air condition JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 368 of 2490

Rear Disc Brake - Brake CaliperVehicles W

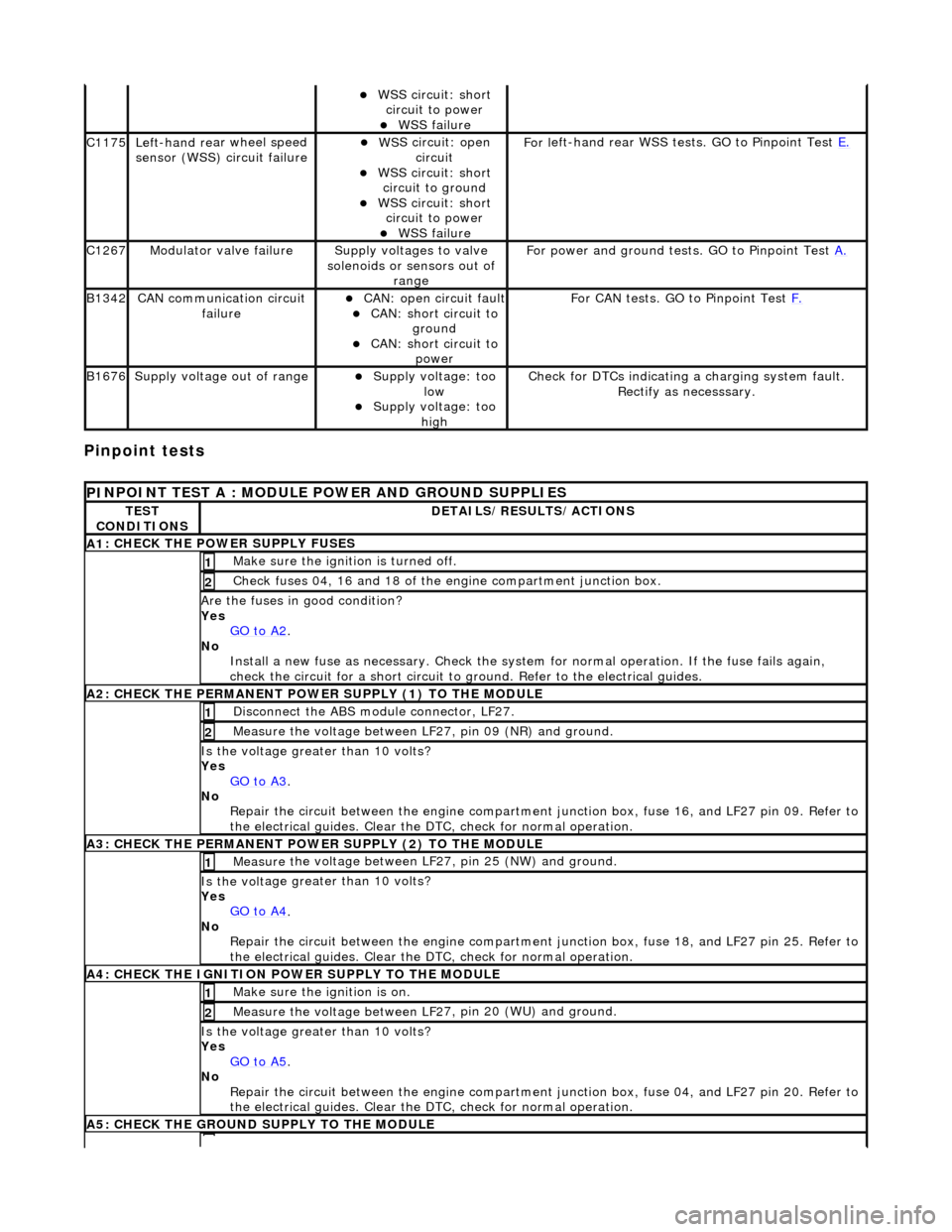

ith: Standard Brakes

Re

mo

val and Installation

Remov

a

l

WA

RNING: BRAKE DUST, IF INHALED CAN DAMAGE YOUR

HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

The brake pad adhesive backing must not be reused, therefore always install new brake pads, irrespective of the

condition of the original pads when replacing a brake caliper. Always replace brake pads as an axle set.

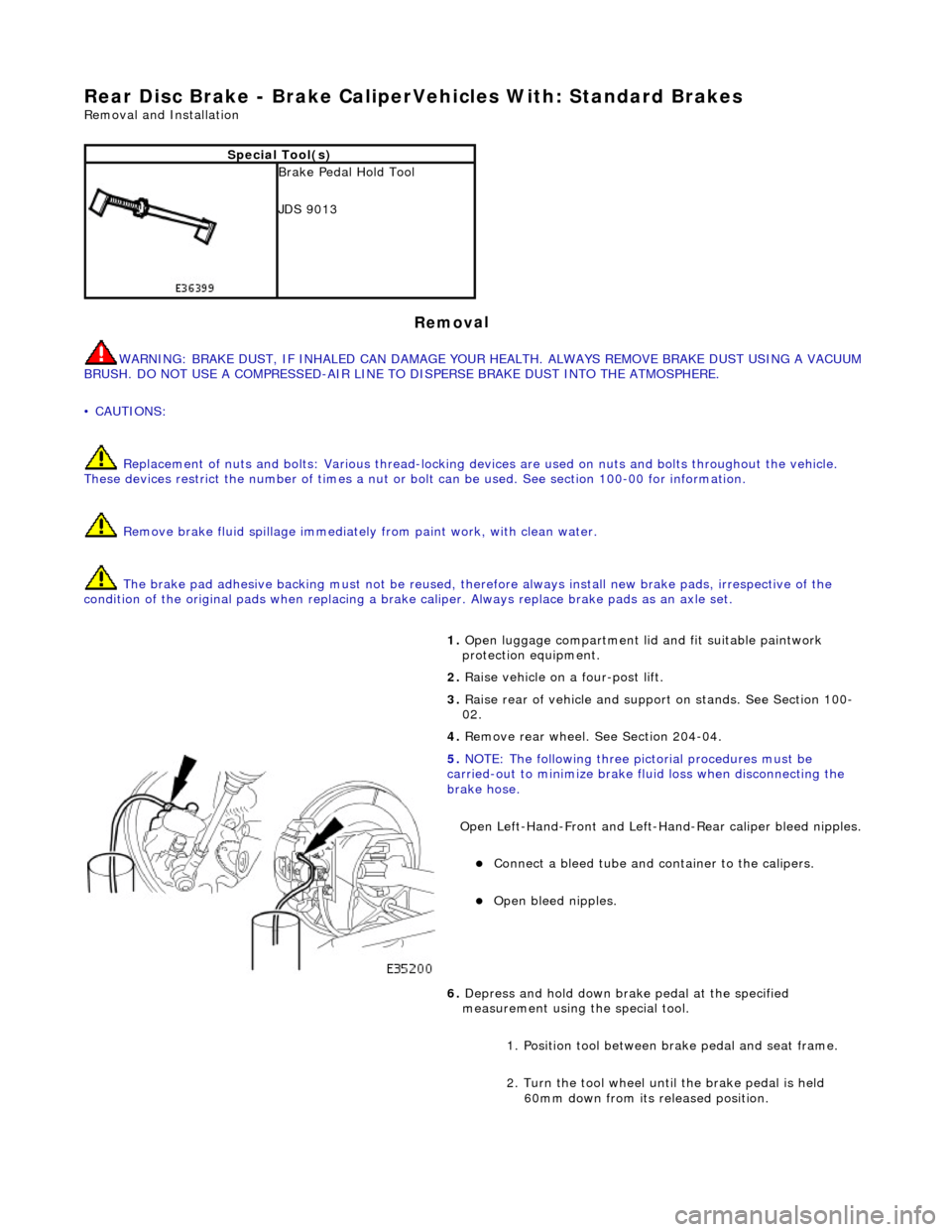

Sp

ecial Tool(s)

Brake Pedal

H

old Tool

JDS 9013

1. Op

en luggage compartment lid and fit suitable paintwork

protection equipment.

2. Raise vehicle on a four-post lift.

3. Raise rear of vehicl e and support on stan ds. See Section 100-

02.

4. Remove rear wheel. See Section 204-04.

5. NOTE

: Th

e following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake hose.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

пЃ¬Connect a

bleed tube and co

ntainer to the calipers.

пЃ¬Op

en bleed nipples.

6. Depress and hold down brak e pedal at the specified

measurement using the special tool.

1. Position tool between brake pedal and seat frame.

2. Turn the tool wheel unti l the brake pedal is held

60mm down from its released position.

Page 376 of 2490

Rear Disc

Brake - Brake DiscVe

hicles With: Standard Brakes

Remo

val and Installation

Remov

a

l

• WAR

N

INGS:

BRAKE DISCS MUST ALWAYS BE REPLACED IN PAIRS.

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH.

DO NOT USE A COMPRESSED-AIR LINE TO DI SPERSE BRAKE DUST INTO THE ATMOSPHERE.

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

1. Op

en engine compartment and fit

paint work protection covers

to fenders.

2. Raise rear of vehicle and support on stands. Refer to section

100-02.

3. Remove rear wheels. Refer to section 204-04.

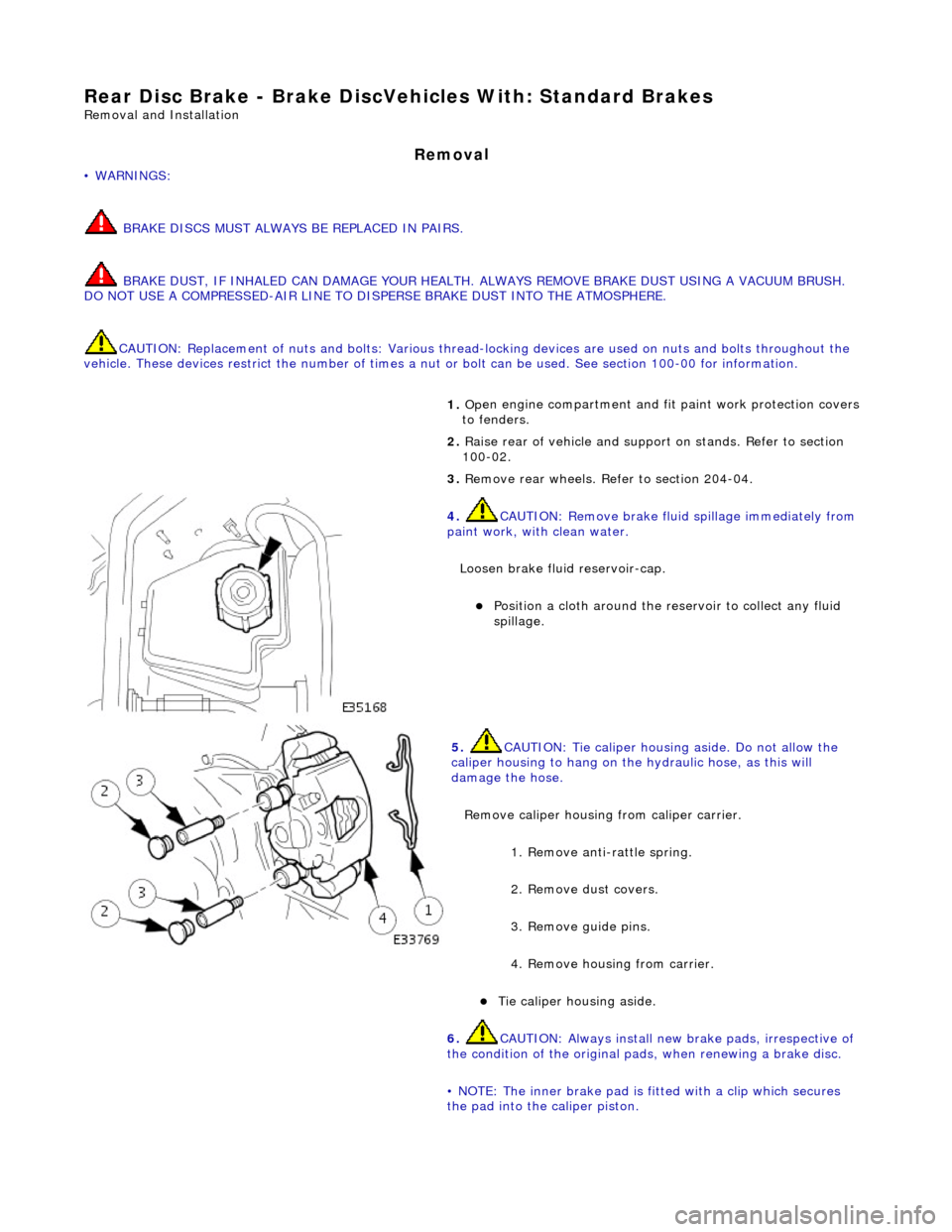

4. CAUTIO

N: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

пЃ¬Position a cloth around the reser

voir to collect any fluid

spillage.

5. CAUT

ION: Tie caliper housing aside. Do not allow the

caliper housing to hang on the hydraulic hose, as this will

damage the hose.

Remove caliper housing from caliper carrier.

1. Remove anti-rattle spring.

2. Remove dust covers.

3. Remove guide pins.

4. Remove housing from carrier.

пЃ¬Tie

caliper housing aside.

6.

CAUTIO

N: Always install new brake pads, irrespective of

the condition of the original pads, when renewing a brake disc.

• NOTE: The inner brake pad is fitted with a clip which secures

the pad into the caliper piston.

Page 380 of 2490

Rear Disc

Brake - Brake DiscVehicl

es With: High Performance Brakes

Remo

val and Installation

Remov

a

l

1.

WAR N

INGS:

BRAKE DISCS MUST ALWAYS BE REPLACED IN PAIRS.

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH.

ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH. DO

NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST

INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

See section 100-00 for information.

The Brembo caliper is aligned to the brake disc when it is

first installed to the vehicle, therefore, care must be taken not to

disturb this alignment. When removing the caliper; remove the

bolts that secure the anchor brac ket to the hub carrier only. DO

NOT loosen any other caliper bolts.

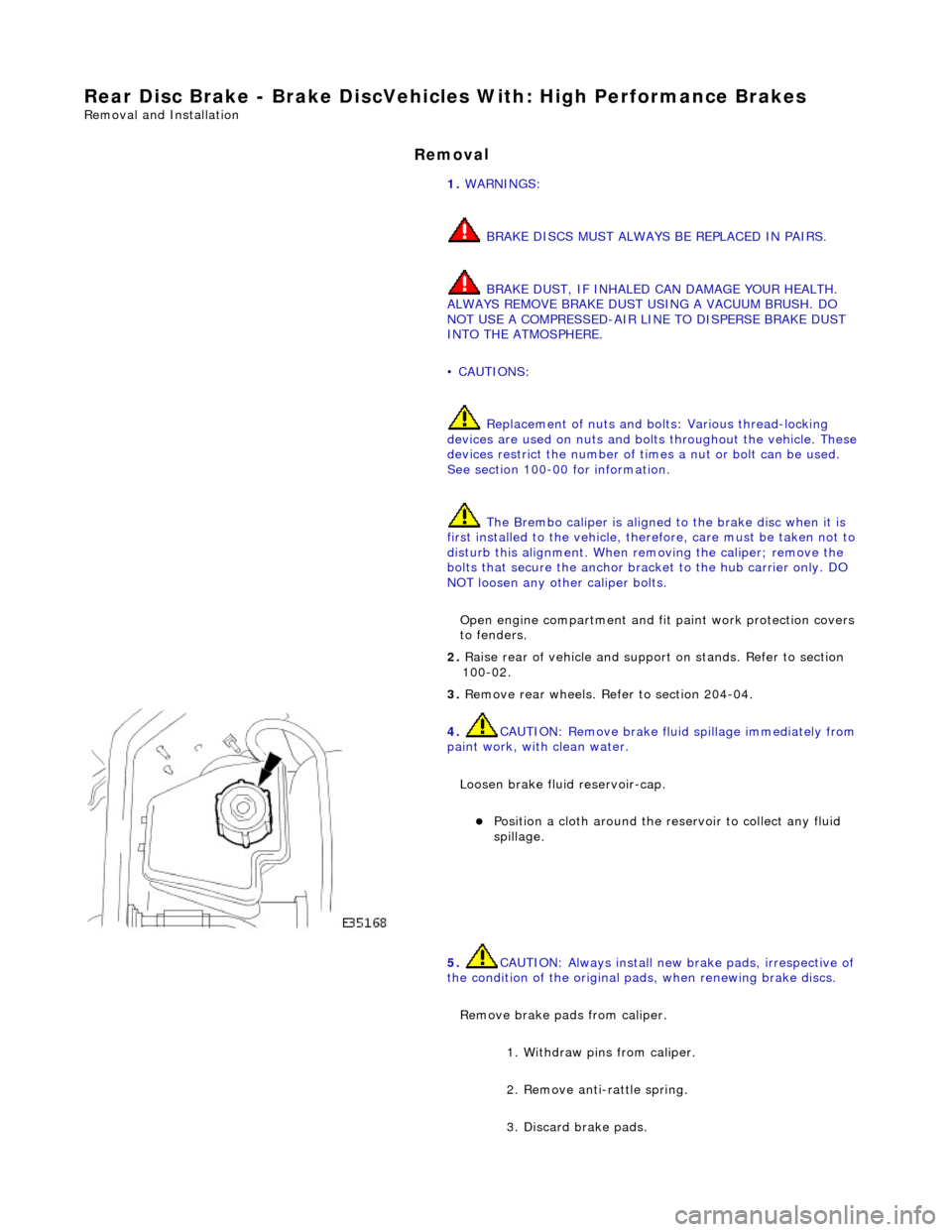

Open engine compartment and fit paint work protection covers

to fenders.

2. Ra

ise rear of vehicle and support

on stands. Refer to section

100-02.

3. Remove rear wheels. Refer to section 204-04.

4. CAUTIO

N: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

пЃ¬Position a cloth around the reser

voir to collect any fluid

spillage.

5. CAUTIO

N: Always install new brake pads, irrespective of

the condition of the original pads, when renewing brake discs.

Remove brake pads from caliper. 1. Withdraw pins from caliper.

2. Remove anti-rattle spring.

3. Discard brake pads.

Page 436 of 2490

Pinpoint tests

пЃ¬W

S

S circuit: short

circuit to power

пЃ¬WSS f

ailure

C1

175Left -hand re

ar wheel speed

sensor (WSS) circuit failure

пЃ¬W S

S circuit: open

circuit

пЃ¬WS

S circuit: short

circuit to ground

пЃ¬W S

S circuit: short

circuit to power

пЃ¬WSS f

ailure

F

or l

eft-hand rear WSS test

s. GO to Pinpoint Test E.

C1267Modulat or valv

e failure

Supply volt

ages

to valve

solenoids or sensors out of range

Fo

r power and ground tests. GO to Pinpoint Test

A.

B1342CAN co

mmunication circuit

failure

пЃ¬CAN :

open circuit fault

пЃ¬CAN:

short circuit to

ground

пЃ¬CAN :

short circuit to

power

Fo

r CAN tests. GO to Pinpoint Test

F.

B1676Supply volt

age out of range

пЃ¬Supply voltage:

too

low

пЃ¬Supply volt age:

too

high

Check fo

r DTCs indicating a charging system fault.

Rectify as necesssary.

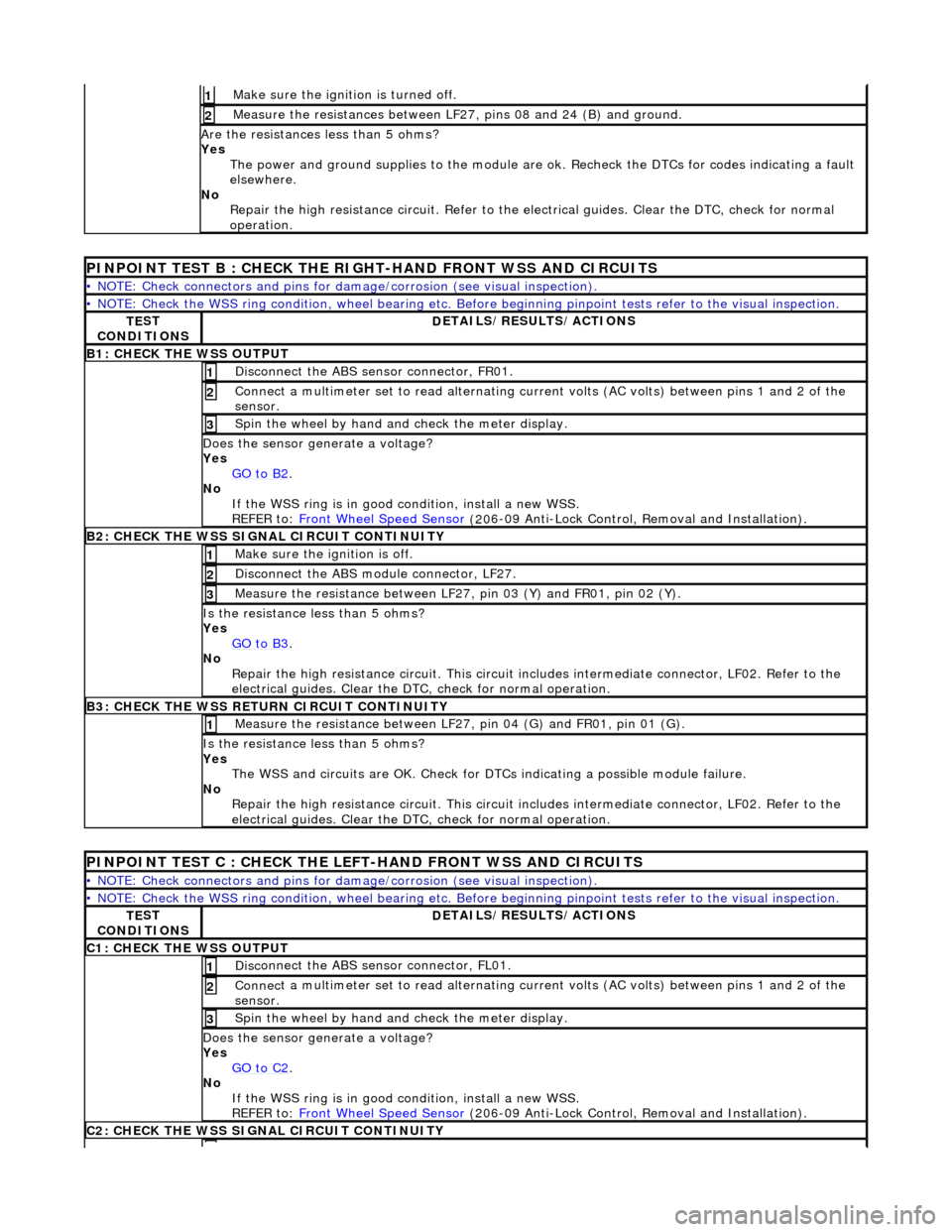

PI

NPOINT TEST A : MODULE

POWER AND GROUND SUPPLIES

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

A

1

: CHECK THE POWER SUPPLY FUSES

Make sure the igniti

on is turned off. 1

Chec

k fuses 04, 16 and 18 of the engine compartment junction box.

2

Are th

e fus

es in good condition?

Yes GO to A2

.

No

Install a new f

use as

necessary. Check the syst em for normal operation. If the fuse fails again,

check the circuit for a short circuit to ground. Refer to the electrical guides.

A2: CHECK THE PERMANENT

POWER SUPPLY (1) TO THE MODULE

Disc

onnect the ABS module connector, LF27.

1

Measure the voltage between LF

2

7, pin 09 (NR) and ground.

2

Is the vol

t

age greater than 10 volts?

Yes GO to A3

.

No Re

pair the circuit between the engine compartment

junction box, fuse 16, and LF27 pin 09. Refer to

the electrical guides. Clear the DTC, check for normal operation.

A3: CHECK THE PERMANENT

POWER SUPPLY (2) TO THE MODULE

Meas

ure t

he voltage between LF27, pin 25 (NW) and ground.

1

Is the vol

t

age greater than 10 volts?

Yes GO to A4

.

No

Re

pair the circuit between the engine compartment ju

nction box, fuse 18, and LF27 pin 25. Refer to

the electrical guides. Clear the DTC, check for normal operation.

A4: CHECK

THE IGNITION POWER SUPPLY TO THE MODULE

Make sure the ignition is on. 1

Measure the

voltage between LF 2

7, pin 20 (WU) and ground.

2

Is the vol

t

age greater than 10 volts?

Yes GO to A5

.

No Re

pair the circuit between the engine compartment ju

nction box, fuse 04, and LF27 pin 20. Refer to

the electrical guides. Clear the DTC, check for normal operation.

A5: CHECK

THE GROUND SUPPLY TO THE MODULE

Page 437 of 2490

Make sure the ignition is turned off. 1

Meas

ure the resistances between LF27,

pins 08 and 24 (B) and ground.

2

Are

the resistances less than 5 ohms?

Yes The power and ground supplies to the module are ok . Recheck the DTCs for codes indicating a fault

elsewhere.

No Repair the high resistance circui t. Refer to the electrical guides. Clear the DTC, check for normal

operation.

PINPOINT TE

ST B : CHECK THE RIGHT-HAND FRONT WSS AND CIRCUITS

•

NOTE: Check connectors and pins for damage/corrosion

(see visual inspection).

•

NOTE: Check the WSS ring condition, whee

l bearing etc. Before beginning pinpoint test s refer to the visual inspection.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

B1: CHECK

THE WSS OUTPUT

Disc

onnect the ABS sensor connector, FR01.

1

Connec

t a multimeter set

to read alternating curr ent volts (AC volts) between pins 1 and 2 of the

sensor.

2

Spin

the wheel by hand and check the meter display.

3

Doe

s the sensor generate a voltage?

Yes GO to B2

.

No

If the WSS ring is in good condition, install a new WSS.

REFER to: Front Wheel Speed Sensor

(20

6-09 Anti-Lock Control, Removal and Installation).

B2:

CHECK THE WSS SIGNAL CIRCUIT CONTINUITY

Make sure the ignition is off. 1

Di

sconnect the ABS module connector, LF27.

2

Meas

ure the resistance between LF27

, pin 03 (Y) and FR01, pin 02 (Y).

3

I

s the resistance less than 5 ohms?

Yes GO to B3

.

No

Repair the high resistance circui t. This circuit includes intermediate connector, LF02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

B3:

CHECK THE WSS RETURN CIRCUIT CONTINUITY

Meas

ure the resistance between LF27

, pin 04 (G) and FR01, pin 01 (G).

1

I

s the resistance less than 5 ohms?

Yes The WSS and circuits are OK. Check for DTCs indicating a possible module failure.

No Repair the high resistance circui t. This circuit includes intermediate connector, LF02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

P

INPOINT TEST C : CHECK THE LEFT-HAND FRONT WSS AND CIRCUITS

•

NOTE: Check connectors and pins for damage/corrosion

(see visual inspection).

•

NOTE: Check the WSS ring condition, whee

l bearing etc. Before beginning pinpoint test s refer to the visual inspection.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

C1

: CHECK THE WSS OUTPUT

Disc

onnect the ABS sensor connector, FL01.

1

Connec

t a multimeter set

to read alternating curr ent volts (AC volts) between pins 1 and 2 of the

sensor.

2

Spin

the wheel by hand and check the meter display.

3

Doe

s the sensor generate a voltage?

Yes GO to C2

.

No

If the WSS ring is in good condition, install a new WSS.

REFER to: Front Wheel Speed Sensor

(20

6-09 Anti-Lock Control, Removal and Installation).

C2

: CHECK THE WSS SIGNAL CIRCUIT CONTINUITY

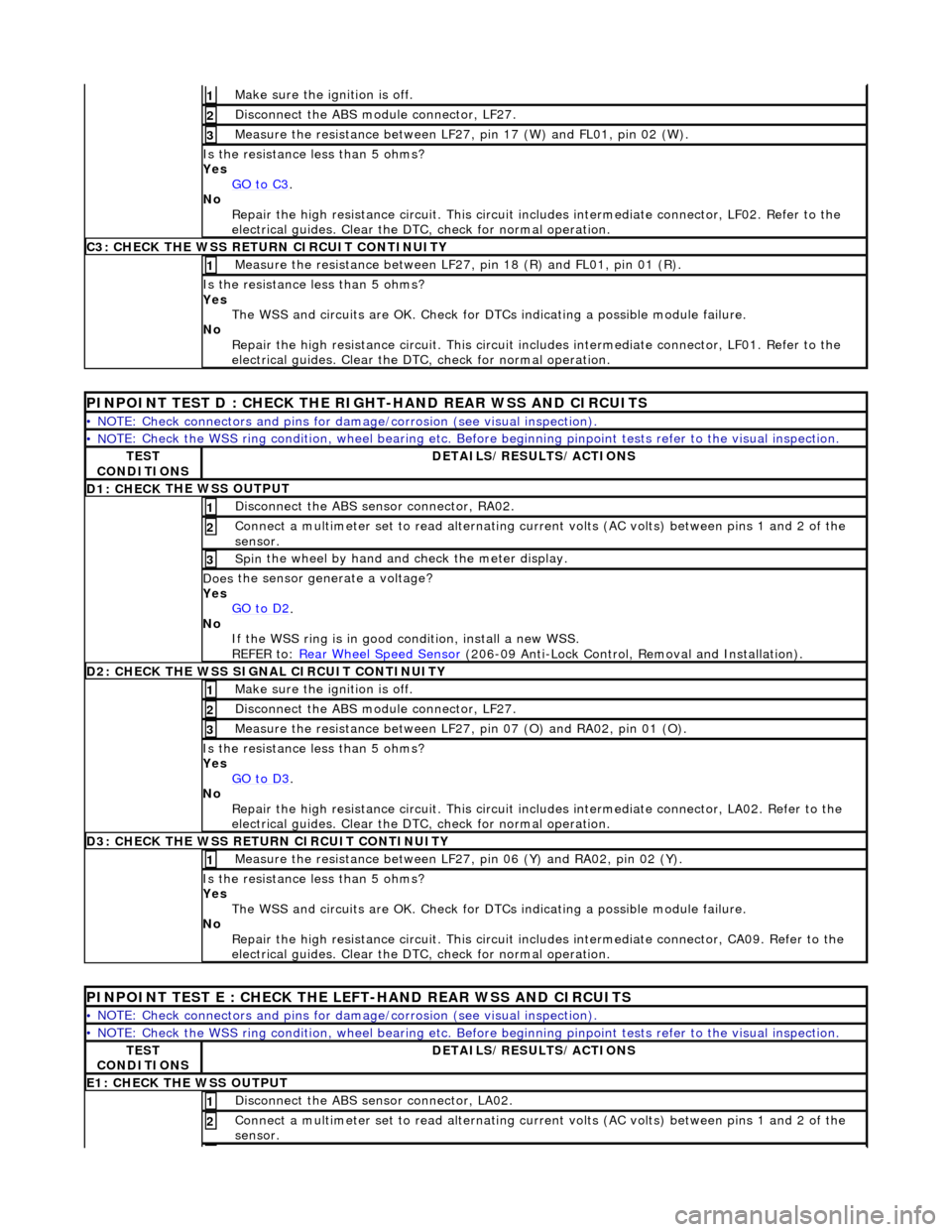

Page 438 of 2490

Make sure the ignition is off. 1

Disc

onnect the ABS module connector, LF27.

2

M

e

asure the resistance between LF27, pin 17 (W) and FL01, pin 02 (W).

3

I

s

the resistance less than 5 ohms?

Yes GO to C3

.

No

Re

pair the high resistance circui

t. This circuit includes intermed iate connector, LF02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

C3: CH

ECK THE WSS RETURN CIRCUIT CONTINUITY

Measure

the resistance between LF27, pin 18 (R) and FL01, pin 01 (R).

1

Is

the resistance less than 5 ohms?

Yes The WSS and circuits are OK. Check for DTCs indicating a possible module failure.

No Repair the high resistance circui t. This circuit includes intermediate connector, LF01. Refer to the

electrical guides. Clear the DTC, check for normal operation.

PI

NPOINT TEST D : CHECK THE RIGH

T-HAND REAR WSS AND CIRCUITS

•

NOTE: Check connectors and pins for damage/corrosion

(see visual inspection).

• NO

TE: Check the WSS ring condition, whee

l bearing etc. Before beginning pinpoint test s refer to the visual inspection.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

D1: CHECK

THE WSS OUTPUT

Disc

onne

ct the ABS sensor connector, RA02.

1

Connec

t

a multimeter set

to read alternating curr ent volts (AC volts) between pins 1 and 2 of the

sensor.

2

Spin

the wheel by hand and check the meter display.

3

Doe

s

the sensor generate a voltage?

Yes GO to D2

.

No

If

the WSS ring is in good condition, install a new WSS.

REFER to: Rear Wheel Speed Sensor

(206-0

9 Anti-Lock Control, Removal and Installation).

D

2

: CHECK THE WSS SIGNAL CIRCUIT CONTINUITY

Make sure the ignition is off. 1

Disc

onnect the ABS module connector, LF27.

2

Measure t

he resistance between LF27

, pin 07 (O) and RA02, pin 01 (O).

3

Is

the resistance less than 5 ohms?

Yes GO to D3

.

No Re

pair the high resistance circui

t. This circuit includes intermed iate connector, LA02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

D3:

CHECK THE WSS RETURN CIRCUIT CONTINUITY

Meas

ure t

he resistance between LF27

, pin 06 (Y) and RA02, pin 02 (Y).

1

Is

the resistance less than 5 ohms?

Yes The WSS and circuits are OK. Check for DTCs indicating a possible module failure.

No Repair the high resistance circui t. This circuit includes intermediate connector, CA09. Refer to the

electrical guides. Clear the DTC, check for normal operation.

PI

NPOINT TEST E : CHECK THE LEFT-HAND REAR WSS AND CIRCUITS

•

NOTE: Check connectors and pins for damage/corrosion

(see visual inspection).

• NO

TE: Check the WSS ring condition, whee

l bearing etc. Before beginning pinpoint test s refer to the visual inspection.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

E1

: CHECK THE W

SS OUTPUT

Disc

onne

ct the ABS sensor connector, LA02.

1

Connec

t

a multimeter set

to read alternating curr ent volts (AC volts) between pins 1 and 2 of the

sensor.

2

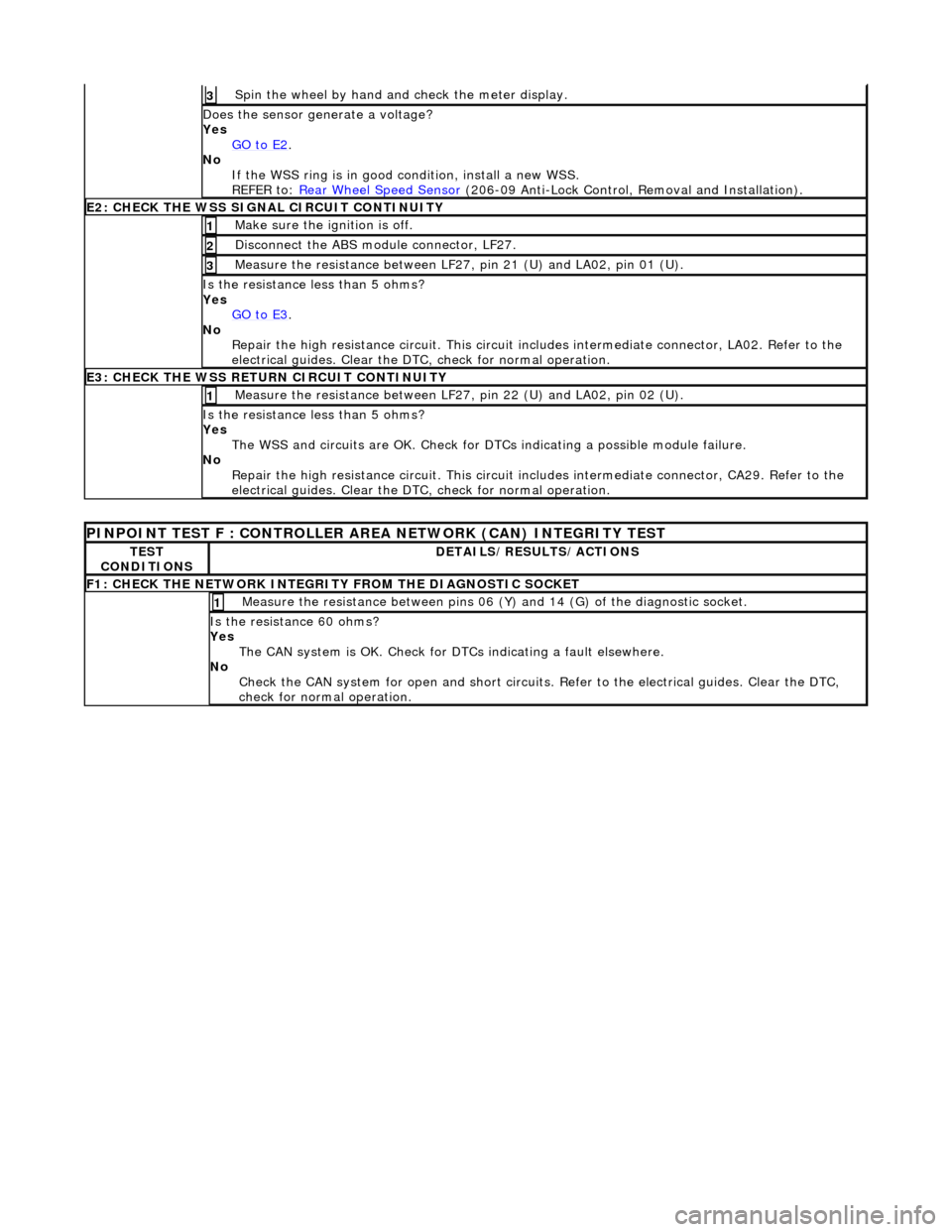

Page 439 of 2490

Spin

the wheel by hand and check the meter display.

3

Doe

s the sensor generate a voltage?

Yes GO to E2

.

No

If the WSS ring is in good condition, install a new WSS.

REFER to: Rear Wheel Speed Sensor

(20

6-09 Anti-Lock Control, Removal and Installation).

E2

: CHECK THE WSS SIGNAL CIRCUIT CONTINUITY

Make sure the ignition is off. 1

Di

sconnect the ABS module connector, LF27.

2

Meas

ure the resistance between LF27

, pin 21 (U) and LA02, pin 01 (U).

3

I

s the resistance less than 5 ohms?

Yes GO to E3

.

No

Repair the high resistance circui t. This circuit includes intermediate connector, LA02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

E3

: CHECK THE WSS RETURN CIRCUIT CONTINUITY

Meas

ure the resistance between LF27

, pin 22 (U) and LA02, pin 02 (U).

1

I

s the resistance less than 5 ohms?

Yes The WSS and circuits are OK. Check for DTCs indicating a possible module failure.

No Repair the high resistance circui t. This circuit includes intermediate connector, CA29. Refer to the

electrical guides. Clear the DTC, check for normal operation.

P

INPOINT TEST F : CONT

ROLLER AREA NETWORK (CAN) INTEGRITY TEST

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

F

1: CHECK THE NETWORK INTEGRITY

FROM THE DIAGNOSTIC SOCKET

M

easure the resistance between pins 06 (Y) and 14 (G) of the diagnostic socket.

1

I

s the resistance 60 ohms?

Yes The CAN system is OK. Check for DTCs indicating a fault elsewhere.

No Check the CAN system for open an d short circuits. Refer to the electrical guides. Clear the DTC,

check for normal operation.

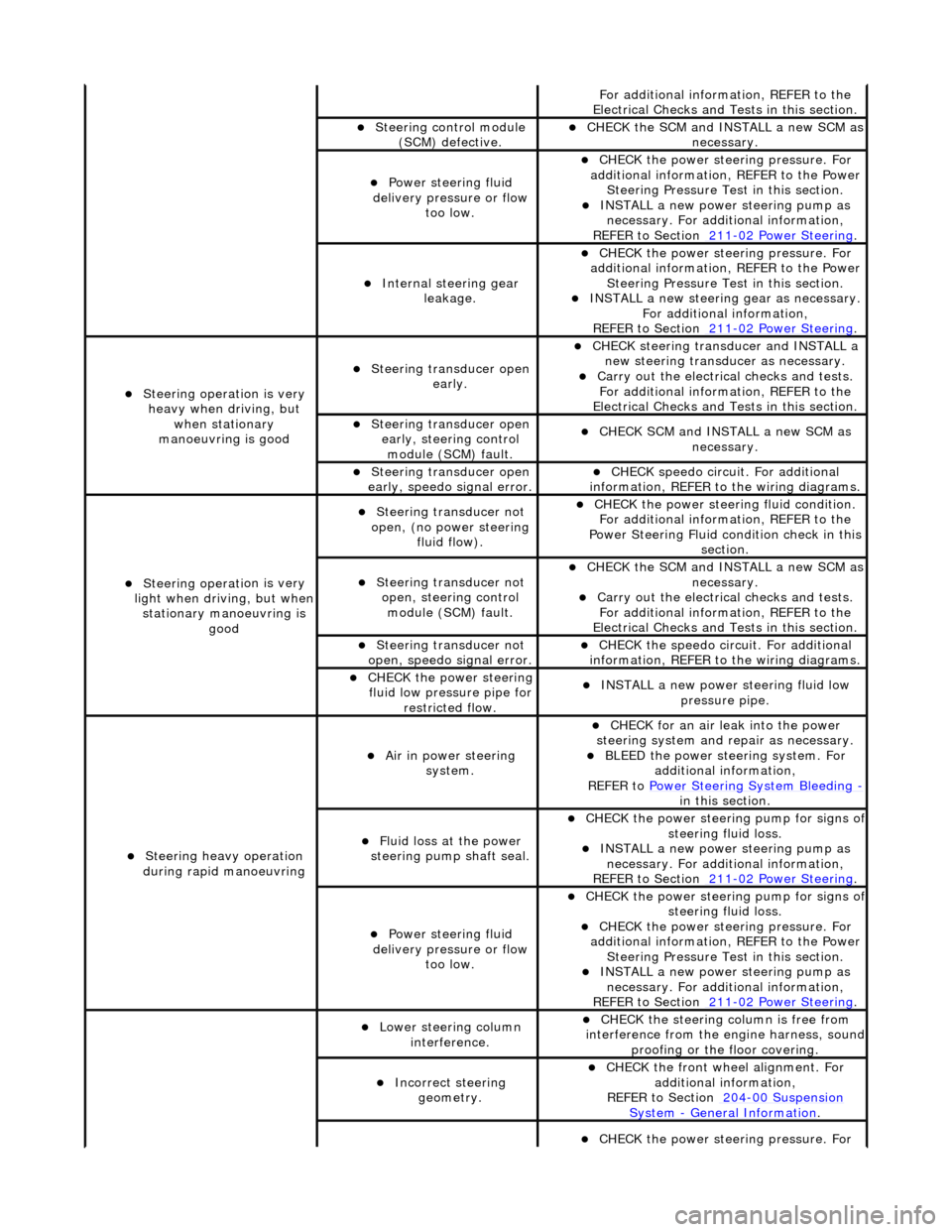

Page 462 of 2490

Fo

r additional information, REFER to the

Electrical Checks and Tests in this section.

пЃ¬Steering control

module

(SCM) defective.

пЃ¬CHECK

the SCM and INSTALL a new SCM as

necessary.

пЃ¬Power steeri ng f

luid

delivery pressure or flow too low.

пЃ¬CHECK

the power stee

ring pressure. For

additional information, REFER to the Power Steering Pressure Test in this section.

пЃ¬INSTALL a ne

w power steering pump as

necessary. For additi onal information,

REFER to Section 211

-0 2

Power Steering

.

пЃ¬Internal steering gear

leakage.

пЃ¬CHECK

the power stee

ring pressure. For

additional information, REFER to the Power Steering Pressure Test in this section.

пЃ¬INSTALL a ne

w steering

gear as necessary.

For additional information,

REFER to Section 211

-0 2

Power Steering

.

пЃ¬Steeri

ng operati

on is very

heavy when driving, but when stationary

manoeuvring is good

пЃ¬Steering transducer open earl

y.

пЃ¬CHECK

steering transducer and INSTALL a

new steering transducer as necessary.

пЃ¬Carry out th

e electrical checks and tests.

For additional information, REFER to the

Electrical Checks and Tests in this section.

пЃ¬Steering transducer open

early,

steering control

module (SCM) fault.

пЃ¬CHECK

SCM and INSTALL a new SCM as

necessary.

пЃ¬Steering transducer open

earl

y, speedo signal error.

пЃ¬CHECK

speedo

circui

t. For additional

information, REFER to the wiring diagrams.

пЃ¬Steeri ng operati

on is very

light when driving, but when

stationary manoeuvring is good

пЃ¬Steering transducer not

o

pen, (no power steering

fluid flow).

пЃ¬CHECK

the power steering fluid condition.

For additional information, REFER to the

Power Steering Fluid condition check in this section.

пЃ¬Steering transducer not o

pen, steering control

module (SCM) fault.

пЃ¬CHECK

the SCM and INSTALL a new SCM as

necessary.

пЃ¬Carry out th

e electrical checks and tests.

For additional information, REFER to the

Electrical Checks and Tests in this section.

пЃ¬Steering transducer not

o

pen, speedo signal error.

пЃ¬CHECK

the speedo circ

uit. For additional

information, REFER to the wiring diagrams.

пЃ¬CHECK

the power steering

fluid low pressure pipe for restricted flow.

пЃ¬INSTALL a ne

w power steering fluid low

pressure pipe.

пЃ¬S t

eering heavy operation

during rapid manoeuvring

пЃ¬Ai r i

n power steering

system.

пЃ¬CHECK for an air l

eak into the power

steering system and re pair as necessary.

пЃ¬BLEED the

power steering system. For

additional information,

REFER to Power Steering System Bleeding

- in t hi

s section.

пЃ¬Fluid loss at the power

steering pump shaft seal.

пЃ¬CHECK the power steer

ing pump for signs o

f steering fl

ui

d loss.

пЃ¬INST

ALL a ne

w power steering pump as

necessary. For additi onal information,

REFER to Section 211

-0 2

Power Steering

.

пЃ¬Power steeri

ng f

luid

delivery pressure or flow too low.

пЃ¬CHECK the power steer

ing pump for signs o

f steering fl

ui

d loss.

пЃ¬CHECK

the power stee

ring pressure. For

additional information, REFER to the Power Steering Pressure Test in this section.

пЃ¬INSTALL a ne

w power steering pump as

necessary. For additi onal information,

REFER to Section 211

-02

Power Steering

.

пЃ¬Lower steeri

ng col

umn

interference.

пЃ¬CHECK

the steering co

lumn is free from

interference from the en gine harness, sound

proofing or the floor covering.

пЃ¬Incorrect steering geometry. пЃ¬CHE

CK the front wheel alignment. For

additional information,

REFER to Section 204

-00 Sus

pension

Sy

ste

m

- General

Information

.

пЃ¬CHECK

the power stee

ring pressure. For

Page 464 of 2490

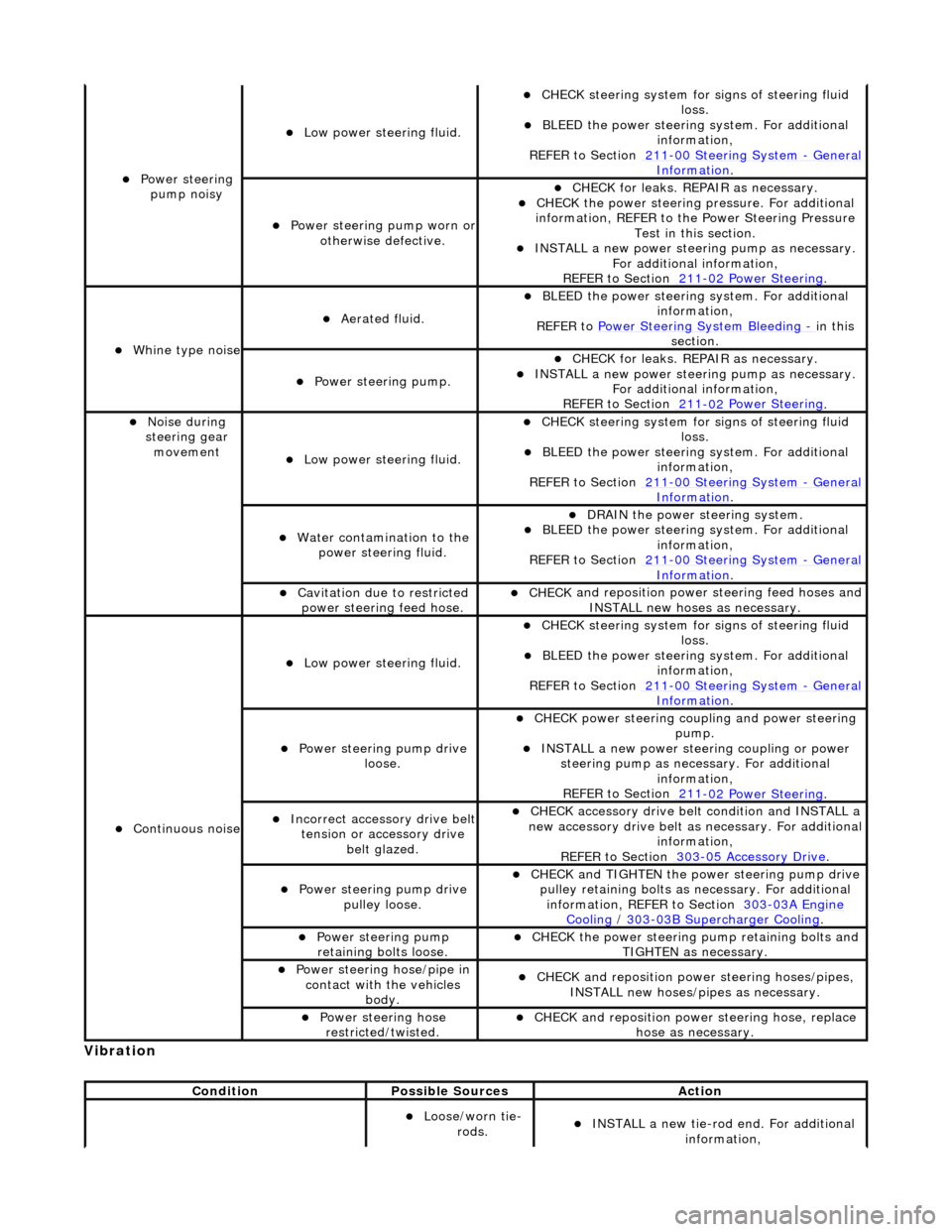

Vibrati

on

пЃ¬Power steeri

ng

pump noisy

пЃ¬Low power steer i

ng fluid.

пЃ¬CHECK

steering system for s

igns of steering fluid

loss.

пЃ¬BLEE D the

power steering system. For additional

information,

REFER to Section 211

-0 0

Steering System

-

Ge n

eral

Informati

o

n

.

пЃ¬Power steeri

ng pump wor

n or

otherwise defective.

пЃ¬CHECK for leaks. R

EPAIR as necessary.

пЃ¬CHECK

the power steering pressure. For additional

information, REFER to th e Power Steering Pressure

Test in this section.

пЃ¬INST ALL a ne

w power steering pump as necessary.

For additional information,

REFER to Section 211

-0 2

Power Steering

.

пЃ¬Wh

in

e type noise

пЃ¬Aerated flui

d.

пЃ¬BLEE

D the

power steering system. For additional

information,

REFER to Power Steering System Bleeding

- in t h

is

section.

пЃ¬Power steering pump.

пЃ¬CHECK for leaks. R

EPAIR as necessary.

пЃ¬INSTALL a ne

w power steering pump as necessary.

For additional information,

REFER to Section 211

-0 2

Power Steering

.

пЃ¬No

i

se during

steering gear movement

пЃ¬Low power steer i

ng fluid.

пЃ¬CHECK

steering system for s

igns of steering fluid

loss.

пЃ¬BLEE D the

power steering system. For additional

information,

REFER to Section 211

-0 0

Steering System

-

Ge n

eral

Informati

o

n

.

пЃ¬Water co

n

tamination to the

power steering fluid.

пЃ¬DR AIN

the power steering system.

пЃ¬BLEE

D the

power steering system. For additional

information,

REFER to Section 211

-00

Steering System

-

Gen

eral

Informati

o

n

.

пЃ¬Cavi

tation due to restricted

po

wer steering feed hose.

пЃ¬CHECK

and reposition power

steering feed hoses and

INSTALL new hoses as necessary.

пЃ¬Continu o

us noise

пЃ¬Low power steer i

ng fluid.

пЃ¬CHECK

steering system for s

igns of steering fluid

loss.

пЃ¬BLEE D the

power steering system. For additional

information,

REFER to Section 211

-0 0

Steering System

-

Ge n

eral

Informati

o

n

.

пЃ¬Power steeri

ng pump dri

ve

loose.

пЃ¬CHECK

power steering coupli

ng and power steering

pump.

пЃ¬IN ST

ALL a new power steering coupling or power

steering pump as nece ssary. For additional

information,

REFER to Section 211

-0 2

Power Steering

.

пЃ¬Incorre

ct

accessory drive belt

tension or accessory drive belt glazed.

пЃ¬CHECK acc

essory drive belt condition and INSTALL a

new accessory drive belt as necessary. For additional

information,

REFER to Section 303

-0 5 Ac

cessory Drive

.

пЃ¬Power steeri

ng pump dri

ve

pulley loose.

пЃ¬CHECK

and TIGHTEN the power steering pump drive

pulley retaining bolts as necessary. For additional

information, REFER to Section 303

-03A En

gine

Coo

ling / 30 3-03

B Supercharger Cooling

.

пЃ¬Power steeri

ng pump

r

etaining bolts loose.

пЃ¬CHECK

the power steering pump retaining bolts and

TIGHTEN as necessary.

пЃ¬Power steering hose/pipe in c

ontact with the vehicles

body.

пЃ¬CHECK

and reposition powe

r steering hoses/pipes,

INSTALL new hoses/pipes as necessary.

пЃ¬Power steeri ng hose

r

estricted/twisted.

пЃ¬CHECK

and reposition powe

r steering hose, replace

hose as necessary.

Conditi

on

Possibl

e Sources

Actio

n

пЃ¬Loose/worn tie-

ro

ds.

пЃ¬INST

ALL a new tie-r

od end. For additional

information,

Page 522 of 2490

diverter val

ve (if fitted) and oil filter.

пЃ¬Main

bearings

which are grooved in the upper positions and plain in

the lower positions. They are manufactured from

aluminium / tin material.

пЃ¬A c

rankshaft with under

cuts and rolled fillets for extra strength.

пЃ¬Fracture

-split connecting rods in sintered-forged steel.

пЃ¬Brackets

bolted to the front of

the cylinder

block are used to mo unt all accessories.

пЃ¬A sin

gle, seven ribbed vee belt

drives the accessories.

пЃ¬An au

tomatic belt tensioner for the front accessory drive,

incorporating a wear indicator.

пЃ¬An advanced en

gine management system inco

rporating electronic throttle control.

пЃ¬The un

it meets the requirements of the CARB OBDII USA legislation.

Ancillary Systems

The an

ci

llary systems, driven by the engine, each have a

detailed Description and Operation along with Diagnostic

Procedures, and Removal and Installation instructions ; refer to the following sections of this manual:

пЃ¬Power Steeri

ng Pump - Section 211-02

пЃ¬Ai

r Conditioning Compressor - Sectio

n 412-03

пЃ¬Engine

C

ooling Pump - Section 303-03

пЃ¬Generator

- Sectio

n 414-02

The drive belt, idler pulley and automatic tensioner are described in Section 303-05.

The engine starting system is described in Section 303-06.

En

gine Management and Emission Control System

Engine Control Modu

le (ECM)

Engine

management and exhaust emissions are controlled by the ECM, which has the

following main functions:

пЃ¬Fu

el injection

пЃ¬Idle

s

peed

пЃ¬Ignition пЃ¬Ev

aporative loss system

пЃ¬Engine

cooling fans пЃ¬Clim

ate control compressor clutch demand

The microprocessor within the ECM receiv es signals from various sensors and other modules and uses a pre-determined

program to compute engine management functions.

Adaptive functions are incorporated in the ECM to cater for co ntinuous adjustments to its computations to suit prevailing

conditions. Because the system also controls emissions to suit all modes, neither CO levels nor idle speed require service

attention or adjustment, except if an error should occur.

On Board Diagnostics are controlled by the ECM with the continuous monitoring of incoming signals and the subsequent

verification against what the module expects to 'see'. Should a si gnal be incorrect or missing, the ECM will substitute a fixed

value to provide the 'limp home mode' and alert the driver of the problem. Fixed values may be adopted for:

пЃ¬Transmission oil

temperature

пЃ¬Mechanica

l

guar

d position

пЃ¬Throttle blade angle пЃ¬Camshaft position

пЃ¬Inta

k

e air temperature

Diagnostic trouble codes (DTC), including OBD II codes, are stored in the ECM memo ry and can be read by an appropriate

retrieval tool.

Should either the ECM or TCM fa il, ensure that the control housing cooling fan is operating correctly. Failure of the cooling

fan MUST be rectified before renewing a control module and details of a fa n failure should accompany a returned control

module.