205-2 JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 231 of 2490

Re

move bearin

g spacer.

Remove ou

ter bearing.

14. Pack new inner and outer bear ings with Shell Retinax 'A'

grease.

15

.

Install outer bearing and usin g special tool 205-234, fully

seat seal in hub carrier.

16

.

Using a press, install hub in carrier/bearing assembly.

17

.

Install inner bearing assembly.

1. Install bearing spacer.

2. Install bearing shim.

3. Install inner bearing.

18. Determine hub end float.

Measure an

d record end-float as a datum.

Calculating from datum, select

a sh

im that will achieve a

0.076 mm end-float.

19. Install new bearing shim.

Page 232 of 2490

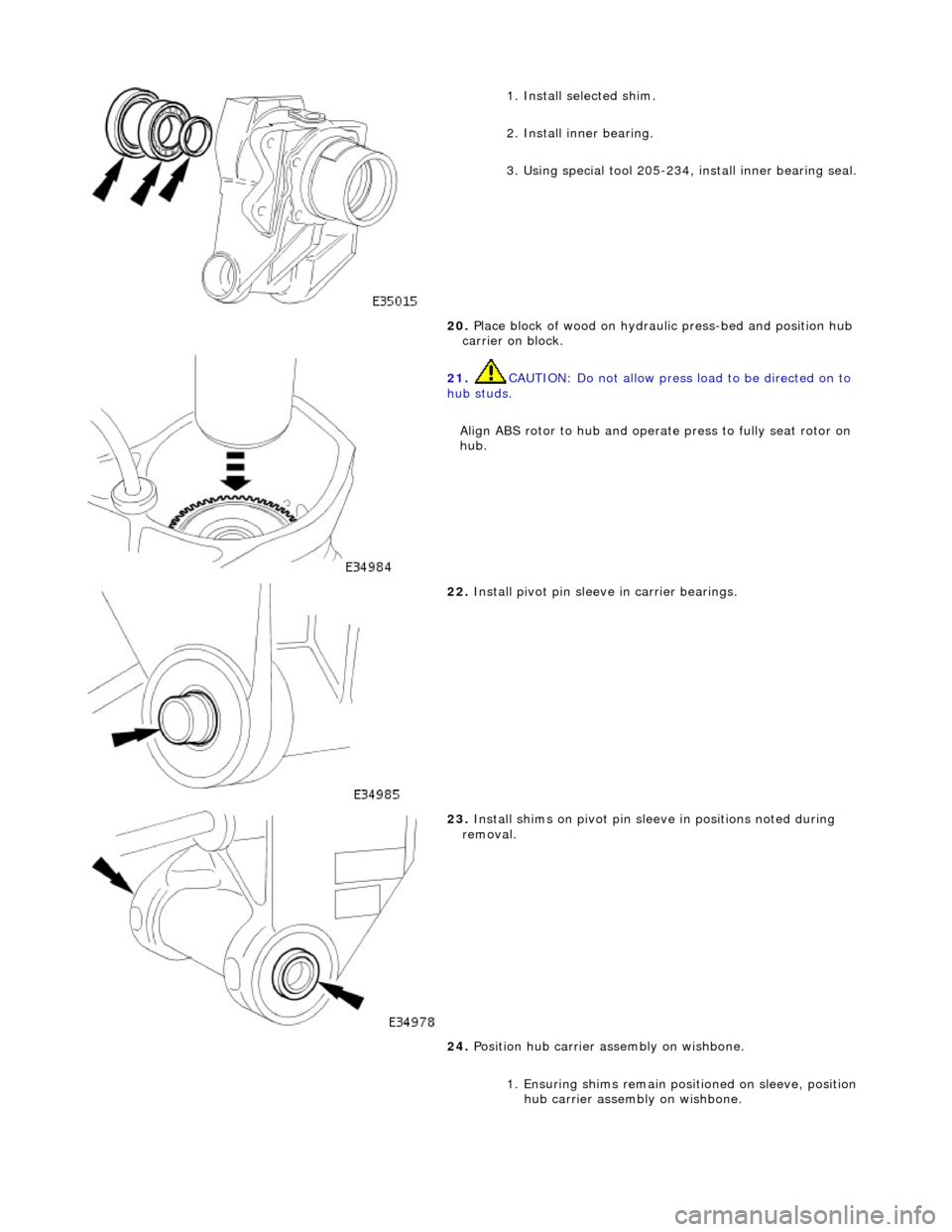

1. Ins

tall selected shim.

2. Install inner bearing.

3. Using special tool 205-234, install inner bearing seal.

20. Place block of wood on hydrau lic press-bed and position hub

carrier on block.

21 . CAUTI

ON: Do not allow press load to be directed on to

hub studs.

Align ABS rotor to hub and operat e press to fully seat rotor on

hub.

22 . Install piv

ot pin sleeve in carrier bearings.

23 . Inst

all shims on pivot pin slee

ve in positions noted during

removal.

24. Position hub carrier as sembly on wishbone.

1. Ensuring shims remain posi tioned on sleeve, position

hub carrier assembly on wishbone.

Page 237 of 2490

Rear Suspension - Wheel Hub

Seal

Re

moval and Installation

Remov

al

S

pecial Tool(s)

Hub Holdin

g Tool

204-195 (JD227)

Hub Pu

ller

204-011 (JD 1D)

R

ear-Hub Remover

204-113 (JD 132)

O

il Seal Remover/Replacer

205-234 (JD 550-1)

1. CAUTION: Replacement of nuts and bolts: Various

thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt

can be used. See section 100-00 for information.

Release parking brake.

2. R

aise the vehicle on a four-post lift.

3. Fully

slacken but do not remove parking brake cable adjuster

nut.

4. Release appropriate side parkin g brake cable from connecting

Page 243 of 2490

I

nstallation

33

.

Using approved cleaning agents:

Wash an

d thoroughly dry inner and outer bearings.

Thorough

ly clean hub carrier payi

ng particular attention to

bearing cups.

Thoroughl

y clean hub.

1. Grease bearings.

Pack inner and outer bea

ring races with Shell Retinax 'A'

grease:

Appl

y a film of shell Retinax

'A' grease to bearing cups

2. Install outer bearing in hu

b carrier and fully seat new seal

using special tool 205-234.

3. Apply a th

in film of Shell Retinax 'A' grease to hub shaft and

install hub in carrier /bearing assembly.

4. Install inner bearing assembly and seal.

1. Install bearing spacer.

Page 244 of 2490

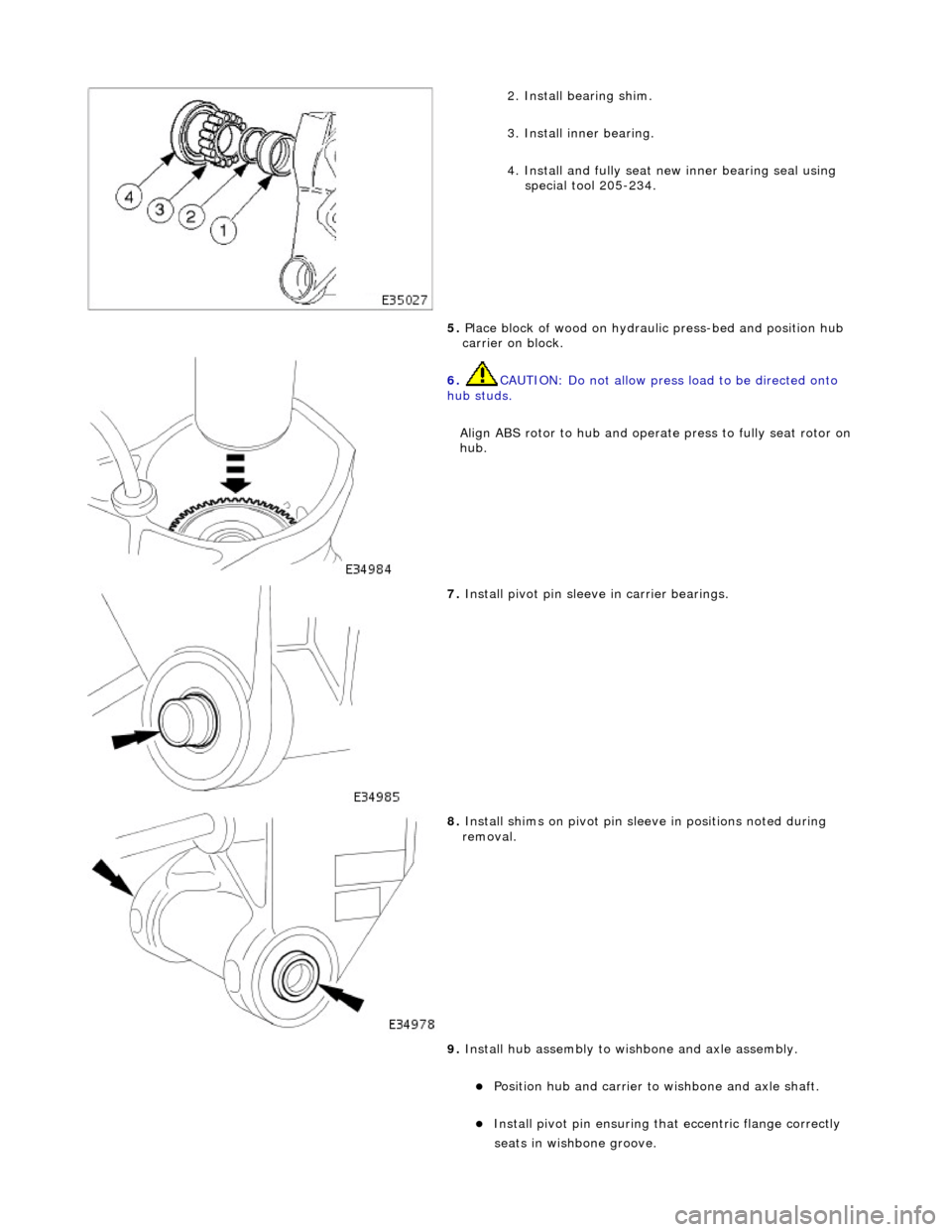

2.

Install bearing shim.

3. Install inner bearing.

4. Install and fully seat new inner bearing seal using special tool 205-234.

5. Place block of wood on hydrau lic press-bed and position hub

carrier on block.

6. CAUTIO

N: Do not allow press

load to be directed onto

hub studs.

Align ABS rotor to hub and operat e press to fully seat rotor on

hub.

7. Install piv o

t pin sleeve in carrier bearings.

8. Inst al

l shims on pivot pin slee

ve in positions noted during

removal.

9. Install hub assembly to wi shbone and axle assembly.

Position hub and carr

ier to wishbone and axle shaft.

Install pivo

t pin ensuring that

eccentric flange correctly

seats i

n wishbone groove.

Page 295 of 2490

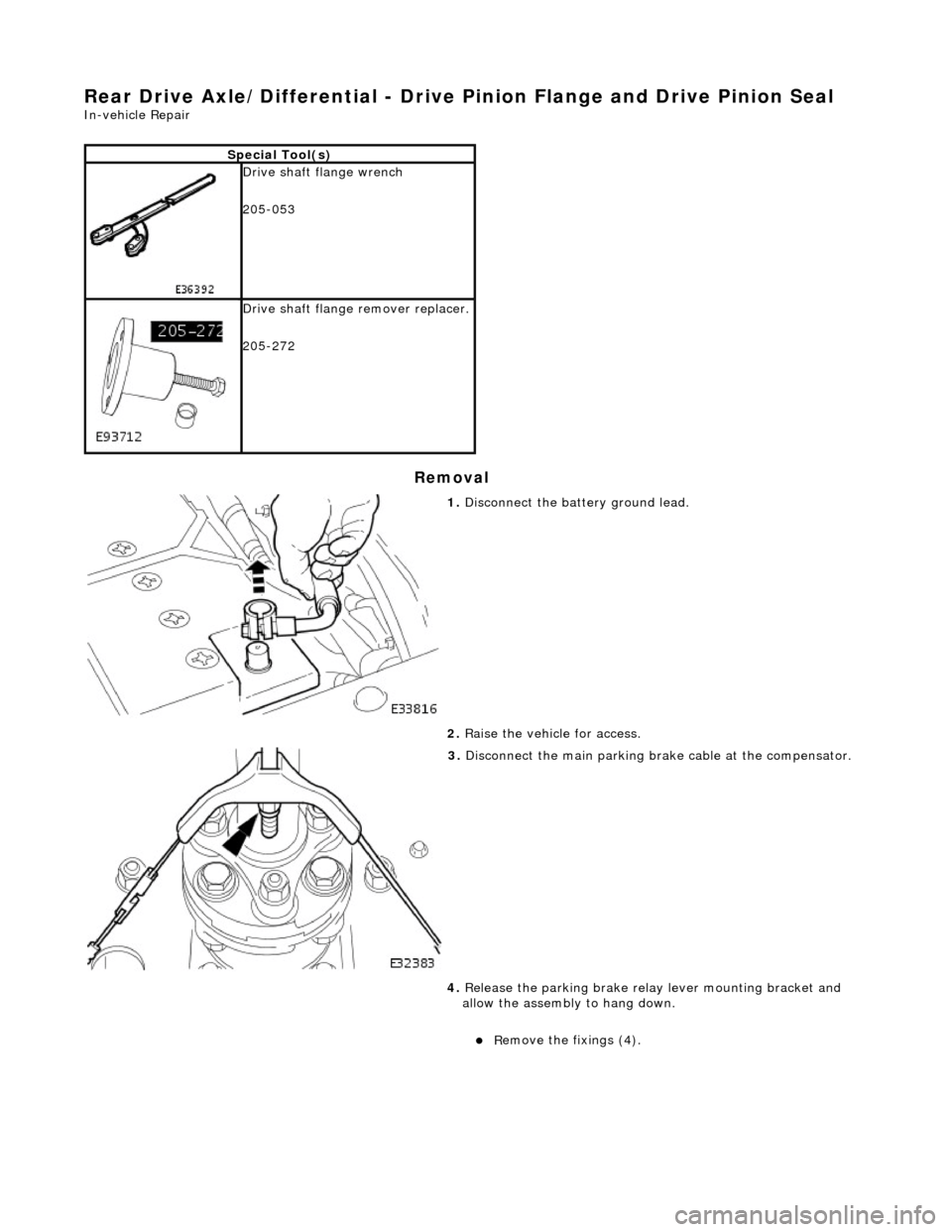

R

ear Drive Axle/Differential - Drive Pinion Flange and Drive Pinion Seal

In-v

ehicle Repair

Remov

al

S

pecial Tool(s)

Drive sh

aft flange wrench

205-053

D

rive shaft flange remover replacer.

205-272

1. Di

sconnect the battery ground lead.

2. Raise the vehicle for access.

3. Disconnect the main parking br ake c

able at the compensator.

4. Release the parking brake relay lever mounting bracket and

allow the assembly to hang down.

R

emove the fixings (4).

Page 296 of 2490

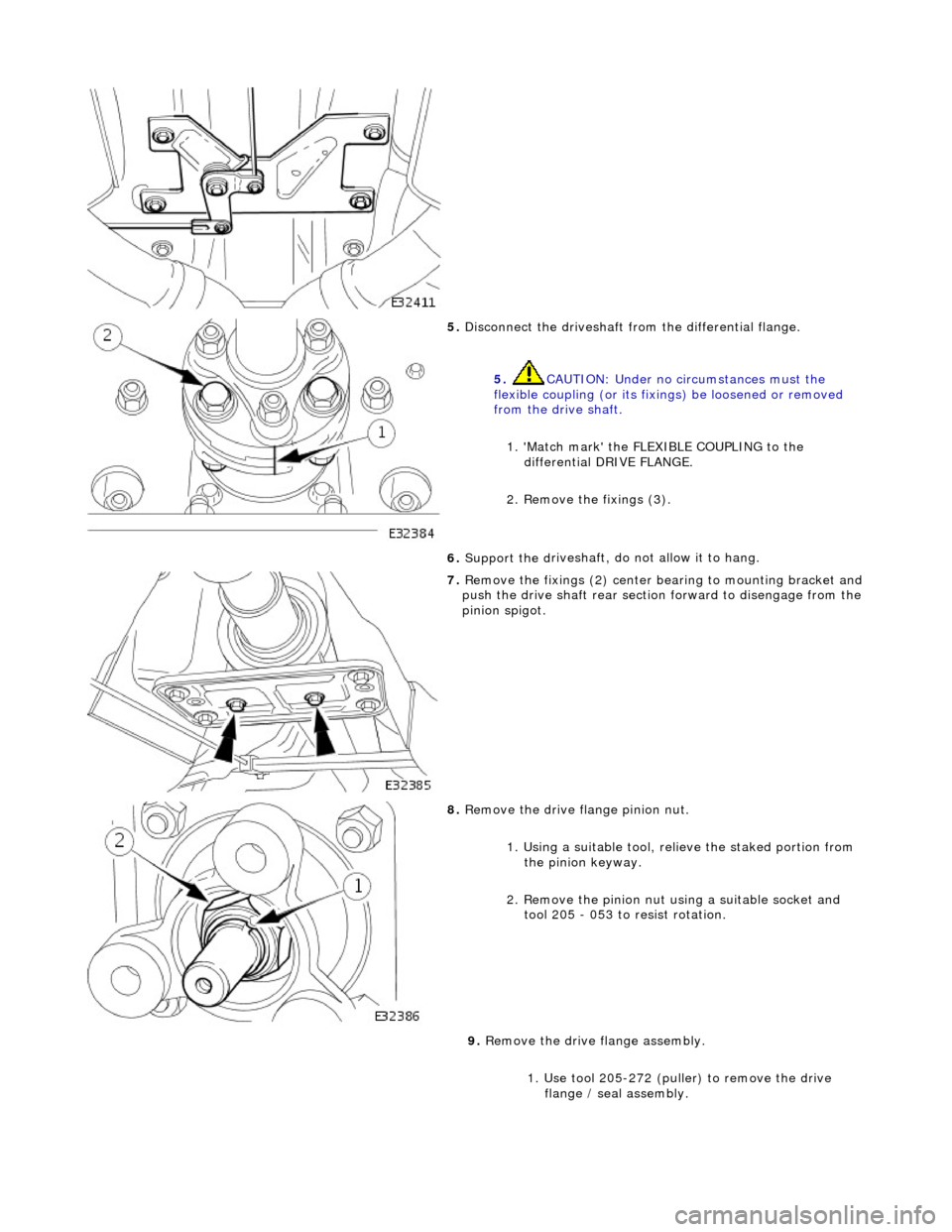

5. Disconne

ct the driveshaft fr

om the differential flange.

5. CAUTION: Under no circumstances must the

flexible coupling (or its fixings) be loosened or removed

from the drive shaft.

1. 'Match mark' the FLEX IBLE COUPLING to the

differential DRIVE FLANGE.

2. Remove the fixings (3).

6. Support the d

riveshaft, do not allow it to hang.

7. Re

move the fixings (2) center

bearing to mounting bracket and

push the drive shaft rear sectio n forward to disengage from the

pinion spigot.

8. Remove the drive flange pinion nu

t.

1. Using a suitable tool, re lieve the staked portion from

the pinion keyway.

2. Remove the pinion nut using a suitable socket and tool 205 - 053 to resist rotation.

9. Remove the drive flange assembly.

1. Use tool 205-272 (puller) to remove the drive flange / seal assembly.