Crankshaft sensor JAGUAR X308 1998 2.G Manual PDF

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1179 of 2490

generates a signal when th

e dr

ive plate passes the sensor

sen

ds the ECM signals indicating crankshaft position and engine speed

is e

ssential for calculating spark timing

En

gine Coolant Temperature (ECT) Sensor

sen

ds the ECM a signal indicating the temperature of the engine coolant

is a t

emperature dependent resistor with a negative temperature coefficient (resistance changes inversely with

respect to temperature) and is constantly monitored by the ECM

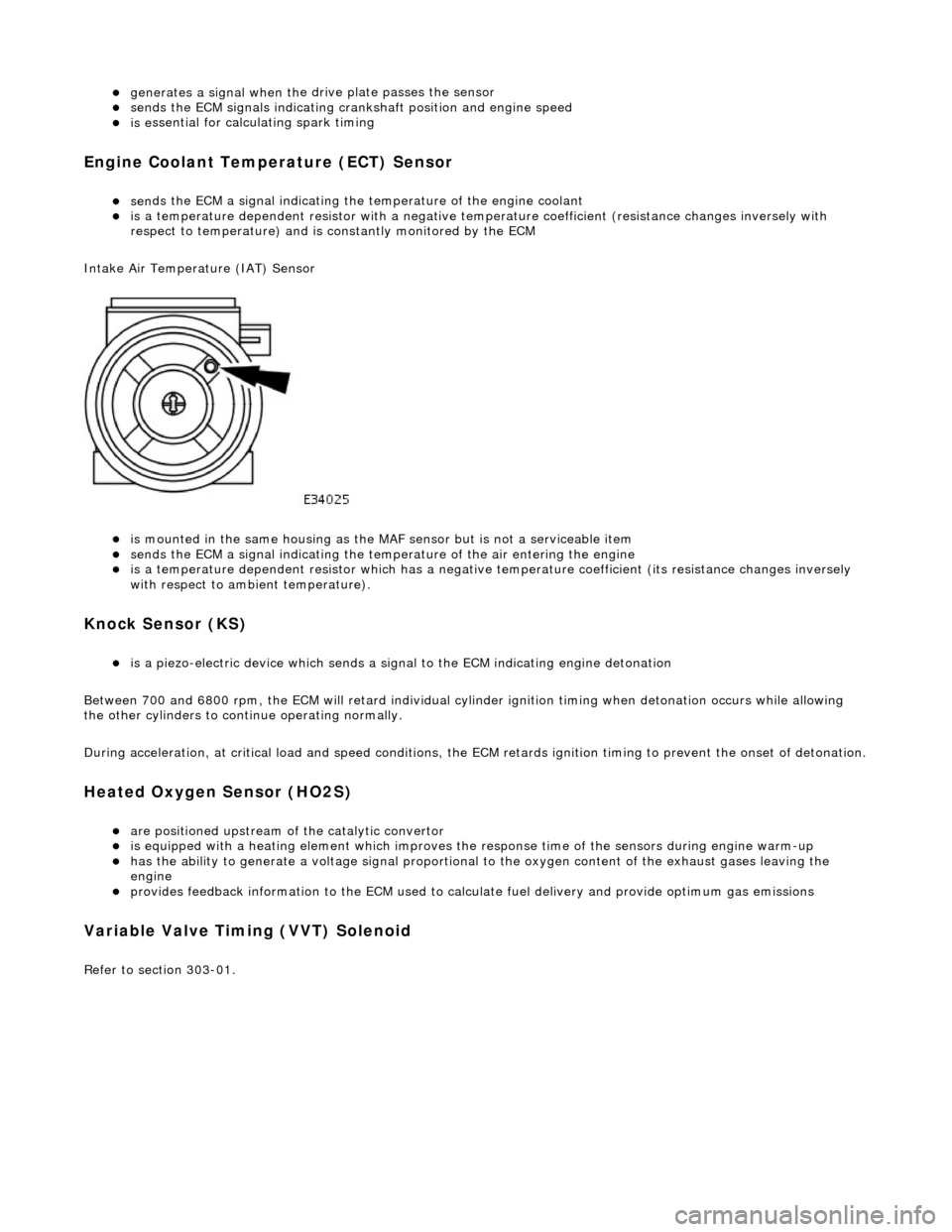

Intake Air Temperature (IAT) Sensor

is m

ounted in the same housing as the MA

F sensor but is not a serviceable item

sen

ds the ECM a signal indicating the temperature of the air entering the engine

is a t

emperature dependent resistor which has a negative

temperature coefficient (its resistance changes inversely

with respect to ambient temperature).

Knock S

ensor (KS)

is a pi

ezo-electric device which sends a signal

to the ECM indicating engine detonation

Between 700 and 6800 rpm, the ECM will retard individual cylinder ignition timing when detonation occurs while allowing

the other cylinders to continue operating normally.

During acceleration, at critical load and speed conditions, the ECM retards ignition timing to prevent the onset of detonation.

H

eated Oxygen Sensor (HO2S)

are

positioned upstream of the catalytic convertor

is equipped with

a heating element wh

ich improves the response time of the sensors during engine warm-up

h

as the ability to generate a voltage signal proportional to the oxygen content of the exhaust gases leaving the

engine

pr

ovides feedback information to the ECM used to calc

ulate fuel delivery and provide optimum gas emissions

Variable V

alve Timing (VVT) Solenoid

R

efer to section 303-01.

Page 1185 of 2490

It

em

Par

t Number

De

scription

1—Cranksh

aft position sensor

2—Engine

control module (ECM)

Crankshaft Posi

tion sensor

Page 1216 of 2490

L3

: CHECK THE KS SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

t

ch to the OFF

position.

1

Me

asure the resistance between PI26, pin 01 (S) and GROUND.

2

Is

t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new KS.

REFER to Knock Sensor (KS)

in this

section.

CLEAR the DTC. TEST the system for normal operation.

P INPOINT TES

T M : DTC P0332, P0333; LEFT-H

AND KNOCK SENSOR (KS) CIRCUIT OUT OF RANGE

(LOW VOLTAGE)

•

NOTE: Before commencing this

test, make sure that the sensor is making a good electrical contact with the cylinder

block. See 'possible causes'.

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

M1: CHECK THE KS SEN

S

E CI

RCUIT FOR HIGH RESISTANCE

Di

sc

onnect the battery negative terminal.

1

Di

sc

onnect the KS electrical connector, PI27.

2

D

i

sconnect the ECM electrical connector, EM13.

3

M

e

asure the resistance between PI27, pin 01 (N) and EM13, pin 17 (N).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to M2

.

M2: CHECK TH

E KS SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

Turn the ignition swi

t

ch to the ON

position.

1

Re

connect the battery negative terminal.

2

Meas

ure t

he voltage between PI27, pin 01 (N) and GROUND.

3

Is th

e volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to M3

.

M3: CHECK TH

E KS SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

t

ch to the OFF

position.

1

Measure t

he resistance between PI27, pin 01 (N) and GROUND.

2

Is

t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new KS.

REFER to Knock Sensor (KS)

in this

section.

CLEAR the DTC. TEST the system for normal operation.

PINPOINT TEST N : DTC P0335;

CRANKSHAFT POSITION (CKP) SENSOR CIRCUIT MALFUNCTION

TE

S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

N

1: CH

ECK THE CKP SENSOR FOR CORRECT INSTALLATION

Turn the ignition swi

t

ch to the OFF

position.

1

Check the CKP sen

sor fo

r correct installation.

2

Is the CK

P sensor correctly installed?

Yes GO to N2

.

No

INST

ALL the CKP sensor correctly.

Page 1217 of 2490

REF

ER to

Crankshaft Position (CKP) Sensor

in this section.

Reconnect the sensor. CLEAR the DTCs. TE ST the system for normal operation.

N

2: CHECK THE CKP SENSOR FOR DEBRIS

Re

move the CKP sensor

and inspect for debris.

1

Is the CKP sensor free of

debris?

Yes GO to N3

.

No

CLEAN the sensor and whee l. INSTALL the sensor.

REFER to Crankshaft Position (CKP) Sensor

in this section.

Reconnect the sensor. CLEAR the DTCs. TE ST the system for normal operation.

N

3: CHECK THE CKP SENSOR SENSE CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM13.

2

Me

asure the resistance between EM13, pin 19 (Y) and PI17, pin 01 (Y).

3

Meas

ure the resistance between EM13, pin 28 (P) and PI17, pin 02 (P).

4

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to N4

.

N

4: CHECK THE CKP SENSOR SENSE CI

RCUIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

Meas

ure the voltage between PI17, pin 19 (Y) and GROUND.

3

M

easure the voltage between PI17, pin 28 (P) and GROUND.

4

Is ei

ther voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to N5

.

N

5: CHECK THE CKP SENSOR SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between EM13, pin 19 (Y) and GROUND.

2

Meas

ure the resistance between EM13, pin 28 (P) and GROUND.

3

Is either resi

stance

less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new CKP sensor.

REFER to Crankshaft Position (CKP) Sensor

in this section.

CLEAR the DTC. TEST the system for normal operation.

P

INPOINT TEST O : DTC P0340;

CAMSHAFT POSITION (CMP) SENSOR CIRCUIT MALFUNCTION

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

O1: CHECK THE CM

P SENSOR FOR CORRECT INSTALLATION

Turn the ignition swi

tch to the OFF

position.

1

Check the CMP

sensor fo

r correct installation.

2

Is th

e CMP sensor correctly installed?

Yes GO to O2

.

No

INSTALL the CMP sensor correctly.

REFER to Camshaft Position (CMP) Sensor

in this section.

CLEAR the DTCs. TEST the system for normal operation.

O2: CHECK THE CM

P SENSOR FOR FOREIGN DEBRIS

Re

move the CMP sensor and

inspect for foreign debris.

1

Is the CMP sensor free of

foreign debris?

Page 1240 of 2490

In

stallation

7.

Re

move crankshaft position sensor.

R

e

move fixing.

Re

mo

ve sensor.

R

e

tain harness clips

1. Installation

is a reversal

of the removal procedure.