engine JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2449 of 2490

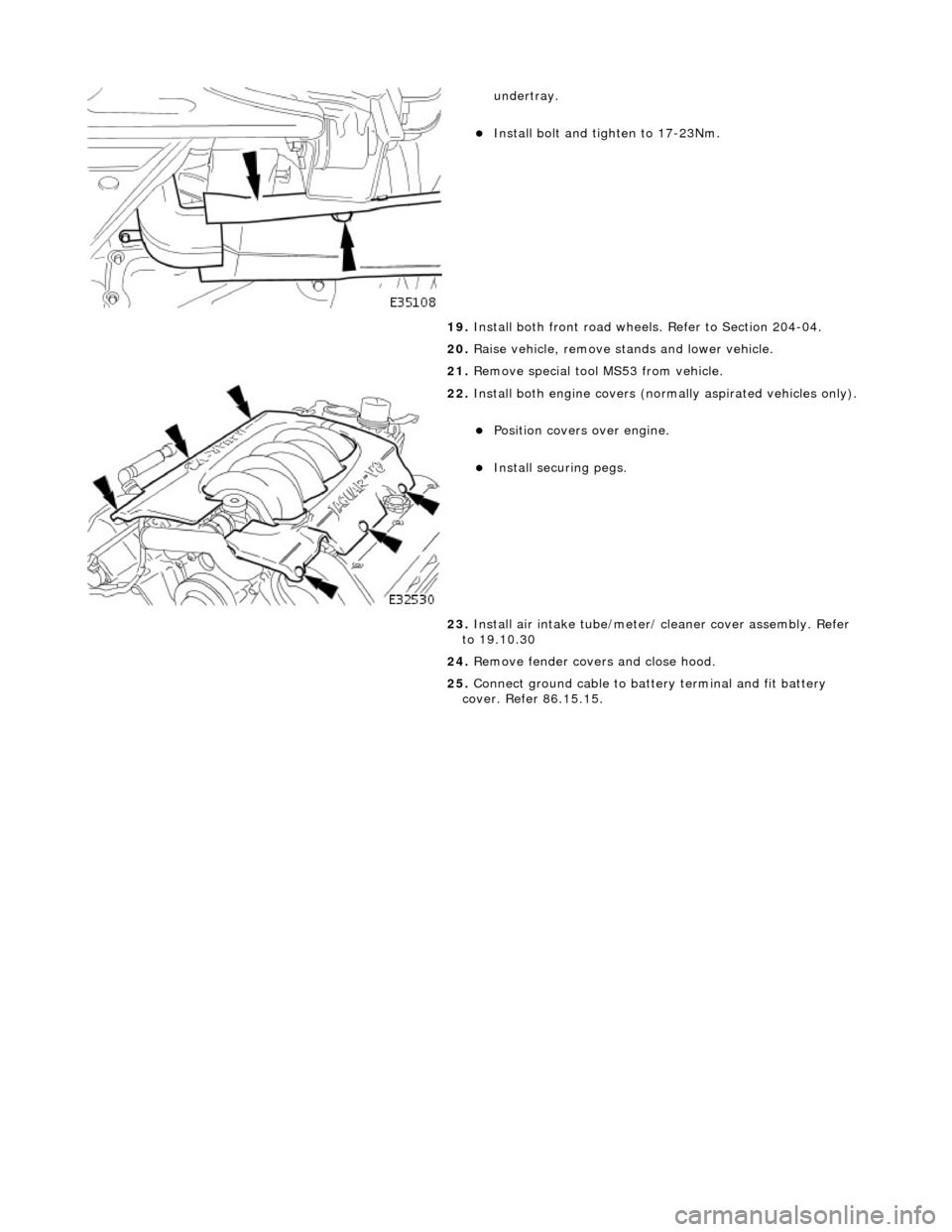

undertray.

пЃ¬Install bolt and tighten to 17-23Nm.

19. Install both front road wheels. Refer to Section 204-04.

20. Raise vehicle, remove st ands and lower vehicle.

21. Remove special tool MS53 from vehicle.

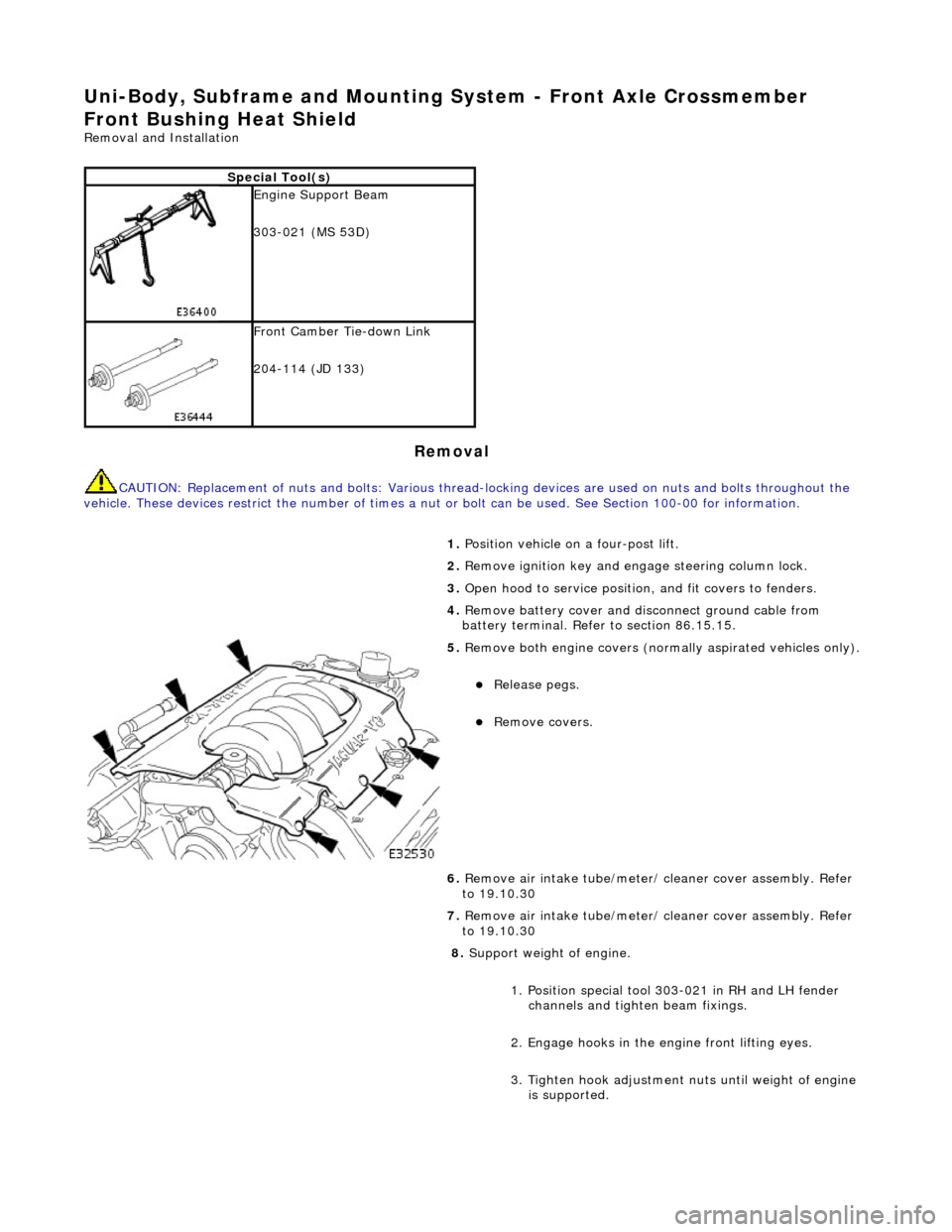

22. Install both engine co vers (normally aspirated vehicles only).

пЃ¬Position covers over engine.

пЃ¬Install securing pegs.

23. Install air intake tube/meter/ cleaner cover assembly. Refer

to 19.10.30

24. Remove fender covers and close hood.

25. Connect ground cable to batt ery terminal and fit battery

cover. Refer 86.15.15.

Page 2450 of 2490

Uni-Body, Subframe and Mounting System - Front Axle Crossmember

Front Bushing Heat Shield

Removal and Installation

Removal

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See Section 100-00 for information.

Special Tool(s)

Engine Support Beam

303-021 (MS 53D)

Front Camber Tie-down Link

204-114 (JD 133)

1. Position vehicle on a four-post lift.

2. Remove ignition key and en gage steering column lock.

3. Open hood to service position, and fit covers to fenders.

4. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to section 86.15.15.

5. Remove both engine covers (nor mally aspirated vehicles only).

пЃ¬Release pegs.

пЃ¬Remove covers.

6. Remove air intake tube/meter/ cleaner cover assembly. Refer

to 19.10.30

7. Remove air intake tube/meter/ cleaner cover assembly. Refer

to 19.10.30

8. Support weight of engine.

1. Position special tool 303-021 in RH and LH fender channels and tighte n beam fixings.

2. Engage hooks in the en gine front lifting eyes.

3. Tighten hook adjustment nuts until weight of engine is supported.

Page 2453 of 2490

21. Remove front road wheels. Refer to Section 100-02.

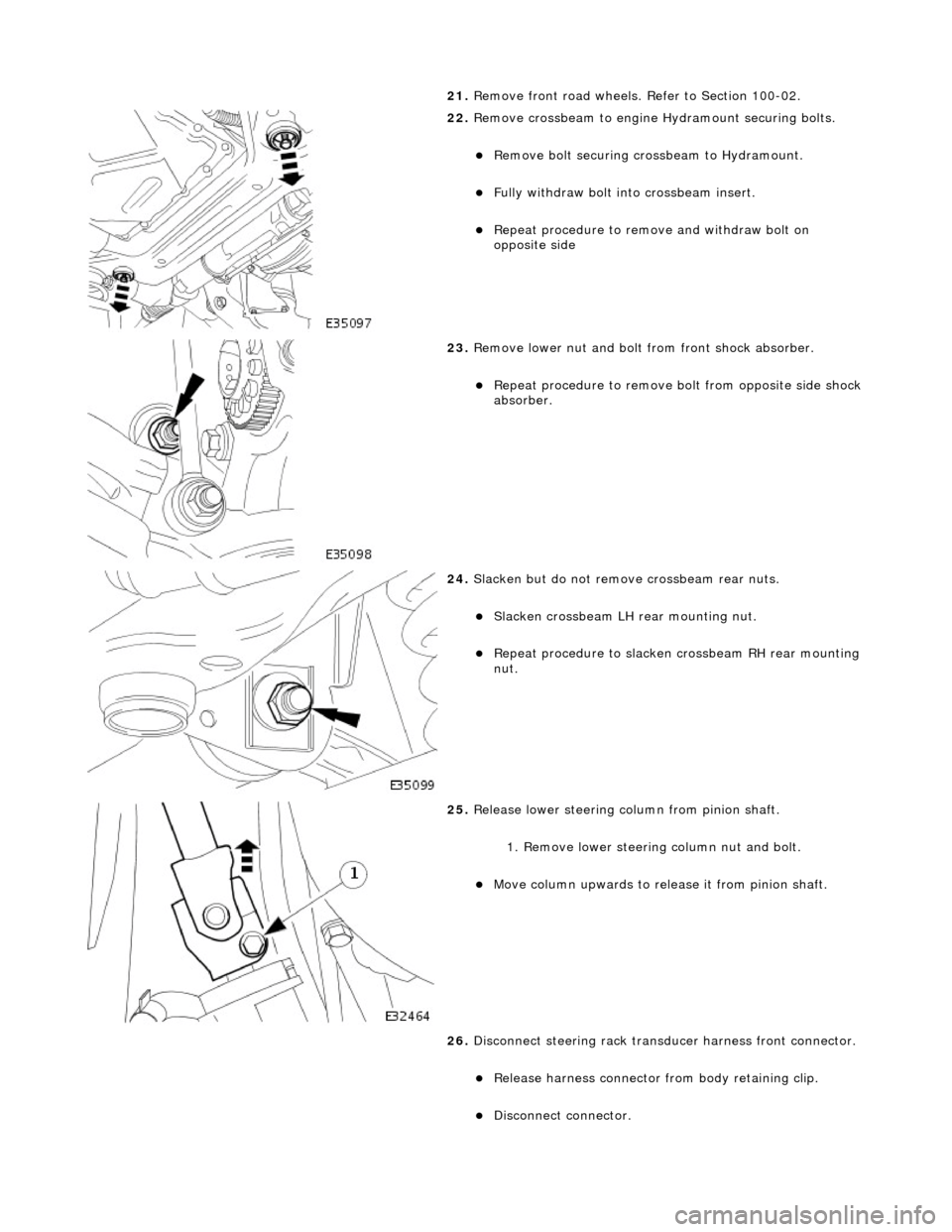

22. Remove crossbeam to engine Hydramount securing bolts.

пЃ¬Remove bolt securing crossbeam to Hydramount.

пЃ¬Fully withdraw bolt into crossbeam insert.

пЃ¬Repeat procedure to remove and withdraw bolt on

opposite side

23. Remove lower nut and bolt from front shock absorber.

пЃ¬Repeat procedure to remove bo lt from opposite side shock

absorber.

24. Slacken but do not remove crossbeam rear nuts.

пЃ¬Slacken crossbeam LH rear mounting nut.

пЃ¬Repeat procedure to slacken crossbeam RH rear mounting

nut.

25. Release lower steering column from pinion shaft.

1. Remove lower steering column nut and bolt.

пЃ¬Move column upwards to release it from pinion shaft.

26. Disconnect steering rack transducer harness front connector.

пЃ¬Release harness connector from body retaining clip.

пЃ¬Disconnect connector.

Page 2454 of 2490

27. Support weight of crossbeam.

пЃ¬Position a jack under crossbeam.

пЃ¬Place a piece of wood between jack and crossbeam.

пЃ¬Raise jack to just support crossbeam.

28. From engine compartment, remo ve crossbeam front RH bolts.

29. Remove power steering fl uid reservoir for access.

пЃ¬Remove reservoir nuts and bolts.

пЃ¬Position reservoir for access.

30. From engine compartment, remo ve crossbeam front LH bolts.

Page 2456 of 2490

correctly seated in body locations.

3. Ensure that both engine hydram ounts are correctly seated in

crossbeam locations.

4. From engine compartment, install but do not tighten

crossbeam front RH bolts.

5. From engine compartment, install crossbeam front LH bolts

and tighten to 22-28Nm.

6. Install power steering fluid reservoir.

пЃ¬Position reservoir on mounting bracket.

пЃ¬Install reservoir securi ng nuts and bolts.

Page 2457 of 2490

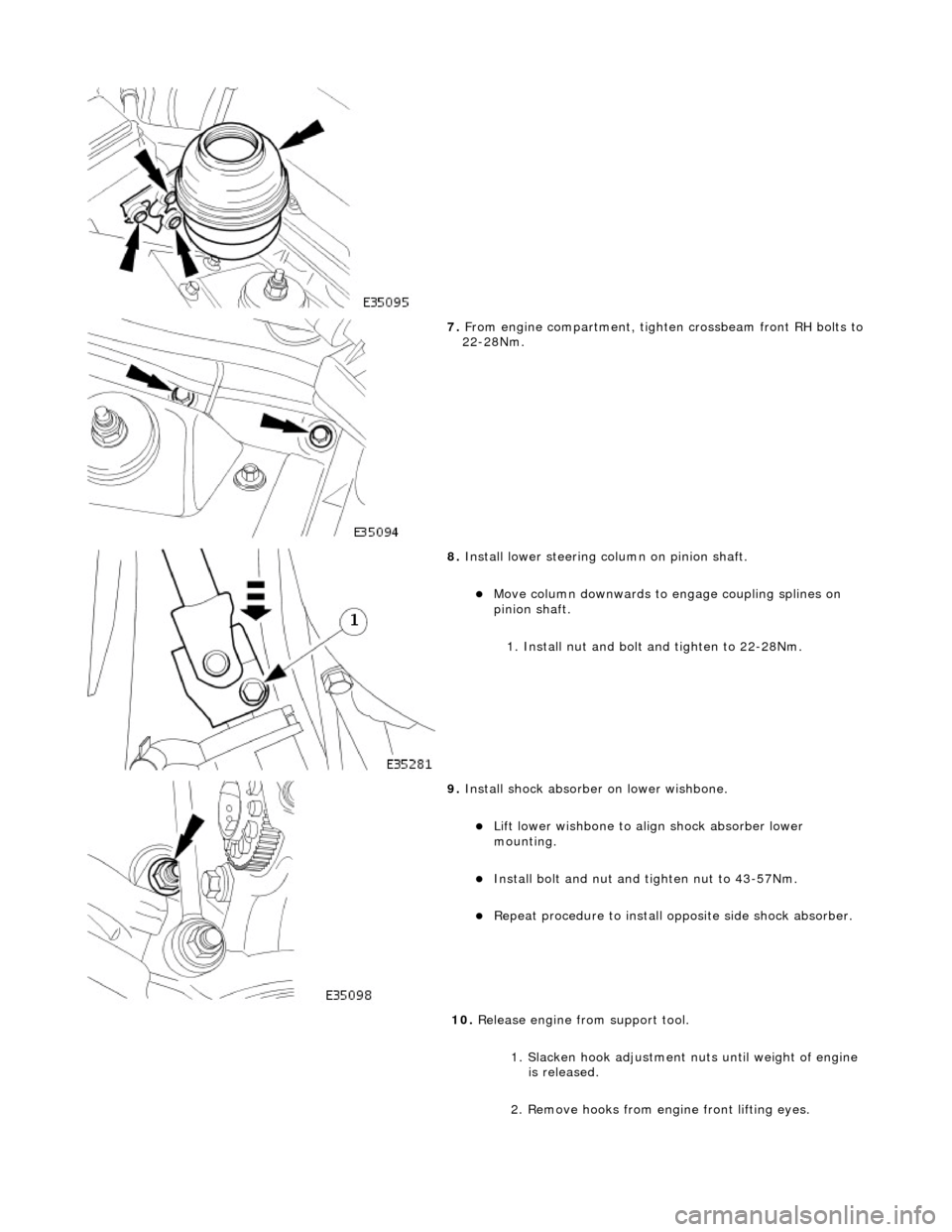

7. From engine compartment, tighten crossbeam front RH bolts to 22-28Nm.

8. Install lower steering column on pinion shaft.

пЃ¬Move column downwards to engage coupling splines on

pinion shaft.

1. Install nut and bolt and tighten to 22-28Nm.

9. Install shock absorber on lower wishbone.

пЃ¬Lift lower wishbone to align shock absorber lower

mounting.

пЃ¬Install bolt and nut and ti ghten nut to 43-57Nm.

пЃ¬Repeat procedure to install opposite side shock absorber.

10. Release engine from support tool.

1. Slacken hook adjustment nuts until weight of engine is released.

2. Remove hooks from engine front lifting eyes.

Page 2458 of 2490

3. Remove special tool 303-021 from fender channel.

11. Install crossbeam to engine Hydramount bolts.

пЃ¬Install bolt securing Hydramou nt to crossbeam and tighten to 34-46Nm.

пЃ¬Repeat procedure to install crossbeam opposite side bolt.

12. Tighten rear mounting bolt and nut to 131-185 Nm.

пЃ¬Repeat procedure to tighten opposite side rear mounting

bolt and nut.

13. Connect steering rack transducer harness front connector.

пЃ¬Connect steering ha rness connector.

пЃ¬Install harness connector on body retaining clip.

14. Slacken adjuster nut and remove camber tie down tool 204-

114 from suspension.

пЃ¬Repeat procedure to remove tie down tool from opposite

side.

Page 2460 of 2490

пЃ¬Install bolt and tighten to 17-23Nm.

19. Install both front road wheels. Refer to Section 204-04.

20. Raise vehicle, remove st ands and lower vehicle.

21. Remove special tool MS53 from vehicle.

22. Install both engine co vers (normally aspirated vehicles only).

пЃ¬Position covers over engine.

пЃ¬Install securing pegs.

23. Install air intake tube/meter/ cleaner cover assembly. Refer

to 19.10.30

24. Remove fender covers and close hood.

25. Connect ground cable to batt ery terminal and fit battery

cover. Refer 86.15.19.

Page 2461 of 2490

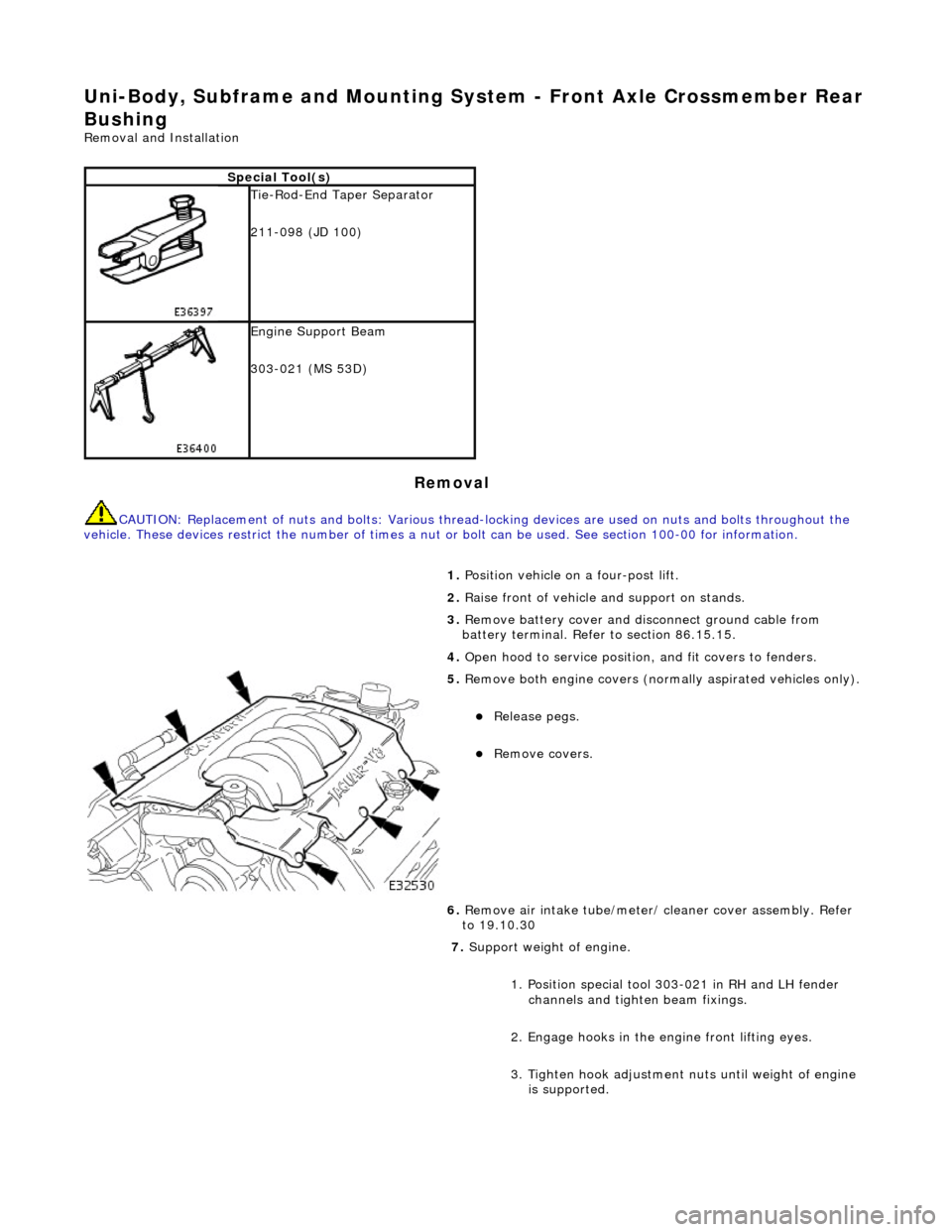

Uni-Body, Subframe and Mounting System - Front Axle Crossmember Rear

Bushing

Removal and Installation

Removal

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Special Tool(s)

Tie-Rod-End Taper Separator

211-098 (JD 100)

Engine Support Beam

303-021 (MS 53D)

1. Position vehicle on a four-post lift.

2. Raise front of vehicle and support on stands.

3. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to section 86.15.15.

4. Open hood to service position, and fit covers to fenders.

5. Remove both engine covers (nor mally aspirated vehicles only).

пЃ¬Release pegs.

пЃ¬Remove covers.

6. Remove air intake tube/meter/ cleaner cover assembly. Refer

to 19.10.30

7. Support weight of engine.

1. Position special tool 303-021 in RH and LH fender channels and tighte n beam fixings.

2. Engage hooks in the en gine front lifting eyes.

3. Tighten hook adjustment nuts until weight of engine is supported.

Page 2466 of 2490

пЃ¬Place a piece of wood between jack and crossbeam.

пЃ¬Raise jack to just support crossbeam.

30. From engine compartment, remove crossbeam front RH

securing bolts.

31. Remove power steering fl uid reservoir for access.

пЃ¬Remove reservoir securing nuts and bolts.

пЃ¬Position reservoir for access.

32. From engine compartment, remove crossbeam front LH

securing bolts.

33. Remove crossbeam to engine Hydramount securing bolts.

пЃ¬Remove bolt securing cros smember to Hydramount.

пЃ¬Fully withdraw bolt into crossmember insert.

пЃ¬Repeat procedure to remove and withdraw bolt on