

1. Disconnect the coolant pump to radiator hose.

2. Disconnect the return hose.

3. Disconnect the bleed pipe.

7. Re

move the two radiator fixing bolts.

8. Displace and re-position the am bient air temperature sensor

and bracket.

Page 1127 of 2490

I

nstallation

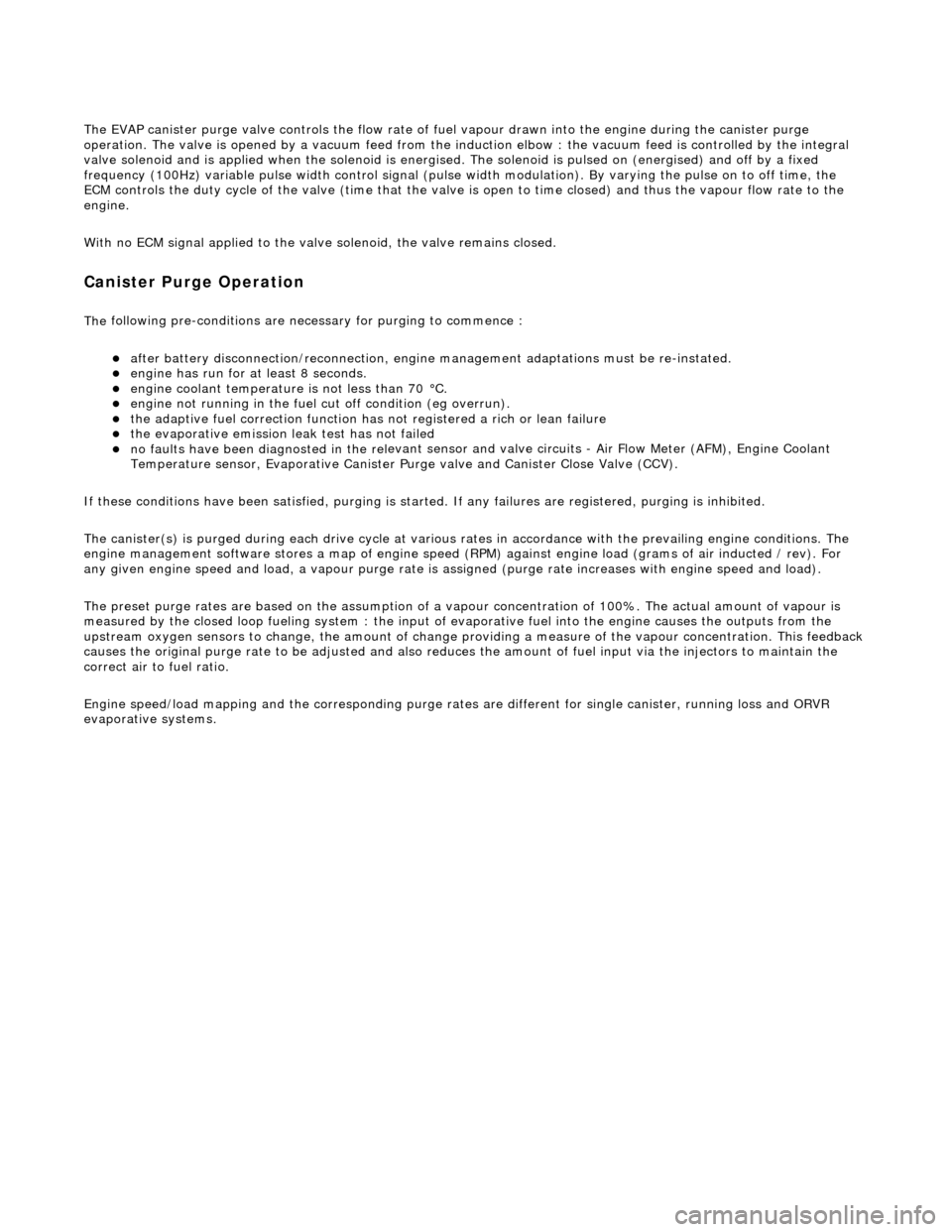

9.

Di

splace the radiator from

the top mounting rubbers.

1. Fit and seat the radiator to the top mounting rubbers.

2. F

it the two securing bolts.

Ensure that the ambient air

temperature sensor mounting bracket is secured by the

lefthand radiator bolt.

3. Re-connect the radiator feed ho se, return hose and bleed pipe.

Fit all hose spring clips.

4. Refill the radiator coolant. Refer to operation 26.10.01.

5. Fit the grill assembly. Refer to operation 76.55.15.

6. Fit the engine radiator and air conditioning condensor

assembly. Refer to operation 26.40.01.

7. Reconnect the battery. Refer to the battery reconnection

procedure in 86.15.15.

8. Remove the paintwork protection sheets and close the engine

cover.

Page 1149 of 2490

The E

VAP canister purge valve controls th

e flow rate of fuel vapour drawn into the engine during the canister purge

operation. The valve is opened by a vacu um feed from the induction elbow : the vacu um feed is controlled by the integral

valve solenoid and is applied when the so lenoid is energised. The solenoid is pulsed on (energised) and off by a fixed

frequency (100Hz) variable pulse width control signal (pulse width modulation). By varying the pulse on to off time, the

ECM controls the duty cycle of the valve (time that the valve is open to time closed) and thus the vapour flow rate to the

engine.

With no ECM signal applied to the va lve solenoid, the valve remains closed.

Can

ister Purge Operation

The

following pre-conditions are ne

cessary for purging to commence :

пЃ¬aft

er battery disconnection/reconnection, engine

management adaptations must be re-instated.

пЃ¬engine has run for

at least 8 seconds.

пЃ¬engi

ne coolant temperature is not less than 70 В°C.

пЃ¬engine

not running in the fuel

cut off condition (eg overrun).

пЃ¬t

he adaptive fuel correction

function has not registered a rich or lean failure

пЃ¬t

he evaporative emission leak test has not failed

пЃ¬no faults have been diagnosted in th

e rel

evant sensor and valve circuits -

Air Flow Meter (AFM), Engine Coolant

Temperature sensor, Evaporativ e Canister Purge valve and Canister Close Valve (CCV).

If these conditions have been satisfied, purging is started. If any failures are registered, purging is inhibited.

The canister(s) is purged during each driv e cycle at various rates in accordance with the prevailing engine conditions. The

engine management software st ores a map of engine speed (RPM) against engine load (grams of air inducted / rev). For

any given engine speed and load, a vapour purge rate is assigned (purge rate increases with engine speed and load).

The preset purge rates are base d on the assumption of a vapour concentratio n of 100%. The actual amount of vapour is

measured by the closed loop fueling system : the input of evaporative fuel into the engine causes the outputs from the

upstream oxygen sensors to change, the am ount of change providing a measure of the vapour concentration. This feedback

causes the original purge rate to be adju sted and also reduces the amount of fuel input via the injectors to maintain the

correct air to fuel ratio.

Engine speed/load mapping and the corresp onding purge rates are different for single canister, running loss and ORVR

evaporative systems.

Page 1161 of 2490

E

vaporative Emissions - Evaporative Emissions

D

iagnosis and Testing

Prelim

inary Inspection

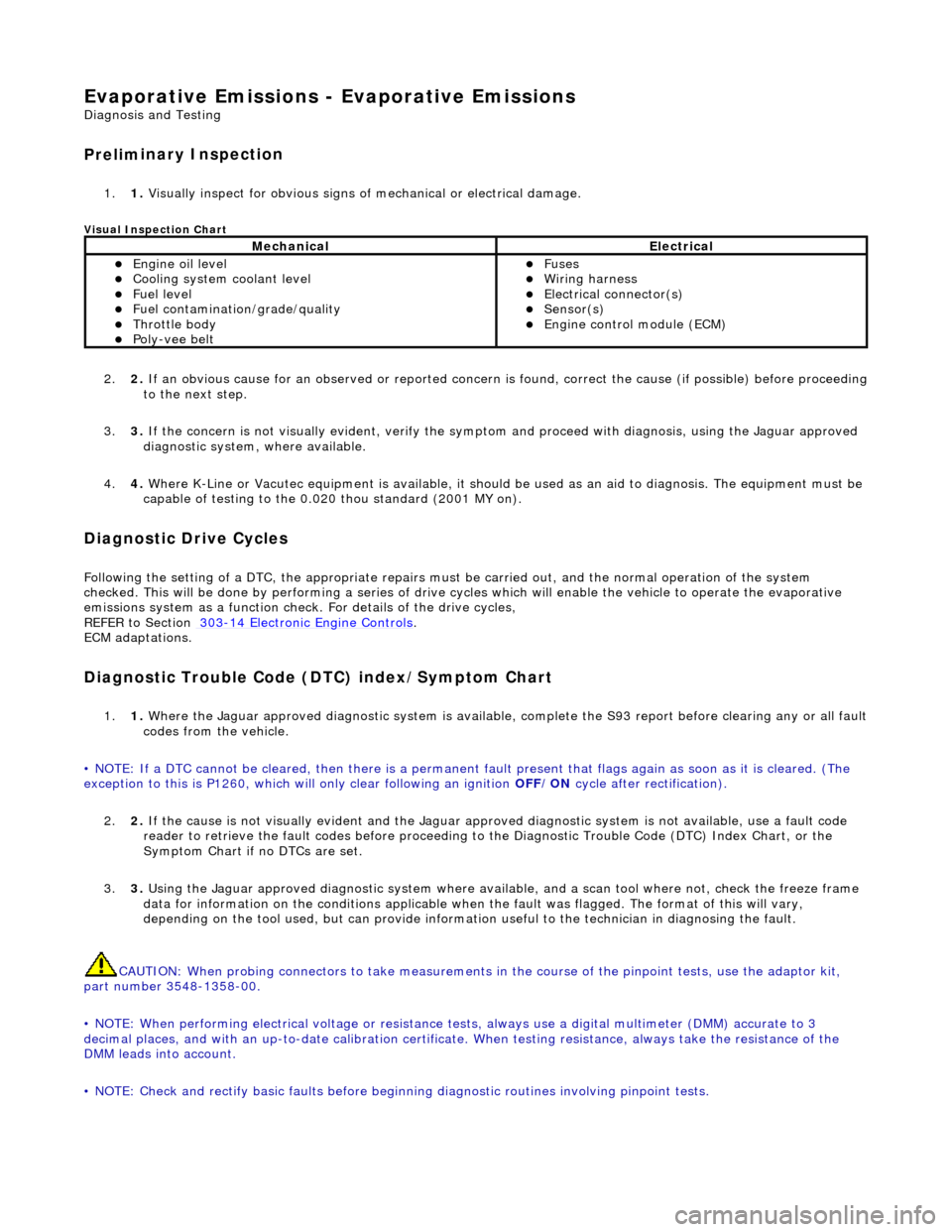

1.

1. Vis

ually inspect for obvious signs of mechanical or electrical damage.

V

isual Inspection Chart

2.

2. If

an obvious cause for an observed or

reported concern is found, correct th e cause (if possible) before proceeding

to the next step.

3. 3. If the concern is not visually evident, verify the symptom and proceed with diagnosis, using the Jaguar approved

diagnostic system, where available.

4. 4. Where K-Line or Vacutec equipment is available, it should be used as an aid to diagnosis. The equipment must be

capable of testing to the 0.020 thou standard (2001 MY on).

Diagnostic Drive Cycles

Following th

e setting of a DTC, the appropriate repairs must

be carried out, and the normal operation of the system

checked. This will be done by performing a series of drive cycles which will enable the vehicle to operate the evaporative

emissions system as a function check. For details of the drive cycles,

REFER to Section 303

-1

4 Electronic Engine Controls

.

ECM adapt

ations.

Diagnostic Trouble Code

(D

TC) index/Symptom Chart

1.

1. Wh

ere the Jaguar approved diagnostic sy

stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared. (The

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

2. 2. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

3. 3. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

depending on the tool used, but can pr ovide information useful to the technician in diagnosing the fault.

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit,

part number 3548-1358-00.

• NOTE: When performing electrical voltag e or resistance tests, always use a digital multimeter (DMM) accurate to 3

decimal places, and with an up-t o-date calibration certificate. When testing resistance, always take the resistance of the

DMM leads into account.

• NOTE: Check and rectify basic faults before beginning diagnostic ro utines involving pinpoint tests.

MechanicalElectrical

пЃ¬Engi

ne oil level

пЃ¬Coo

ling system coolant level

пЃ¬Fue

l level

пЃ¬Fuel contaminatio

n

/grade/quality

пЃ¬Throttle body пЃ¬Poly

-vee belt

пЃ¬F

uses

пЃ¬W

iring harness

пЃ¬E

lectrical connector(s)

пЃ¬Sens

or(s)

пЃ¬Engine

control module (ECM)

Page 1162 of 2490

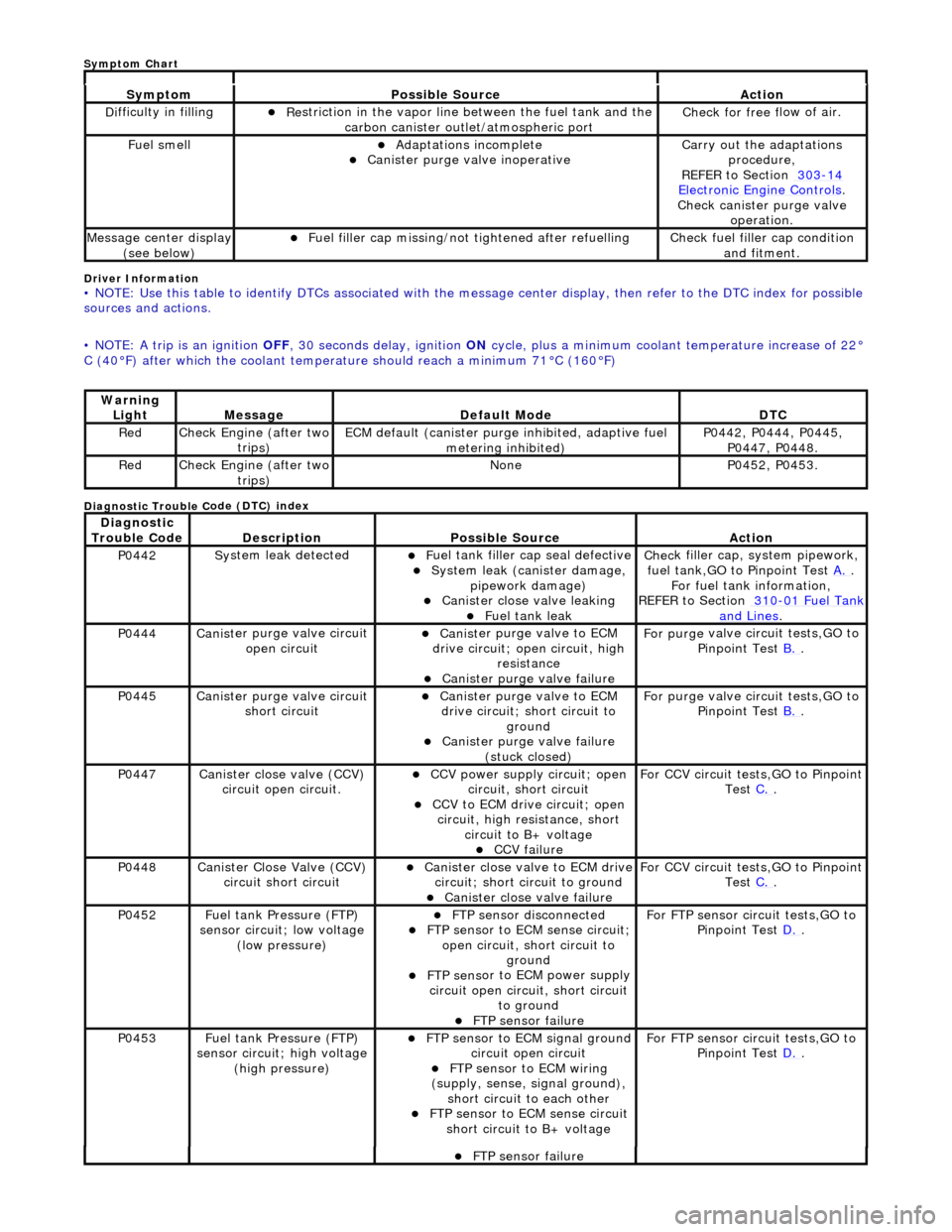

Driver Info

rmation

•

NOTE: Use this table to identify DTCs associated with the me

ssage center display, then refer to the DTC index for possible

sources and actions.

• NOTE: A trip is an ignition OFF, 30 seconds delay, ignition ON cycle, plus a minimum coolant temperature increase of 22°

C (40В°F) after which the coolant temperat ure should reach a minimum 71В°C (160В°F)

Diagnostic Trouble C

ode (DTC) index

Sy

m

ptom

Possib

l

e Source

Acti

o

n

D

i

fficulty in filling

пЃ¬R

e

striction in the vapor line between the fuel tank and the

carbon canister outlet/atmospheric port

Check f or free f

low of air.

F

u

el smell

пЃ¬Adaptat

i

ons incomplete

пЃ¬Cani

st

er purge valve inoperative

Carry

o

ut the adaptations

procedure,

REFER to Section 303

-14 Ele c

tronic Engine Controls

.

Chec k cani

ster purge valve

operation.

M e

ssage center display

(see below)

пЃ¬Fue l

filler cap missing/not

tightened after refuelling

Check fu

el filler cap condition

and fitment.

Warning Li

ght

Mess

age Defaul

t Mode

DT

C

RedCheck Engine (after two

trip

s)

ECM de

fa

ult (canister purge inhibited, adaptive fuel

metering inhibited)

P0442,

P0444, P0445,

P0447, P0448.

Re dCheck Engine (after two

trip

s)

No

neP04 52,

P0453.

Di

agno

stic

Trouble Code

De scr

iption

Possib

l

e Source

Acti

o

n

P0442Sy

st

em leak detected

пЃ¬F

u

el tank filler cap seal defective

пЃ¬Sy

ste

m leak (c

anister damage,

pipework damage)

пЃ¬Cani st

er close valve leaking

пЃ¬F

u

el tank leak

Chec

k fi

ller cap,

system pipework,

fuel tank,GO to Pinpoint Test A.

.

F o

r fuel tank information,

REFER to Section 310

-01 Fu

el Tank

and Lines.

P0444Canist

er purge valve circuit

open circuit

пЃ¬Cani st

er purge valve to ECM

drive circuit; open circuit, high

resistance

пЃ¬Cani st

er purge valve failure

F

or purge

valve circuit tests,GO to

Pinpoint Test B.

.

P0445Canist

er purge valve circuit

short circuit

пЃ¬Cani st

er purge valve to ECM

drive circuit; short circuit to ground

пЃ¬Canist

er purge valve failure

(stuck closed)

F or purge

valve circuit tests,GO to

Pinpoint Test B.

.

P0447Canist

er close valve (CCV)

circuit open circuit.

пЃ¬CCV power su pply ci

rcuit; open

circuit, short circuit

пЃ¬CCV to ECM drive circuit;

open

circuit, high resistance, short circuit to B+ voltage

пЃ¬CCV failure

Fo

r CCV circuit tests,GO to Pinpoint

Test C.

.

P0448Canist

er Close Valve (CCV)

circuit short circuit

пЃ¬Cani st

er close valve to ECM drive

circuit; short circuit to ground

пЃ¬Cani st

er close valve failure

F

o

r CCV circuit tests,GO to Pinpoint

Test C.

.

P0452 Fu

el tank Pressure (FTP)

sensor circuit; low voltage (low pressure)

пЃ¬FTP sen

sor disconnected

пЃ¬FTP sen

sor to ECM sense circuit;

open circuit, short circuit to ground

пЃ¬FTP sens

or to ECM power supply

circuit open circuit, short circuit to ground

пЃ¬FT

P sensor failure

For FT

P se

nsor circuit tests,GO to

Pinpoint Test D.

.

P0453Fu

el tank Pressure (FTP)

sensor circuit; high voltage

(high pressure)

пЃ¬FTP sen

sor to ECM signal ground

circuit open circuit

пЃ¬F T

P sensor to ECM wiring

(supply, sense, signal ground),

short circuit to each other

пЃ¬FTP sen

sor to ECM sense circuit

short circuit to B+ voltage

For FT P se

nsor circuit tests,GO to

Pinpoint Test D.

.

пЃ¬FT

P sensor failure

Sym

ptom Chart

Page 1163 of 2490

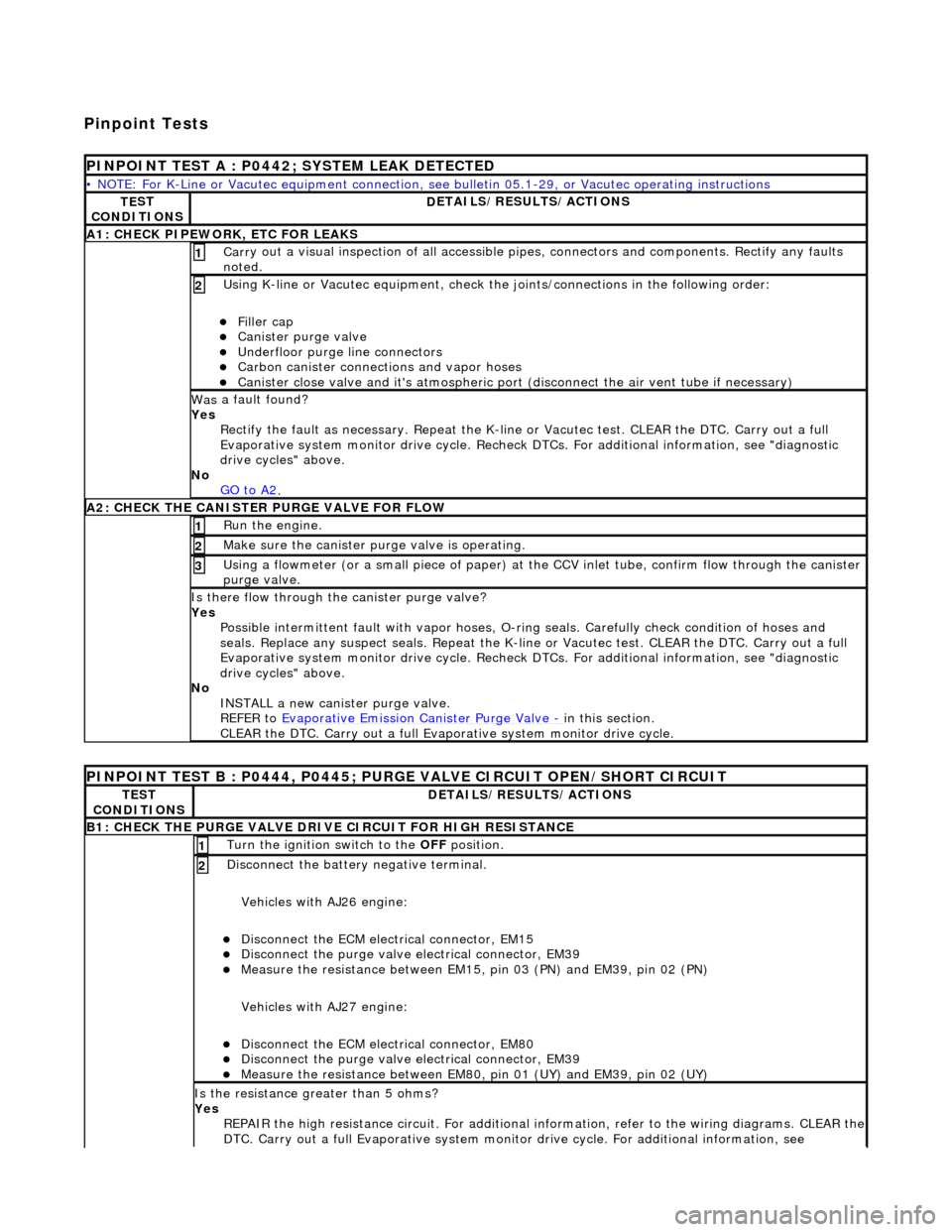

Pinpoint Tests

P

INPOINT TEST A : P0442; SYSTEM LEAK DETECTED

•

NOTE: For K-Line or Vacutec equipment connection, see bulletin 05.1-29, or Vacutec operating instructions

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A

1: CHECK PIPEWORK, ETC FOR LEAKS

Carr

y out a visual inspection of all accessible pipes, connectors and components. Rectify any faults

noted.

1

U

sing K-line or Vacutec equipment, check the

joints/connections in the following order:

пЃ¬Fi

ller cap

пЃ¬Cani

ster purge valve

пЃ¬Underfl

oor purge line connectors

пЃ¬Carbon

canister connections and vapor hoses

пЃ¬Cani

ster close valve and it's atmospheric port (disconnect the air vent tube if necessary)

2

Was

a fault found?

Yes Rectify the fault as necessary. Re peat the K-line or Vacutec test. CLEAR the DTC. Carry out a full

Evaporative system monitor drive cycle. Recheck DT Cs. For additional information, see "diagnostic

drive cycles" above.

No GO to A2

.

A2: CHECK

THE CA

NISTER PURGE VALVE FOR FLOW

Ru

n the engine.

1

Make sure the canister purge

valve is operating.

2

Using a flowmeter

(or a small piece

of paper) at the CCV inlet tube, confirm flow through the canister

purge valve.

3

Is th

ere flow through the canister purge valve?

Yes Possible intermittent faul t with vapor hoses, O-ring seals. Carefully check condition of hoses and

seals. Replace any suspect seals. Repeat the K-line or Vacutec test. CLEAR the DTC. Carry out a full

Evaporative system monitor drive cycle. Recheck DT Cs. For additional information, see "diagnostic

drive cycles" above.

No INSTALL a new canister purge valve.

REFER to Evaporative Emission Canister Purge Valve

- in t

his section.

CLEAR the DTC. Carry out a full Evap orative system monitor drive cycle.

P

INPOINT TEST B : P0444, P0445; PURGE VALVE CIRCUIT OPEN/SHORT CIRCUIT

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

B1: CHECK

THE PURGE VALVE DRIV

E CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

tch to the OFF

position.

1

Di

sconnect the battery negative terminal.

Vehicles with AJ26 engine:

пЃ¬Disc

onnect the ECM electrical connector, EM15

пЃ¬Di

sconnect the purge valve electrical connector, EM39

пЃ¬Meas

ure the resistance between EM15,

pin 03 (PN) and EM39, pin 02 (PN)

Vehicles with AJ27 engine:

пЃ¬Disc

onnect the ECM electrical connector, EM80

пЃ¬Di

sconnect the purge valve electrical connector, EM39

пЃ¬Meas

ure the resistance between EM80, pin 01 (UY) and EM39, pin 02 (UY)

2

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. Carry out a full Evaporative system monitor drive cycle. For additional information, see

Page 1164 of 2490

"d

iagnostic drive cycles" above.

No GO to B2

.

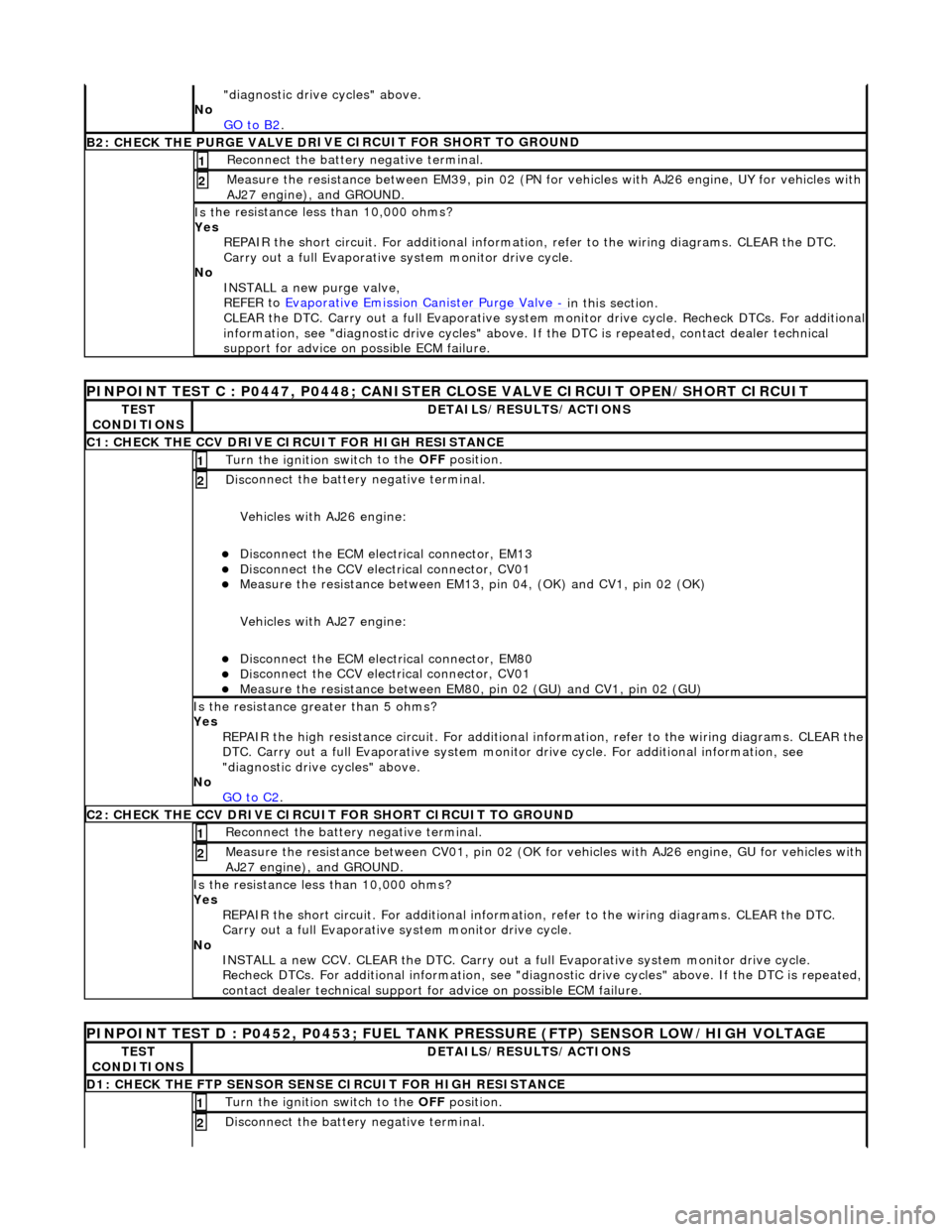

B2: CHECK THE PURGE VALVE DR

IV

E CIRCUIT FOR SHORT TO GROUND

Re

connect the battery negative terminal.

1

Meas

ure t

he resistance between EM39, pin 02 (PN for vehicles with AJ26

engine, UY for vehicles with

AJ27 engine), and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

Carry out a full Evaporative system monitor drive cycle.

No INSTALL a new purge valve,

REFER to Evaporative Emission Canister Purge Valve

- in thi

s section.

CLEAR the DTC. Carry out a full Evaporative system monitor drive cycle. Recheck DTCs. For additional

information, see "diagnostic drive cycles" above. If the DTC is repeated, contact dealer technical

support for advice on possible ECM failure.

PI

NPOINT TEST C : P0447, P0448; CANISTER CLOSE VALVE CIRCUIT OPEN/SHORT CIRCUIT

TE

S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

C1

: CH

ECK THE CCV DRIVE CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

t

ch to the

OFF position.

1

Disc

onnect the battery negative terminal.

Vehicles with AJ26 engine:

пЃ¬Disc onne

ct the ECM electrical connector, EM13

пЃ¬Di

sc

onnect the CCV electrical connector, CV01

пЃ¬Meas

ure t

he resistance between EM13, pi

n 04, (OK) and CV1, pin 02 (OK)

Vehicles with AJ27 engine:

пЃ¬Disc onne

ct the ECM electrical connector, EM80

пЃ¬Di

sc

onnect the CCV electrical connector, CV01

пЃ¬Meas

ure t

he resistance between EM80,

pin 02 (GU) and CV1, pin 02 (GU)

2

Is the res

istance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. Carry out a full Evaporative system monitor drive cycle. For additional information, see

"diagnostic drive cycles" above.

No GO to C2

.

C2: CH

ECK THE CCV DRIVE CIRCUI

T FOR SHORT CIRCUIT TO GROUND

Re

connect the battery negative terminal.

1

Meas

ure t

he resistance between CV01,

pin 02 (OK for vehicles with AJ26 engine, GU for vehicles with

AJ27 engine), and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

Carry out a full Evaporative system monitor drive cycle.

No INSTALL a new CCV. CLEAR the DTC. Carry out a fu ll Evaporative system monitor drive cycle.

Recheck DTCs. For additional inform ation, see "diagnostic drive cycles" above. If the DTC is repeated,

contact dealer technical support for advice on possible ECM failure.

P INPOINT TES

T D : P0452, P0453; FUEL TANK

PRESSURE (FTP) SENSOR LOW/HIGH VOLTAGE

TES

T

CONDITIONS

DE

TAILS/RESULTS/ACTIONS

D

1:

CHECK THE FTP SENSOR SENSE CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

t

ch to the OFF

position.

1

Disc

onnect the battery negative terminal.

2

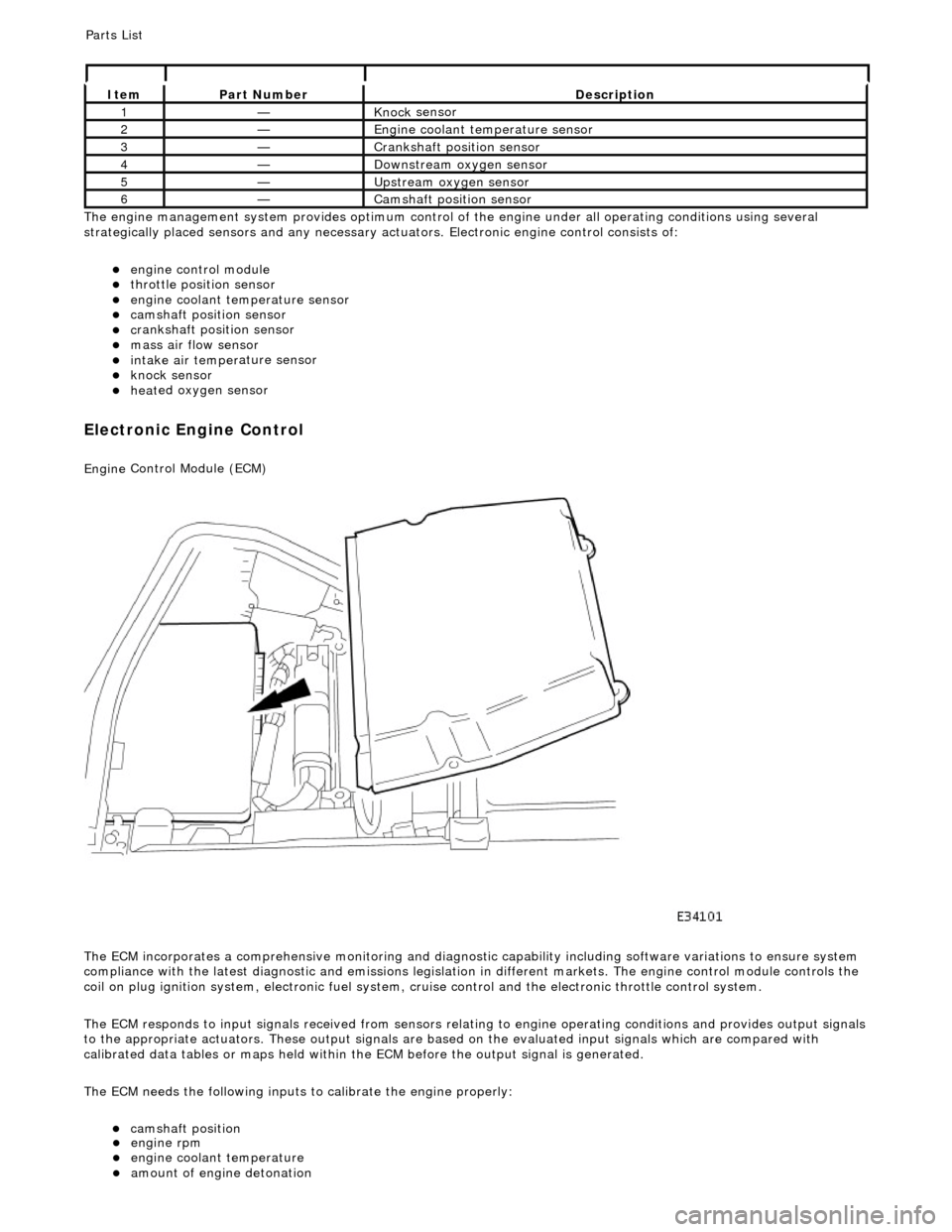

Page 1177 of 2490

Th

e engine management system provides optimum control of

the engine under all operating conditions using several

strategically placed sensors and any necessary actuators. Electronic engine control consists of:

пЃ¬engine

control module

пЃ¬throttle posi

tion sensor

пЃ¬engi

ne coolant temperature sensor

пЃ¬cam

shaft position sensor

пЃ¬c

rankshaft position sensor

пЃ¬mass air

flow sensor

пЃ¬intake air temper

ature sensor

пЃ¬kn

ock sensor

пЃ¬heat

ed oxygen sensor

Electronic Engine Control

Engine

Control Module (ECM)

The ECM incorporates a comprehensive monitoring and diagnostic capability including software variations to ensure system

compliance with the latest diagnostic and emissions legislation in different markets. The engine control module controls the

coil on plug ignition system, electronic fuel system, cr uise control and the electronic throttle control system.

The ECM responds to input signals received from sensors relating to engine operatin g conditions and provides output signals

to the appropriate actuators. These outp ut signals are based on the evaluated input signals which are compared with

calibrated data tables or maps held within th e ECM before the output signal is generated.

The ECM needs the following inputs to calibrate the engine properly:

пЃ¬cam

shaft position

It

em

Par

t Number

De

scription

1—Knock

sensor

2—Engine

coolant temperature sensor

3—Cranksh

aft position sensor

4—D

ownstream oxygen sensor

5—Upstream oxygen sensor

6—Camshaft position

sensor

P

arts List

пЃ¬engi

ne rpm

пЃ¬engi

ne coolant temperature

пЃ¬amount

of engine detonation

Page 1179 of 2490

пЃ¬generates a signal when th

e dr

ive plate passes the sensor

пЃ¬sen

ds the ECM signals indicating crankshaft position and engine speed

пЃ¬is e

ssential for calculating spark timing

En

gine Coolant Temperature (ECT) Sensor

пЃ¬sen

ds the ECM a signal indicating the temperature of the engine coolant

пЃ¬is a t

emperature dependent resistor with a negative temperature coefficient (resistance changes inversely with

respect to temperature) and is constantly monitored by the ECM

Intake Air Temperature (IAT) Sensor

пЃ¬is m

ounted in the same housing as the MA

F sensor but is not a serviceable item

пЃ¬sen

ds the ECM a signal indicating the temperature of the air entering the engine

пЃ¬is a t

emperature dependent resistor which has a negative

temperature coefficient (its resistance changes inversely

with respect to ambient temperature).

Knock S

ensor (KS)

пЃ¬is a pi

ezo-electric device which sends a signal

to the ECM indicating engine detonation

Between 700 and 6800 rpm, the ECM will retard individual cylinder ignition timing when detonation occurs while allowing

the other cylinders to continue operating normally.

During acceleration, at critical load and speed conditions, the ECM retards ignition timing to prevent the onset of detonation.

H

eated Oxygen Sensor (HO2S)

пЃ¬are

positioned upstream of the catalytic convertor

пЃ¬is equipped with

a heating element wh

ich improves the response time of the sensors during engine warm-up

пЃ¬h

as the ability to generate a voltage signal proportional to the oxygen content of the exhaust gases leaving the

engine

пЃ¬pr

ovides feedback information to the ECM used to calc

ulate fuel delivery and provide optimum gas emissions

Variable V

alve Timing (VVT) Solenoid

R

efer to section 303-01.

Page 1189 of 2490

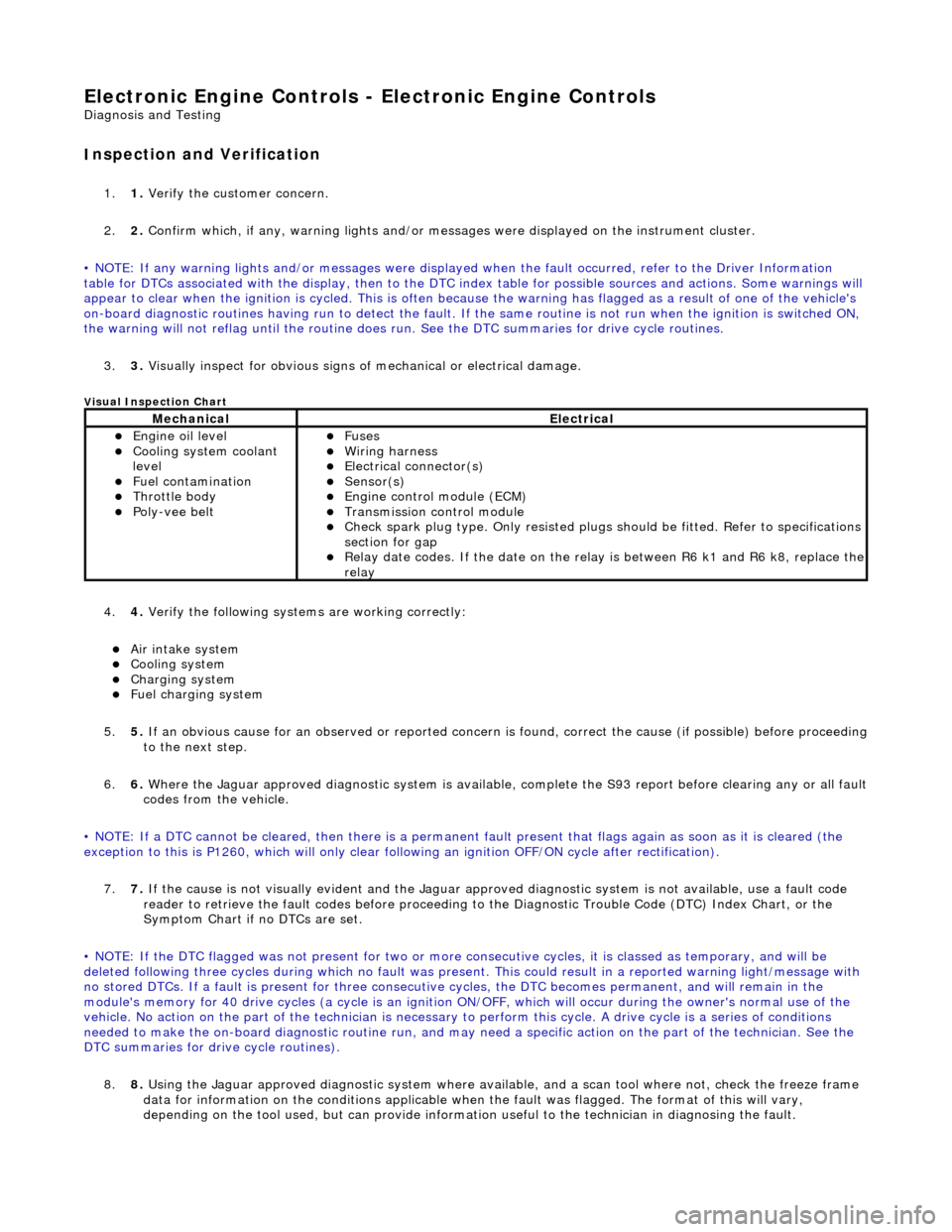

E

lectronic Engine Controls -

Electronic Engine Controls

D

iagnosis and Testing

I

nspection and Verification

1.

1. Veri

fy the customer concern.

2. 2. Confirm which, if any, warning li ghts and/or messages were displayed on the instrument cluster.

• NOTE: If any warning lights and/or me ssages were displayed when the fault occurred, refer to the Driver Information

table for DTCs associated with the display, then to the DTC index table for possible sources and actions. Some warnings will

appear to clear when the ignition is cycl ed. This is often because the warning has flagged as a resu lt of one of the vehicle's

on-board diagnostic routines having run to detect the fault. If the same routine is not run when the ignition is switched ON,

the warning will not reflag until the routine does run. See the DTC summaries for drive cycle routines.

3. 3. Visually inspect for obvious signs of mechanical or electrical damage.

V

isual Inspection Chart

4.

4. Veri

fy the following syst

ems are working correctly:

пЃ¬Air in

take system

пЃ¬Coo

ling system

пЃ¬Charging system

пЃ¬F

uel charging system

5. 5. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding

to the next step.

6. 6. Where the Jaguar approved diagnostic sy stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared (the

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

7. 7. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

• NOTE: If the DTC flagged was not present for two or more co nsecutive cycles, it is classed as temporary, and will be

deleted following three cycl es during which no fault was present. This could result in a reported wa rning light/message with

no stored DTCs. If a fault is present for three consecutive cycles, the DTC becomes permanent, and will remain in the

module's memory for 40 drive cycles (a cy cle is an ignition ON/OFF, which will occur during the owner's normal use of the

vehicle. No action on the part of the technician is necessary to perform this cycle. A drive cycle is a series of conditions

needed to make the on-board diagnostic ro utine run, and may need a specific action on the part of the technician. See the

DTC summaries for driv e cycle routines).

8. 8. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

dependin

g o

n the tool used, but can provide information useful to the technician in dia

gnos

in

g th

e fault.

MechanicalElectrical

пЃ¬Engi

ne oil level

пЃ¬Coo

ling system coolant

level

пЃ¬Fuel contamination

пЃ¬Throttle body пЃ¬Poly

-vee belt

пЃ¬F

uses

пЃ¬W

iring harness

пЃ¬E

lectrical connector(s)

пЃ¬Sens

or(s)

пЃ¬Engine

control module (ECM)

пЃ¬Tran

smission control module

пЃ¬Check spark plu

g type. Only re

sisted plugs should be fitted. Refer to specifications

section for gap

пЃ¬Relay date codes.

If the date on the rela

y is between R6 k1 and R6 k8, replace the

relay