fuel ratio JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1190 of 2490

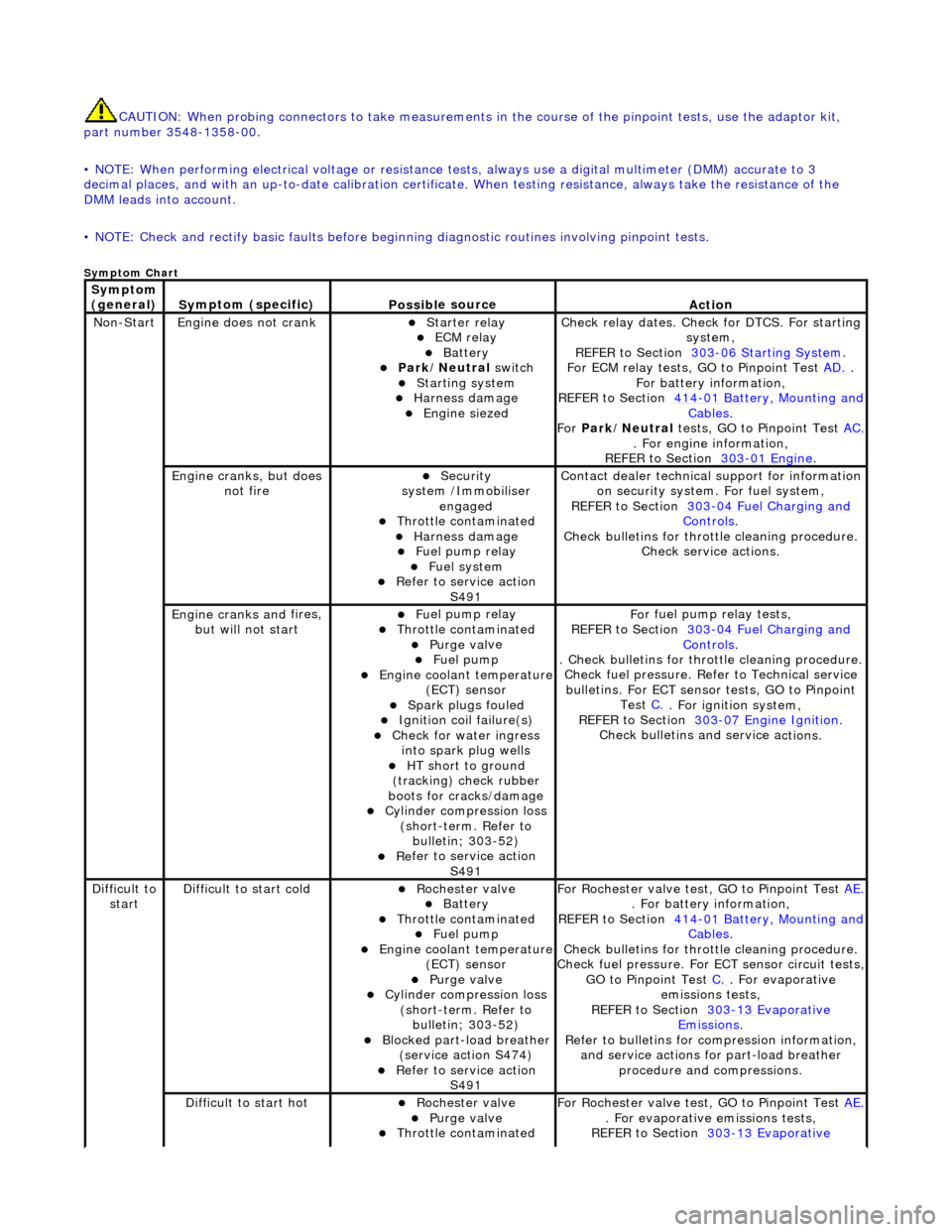

CAUTIO

N: When probing connectors to take

measurements in the course of the pinpoint tests, use the adaptor kit,

part number 3548-1358-00.

• NOTE: When performing electrical voltag e or resistance tests, always use a digital multimeter (DMM) accurate to 3

decimal places, and with an up-t o-date calibration certificate. When testing resistance, always take the resistance of the

DMM leads into account.

• NOTE: Check and rectify basic faults before beginning diagnostic ro utines involving pinpoint tests.

Sym

ptom Chart

Sym

ptom

(general)

S y

mptom (specific)

Possib

l

e source

Acti

o

n

No

n

-Start

Engine

does not cran

k

Starter relay ECM relay Batt

ery Park

/Neutral

switch

Starting system

Harness damage

Engine s

iezed

Check r

e

lay dates. Check

for DTCS. For starting

system,

REFER to Section 303

-06 Sta r

ting System

.

F or ECM

relay tests, GO to Pinpoint Test

AD.

.

F o

r battery information,

REFER to Section 414

-0 1

Battery, Mounting and

Cables.

Fo r

Park/Neutral tests, GO to Pinpoint Test AC.

. Fo

r engine information,

REFER to Section 303

-01 En

gine

.

Engine cranks, but does

not fireSecurity

syst

em /Immobiliser

engaged

Thr o

ttle contaminated

Harness damage

Fu

el pump relay

Fue

l

system

R

e

fer to service action

S491

Contact dealer techni

cal

support for information

on security system. For fuel system,

REFER to Section 303

-0 4

Fuel Charging and

Controls.

Check bull etins for throttl

e cleaning procedure.

Check service actions.

Engine cranks an d

fires,

but will not start

F u

el pump relay

Thr

o

ttle contaminated

Purge

val

ve

Fue

l

pump

Engine coolan

t

temperature

(ECT) sensor

Spark plugs

fouled

Ignition coil

fail

ure(s)

Check f

o

r water ingress

into spark plug wells

HT sh o

rt to ground

(tracking) check rubber

boots for cracks/damage

Cyli

nder compression loss

(short-term. Refer to bulletin; 303-52)

Re

fer to service action

S491

Fo

r fuel pump relay tests,

REFER to Section 303

-0 4

Fuel Charging and

Controls.

. Check bulletins for throttl

e cleaning procedure.

Check fuel pressure. Refe r to Technical service

bulletins. For ECT sensor tests, GO to Pinpoint Test C.

. Fo

r ignition system,

REFER to Section 303

-07 En

gine Ignition

.

Check bulletins an d service a

ctions.

Di

f

ficult to

start

D iff

icult to start cold

Roc

h

ester valve

Batt

ery Thro

ttle contaminated

Fue

l

pump

Engine coolan

t

temperature

(ECT) sensor

Purge val

ve

Cyl

i

nder compression loss

(short-term. Refer to bulletin; 303-52)

Blocked part-load breather (s

ervice action S474)

R

e

fer to service action

S491

For R

ochester valv

e test, GO to Pinpoint Test AE.

. Fo

r battery information,

REFER to Section 414

-0 1

Battery, Mounting and

Cables.

Check bull etins for throttl

e cleaning procedure.

Check fuel pressure. For ECT sensor circuit tests,

GO to Pinpoint Test C.

. F

or evaporative

emissions tests,

REFER to Section 303

-1 3

Evaporative

Emiss

i

ons

.

R e

fer to bulletins for co

mpression information,

and service actions for part-load breather procedure and compressions.

Diff

icult to start hot

Roc

h

ester valve

Purge

val

ve

Thr

o

ttle contaminated

F

or R

ochester valv

e test, GO to Pinpoint Test AE.

. F

or evaporative emissions tests,

REFER to Section 303

-1 3

Evaporative

Page 1192 of 2490

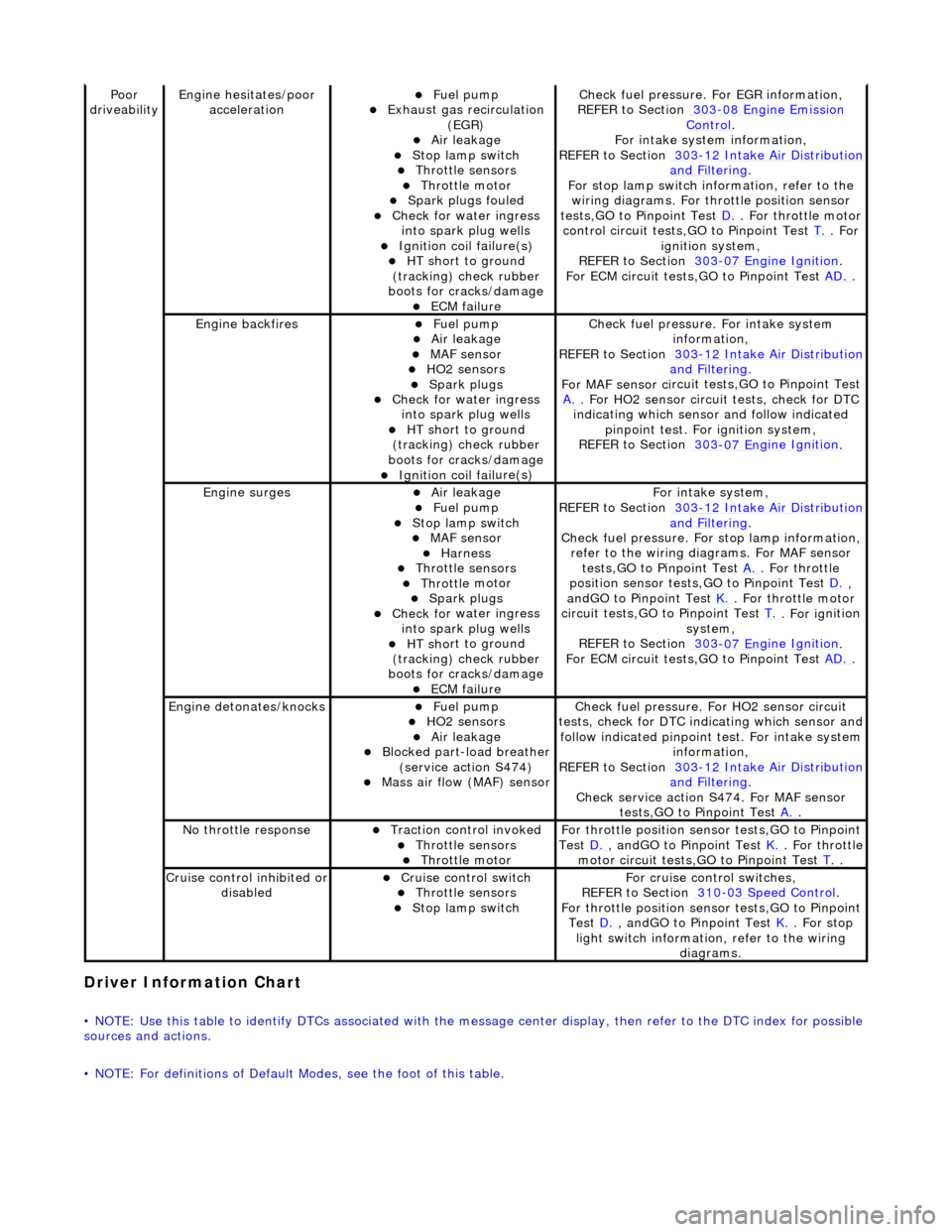

Driver Information

Chart

•

NOTE: Use this table to identify DTCs associated with the me

ssage center display, then refer to the DTC index for possible

sources and actions.

• NOTE: For definitions of Default Modes, see the foot of this table.

Poor

dr iveabilityEngine h e

sitates/poor

acceleration

Fue l

pump

Exhaus

t gas

recirculation

(EGR)

Air leakage Stop lamp swi t

ch

Throttl

e

sensors

Throttl

e

motor

Spark

plugs

fouled

Check f

o

r water ingress

into spark plug wells

Ignition coil fail

ure(s)

HT sh

o

rt to ground

(tracking) check rubber

boots for cracks/damage

ECM failu r

e

Check f

u

el pressure. For EGR information,

REFER to Section 303

-08 En gin

e Emission

Control.

F or i

ntake system information,

REFER to Section 303

-1 2

Intake Air Distribution

and F

ilt

ering

.

F or stop l

amp switch in

formation, refer to the

wiring diagrams. For throttle position sensor

tests,GO to Pinpoint Test D.

. Fo

r throttle motor

control circuit tests,GO to Pinpoint Test T.

. For

igni t

ion system,

REFER to Section 303

-07 En

gine Ignition

.

F or ECM

circuit tests,GO to Pinpoint Test

AD.

.

Engine backfiresFuel

pump

Air leakage MAF se

nsor

HO2 sensors

Spark plugs Check fo

r water ingress

into spark plug wells

HT sh o

rt to ground

(tracking) check rubber

boots for cracks/damage

Ignition coil fail

ure(s)

Chec

k fu

el pressure. For intake system

information,

REFER to Section 303

-12

Intake Air Distribution

and Filt

ering

.

F or MAF sensor ci

rcuit test

s,GO to Pinpoint Test

A.

. F or HO2 sensor

circui

t tests, check for DTC

indicating which sensor and follow indicated pinpoint test. For ignition system,

REFER to Section 303

-07 En

gine Ignition

.

Engine

s

urges

Air leakage

Fuel

pump

Stop lamp swit

ch

MAF s

e

nsor

Harness Throttl

e

sensors

Throttl

e

motor

Spark plugs

Check fo

r water ingress

into spark plug wells

HT sh o

rt to ground

(tracking) check rubber

boots for cracks/damage

ECM failu r

e

Fo

r

intake system,

REFER to Section 303

-1 2

Intake Air Distribution

and Filt

ering

.

Check fu

el pressure. For

stop lamp information,

refer to the wiring diagrams. For MAF sensor tests,GO to Pinpoint Test A.

. Fo

r throttle

position sensor tests,GO to Pinpoint Test D.

,

a n

dGO to Pinpoint Test

K.

. Fo

r throttle motor

circuit tests,GO to Pinpoint Test T.

. For ig

nition

system,

REFER to Section 303

-07 En

gine Ignition

.

F or ECM

circuit tests,GO to Pinpoint Test

AD.

.

Engine detonates/k

nocks

Fue

l

pump

HO2 sensors

Air leakage Blocked part-load breather

(s

ervice action S474)

Mass ai

r fl

ow (MAF) sensor

Chec

k fu

el pressure. Fo

r HO2 sensor circuit

tests, check for DTC indicating which sensor and

follow indicated pinpoint test. For intake system

information,

REFER to Section 303

-1 2

Intake Air Distribution

and Filt

ering

.

Check service action S474

. For MAF sensor

tests,GO to Pinpoint Test A.

.

No t

hrottle response

Traction contr

o

l invoked

Throttl

e

sensors

Throttl

e

motor

Fo

r th

rottle position sensor tests,GO to Pinpoint

Test D.

, andG O to Pinpoint

Test

K.

. Fo

r throttle

motor circuit tests,GO to Pinpoint Test T.

.

Cru i

se control inhibited or

disabled

Cru i

se control switch

Throttle

sensors

Stop lamp swit

ch

For cru

i

se control switches,

REFER to Section 310

-03

Speed Control

.

For th

rottle position sensor tests,GO to Pinpoint

Test D.

, andG O to Pinpoint

Test

K.

. For s t

op

light switch information, refer to the wiring diagrams.

Page 1194 of 2490

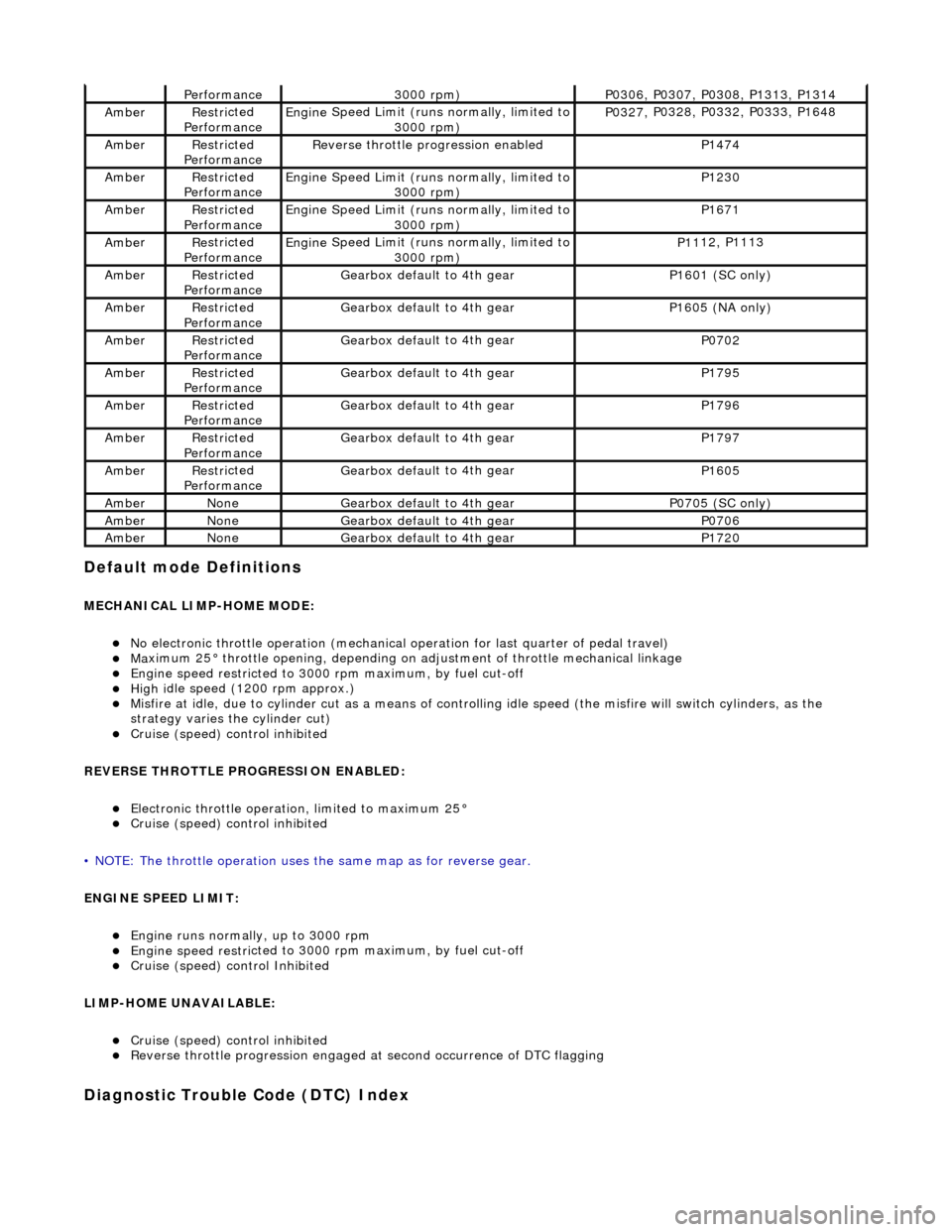

Default mode Definitions

MECHANIC

AL LIMP-HOME MODE:

No elec

tronic throttle operation (mechanical

operation for last quarter of pedal travel)

Ma

ximum 25° throttle opening,

depending on adjustment of th rottle mechanical linkage

Engine speed restri

cted to 3000

rpm maximum, by fuel cut-off

High i

dle speed (1200 rpm approx.)

Misfire

at idle, due

to cylinder cut as a means of control

ling idle speed (the misfire will switch cylinders, as the

strategy varies th e cylinder cut)

Cruise (speed) contr

o

l inhibited

REVERSE THROTTLE PROGRESSION ENABLED:

Elec

tronic throttle operation, limited to maximum 25°

Cruise (speed) contr

o

l inhibited

• NOTE: The throttle oper ation uses the same map as for reverse gear.

ENGINE SPEED LIMIT:

Engine runs

normally, up to 3000 rpm

Engine

speed restri

cted to 3000

rpm maximum, by fuel cut-off

Cruise (speed) contr o

l Inhibited

LIMP-HOME UNAVAILABLE:

Cruise (speed) contro

l inhibited

R

e

verse throttle pr

ogression engaged at second occurrence of DTC flagging

Diagnostic Trouble Code (D TC) Index

Performance3000

rpm)

P03

06,

P0307, P0308, P1313, P1314

Ambe

rRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P03 27,

P0328, P0332, P0333, P1648

Ambe

rRestri

cted

Performance

R e

verse throttle pr

ogression enabled

P1474

AmberRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P1230

Ambe rRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P1671

Ambe rRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P11 12,

P1113

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1601 (SC on

ly)

AmberRestri

cted

Performance

Gearbox defau l

t to 4th gear

P16

05 (

NA only)

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P0702

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1795

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1796

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1797

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1605

Ambe

rNoneGearbox defau l

t to 4th gear

P0705 (SC on

ly)

Ambe

rNoneGearbox defau l

t to 4th gear

P0706

Ambe

rNoneGearbox defau l

t to 4th gear

P1720

Page 1207 of 2490

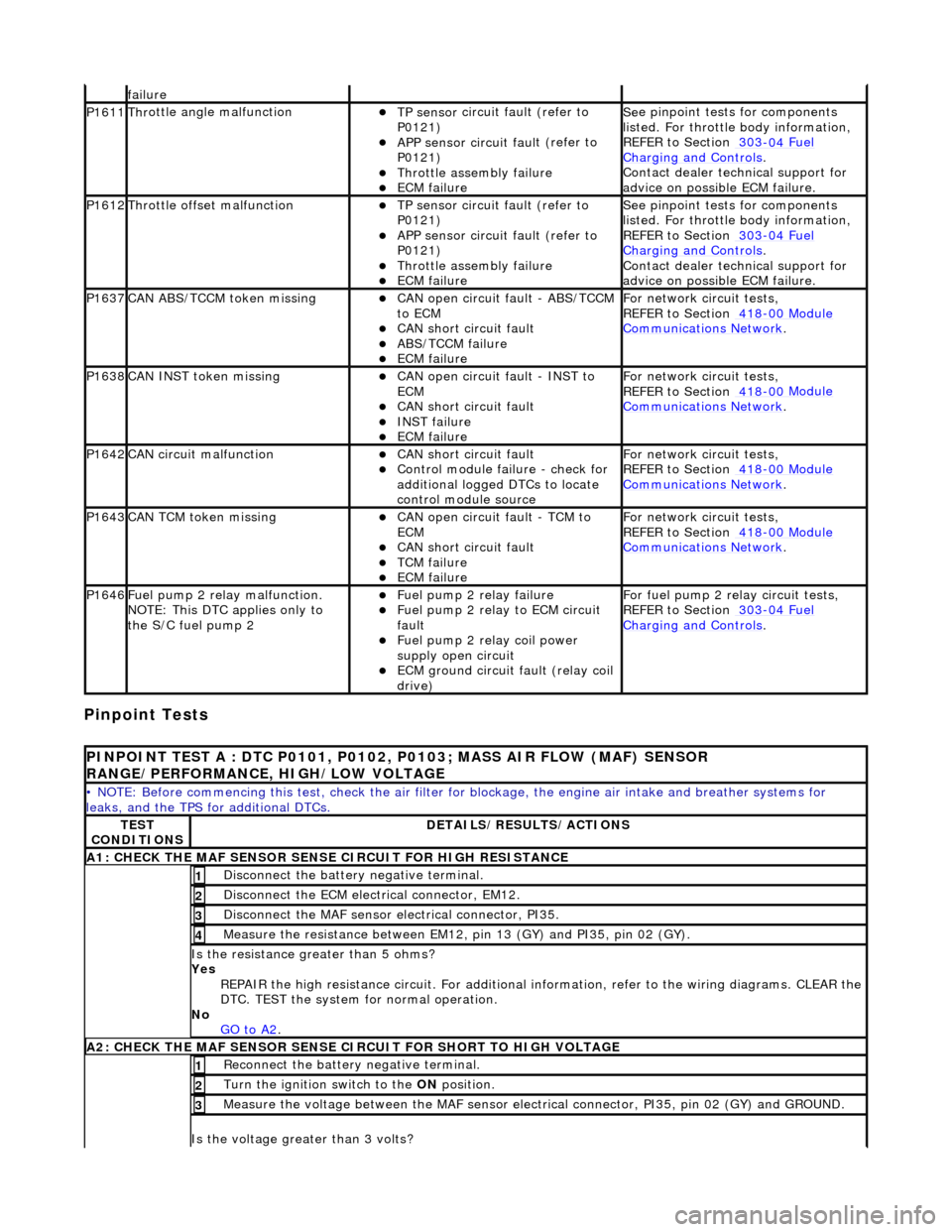

Pinpoint Tests

f

ailure

P1611Thr

ottle angle malfunction

TP sensor

circuit fault (refer to

P0121)

APP sensor circuit faul

t (refer to

P0121)

Throttl

e assembly failure

ECM failu

re

Se

e pinpoint tests for components

listed. For throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

Contact deal

er technical support for

advice on possible ECM failure.

P1612Throttl

e offset malfunction

TP sensor

circuit fault (refer to

P0121)

APP sensor circuit faul

t (refer to

P0121)

Throttl

e assembly failure

ECM failu

re

Se

e pinpoint tests for components

listed. For throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

Contact deal

er technical support for

advice on possible ECM failure.

P1637CAN AB

S/TCCM token missing

CAN

open circuit fault - ABS/TCCM

to ECM

CAN s

hort circuit fault

ABS/TCCM failu

re

ECM failu

re

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1638CAN INST token missingCAN

open circuit fault - INST to

ECM

CAN s

hort circuit fault

INST

failure

ECM failu

re

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1642CAN c

ircuit malfunction

CAN s

hort circuit fault

Control modul

e failure - check for

additional logged DTCs to locate

control module source

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1643CAN TC

M token missing

CAN

open circuit fault - TCM to

ECM

CAN s

hort circuit fault

TCM failure

ECM failu

re

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1646F

uel pump 2 relay malfunction.

NOTE: This DTC applies only to

the S/C fuel pump 2

F

uel pump 2 relay failure

F

uel pump 2 relay to ECM circuit

fault

F

uel pump 2 relay coil power

supply open circuit

ECM ground circuit faul

t (relay coil

drive)

F

or fuel pump 2 relay circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P

INPOINT TEST A : DTC P0101, P0102, P0103; MASS AIR FLOW (MAF) SENSOR

RANGE/PERFORMANCE, HIGH/LOW VOLTAGE

•

NOTE: Before commencing this

test, check the air filter for blockage, the engine air inta ke and breather systems for

leaks, and the TPS for additional DTCs.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1: CHECK

THE MAF SENSOR SENS

E CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM12.

2

Di

sconnect the MAF sensor electrical connector, PI35.

3

Meas

ure the resistance between EM12, pin 13 (GY) and PI35, pin 02 (GY).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to A2

.

A2: CHECK

THE MAF SENSOR SENSE CI

RCUIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

M

easure the voltage between the MAF sensor electrical connector, PI35, pin 02 (GY) and GROUND.

3

Is th

e voltage greater than 3 volts?

Page 1223 of 2490

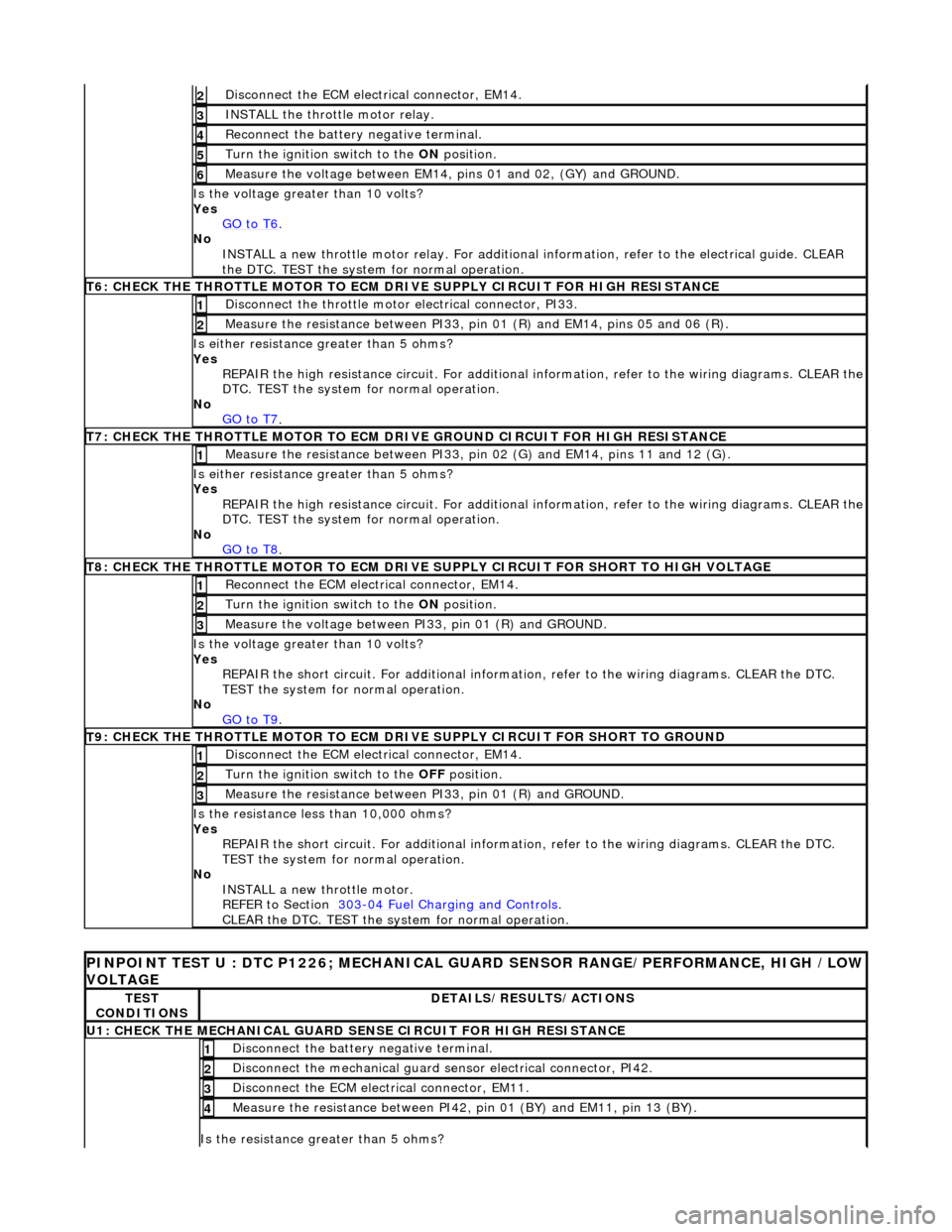

D

isconnect the ECM electrical connector, EM14.

2

IN

STALL the throttle motor relay.

3

R

econnect the battery negative terminal.

4

Turn the ignition swi

tch to the

ON position.

5

Measure the

voltage between EM14, pi

ns 01 and 02, (GY) and GROUND.

6

Is the vol

tage greater than 10 volts?

Yes GO to T6

.

No

INSTALL a new throttle motor relay. For additional information, refer to the electrical guide. CLEAR

the DTC. TEST the system for normal operation.

T

6: CHECK THE THROTTLE MOTOR TO ECM DRIVE SUPPLY CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the throttle motor electrical connector, PI33.

1

Meas

ure the resistance between PI33, pi

n 01 (R) and EM14, pins 05 and 06 (R).

2

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to T7

.

T

7: CHECK THE THROTTLE MOTOR TO ECM DRIVE GROUND CIRCUIT FOR HIGH RESISTANCE

Meas

ure the resistance between PI33, pin

02 (G) and EM14, pins 11 and 12 (G).

1

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to T8

.

T

8: CHECK THE THROTTLE MOTOR TO ECM DRIVE SU

PPLY CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the ECM electrical connector, EM14.

1

Turn the ignition swi

tch to the

ON position.

2

M

easure the voltage between PI33, pin 01 (R) and GROUND.

3

Is the vol

tage greater than 10 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to T9

.

T

9: CHECK THE THROTTLE MOTOR TO ECM DRIVE SUPPLY CIRCUIT FOR SHORT TO GROUND

D

isconnect the ECM electrical connector, EM14.

1

Turn the ignition swi

tch to the

OFF position.

2

Meas

ure the resistance between PI33, pin 01 (R) and GROUND.

3

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new throttle motor.

REFER to Section 303

-0

4 Fuel Charging and Controls

.

CLEAR t

he DTC. TEST the system for normal operation.

P

INPOINT TEST U : DTC P1226; MECHANICAL

GUARD SENSOR RANGE/PERFORMANCE, HIGH /LOW

VOLTAGE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

U1: CHECK T

HE MECHANICAL GUARD SENSE CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

Di

sconnect the mechanical guard sensor electrical connector, PI42.

2

D

isconnect the ECM electrical connector, EM11.

3

Me

asure the resistance between PI42, pin 01 (BY) and EM11, pin 13 (BY).

4

Is th

e resistance greater than 5 ohms?

Page 1224 of 2490

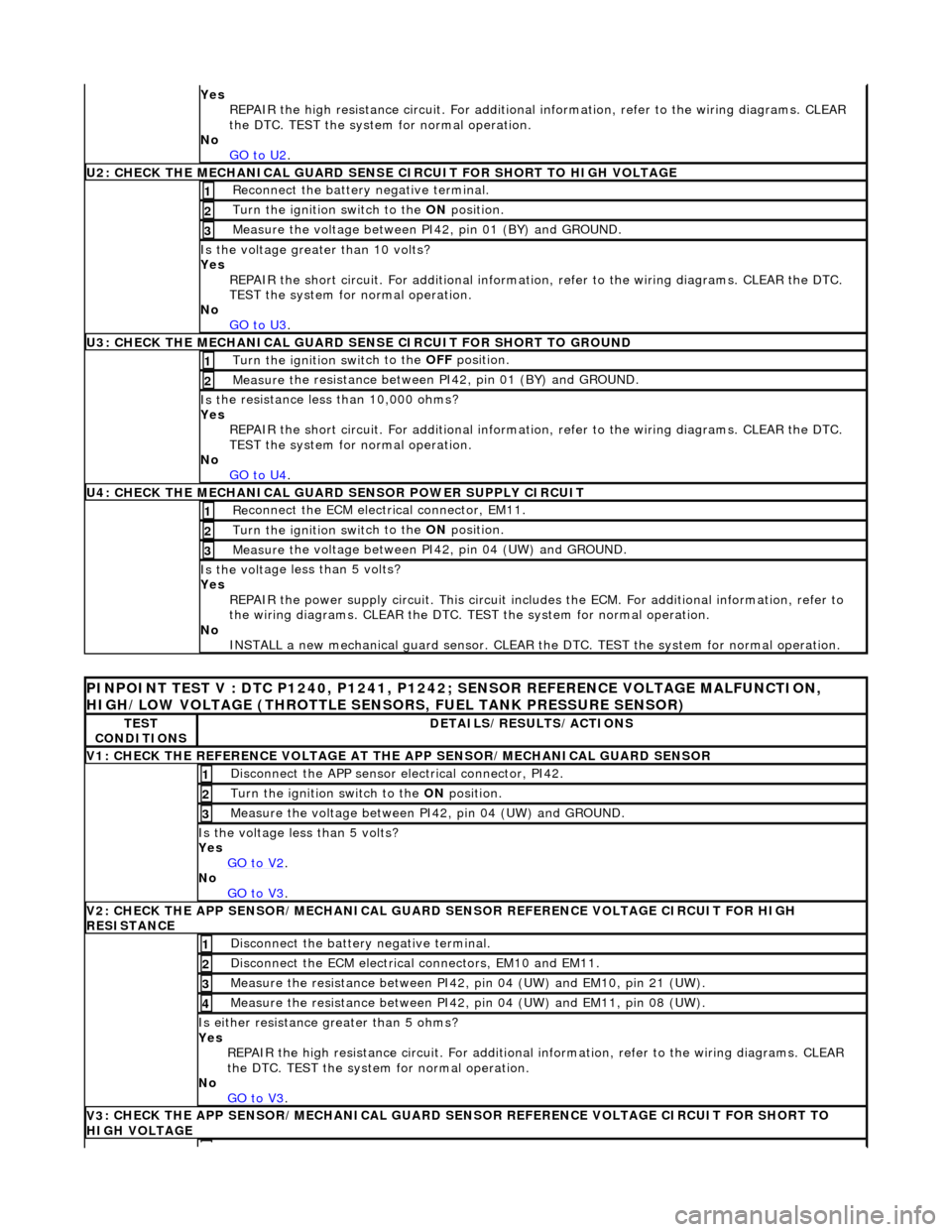

Yes

R

EPAIR the high resistance circui

t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to U2

.

U2: CHECK T H

E MECHANICAL GUARD SENSE

CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure t

he voltage between PI42, pin 01 (BY) and GROUND.

3

Is the volt

age greater than 10 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to U3

.

U3: CHECK T H

E MECHANICAL GUARD SE

NSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swit

ch to the OFF

position.

1

Measure t

he resistance between PI42, pin 01 (BY) and GROUND.

2

Is

t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to U4

.

U4: CHECK THE MEC H

ANICAL GUARD SENSOR POWER SUPPLY CIRCUIT

Re

conn

ect the ECM electrical connector, EM11.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure t

he voltage between PI42, pin 04 (UW) and GROUND.

3

Is th

e volt

age less than 5 volts?

Yes

REPAIR the power supply circuit. This circuit includ es the ECM. For additional information, refer to

the wiring diagrams. CLEAR the DTC. TE ST the system for normal operation.

No INSTALL a new mechanical guard sensor. CLEAR the DTC. TEST the system for normal operation.

PINPO

INT TEST V : DTC P1240, P1241, P1242

; SENSOR REFERENCE VOLTAGE MALFUNCTION,

HIGH/LOW VOLTAGE (THROTTLE SENSORS, FUEL TANK PRESSURE SENSOR)

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

V

1

: CHECK THE REFERENCE VOLTAGE AT TH

E APP SENSOR/MECHANICAL GUARD SENSOR

Disc

onnect the APP sensor electrical connector, PI42.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure the voltage between PI

42,

pin 04 (UW) and GROUND.

3

Is th

e volt

age less than 5 volts?

Yes GO to V2

.

No

GO to V3

.

V2

: CHECK THE APP SENSOR/MECHA

NICAL GUARD SENSOR REFERENCE VOLTAGE CIRCUIT FOR HIGH

RESISTANCE

Di sc

onnect the battery negative terminal.

1

D

i

sconnect the ECM electrical connectors, EM10 and EM11.

2

Me

asure

the resistance between PI42, pin 04 (UW) and EM10, pin 21 (UW).

3

Me

asure

the resistance between PI42, pin 04 (UW) and EM11, pin 08 (UW).

4

Is either resi

stance greater

than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to V3

.

V3

: CHECK THE APP SENSOR/MECHA

NICAL GUARD SENSOR REFERENCE VOLTAGE CIRCUIT FOR SHORT TO

HIGH VOLTAGE

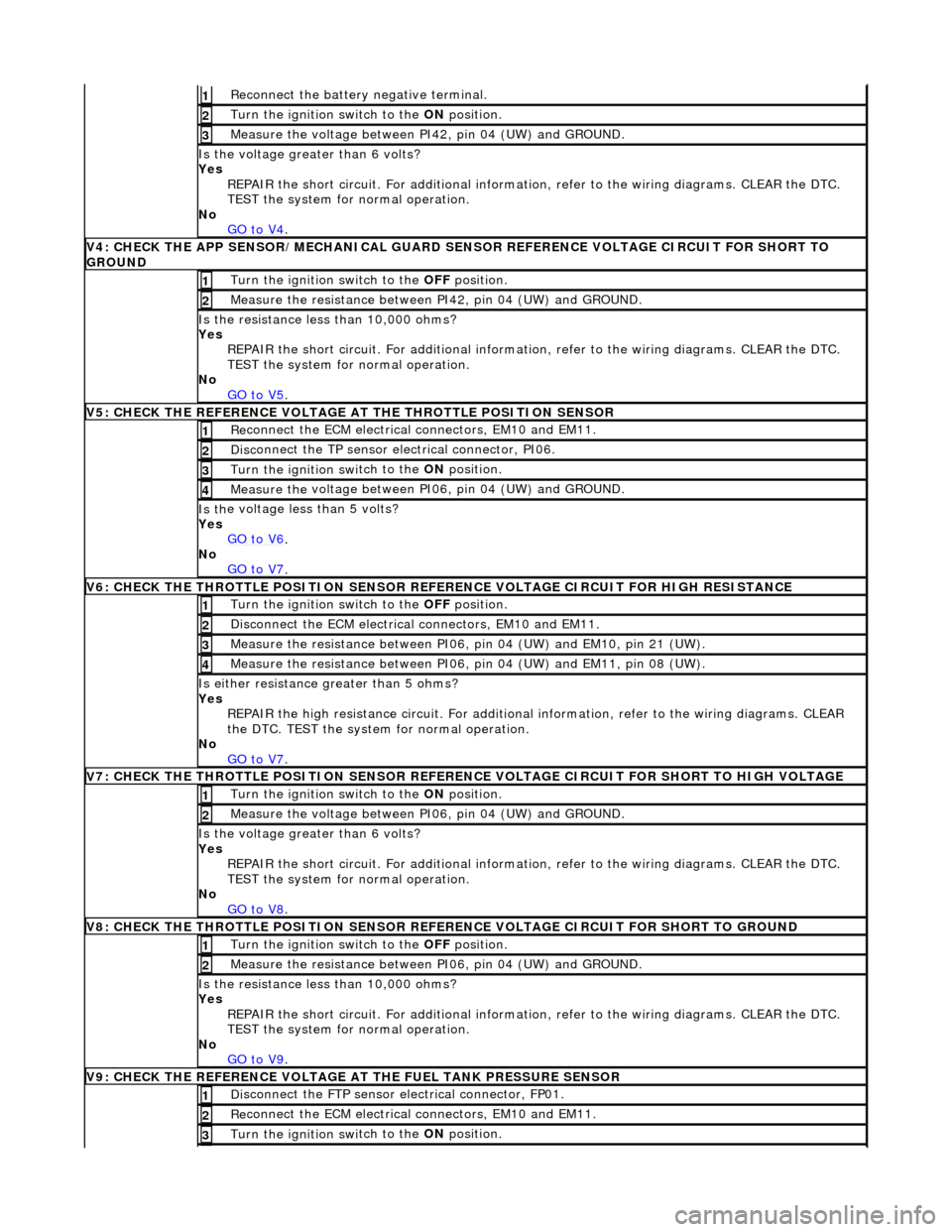

Page 1225 of 2490

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

Measure the

voltage between PI

42, pin 04 (UW) and GROUND.

3

Is th

e voltage greater than 6 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to V4

.

V

4: CHECK THE APP SENSOR/MECHA

NICAL GUARD SENSOR REFERENCE VOLTAGE CIRCUIT FOR SHORT TO

GROUND

Turn the ignition swi

tch to the

OFF position.

1

Meas

ure the resistance between PI42, pin 04 (UW) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to V5

.

V

5: CHECK THE REFERENCE VOLTAGE AT THE THROTTLE POSITION SENSOR

Re

connect the ECM electrical connectors, EM10 and EM11.

1

Disc

onnect the TP sensor electrical connector, PI06.

2

Turn the ignition swi

tch to the ON

position.

3

Measure the

voltage between PI

06, pin 04 (UW) and GROUND.

4

Is th

e voltage less than 5 volts?

Yes GO to V6

.

No

GO to V7

.

V

6: CHECK THE THROTTLE POSITION SENSOR REFE

RENCE VOLTAGE CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

tch to the OFF

position.

1

D

isconnect the ECM electrical connectors, EM10 and EM11.

2

Me

asure the resistance between PI06, pin 04 (UW) and EM10, pin 21 (UW).

3

Me

asure the resistance between PI06, pin 04 (UW) and EM11, pin 08 (UW).

4

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to V7

.

V

7: CHECK THE THROTTLE POSITION SENSOR REFERENCE VOLTAGE CIRCUIT FOR SHORT TO HIGH VOLTAGE

Turn the ignition swi

tch to the ON

position.

1

Measure the

voltage between PI

06, pin 04 (UW) and GROUND.

2

Is th

e voltage greater than 6 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No

GO to V8

.

V

8: CHECK THE THROTTLE POSITION SENSOR REFE

RENCE VOLTAGE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between PI06, pin 04 (UW) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to V9

.

V

9: CHECK THE REFERENCE VOLTAGE AT THE FUEL TANK PRESSURE SENSOR

Di

sconnect the FTP sensor electrical connector, FP01.

1

Re

connect the ECM electrical connectors, EM10 and EM11.

2

Turn the ignition swi

tch to the ON

position.

3

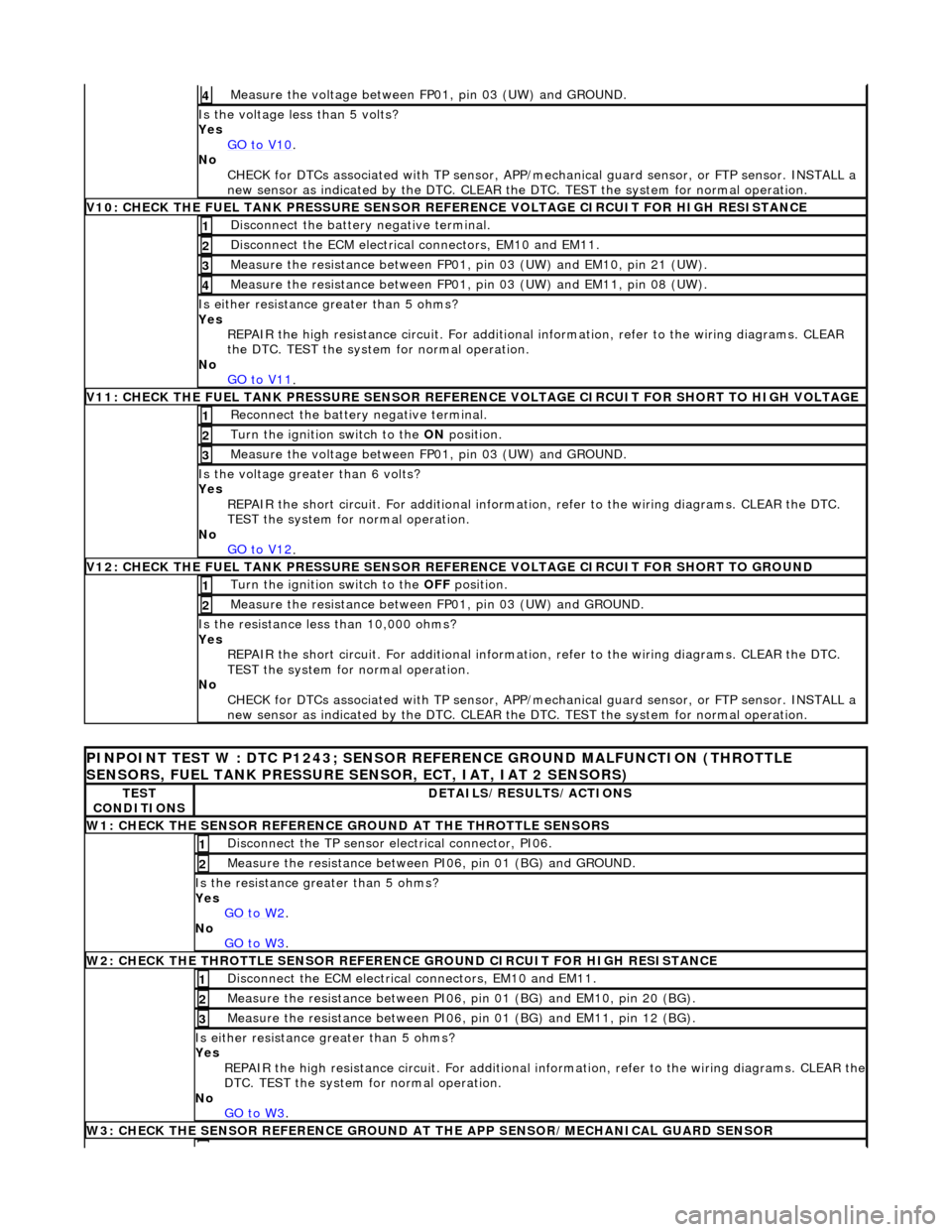

Page 1226 of 2490

Measure the voltage between FP 01

, pin 03 (UW) and GROUND.

4

Is th

e volt

age less than 5 volts?

Yes GO to V10

.

No

CHECK

for DTCs associated with

TP sensor, APP/mechanical guard sensor, or FTP sensor. INSTALL a

new sensor as indicated by the DTC. CLEAR the DTC. TEST the system for normal operation.

V

10: CHECK

THE FUEL TANK PRESSURE SENSOR

REFERENCE VOLTAGE CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

D

i

sconnect the ECM electrical connectors, EM10 and EM11.

2

Measure t

he resistance between FP01,

pin 03 (UW) and EM10, pin 21 (UW).

3

Measure t

he resistance between FP01,

pin 03 (UW) and EM11, pin 08 (UW).

4

Is either resistance greater

than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to V11

.

V11: CHECK

THE FUEL TANK PRESSURE SENSOR REFE

RENCE VOLTAGE CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure the voltage between FP 01

, pin 03 (UW) and GROUND.

3

Is th

e volt

age greater than 6 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to V12

.

V12: CHECK

THE FUEL TANK PRESSURE SENSOR

REFERENCE VOLTAGE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swit

ch to the OFF

position.

1

Measure t

he resistance between

FP01, pin 03 (UW) and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No CHECK for DTCs associated with TP sensor, APP/mechanical guard sensor, or FTP sensor. INSTALL a

new sensor as indicated by the DTC. CLEAR the DTC. TEST the system for normal operation.

PI

NPOINT TEST W : DTC P1243; SENSOR RE

FERENCE GROUND MALFUNCTION (THROTTLE

SENSORS, FUEL TANK PRESSURE SENSOR, ECT, IAT, IAT 2 SENSORS)

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

W1: CHECK THE SENSO

R

REFERENCE

GROUND AT THE THROTTLE SENSORS

Disc

onne

ct the TP sensor electrical connector, PI06.

1

Meas

ure t

he resistance between PI06, pin 01 (BG) and GROUND.

2

Is th

e res

istance greater than 5 ohms?

Yes GO to W2

.

No

GO to W3

.

W2: CHECK TH

E THROTTLE SENSOR REFERENCE GROUND CIRCUIT FOR HIGH RESISTANCE

D

i

sconnect the ECM electrical connectors, EM10 and EM11.

1

Meas

ure t

he resistance between PI06,

pin 01 (BG) and EM10, pin 20 (BG).

2

Measure t

he resistance between PI06,

pin 01 (BG) and EM11, pin 12 (BG).

3

Is either resistance greater

than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to W3

.

W3: CHECK THE SENSO R

REFERENCE GROUND AT

THE APP SENSOR/MECHANICAL GUARD SENSOR

Page 1227 of 2490

Di

sconnect the APP sensor/mechanical guard sensor electrical connector, PI42.

1

Re

connect the ECM electrical connectors, EM10 and EM11.

2

Meas

ure the resistance between PI42, pin 02 (BG) and GROUND.

3

Is th

e resistance greater than 5 ohms?

Yes GO to W4

.

No

GO to W5

.

W4: CHECK THE APP

SENSOR/MECHANICAL GUARD SE

NSOR REFERENCE GROUND CIRCUIT FOR HIGH

RESISTANCE

D

isconnect the ECM electrical connectors, EM10 and EM11.

1

Meas

ure the resistance between PI42,

pin 02 (BG) and EM10, pin 20 (BG).

2

Meas

ure the resistance between PI42,

pin 02 (BG) and EM11, pin 12 (BG).

3

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to W5

.

W5: CHECK THE SENSO

R REFERENCE GROUND AT THE FUEL TANK PRESSURE SENSOR

Di

sconnect the FTP sensor electrical connector, FP01.

1

Re

connect the ECM electrical connectors, EM10 and EM11.

2

Meas

ure the resistance between

FP01, pin 01 (BG) and GROUND.

3

Is th

e resistance greater than 5 ohms?

Yes GO to W6

.

No

GO to W7

.

W6: CHECK THE FUEL

TANK PRESSURE SENSOR RE

FERENCE GROUND CIRCUIT FOR HIGH RESISTANCE

D

isconnect the ECM electrical connectors, EM10 and EM11.

1

Meas

ure the resistance between FP01,

pin 01 (BG) and EM10, pin 20 (BG).

2

Meas

ure the resistance between FP01,

pin 01 (BG) and EM11, pin 12 (BG).

3

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to W7

.

W7: CHECK THE SENSO

R REFERENCE GROUND AT THE ECT SENSOR

Re

connect the ECM electrical connectors, EM10 and EM11.

1

D

isconnect the ECT sensor electrical connector, PI04.

2

Meas

ure the resistance between PI04, pin 01 (BG) and GROUND.

3

Is th

e resistance greater than 5 ohms?

Yes GO to W8

.

No

GO to W9

.

W8: CHECK THE ECT SEN

SOR REFERENCE

GROUND CIRCUIT FOR HIGH RESISTANCE

D

isconnect the ECM electrical connectors, EM10 and EM11.

1

Meas

ure the resistance between PI04,

pin 01 (BG) and EM10, pin 20 (BG).

2

Meas

ure the resistance between PI04,

pin 01 (BG) and EM11, pin 12 (BG).

3

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to W9

.

W9: CHECK THE SENSO

R REFERENCE GR

OUND AT THE IAT SENSOR (MAF)

Re

connect the ECM electrical connectors, EM10 and EM11.

1

Di

sconnect the IAT sensor (MAF) electrical connector, PI35.

2

Meas

ure the resistance between PI35, pin 04 (BG) and GROUND.

3

Page 1241 of 2490

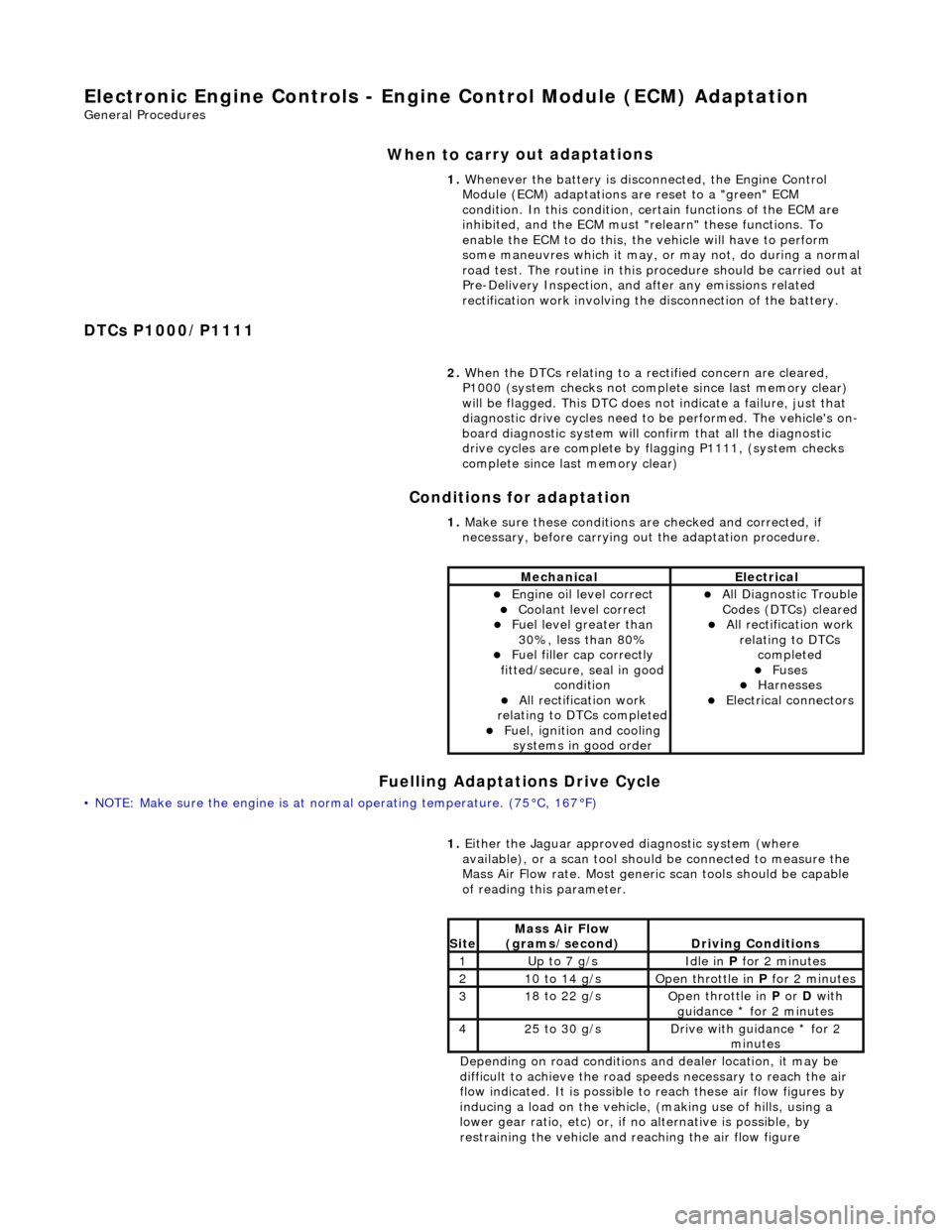

E

lectronic Engine Controls - Engine

Control Module (ECM) Adaptation

Gen

eral Procedures

When to car

ry out adaptations

DTCs P1000/P1111 Conditions for adaptation

Fuelling Adaptations Drive Cycle

•

NOTE: Make sure the engine is at normal operating

temperature. (75°C, 167°F) 1.

Whenever the battery is disconnected, the Engine Control

Module (ECM) adaptations are reset to a "green" ECM

condition. In this condition, certain functions of the ECM are

inhibited, and the ECM must "r elearn" these functions. To

enable the ECM to do this, the vehicle will have to perform

some maneuvres which it may, or may not, do during a normal

road test. The routine in this pr ocedure should be carried out at

Pre-Delivery Inspection, and after any emissions related

rectification work involving the disconnection of the battery.

2. When the DTCs relating to a rectified concern are cleared,

P1000 (system checks not complete since last memory clear)

will be flagged. This DTC does no t indicate a failure, just that

diagnostic drive cycles need to be performed. The vehicle's on-

board diagnostic system will confirm that all the diagnostic

drive cycles are complete by flagging P1111, (system checks

complete since last memory clear)

1. Make sure these conditions are checked and corrected, if

necessary, before carrying ou t the adaptation procedure.

MechanicalElectrical

Engi

ne oil level correct

Coo

lant level correct

F

uel level greater than

30%, less than 80%

F

uel filler cap correctly

fitted/secure, seal in good condition

Al

l rectification work

relating to DTCs completed

F

uel, ignition and cooling

systems in good order

Al

l Diagnostic Trouble

Codes (DTCs) cleared

Al

l rectification work

relating to DTCs completed

F

uses

Harnes

ses

E

lectrical connectors

1.

Either

the Jaguar approved diagnostic system (where

available), or a scan tool should be connected to measure the

Mass Air Flow rate. Most generi c scan tools should be capable

of reading this parameter.

Depending on road conditions and dealer location, it may be

difficult to achieve the road sp eeds necessary to reach the air

flow indicated. It is possible to reach these air flow figures by

inducing a load on the vehicle, (making use of hills, using a

lower gear ratio, etc) or, if no alternative is possible, by

restraining the vehicle and re aching the air flow figure

Si

te

Mass Air Flow

(gra

ms/second)

D

riving Conditions

1Up t

o 7 g/s

Idle

in

P for 2 minutes

21

0 to 14 g/s

O

pen throttle in

P for 2 minutes

31

8 to 22 g/s

O

pen throttle in

P or D with

guidance * for 2 minutes

42

5 to 30 g/s

D

rive with guidance * for 2

minutes