relay JAGUAR X308 1998 2.G Manual PDF

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1597 of 2490

Pinpoint test F: P0153

With EM010 and EM015 disconnected, measure the

voltage between EM010/023 and EM015/001. 1

Is the voltage B+?

Yes Remove link lead and reconnect all connectors.

GO to E18

No Check integrity of EMS fuse F1 4, EMS control relay (relay

1) is energized and all connections are made.

GO to E18

E18: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST F : P0153

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

F1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1609 of 2490

Pinpoint test G: P0157, P0158

With EM010 and EM015 disconnected, measure the

voltage between EM010/023 and EM015/002. 1

Is the voltage B+?

Yes Remove link lead and reconnect all connectors.

GO to F19

No Check integrity of EMS fuse F1 4, EMS control relay (relay

1) is energized and all connections made.

GO to F19

F19: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST G : P0157, P0158

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

G1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1693 of 2490

Filler Cap and P

ipe

The fuel

filler cap with bayonet-type fixi

ng is located beneath a remote-release sp ring-latched lid on the rear saddle panel

on the left-hand-side of the vehicle.

Fuel Pum

p

The fu

el pump(s) is energized by an ECM co

ntrolled relay. Fuel is drawn by this pu mp and supplied to the fuel injectors via

the fuel line, filter and fuel rails.

Servicing of the fuel pump re quires fuel tank removal.

Ev

aporative Loss Flange Assembly

The evaporative-loss flan

ge asse

mbly is mounted centrally on top of the tank. The flange assembly consists of a removeable

steel cap which mounts the evaporative emissions system vapor outlet valves and, if applicable, a pressure sensor. The

external electrical supply to th e fuel pump(s) is also made via a connector on the flange.

The flange assembly is fixed to the tank by a locking ring which is turned usin g special tool JD-174. A seal is fitted between

the flange assembly and the tank. Three di fferent flange assemblies are applicable according to the evaporative emission

system fitted to the vehicle. The fl ange size and fixing are identical fo r the three systems, as described.

Removal of the evaporative flange assembly is necessary to gain access to th e fuel pump(s) and other internal components.

To remove the evaporative fl ange assembly the fuel tank must first be removed.

The evaporative flange variant assemblies are described, together with service information, in Section 303-13.

Fuel R

eturn

Excess fuel

is directed back to

the fuel tank via a return line.

Fuel Pum

p Relay

The

fuel pump relay,

under control of the ECM, switches power to the fuel pump motor.

I

nertia Fuel Shutoff (IFS) Switch

The IF

S switch is located in the right-hand

side footwell behind the footboard carpet . When activated the switch isolates the

ignition system and fuel pump, releases any locked doors and disables unnecessary electrical systems. The system can be

reset by pressing down the flexible cover on the top of the switch.

• NOTE: The doors will not unlock if the IFS switch is tripped when the ignition switch is in position '0'.

Page 1698 of 2490

Fuel Tank and Lines - Fuel Tank and Li

nes

D

iagn

osis and Testing

Sym

p

tom Chart

Sy

m

ptom Chart

Pinpoint test A: P1230

S

p

ecial Tool(s)

D

i

gital multimeter

Generi

c scan tool

F

u

el tank sender (sensor) unit wrench

18G 1001

Sy m

ptom

Possib

l

e Sources

Acti

o

n

D

T

C P1230 Fuel pump relay

malfunction

Re lay

failure

Harness fault

Connector loose or corroded

Connector pins(s) bent or tracking between connections

Ground failure

*

*

*

*

*

GO to Pinpoint

Test A

*

D

T

C P1646 Secondary fuel pump

relay malfunction

Re lay

failure

Harness fault

Connector loose or corroded

Connector pins(s) bent or tracking between connections

Ground failure

*

*

*

*

*

GO to Pinpoint

Test B

*

D

T

C P0460 Fuel level sensor circuit

malfunction

Worn

or damaged sensor tracks

Harness fault

Connector loose or corroded

Connector pin/s bent or tracking between connections

Fuel level sensor to instrument pack circui ts intermittent short

or open circuit or high resistance. Fuel level sensor failure

Instrument pack fault (inc orrect fuel level data)

*

*

*

*

*

*

*

GO to Pinpoint

Test C

*

P

INPOINT TES

T A : A: P1230

T

E

ST CONDITIONS

D

E

TAILS/RESULTS/ACTIONS

A1

: RETRIEV

E DTCS

•

NOTE

: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

Page 1700 of 2490

Wi

th EM013 disconnected, check for battery voltage

between EM013/001 and ground BT020L.

1

B+ ?

Yes

GO t

o A13

No GO to A4

A4: CHECK

SUPPLY VOLTAGE

•

NOTE: Do not replace relay.

Page 1701 of 2490

W

ith relay 4 removed, check for battery voltage at relay

socket between pins 3 and 5.

1

B+

Yes GO to A5

No GO to A11

A5

: CHECK CIRCUIT CONTINUITY

•

NOTE: Do not replace relay.

Page 1702 of 2490

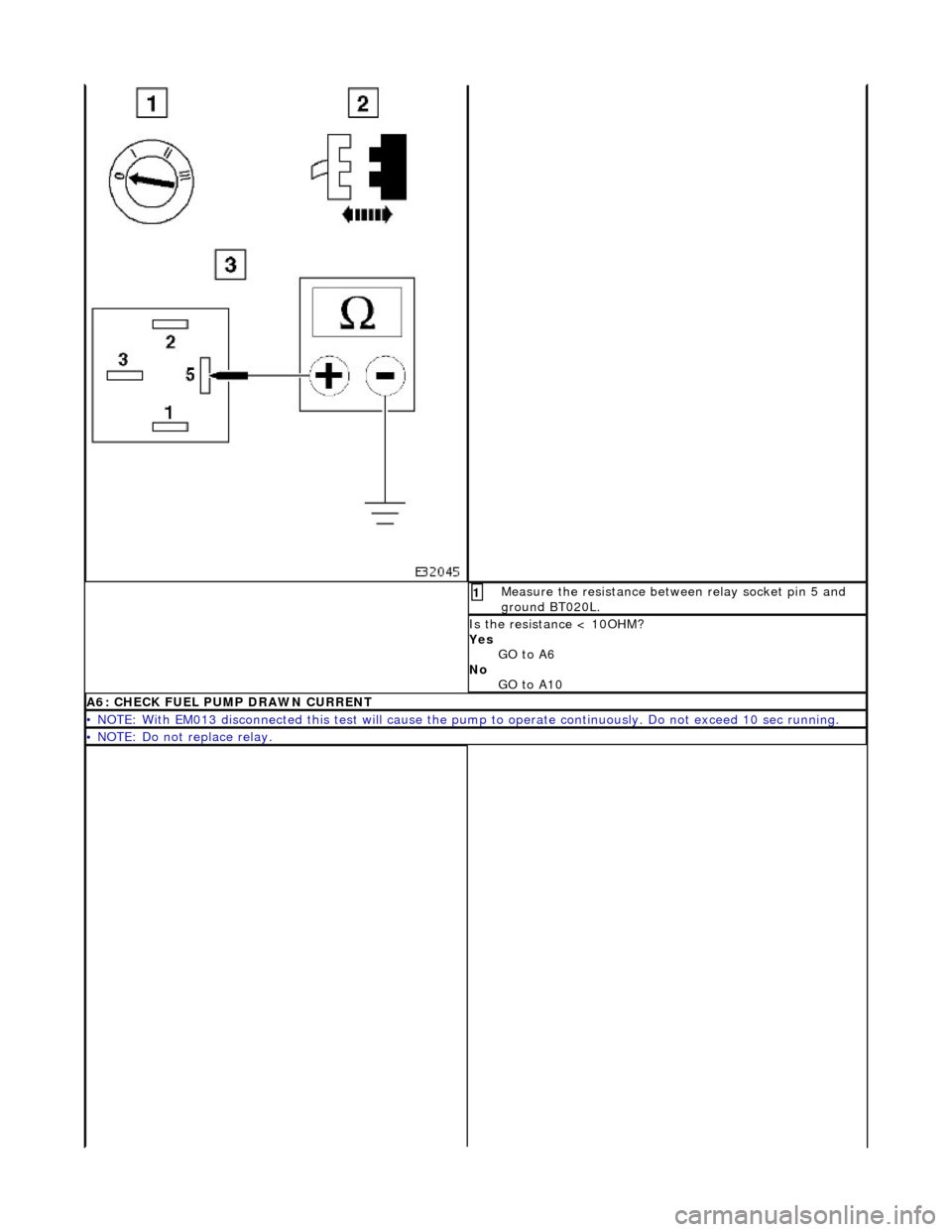

Measure t

he resistance between relay socket pin 5 and

ground BT020L.

1

I s

the resistance < 10OHM?

Yes GO to A6

No GO to A10

A6: CHECK FUEL

PUMP DRAWN CURRENT

•

NOTE

: With EM013 disconnected this test will cause the pump to operate continuously. Do not exceed 10 sec running.

•

NOTE: Do not replace relay.

Page 1703 of 2490

Wi

th the ignition energized, measure the current drawn

between relay socket pins 3 and 5.

1

Is

the current between 2.5 and 9 A?

Yes GO to A7

No GO to A10

A7

: CHECK B+ AT RELAY COIL

•

NOTE: Do not replace relay.

Page 1704 of 2490

Us

ing a link lead, connect EM013/001 to ground BT020L.

1

W

i

th ignition energized, check for battery voltage at relay

socket between pins 2 and 1.

2

B+?

Yes

GO t

o A10

No GO to A8

A8: CH

ECK RELAY COIL

CIRCUIT CONTINUITY

Page 1705 of 2490

W

ith EM013 disconnected, measure the resistance

between EM013/001 and relay socket pin 1.

1

I

s the resistance < 0.5 OHM?

Yes GO to A9

No Inspect harness / connec tors EM013, EM003/005,

FC001/42, BT004/019 and BT011/010 for corrosion,

damage, bent or pushed back pins. Repair as required

and test the system for normal operation.

A9: CHECK

ECM GROUND CONTINUITY