head bolt JAGUAR X308 1998 2.G Manual Online

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1233 of 2490

E

lectronic Engine Controls - Ca

mshaft Position (CMP) Sensor

Re

moval and Installation

Remov

al

1.

Disc

onnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Remove engine covers ; refer to 12.30.06.

3. WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

De-pressurize fuel system; refer to 19.50.02.

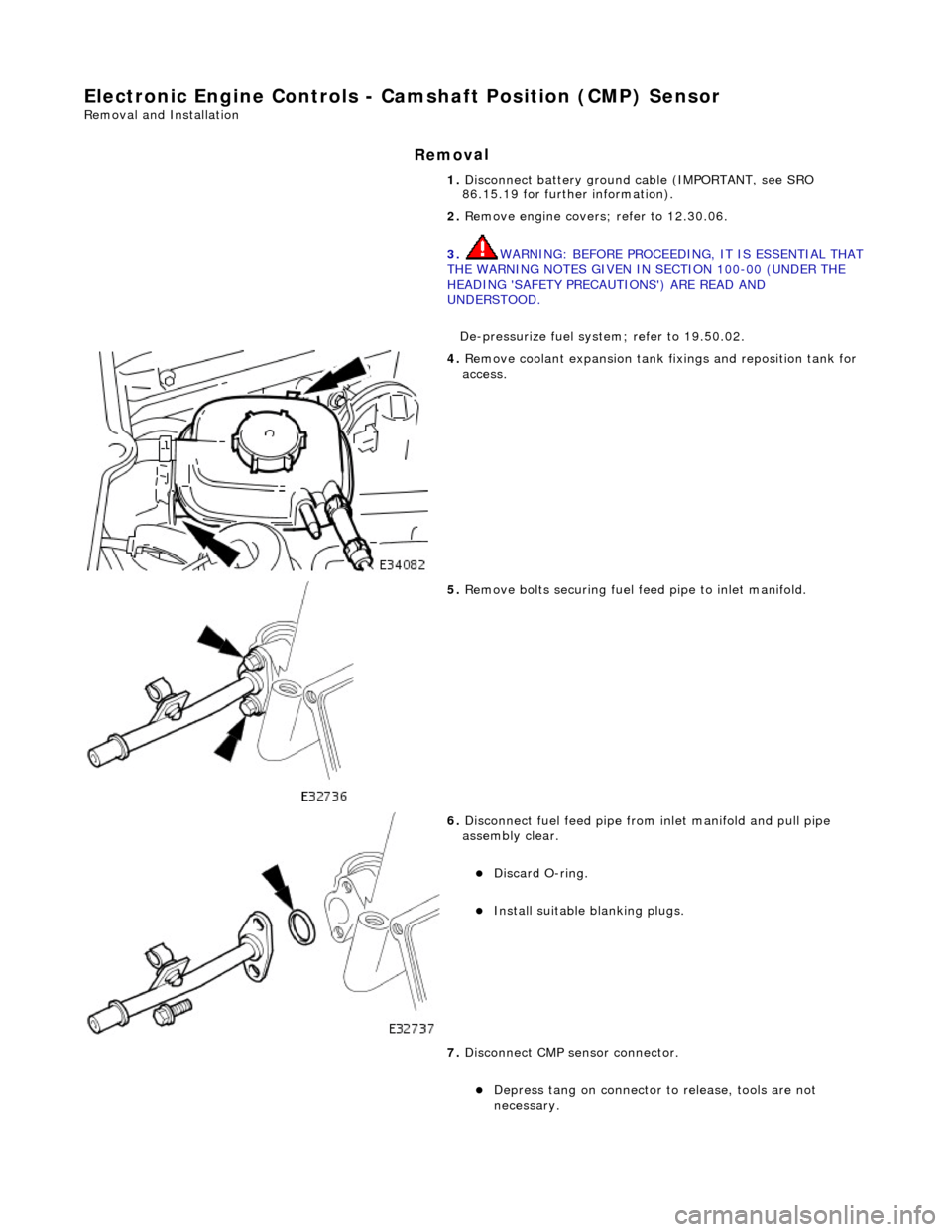

4. R

emove coolant expansion tank fixings and reposition tank for

access.

5. R

emove bolts securing fuel fe

ed pipe to inlet manifold.

6. Di

sconnect fuel feed pipe from inlet manifold and pull pipe

assembly clear.

Di

scard O-ring.

Inst

all suitable blanking plugs.

7. Disconnect CMP sensor connector.

De

press tang on connector to release, tools are not

necessary.

Page 1387 of 2490

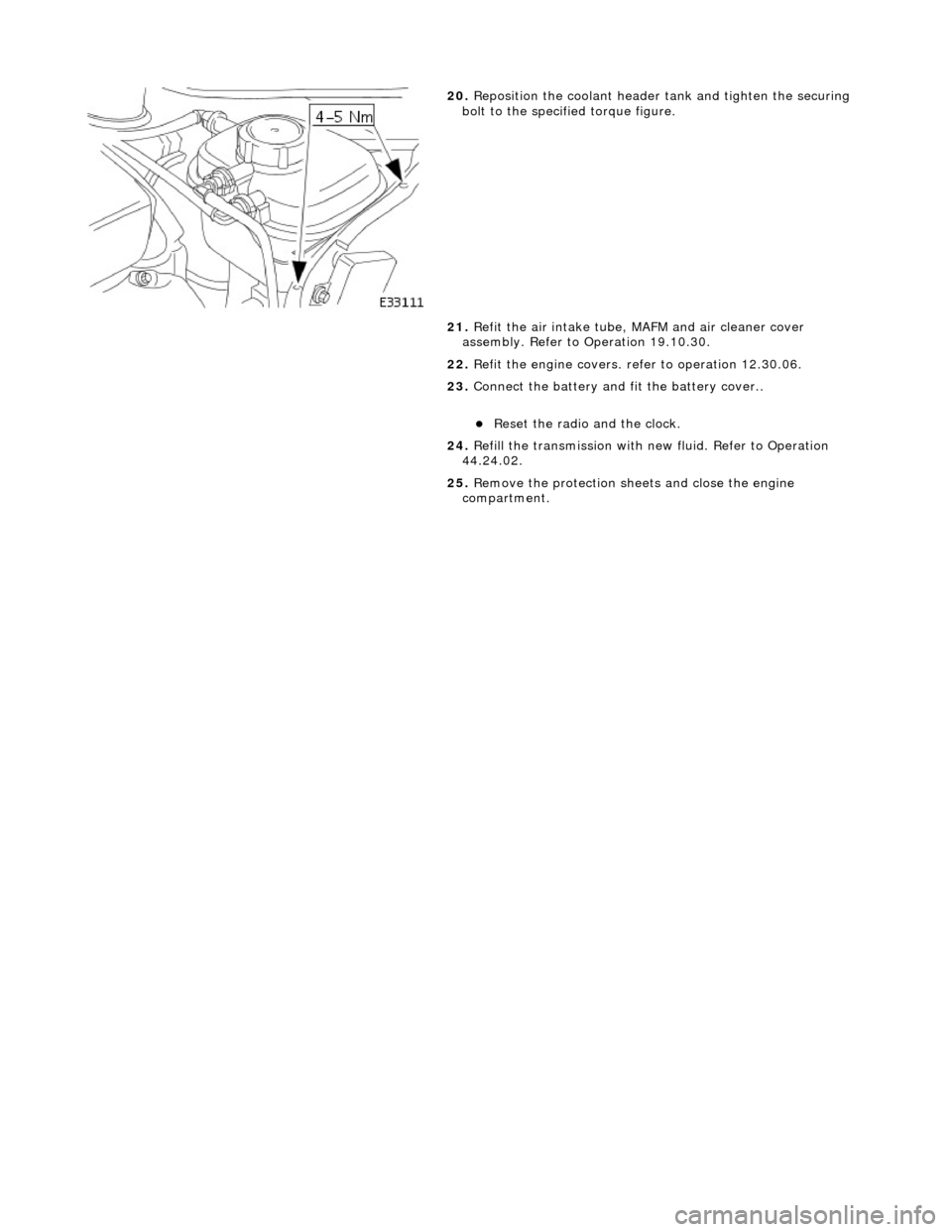

20. Reposition the coolant header tank and tighten the securing

bolt to the specified torque figure.

21. Refit the air intake tube, MAFM and air cleaner cover

assembly. Refer to Operation 19.10.30.

22. Refit the engine covers. re fer to operation 12.30.06.

23. Connect the battery and fit the battery cover..

Reset the radio and the clock.

24. Refill the transmission with new fluid. Refer to Operation

44.24.02.

25. Remove the protection sheets and close the engine

compartment.

Page 1388 of 2490

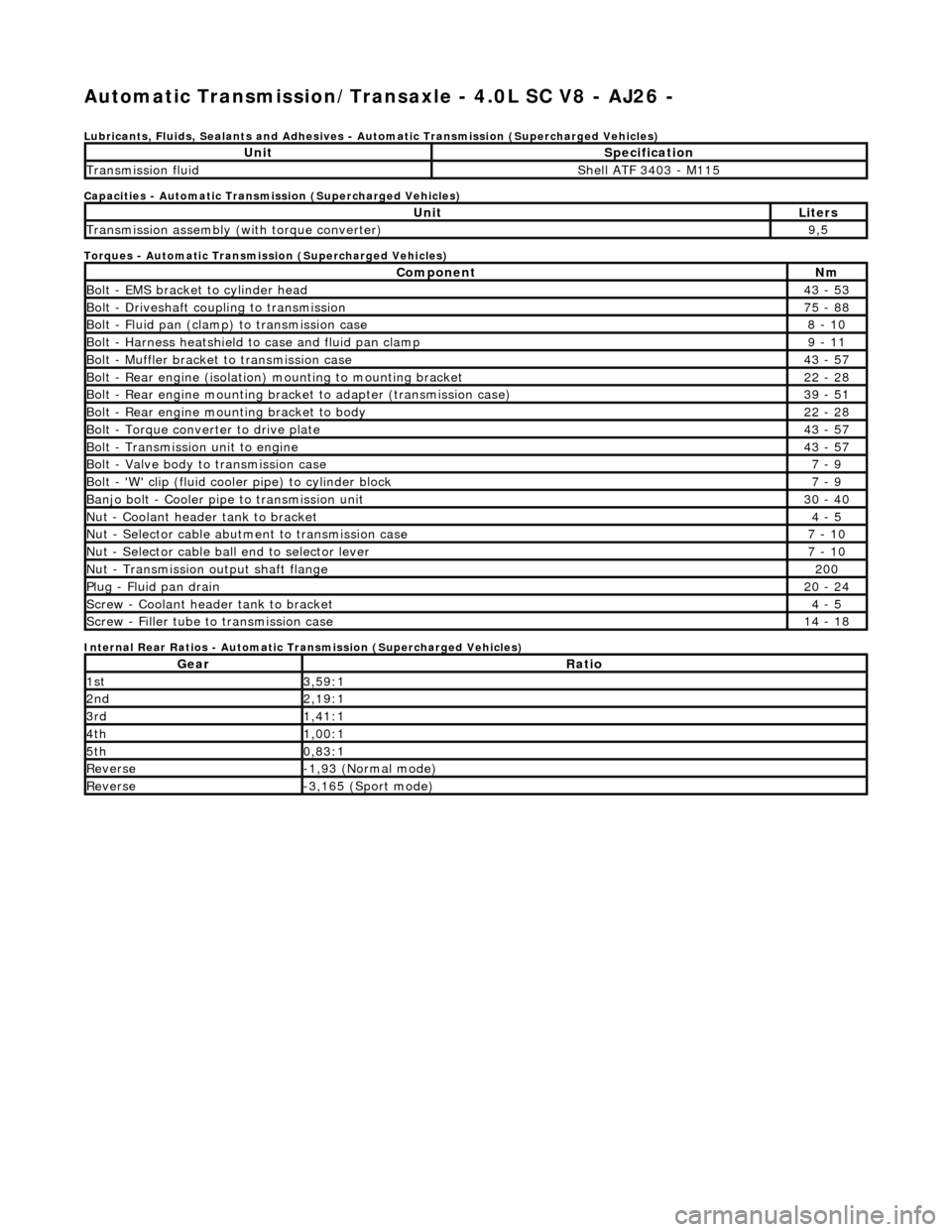

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 -

Lubricants, Fluids, Sealants and Adhesives - Automatic Transmission (Supercharged Vehicles)

Capacities - Automatic Transmission (Supercharged Vehicles)

Torques - Automatic Transmission (Supercharged Vehicles)

Internal Rear Ratios - Automatic Transmission (Supercharged Vehicles)

UnitSpecification

Transmission fluidShell ATF 3403 - M115

UnitLiters

Transmission assembly (with torque converter)9,5

ComponentNm

Bolt - EMS bracket to cylinder head43 - 53

Bolt - Driveshaft coupling to transmission75 - 88

Bolt - Fluid pan (clamp) to transmission case8 - 10

Bolt - Harness heatshield to case and fluid pan clamp9 - 11

Bolt - Muffler bracket to transmission case43 - 57

Bolt - Rear engine (isolation) mounting to mounting bracket22 - 28

Bolt - Rear engine mounting brac ket to adapter (transmission case)39 - 51

Bolt - Rear engine mounting bracket to body22 - 28

Bolt - Torque converter to drive plate43 - 57

Bolt - Transmission unit to engine43 - 57

Bolt - Valve body to transmission case7 - 9

Bolt - 'W' clip (fluid cooler pipe) to cylinder block7 - 9

Banjo bolt - Cooler pipe to transmission unit30 - 40

Nut - Coolant header tank to bracket4 - 5

Nut - Selector cable abutment to transmission case7 - 10

Nut - Selector cable ball end to selector lever7 - 10

Nut - Transmission output shaft flange200

Plug - Fluid pan drain20 - 24

Screw - Coolant header tank to bracket4 - 5

Screw - Filler tube to transmission case14 - 18

GearRatio

1st3,59:1

2nd2,19:1

3rd1,41:1

4th1,00:1

5th0,83:1

Reverse-1,93 (Normal mode)

Reverse-3,165 (Sport mode)

Page 1448 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Transmission

Removal

Removal

Special Tool(s)

Engine support

303-021

Engine lifting brackets

303-536

1. Select N gear position.

2. Disconnect the battery ground lead.

3. Remove the engine covers. Re fer to Operation 12.30.06.

4. Remove the air intake tube, MAFM and air cleaner cover

assembly. Refer to Operation 19.10.30.

5. Disconnect the transmission link lead connector.

1. Release the connector fr om its mounting bracket.

2. Disconnect the multiplug.

6. Remove the EMS harness mounting bracket.

Release the bolt, bracket to cylinder head.

7. Fit engine lifting bracket 307 - 536 at the rear RH.

Page 1640 of 2490

2. Fit a ne

w gasket to the mani

fold mating flange on the

downpipe.

3. Fit

the downpipe catalytic converter.

Fit the down

pipe assemb l

y to the manifold.

Fi

t,

but do not fully tighten, the mounting bracket securing

bolts. (Leave loose until the nu ts securing the downpipe to

the exhaust manifold are fitted.)

4. Lower the ramp.

5. Tighte

n the nuts securing the downpipe flange to the manifold

flange.

6. Connec t

the oxygen sensor multiplugs.

Con

n

ect the plug(s) to the respective (previously noted)

sensor(s).

Cor r

ectly position the multiplu

gs on the mounting bracket.

7. Fit the coolant header tank.

1. Reposition the tank and fit the securing nuts.

Page 1645 of 2490

6. Connec

t the oxygen sensor multiplugs.

Con

nect the plug(s) to the respective (previously noted)

sensor(s).

Cor

rectly position the multiplu

gs on the mounting bracket.

7. F

it the coolant header tank.

1. Reposition the tank and fit the securing nuts.

2. Connect the harness connector

8. R

efit the centre trim panel and th

e left hand enclosure panel to

the engine compartment.

1. Refit the centre trim panel.

2. Refit the left hand enclosure panel.

9. Raise the vehicle on the ramp.

10. Tighten the mounting brac ket securing bolts.

Page 1656 of 2490

5. Connec t

the oxygen sensor multiplugs.

Con

n

ect the plug(s) to the respective (previously noted)

sensor(s).

Cor r

ectly position the multiplu

gs on the mounting bracket.

6. Fi

t the coolant header tank.

1. Reposition the tank and fit the securing nuts.

2. Connect the harness connector

7. Re

fit the centre trim panel and th

e left hand enclosure panel to

the engine compartment.

1. Refit the centre trim panel.

2. Refit the left hand enclosure panel.

8. Raise the ramp.

9. Tighten the mounting brac ket securing bolts.

Page 1660 of 2490

In

stallation

1.

Fit a ne

w gasket to the mani

fold mating flange on the

downpipe.

2. Fit

the downpipe catalytic converter.

1. Fit the downpipe assembly to the manifold.

Fit,

but do not fully tighten, the mounting bracket securing

bolts. (Leave loose until the nu ts securing the downpipe to

the exhaust manifold are fitted.)

3. Lower the ramp.

4. Tigh te

n the nuts securing the downpipe flange to the manifold

flange.

5. Connec t

the oxygen sensor multiplugs.

Con

n

ect the plug(s) to the respective (previously noted)

sensor(s).

Cor r

ectly position the multiplu

gs on the mounting bracket.

6. Fi

t the coolant header tank.

1. Reposition the tank and fit the securing nuts.

2. Connect the harness connector

7. Refit the centre trim panel and th e left hand enclosure panel to

the engine compartment.

Page 1733 of 2490

Fuel Tank and Li

nes - Fuel Pump

Re

moval and Installation

Remov

al

Installation

1.

WARNING: B

EFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Remove the battery. For additional information, refer to Section

414

-0

1 Battery, Mounting and Cables

.

2.

Drain th

e fuel tank using a suitab

le suction pump/tanker. If the

On-board Refueling Vapour Recove ry (ORVR) system is fitted,

refer to Section 310

-00

Fuel System

- General

Information

.

3. R

emove the fuel tank. For addi

tional information, refer to Fuel

Tank

in this section.

4. Remove the fuel tank evaporativ e loss flange sealing ring. For

additional information, refer to Section 303

-13

.

5. R

emove fuel feed hose from tank.

U

sing special tool JD175, slacken fuel feed hose to tank

stub securing clip.

Di

sconnect hose from tank stub.

6. Remove fuel pump assembly.

R

elease bolt securing fuel

pump mounting bracket and

place assembly to front.

Slac

ken securing clip and disc

onnect hose from fuel pump.

R

emove link lead from fuel pump.

Re

move pump.

1. NOTE: Install new sealing ring to evaporative loss flange. For

additional information, refer to Section 303

-13

.

In

stallation is th

e reverse of the removal procedure.

Page 1848 of 2490

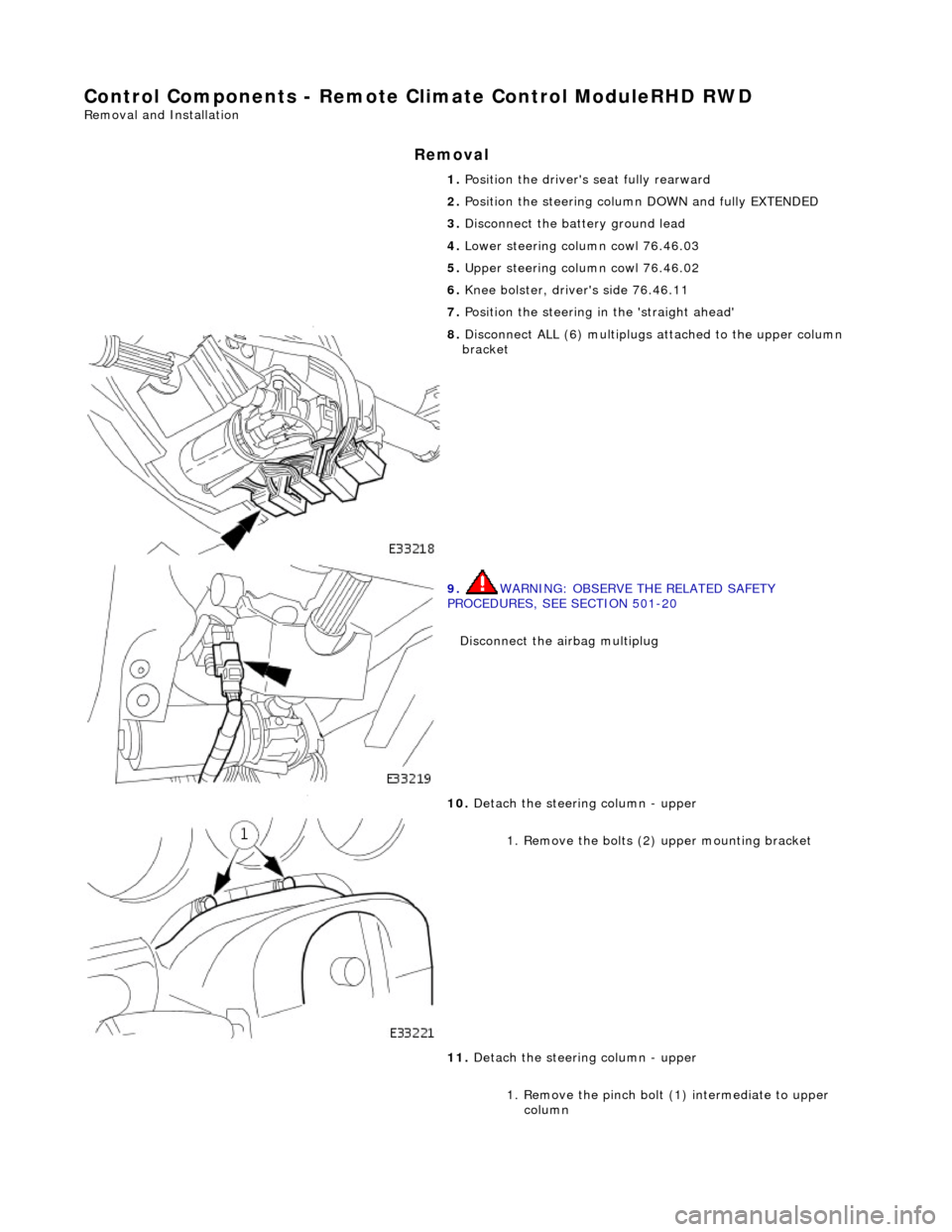

Control Components - Remote Climate Control ModuleRHD RWD

Removal and Installation

Removal

1. Position the driver's seat fully rearward

2. Position the steering column DOWN and fully EXTENDED

3. Disconnect the battery ground lead

4. Lower steering column cowl 76.46.03

5. Upper steering column cowl 76.46.02

6. Knee bolster, driver's side 76.46.11

7. Position the steering in the 'straight ahead'

8. Disconnect ALL (6) multiplugs attached to the upper column

bracket

9. WARNING: OBSERVE THE RELATED SAFETY

PROCEDURES, SEE SECTION 501-20

Disconnect the airbag multiplug

10. Detach the steering column - upper

1. Remove the bolts (2 ) upper mounting bracket

11. Detach the steering column - upper

1. Remove the pinch bolt (1) intermediate to upper column