relay JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1222 of 2490

Disc

onnect the battery negative terminal.

1

D

i

sconnect the ECM electrical connectors, EM10 and EM11.

2

Meas

ure t

he resistance between EM10,

pin 20 (BG) and PI42, pin 02 (BG).

3

Measure t

he resistance between EM11,

pin 12 (BG) and PI42, pin 02 (BG).

4

Is either resistance greater

than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No Check the ECM GROUND circuits. If the GROUND circuits are sound, contact dealer technical

support for advice on possible ECM failure.

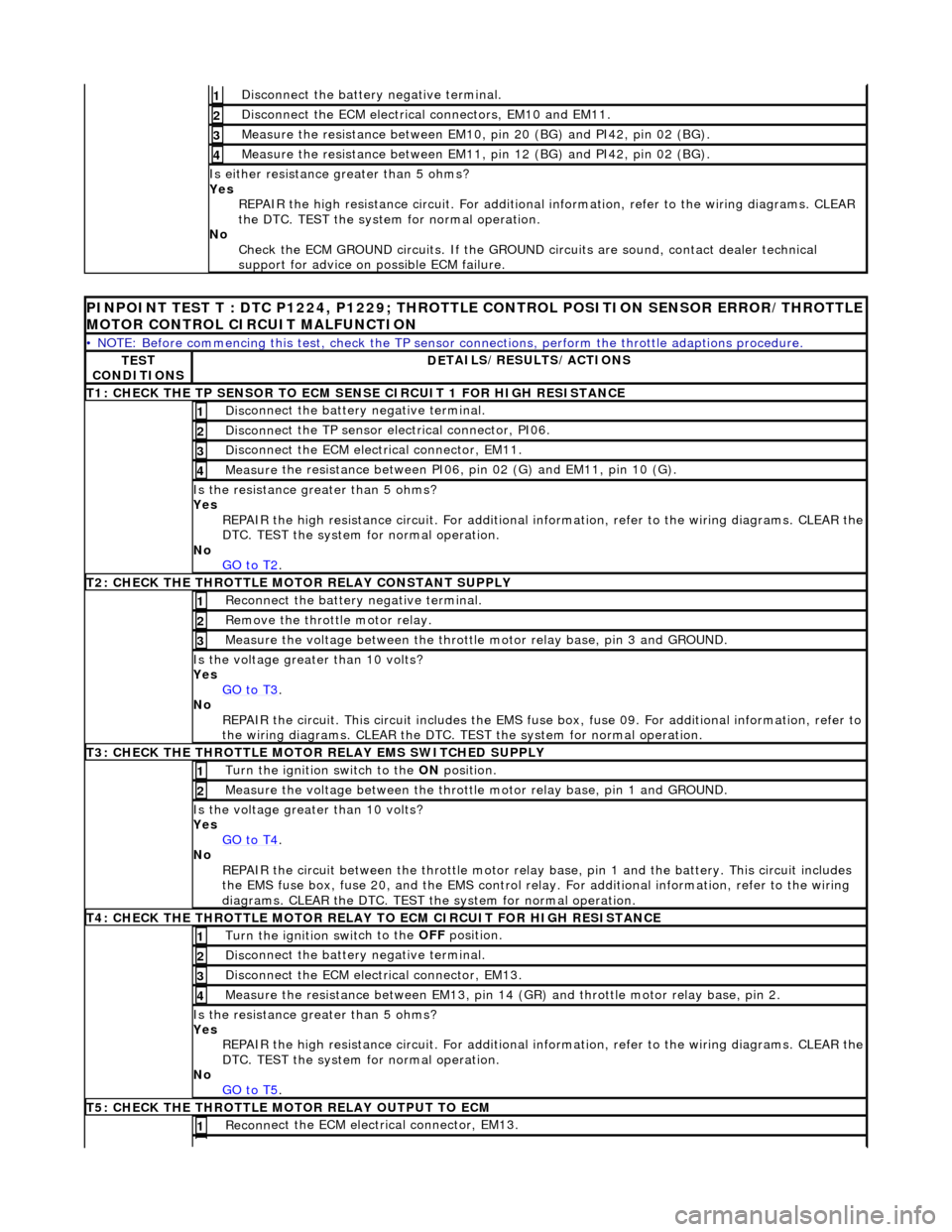

PINPOINT TES

T T : DTC P1224, P1229; THROTTLE

CONTROL POSITION SENSOR ERROR/THROTTLE

MOTOR CONTROL CIRCUIT MALFUNCTION

•

NOTE: Before commencing this test, check the TP sensor

connections, perform the throttle adaptions procedure.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

T

1: CH

ECK THE TP SENSOR TO ECM SE

NSE CIRCUIT 1 FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

Disc

onne

ct the TP sensor electrical connector, PI06.

2

D

i

sconnect the ECM electrical connector, EM11.

3

Me

asure

the resistance between PI06, pin 02 (G) and EM11, pin 10 (G).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to T2

.

T2

: CHECK THE THROTTLE MOTOR RELAY CONSTANT SUPPLY

R

e

connect the battery negative terminal.

1

R

e

move the thrott

le motor relay.

2

Measure t

he voltage between the throttle

motor relay base, pin 3 and GROUND.

3

Is the volt

age greater than 10 volts?

Yes GO to T3

.

No

R

EPAIR the circuit. This ci

rcuit includes the EMS fuse box, fuse 09. For addi tional information, refer to

the wiring diagrams. CLEAR the DTC. TE ST the system for normal operation.

T3

: CHECK THE THROTTLE MOTOR

RELAY EMS SWITCHED SUPPLY

Turn the ignition swit

ch to the

ON position.

1

Meas ure t

he voltage between the throttle

motor relay base, pin 1 and GROUND.

2

Is the volt

age greater than 10 volts?

Yes GO to T4

.

No

REP

AIR the circuit between the throttle motor relay

base, pin 1 and the battery. This circuit includes

the EMS fuse box, fuse 20, and the EMS control relay. For addition al information, refer to the wiring

diagrams. CLEAR the DTC. TEST th e system for normal operation.

T4

: CHECK THE THROTTLE MOTOR RELAY TO

ECM CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swit

ch to the

OFF position.

1

Disc

onnect the battery negative terminal.

2

Di

sconnect the ECM electrical connector, EM13.

3

Measure t

he resistance between EM13, pin 14 (G

R) and throttle motor relay base, pin 2.

4

Is the res

istance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to T5

.

T5

: CHECK THE THROTTLE MOTOR RELAY OUTPUT TO ECM

Re

conn

ect the ECM electrical connector, EM13.

1

Page 1223 of 2490

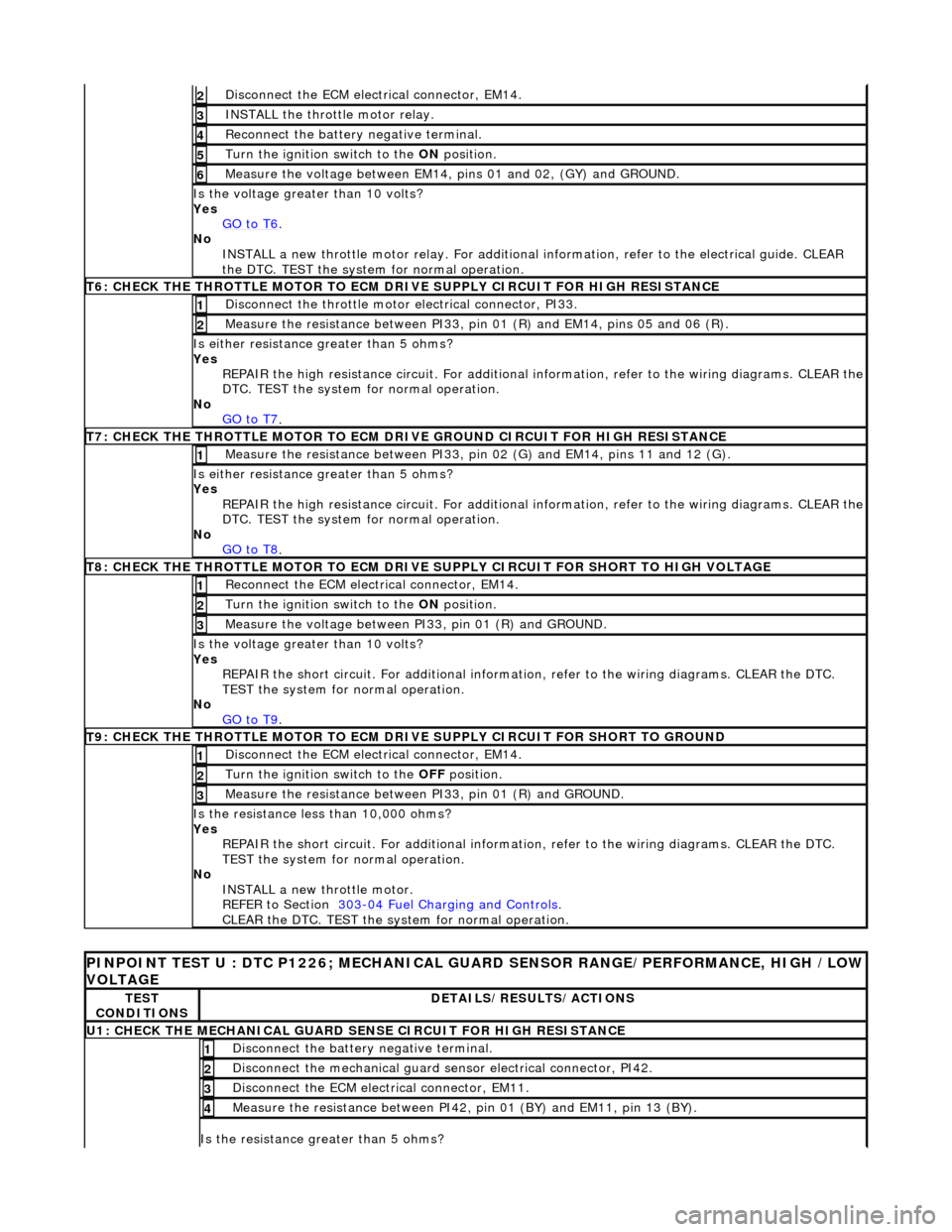

D

isconnect the ECM electrical connector, EM14.

2

IN

STALL the throttle motor relay.

3

R

econnect the battery negative terminal.

4

Turn the ignition swi

tch to the

ON position.

5

Measure the

voltage between EM14, pi

ns 01 and 02, (GY) and GROUND.

6

Is the vol

tage greater than 10 volts?

Yes GO to T6

.

No

INSTALL a new throttle motor relay. For additional information, refer to the electrical guide. CLEAR

the DTC. TEST the system for normal operation.

T

6: CHECK THE THROTTLE MOTOR TO ECM DRIVE SUPPLY CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the throttle motor electrical connector, PI33.

1

Meas

ure the resistance between PI33, pi

n 01 (R) and EM14, pins 05 and 06 (R).

2

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to T7

.

T

7: CHECK THE THROTTLE MOTOR TO ECM DRIVE GROUND CIRCUIT FOR HIGH RESISTANCE

Meas

ure the resistance between PI33, pin

02 (G) and EM14, pins 11 and 12 (G).

1

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to T8

.

T

8: CHECK THE THROTTLE MOTOR TO ECM DRIVE SU

PPLY CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the ECM electrical connector, EM14.

1

Turn the ignition swi

tch to the

ON position.

2

M

easure the voltage between PI33, pin 01 (R) and GROUND.

3

Is the vol

tage greater than 10 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to T9

.

T

9: CHECK THE THROTTLE MOTOR TO ECM DRIVE SUPPLY CIRCUIT FOR SHORT TO GROUND

D

isconnect the ECM electrical connector, EM14.

1

Turn the ignition swi

tch to the

OFF position.

2

Meas

ure the resistance between PI33, pin 01 (R) and GROUND.

3

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new throttle motor.

REFER to Section 303

-0

4 Fuel Charging and Controls

.

CLEAR t

he DTC. TEST the system for normal operation.

P

INPOINT TEST U : DTC P1226; MECHANICAL

GUARD SENSOR RANGE/PERFORMANCE, HIGH /LOW

VOLTAGE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

U1: CHECK T

HE MECHANICAL GUARD SENSE CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

Di

sconnect the mechanical guard sensor electrical connector, PI42.

2

D

isconnect the ECM electrical connector, EM11.

3

Me

asure the resistance between PI42, pin 01 (BY) and EM11, pin 13 (BY).

4

Is th

e resistance greater than 5 ohms?

Page 1228 of 2490

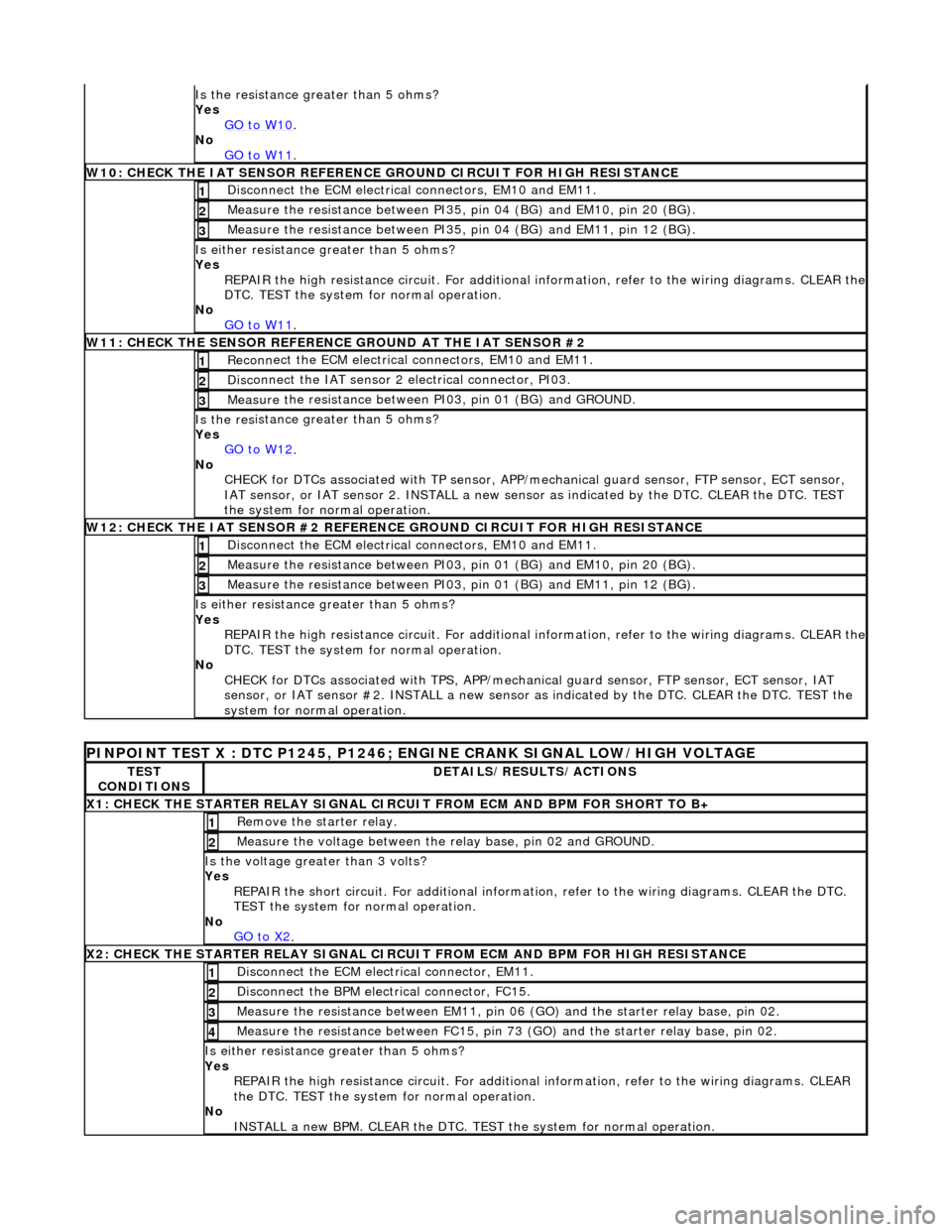

Is the res

istance greater than 5 ohms?

Yes GO to W10

.

No

GO to W11

.

W10 :

CHECK THE IAT SENSOR REFERENCE

GROUND CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the ECM electrical connectors, EM10 and EM11.

1

Meas

ure t

he resistance between PI35,

pin 04 (BG) and EM10, pin 20 (BG).

2

Measure t

he resistance between PI35,

pin 04 (BG) and EM11, pin 12 (BG).

3

Is either resistance greater

than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to W11

.

W11 :

CHECK THE SENSOR REFERENCE GROUND AT THE IAT SENSOR #2

Re

conn

ect the ECM electrical connectors, EM10 and EM11.

1

Di

sc

onnect the IAT sensor 2 electrical connector, PI03.

2

Meas

ure t

he resistance between PI03, pin 01 (BG) and GROUND.

3

Is th

e res

istance greater than 5 ohms?

Yes GO to W12

.

No

CHECK

for DTCs associated with TP sensor, APP/

mechanical guard sensor, FTP sensor, ECT sensor,

IAT sensor, or IAT sensor 2. INST ALL a new sensor as indicated by the DTC. CLEAR the DTC. TEST

the system for normal operation.

W12 :

CHECK THE IAT SENSOR #2 REFERENC

E GROUND CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the ECM electrical connectors, EM10 and EM11.

1

Meas

ure t

he resistance between PI03,

pin 01 (BG) and EM10, pin 20 (BG).

2

Measure t

he resistance between PI03,

pin 01 (BG) and EM11, pin 12 (BG).

3

Is either resistance greater

than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No CHECK for DTCs associated with TPS, APP/mechanical guard sensor, FTP sensor, ECT sensor, IAT

sensor, or IAT sensor #2. INSTALL a new sensor as indicated by the DTC. CLEAR the DTC. TEST the

system for normal operation.

PINPO

INT TEST X : DTC P1245, P1246; ENGINE CRANK SIGNAL LOW/HIGH VOLTAGE

TE

S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

X

1

: CHECK THE STARTER RELAY SIGNAL CIRC

UIT FROM ECM AND BPM FOR SHORT TO B+

Re

move the starter relay.

1

Meas

ure t

he voltage between the

relay base, pin 02 and GROUND.

2

Is the volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to X2

.

X2

: CHECK THE STARTER RELAY SIGNAL CIRCUI

T FROM ECM AND BPM FOR HIGH RESISTANCE

Di

sconnect the ECM electrical connector, EM11.

1

Disc

onne

ct the BPM electrical connector, FC15.

2

Meas

ure t

he resistance between EM11, pin 06

(GO) and the starter relay base, pin 02.

3

Measure t

he resistance between FC15, pin 73

(GO) and the starter relay base, pin 02.

4

Is either resistance greater

than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No INSTALL a new BPM. CLEAR the DTC. TEST the system for normal operation.

Page 1229 of 2490

P

INPOINT TEST Y : DTC P1260; SECURITY INPUT MALFUNCTION

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

Y1

: CHECK THE KTM TO ECM CIRCUIT FOR HIGH RESISTANCE

D

isconnect the ECM electrical connector, EM10.

1

D

isconnect the KTM electrical connector, FC22.

2

Me

asure the resistance between EM10, pin 06 (O) and FC22, pin 16 (O).

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No INSTALL a new KTM. CLEAR the DTC. TEST the system for normal operation.

PINPO

INT TEST Z : DTC P1474; INTERCOOLER COOLANT PUMP RELAY MALFUNCTION

•

NOTE: Early production vehicl

es have connector pin numbers that differ fro m the volume production pin numbers shown.

Use the wire color code for pin identifi cation on early production vehicles.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

Z1

: CHECK THE INTERCOOLER PUMP RELAY TO ECM DRIVE CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

R

emove the intercooler pump relay.

2

D

isconnect the ECM electrical connector, EM13.

3

Meas

ure the resistance between the rela

y base, pin 01 and EM13, pin 10 (RY).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to Z2

.

Z2

: CHECK THE INTERCOOLER PUMP RELAY TO EC

M DRIVE CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

Meas

ure the voltage between the

relay base, pin 01 and GROUND.

3

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to Z3

.

Z3

: CHECK THE INTERCOOLER PUMP RELAY TO

ECM DRIVE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between th

e relay base, pin 01 and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to Z4

.

Z4: CHECK THE INTER

COOLER PUMP RELAY GROUND CIRCUIT

Meas

ure the resistance between th

e relay base, pin 02 and GROUND.

1

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No INSTALL a new intercooler pump re lay. CLEAR the DTC. TEST the system for normal operation.

P

INPOINT TEST AA : DTC P1475; RADIATOR

FANS SLOW (SERIES) CIRCUIT MALFUNCTION

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

Page 1230 of 2490

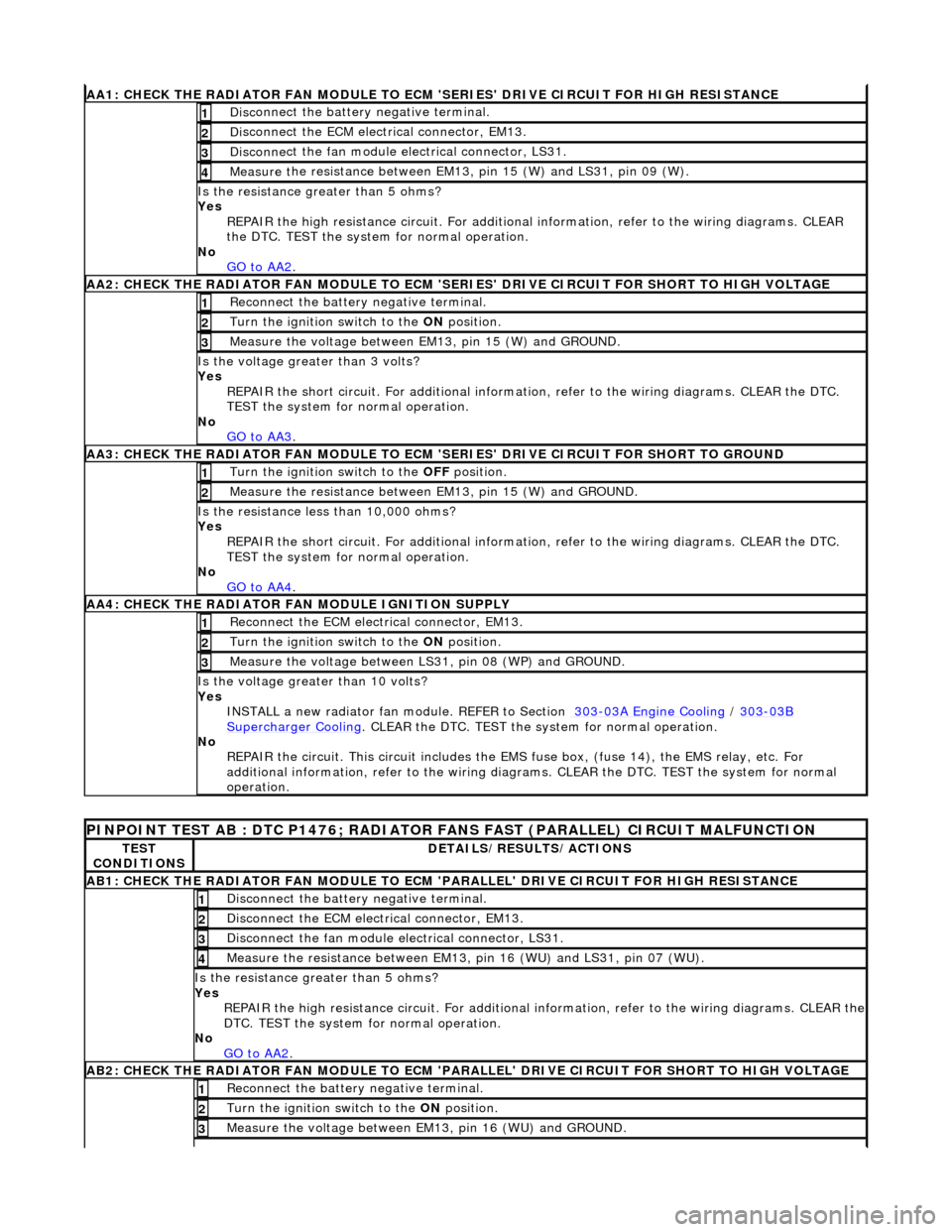

AA1: CHECK THE RA

DIATOR FAN MODULE TO ECM

'SERIES' DRIVE CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

D

i

sconnect the ECM electrical connector, EM13.

2

Disc

onne

ct the fan module electrical connector, LS31.

3

Meas

ure t

he resistance between EM13, pin 15 (W) and LS31, pin 09 (W).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to AA2

.

AA2: CHECK THE RA

DIATOR FAN MODULE TO ECM 'SER

IES' DRIVE CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the battery negative terminal.

1

Turn the ignition swit

ch to the

ON position.

2

Measure t

he voltage between EM13, pin 15 (W) and GROUND.

3

Is the volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to AA3

.

AA3: CHECK THE R A

DIATOR FAN MODULE TO ECM

'SERIES' DRIVE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swit

ch to the

OFF position.

1

Meas ure t

he resistance between EM13, pin 15 (W) and GROUND.

2

Is

t

he resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to AA4

.

AA4:

CHECK THE RADIATOR FAN MODULE IGNITION SUPPLY

Reconn

ect the ECM electrical connector, EM13.

1

Turn the ignition swit

ch to the

ON position.

2

Measure the voltage between LS 31,

pin 08 (WP) and GROUND.

3

Is the vol

t

age greater than 10 volts?

Yes INSTALL a new radiator fan module. REFER to Section 303

-03

A Engine Cooling

/

303-03B Supercharger Cooli

ng

. CLEA

R the DTC. TEST the sy stem f

or normal operation.

No REPAIR the circuit. This circui t includes the EMS fuse box, (f use 14), the EMS relay, etc. For

additional information, refer to the wiring diagrams. CLEAR the DT C. TEST the system for normal

operation.

PINPOINT TE ST

AB : DTC P1476; RADIATOR

FANS FAST (PARALLEL) CIRCUIT MALFUNCTION

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

AB1

:

CHECK THE RADIATOR FAN MODULE TO ECM

'PARALLEL' DRIVE CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

D

i

sconnect the ECM electrical connector, EM13.

2

Disc

onne

ct the fan module electrical connector, LS31.

3

Meas

ure t

he resistance between EM13, pin 16 (WU) and LS31, pin 07 (WU).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to AA2

.

AB2:

CHECK THE RADIATOR FAN MODULE TO ECM 'PARALLEL' DRIVE CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

e

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure t

he voltage between EM13, pin 16 (WU) and GROUND.

3

Page 1231 of 2490

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to AB3

.

AB3

: CHECK THE RADIATOR FAN MODULE TO ECM

'PARALLEL' DRIVE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between EM13, pin 16 (WU) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to AA4

.

AB4

: CHECK THE RADIATOR FAN MODULE IGNITION SUPPLY

Re

connect the ECM electrical connector, EM13.

1

Turn the ignition swi

tch to the ON

position.

2

Measure the

voltage between LS

31, pin 08 (WP) and GROUND.

3

Is the vol

tage greater than 10 volts?

Yes INSTALL a new radiator fan module. REFER to Section 303

-0

3A Engine Cooling

/

30

3

-03

B

Supercharger

Cooling

. CLEA

R the DTC. TEST the sy

stem for normal operation.

No REPAIR the circuit between LS31, pin 08 (WP) and battery. This circuit includes the EMS fuse box-

(fuse 14), the EMS relay, etc. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

P

INPOINT TEST AC : DTC P1516, P1517; GEAR

CHANGE PARK/NEUTRAL DRIVING MALFUNCTION

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

AC1: CH

ECK THE TRANSMISSION RANGE (TR) SE

NSOR TO ECM CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

Di

sconnect the TR sensor el

ectrical connector, EM47.

2

D

isconnect the ECM electrical connector, EM10.

3

Meas

ure the resistance between EM47, pin K (RU) and EM10, pin 15 (RU).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to AC2

.

AC2: CH

ECK THE TRANSMISSION RANGE (TR)

SENSOR PARK/NEUTRAL SWITCHING ACTION

Meas

ure the resistance between pi

ns J and K of the TR sensor.

1

Mo

ve the selector lever from

PARK to NEUTRAL and back.

2

D

oes the resistance switch between open ci

rcuit and continuity as the lever moves?

Yes GO to AC3

.

No

INSTALL a new transmission range sensor. CLEAR th e DTC. TEST the system for normal operation.

AC3: CH

ECK THE D-4 SWITCH TO

TCM CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the D-4 switch electrical connector, CC07.

1

Di

sconnect the TCM electrical connector, EM07.

2

Meas

ure the resistance between CC07,

pin 01 (US) and EM07, pin 13 (US).

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No INSTALL a new transmission range sensor. CLEAR th e DTC. TEST the system for normal operation.

P

INPOINT TEST AD : DTC P1606;

EMS CONTROL RELAY MALFUNCTION

Page 1232 of 2490

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

AD1

:

CHECK THE EMS RELAY PERMANENT B+ SUPPLY

R

e

move the EMS relay.

1

Meas

ure t

he voltage between the rela

y base, pins 02 and 03 and GROUND.

2

Are both vol

tages greater than 10 volts?

Yes GO to AD2

.

No

R

EPAIR the circuit between the rela

y base and battery. This circuit includes the high power protection

module. For additional information, refer to the wiring diagrams. CLEAR the DTC. TEST the system

for normal operation.

AD2 :

CHECK THE EMS RELAY TO ECM CIRCUIT FOR HIGH RESISTANCE

Di

sc

onnect the battery negative terminal.

1

D

i

sconnect the ECM electrical connector, EM10.

2

Meas

ure t

he resistance between the rela

y base, pin 01 and EM10, pin 16 (PK).

3

Is the res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No INSTALL a new EMS relay. CLEAR the DTC. TEST the system for normal operation.

PINPOINT TEST AE : CHECK

ROCHESTER VALVE FUNCTION

T

E

ST CONDITIONS

D

E

TAILS/RESULTS/ACTIONS

AE1: CHEC

K VAC

UUM INTEGRITY OF ROCHESTER VALVE

Di

sc

onnect hoses from the Rochester valve.

1

Bl

a

nk off outlet side of valve.

2

Con

n

ect a hand-held vacuum pump to the vacuum inlet of the valve.

3

Appl

y a vacuum t

o the valve and mo

nitor the reading for 2 minutes.

4

Do

es the valve hold vacuum?

Yes Inspect the pipes at either side of the valve for leaks/damage. Rectify as necessary.

No INSTALL a new Rochester valve. TEST the system for normal operation.

Page 1265 of 2490

Voltage is monitored at the regulators and solenoids for continuity and shorts. For example, when a solenoid is ON the

voltage on the TCM side should be ground , when OFF the voltage should be +12.

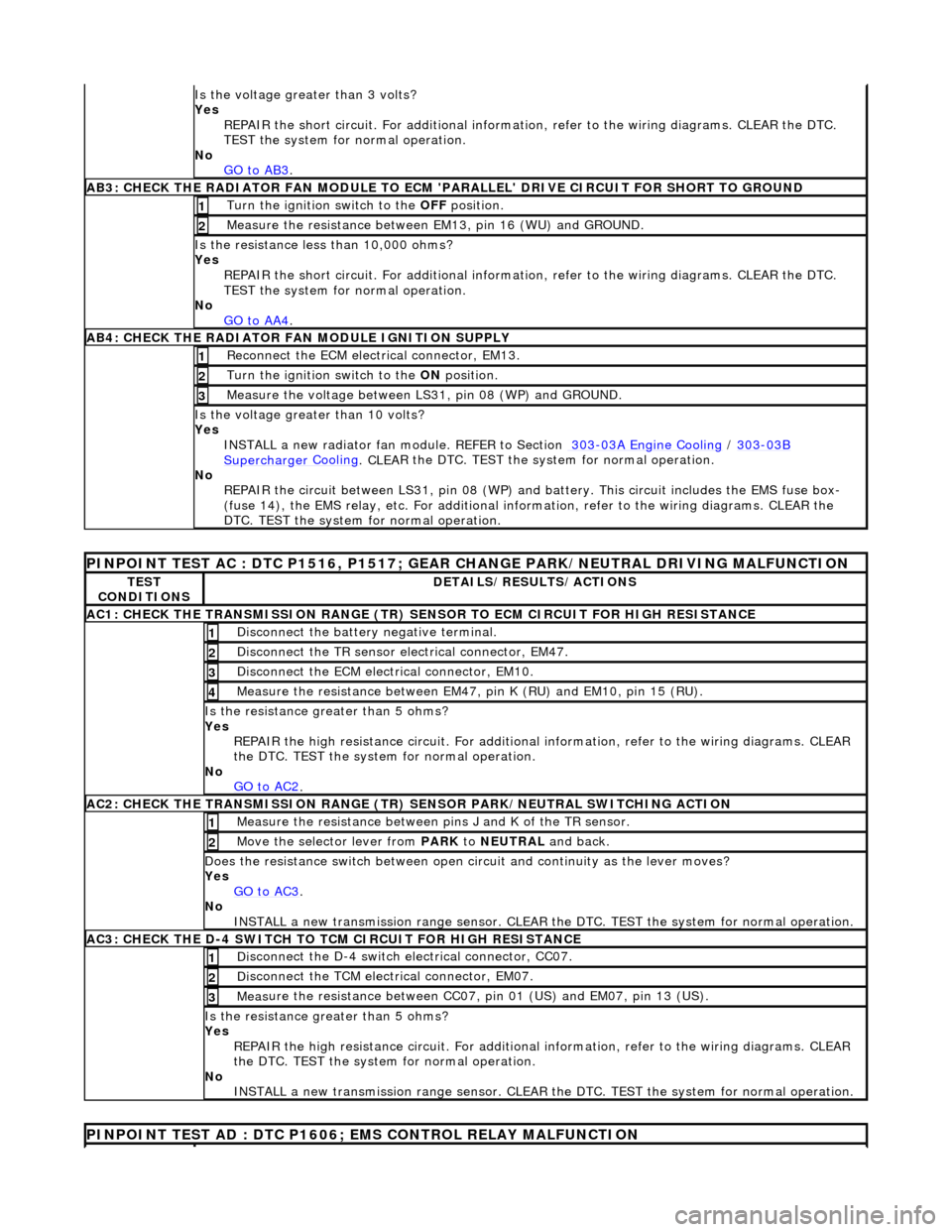

Shift Solenoid

The function of the three soleno id valves is to control the flow of transmissi on oil to the various transmission components.

Three solenoid valves are located wi thin the transmission assembly, and are closed when not energized.

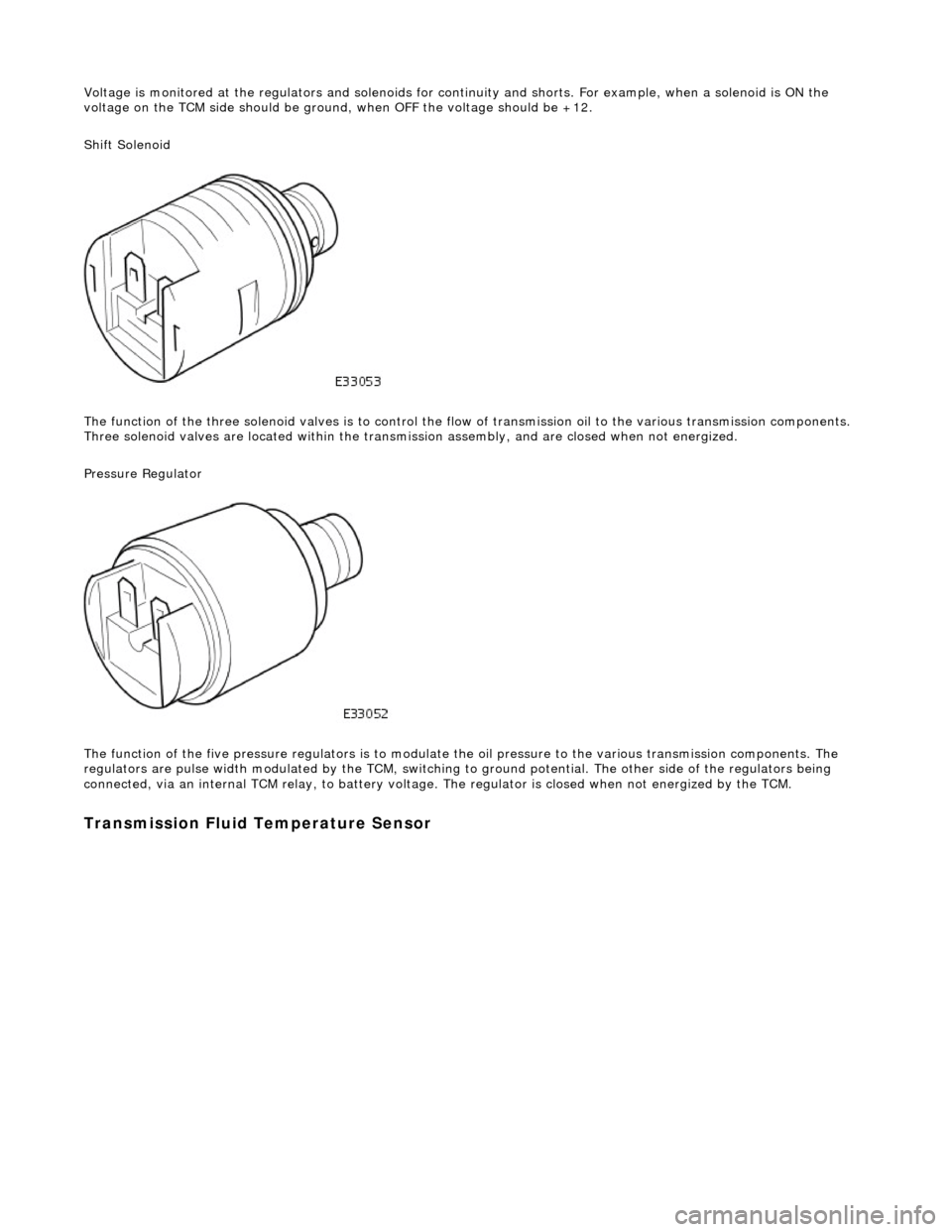

Pressure Regulator

The function of the five pressu re regulators is to modulate the oil pressure to the various transmission components. The

regulators are pulse width modulated by the TCM, switching to ground potential. The other side of the regulators being

connected, via an internal TCM relay, to battery voltage. The regulator is closed when not energized by the TCM.

Transmission Fluid Temperature Sensor

Page 1545 of 2490

Pinpoint test B: P0133

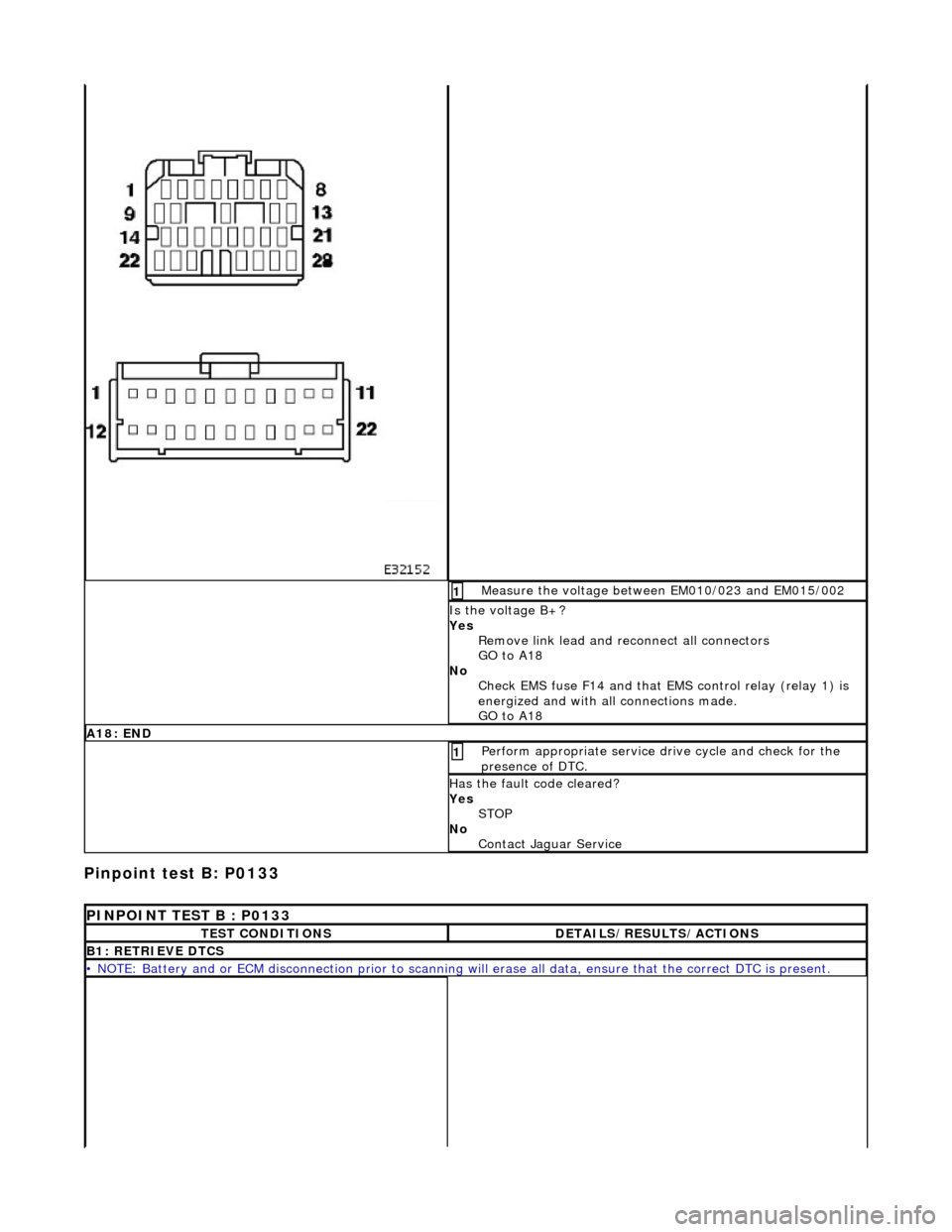

Measure the voltage between EM010/023 and EM015/002 1

Is the voltage B+?

Yes Remove link lead and reconnect all connectors

GO to A18

No Check EMS fuse F14 and that EMS control relay (relay 1) is

energized and with all connections made.

GO to A18

A18: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST B : P0133

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

B1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1557 of 2490

Pinpoint test C: P0137, P0138

Measure the voltage between EM010/023 and EM015/002. 1

Is the voltage B+?

Yes Remove link lead and reconnect all connectors.

GO to B19

No Check EMS fuse F14 and that EMS control relay (relay 1) is

energized and with all connections made.

GO to B19

B19: END

Perform appropriate service drive cycle and check for the

presence of DTC 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST C : P0137, P0138

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

C1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.