egr JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 14 of 2490

303‐07: En gine Ignition

Specification

Diagnosis and Testing

Engine Ignition

Diagnosis and Testing

Engine Ignition

Inspection and Verification

Driver Information Chart

Default mode Definitions

Diagnostic Trouble Code (DTC) index

Pinpoint Tests

Removal and Installation

Ignition Coil ‐On ‐Plug LH (18.20.44)

Ignition Coil ‐On ‐Plug RH (18.20.43)

Ignition Module (18.20.30)

Spark Plugs (18.20.02)

303‐08: En

gine Emission Control

Specification

Diagnosis and Testing

Engine Emission Control

Inspection and Verification

Diagnostic Trouble Code (DTC) Index

Pinpoint Tests

Removal and Installation

Exhaust Gas Recirculation (EGR) Valve (17.45.01)

Exhaust Manifold to Exhaust Gas Recirculation (E

GR) Valve Tube (17.45.11)

303‐12: Intake Air Distribution and Filtering

Removal and Installation

Air Cleaner (19.10.05)

Air Cleaner Element (19.10.08)

Charge Air Cooler LH (18.50.19)

Charge Air Cooler RH (18.50.18)

Charge Air Cooler Gasket LH (18.50.22)

Charge Air Cooler Gasket RH (18.50.21)

Supercharger (18.50.

15)

Page 35 of 2490

General Infor

mation - Gene

ral Service Information

Description an

d Operation

Safety Notice

Appropri

ate service me

thods and proper repair procedures are essential for the safe, reliable operation of all motor vehicles,

as well as the safety of the person do ing the work. This manual provides genera l directions for accomplishing service and

repair work with tested, effect ive, techniques. Following them will help assure reliability.

There are numerous variations in procedures, techniques, tools, and parts for servicing vehicles, as well as in the skill of the

person doing the work. This manual cannot possibly anticipate all such variations and provide advice or cautions as to each.

Accordingly, anyone who depart s from the instructions provided in the manua l must first establish that neither personal

safety nor vehicle integrity is compromised from choices of methods, tools or parts.

Notes, Ca

utions and Warnings

Throughout

this manual, important inform

ation is highlighted by the use of notes, cautions and warnings. NOTES give

additional information on a topic or proc edure, CAUTIONS are given to prevent da mage to the vehicle, and WARNINGS are

given to prevent personal injury.

Worksh

op Manual Organization

This

manual incorporates descript

ive, diagnostic, and repair information to help trained Jaguar technicians complete service

and rectification procedures. The informat ion can be accessed by choosing the appropriate five digit section number. For

example, Section 412-03 covers air conditioning , which is part of the Climate Control System.

The manual is organized into groups covering generic aspects of the vehicle systems; the first digit of the section

number represents a group se lected from the following:

1. General Information.

2. Chassis.

3. Powertrain.

4. Electrical.

5. Body and Paint.

Each of the groups comprises sections re lating to specific areas of the vehicle.

The second and third digits of the section number indicate the vehicle system.

The last two digits of the se ction number define the system covered, more specifically.

Each section comprises one or more of the following sub-sections:

Specification

Page 39 of 2490

Before inspecting a component for wear or per

forming a dimensional check,

ensure that it is absolutely clean; a slight smear

of grease can conceal an incipient failure. When a component is to be checked dimensionally against figures quoted for it,

use the correct equipment (surface plates, micrometers, dial gauges etc.) in serviceable condition. The use of makeshift

equipment can be dangerous. Reject a component if its dimensio ns are outside the limits quoted, or if damage is apparent.

A part may be refitted if its critical di mension is exactly to the limit size and it is otherwise satisfactory. Use Plastigauge 12

Type PG-1 for checking bearing surface clearance, e.g. big end bearing shell to crank jour nal. Instructions for the use of

Plastigauge and a scale giving bearing clearances in steps of 0.0025 mm (0.0001 in) are supplied with the package.

Safety

Precautions

• WAR

NINGS:

WORKING ON THE FUEL SYSTEM RESULTS IN FUEL AND FUEL VAPOUR BEING PRESENT IN THE ATMOSPHERE. FUEL

VAPOUR IS EXTREMELY FLAMMABLE, HENCE GREAT CARE MUST BE TAKEN WHILST WORKING ON THE FUEL SYSTEM.

ADHERE STRICTLY TO THE FOLLOWING PRECAUTIONS:

DO

NOT SMOKE IN THE WORK AREA.

DISP

LAY 'NO SMOKING' SIGNS AROUND THE AREA.

DISCONNECT TH

E BATTERY BEFORE WORKING ON THE FUEL SYSTEM.

DO NOT CONNEC

T/DISCONNECT ELECTRICAL CIRCUITS

, USE ELECTRICAL EQUIPMENT OR OTHER TOOLS OR

ENGAGE IN WORKING PRACTICES WHICH IN ANY WAY MAY RESULT IN THE PRODUCTION OF SPARKS.

ENS

URE THAT A CO2 FIRE EXTINGUISHER IS CLOSE AT HAND.

ENS

URE THAT DRY SAND IS AVAILABLE TO SOAK UP ANY FUEL SPILLAGE.

EMP

TY FUEL USING SUITABLE FIRE PROOF EQUIPMENT IN

TO AN AUTHORIZED EXPLOSION PROOF CONTAINER.

DO NOT EMP

TY FUEL WHILE WORKING IN A WORKSHOP OR A PIT.

ENS

URE THAT WORKING AREA IS WELL VENTILATED.

ENS

URE THAT ANY WORK ON THE FUEL SYSTEM IS ON

LY CARRIED OUT BY EXPERIENCED AND WELL QUALIFIED

MAINTENANCE PERSONNEL.

ENS

URE THAT FUME EXTRACTION EQUIPMENT IS USED WHERE APPROPRIATE.

FUME EXTRACTION EQUIPMENT MUST BE IN OPERATION WHEN SOLVENTS ARE USED E.G. TRICHLOROETHANE,

WHITE SPIRIT, SBP3, METHYLENE CHLORIDE, PERCHLORETHY LENE. DO NOT SMOKE IN THE VICINITY OF VOLATILE

DEGREASING AGENTS.

General workshop practices:

Disc

onnect the grounded termin

al of the vehicle battery.

D

o not apply heat in an attempt to free seized nuts or fitt

ings; as well as causing damage to protective coatings,

there is a risk of damage from stray heat to electronic equipment and brake lines.

Keep oils and solven

ts away from naked flames and other sour

ces of ignition.

Adhere str

ictly to handling and safety inst

ructions given on containers and labels.

E

nsure that a suitab

le form of fire extinguisher is conveniently located.

Wh

en using electrical tools and equipment, inspect the power

lead for damage and check that it is properly earthed.

D

o not leave tools, equipment, spilt oil etc. around the work area.

Working beneath a vehicle:

Wh

enever possible, use a ramp or

pit in preference to jacking.

Posit

ion chocks at the wheels as we

ll as applying the parking brake.

N

ever rely on a jack alone to support a

vehicle; use axle stands, or blocks care fully placed at the jacking points, to

provide a rigid location.

Ch

eck that any lifting equipment used has adeq

uate capacity and is fully serviceable.

Working on air conditioning systems:

D

o not disconnect any pipes of the refrigeration system

unless you are trained and instructed to do so; a refrigerant

is used which can cause blindness if allowed to come into contact with the eyes.

Health Protection

P

rolonged and repeated contact with mineral oil will result in the removal of natural oils from the skin, leading to dryness,

In

spection

Page 40 of 2490

irri

tation and dermatitis. In addition, used engine oil contains potentially harmful contaminants which may cause skin

cancer. Washing facilities and adequate means of skin protection should be provided.

Observe these recommendations:

Wear pro t

ective clothing and impe

rvious gloves when necessary.

Do not put oily

rags in pockets. Avoid contaminat

ing clothes, particularly underwear, with oil.

Overal

ls must be cleaned re

gularly; discard oil impregna ted clothing and footwear wh ich cannot be washed or

cleaned.

Fi rst

Aid treatment should be obtained

immediately for open cuts or wounds.

Use barrier

creams, applying before each work period, to en

able easier removal of dirty oil and grease from the skin.

Wa

sh with soap and water to ensure th

at all oil is removed (skin cleaner and a nail brush will help). The use of

preparations containing lanolin will help to replace the natural skin oils which have been removed.

Do

not use petrol, kerosene, gas oil, th

inners or solvents for washing skin.

If

skin disorders develop, obtain medical advice immediately.

Wh

ere prac

ticable, degrease components prior to handling.

W

h

ere there is a risk of fluids coming into contact with th

e eyes, suitable eye protection should be worn - goggles or

face shield. An eye wash facility should be provided.

Ensure that a

dequate ventilation is provided when volatile degreasing agents are being used.

E

n

vironmental Protection

In so

m

e countries it is illegal to pour used oil onto the ground

, down sewers or drains, or into water courses. The burning of

used engine oil in small space heaters or boilers is not reco mmended unless emission control equipment is fitted. Dispose of

used oil through authorized waste disposal contractors, to licensed waste disposal sites or to the waste oil reclamation

trade. If in doubt, contact the Local Authority for advice on disposal facilities.

On-Board Diagnostics (OBD)

Ve

hicles use programmed electronic control systems to prov

ide engine management and emission regulation, automatic

transmission operation and anti -lock braking control. These control systems ha ve an integral On-Board Diagnostics (OBD)

facility for use in conjunction with either Jaguar diagnostic equipment or a scan t ool which is capable of retrieving DTCs,

PIDs and performing active commands.

The OBD information in this manual provid es diagnostic and rectification procedures for emission related electrical and

mechanical systems. The informat ion is intended to facilitate fault diagnosis and the subsequent rectification of vehicles

without recourse to the portab le diagnostic unit (PDU).

OBD related information can be fo und in the following sections:

General Information

Engine M

anagement System

Auto

matic Transmission

Anti-lock Br

aking System

Where appropriate a section comprises the following sub-sections:

Description and Operation

A ge

neral illustration and parts list to help the identi

fication of the particular system or component.

A b

rief description of the system operating characteristics and monitoring procedure

accompanied by a component

illustration.

Addi ti

onal information, where appropriat

e, is provided in the form of component calibrations, characteristics and

cross sectional views.

A localized circui

t diagram is included to provide circuit iden

tification and details of connectors, splices, fuses, wire

gauge and colors. See Circuit Diagrams.

Diagnosis and Testing (dedicated to fault analysis and rectification)

Recommended special tools. Symptom chart; a ch

art contai

ning all relevant Diagnostic Trouble Code s (DTC), their possible causes and an

indication of the appropriate test.

Sp

ecific pinpoint test(s), de

signed so that fault diagnosis can be carr ied out in a logical and efficient manner.

Page 43 of 2490

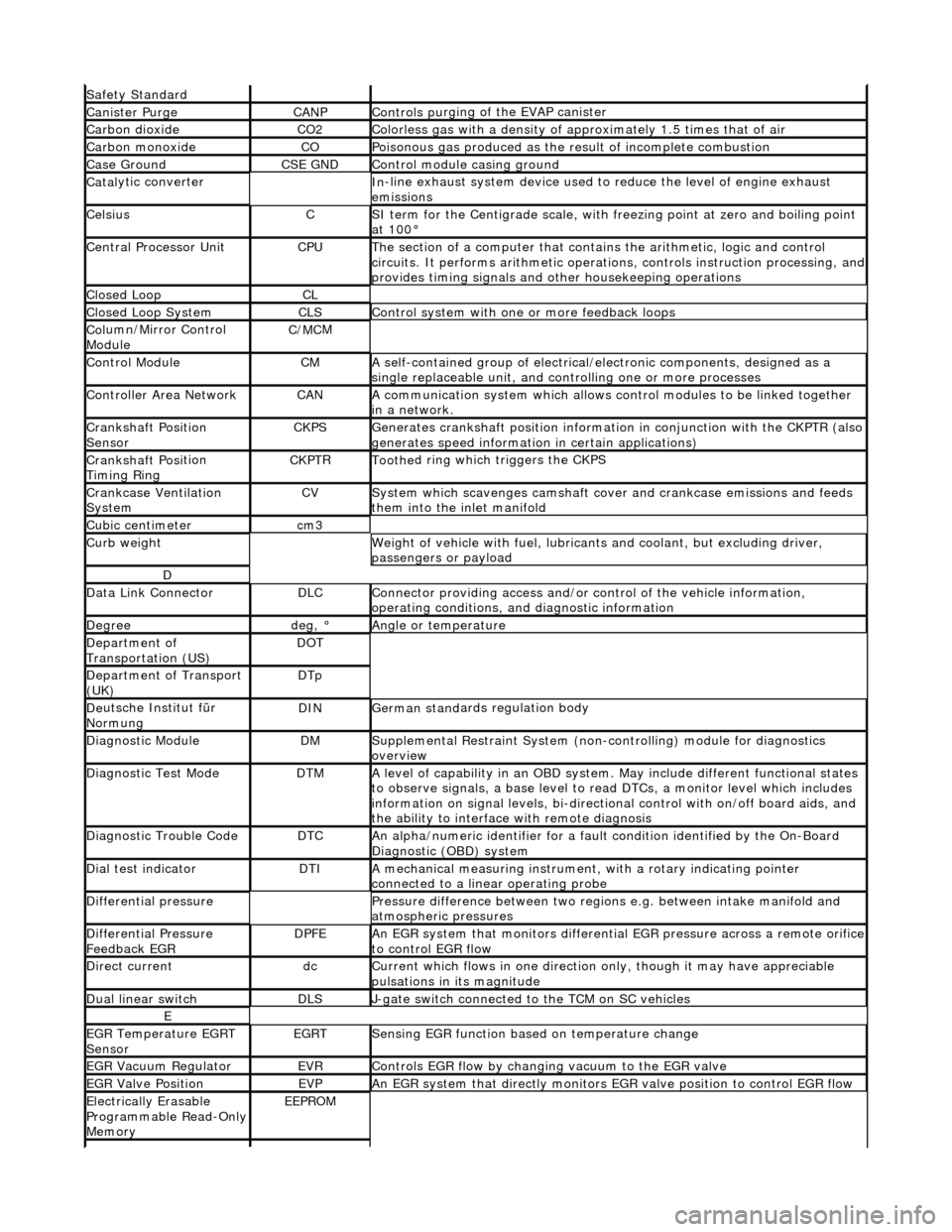

Safety Standard

Canister PurgeCANPControls pu

rging of the EVAP canister

Carbon dioxideCO2Colorless gas with

a density of a

pproximately 1.5 ti mes that of air

Carbon mon

oxide

COPoi

sonous gas produced as the re

sult of incomplete combustion

Case G

round

CSE GNDControl modu

le casing ground

Catal

ytic converter

In

-line exhaust system device used to reduce the level of engine exhaust

emissions

Ce

lsius

CSI ter

m for the Centigrade scale, with

freezing point at zero and boiling point

at 100°

Central

Processor Unit

CPUTh

e section of a computer that contai

ns the arithmetic, logic and control

circuits. It performs arithm etic operations, controls instruction processing, and

provides timing signals and other housekeeping operations

Cl

osed Loop

CL

Cl

osed Loop System

CLSControl

system with one

or more feedback loops

Col

umn/Mirror Control

Module

C/MC

M

Control ModuleCMA

self-contained group of electrical/electronic components, designed as a

single replaceable un it, and controlling one or more processes

Controll

er Area Network

CANA

communication system which allows control modules to be linked together

in a network.

Crankshaft Posi

tion

Sensor

CKPSGenerates crankshaft positi on informa

tion in conjunct

ion with the CKPTR (also

generates speed information in certain applications)

Crankshaft Posi

tion

Timing Ring

CKPT

R

Toothe

d ring which

triggers the CKPS

Crankcase Ventila

tion

System

CVSys

tem which scavenges camshaft cover and crankcase emissions and feeds

them into the inlet manifold

Cubic ce nt

imeter

cm

3

Curb weightWe

ight of vehicle with fuel, lubrican

ts and coolant, but excluding driver,

passengers or payload

D

Dat

a Link Connector

DLCConne

ctor providing access and/or control of the vehicle information,

operating conditions, and diagnostic information

De

gree

deg, °Angle or tempe

rature

D

epartment of

Transportation (US)

DO

T

D

epartment of Transport

(UK)

DTp

De

utsche In

stitut für

Normung

DINGerman stand

ards regulation body

Di

agnostic Module

DMSuppl

emental Restraint System (non-c

ontrolling) module for diagnostics

overview

Di

agnostic Test Mode

DTMA le

vel of capability in an OBD system.

May include different functional states

to observe signals, a base level to re ad DTCs, a monitor level which includes

information on signal levels, bi-directional control with on /off board aids, and

the ability to interface with remote diagnosis

Diagnostic Trouble CodeDTCAn al

pha/numeric identifier for a fault

condition identified by the On-Board

Diagnostic (OBD) system

D

ial test indicator

DTIA mechan

ical measuring

instrument, with a rotary indicating pointer

connected to a linear operating probe

D

ifferential pressure

Pressure di

fference betwee

n two regions e.g. between intake manifold and

atmospheric pressures

D

ifferential Pressure

Feedback EGR

DP

FE

An

EGR system that monito

rs differential EGR pressure across a remote orifice

to control EGR flow

D

irect current

dcCurrent which f

lows in on

e direction only, though it may have appreciable

pulsations in its magnitude

Du

al linear switch

DLSJ

-gate switch connected to the TCM on SC vehicles

E

EGR

Temperature EGRT

Sensor

EGRTSens

ing EGR function based on temperature change

EGR Vacu

um Regulator

EVRControls EGR

flow by changi

ng vacuum to the EGR valve

EGR Valve

Position

EVPAn EGR

system that direct

ly monitors EGR valve position to control EGR flow

Electrically E

rasable

Programmable Read-Only

Memory

EEP

ROM

Page 44 of 2490

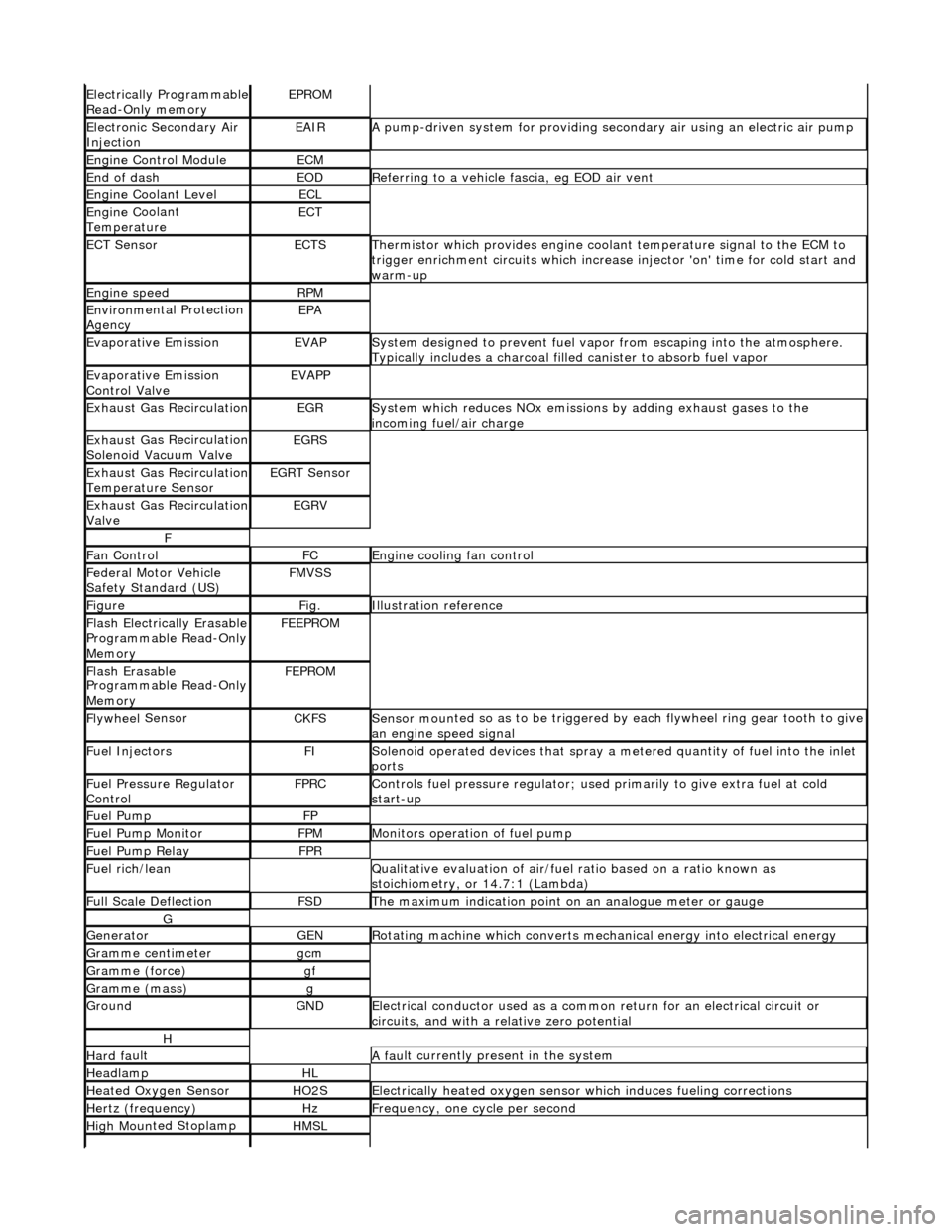

Electrically Programmable

R

ead-Only memory

EPROM

Ele

c

tronic Secondary Air

Injection

EAIRA p

ump-driven system for providing seco

ndary air using an electric air pump

Engine C

ontrol Module

ECM

End of dashEODR

e

ferring to a vehicle fascia, eg EOD air vent

Engine

C

oolant Level

ECL

Engine

C

oolant

Temperature

ECT

ECT Sen s

or

ECTSTherm

i

stor which provides engine coolant temperature signal to the ECM to

trigger enrichment circuits which increase injector 'on' time for cold start and

warm-up

Engine s

peed

RP

M

Environ m

ental Protection

Agency

EPA

Evaporative EmissionEVAPSy stem designed to prevent fu

el vapor from escaping into the atmosphere.

Typically includes a charcoal filled canister to absorb fuel vapor

Evaporative Emission

Control ValveEVAPP

Exhaust G

as Recirculation

EGRSys

t

em which reduces NOx emissions by adding exhaust gases to the

incoming fuel/air charge

Exhaus t G

as Recirculation

Solenoid Vacuum Valve

EGRS

Exhaus t G

as Recirculation

Temperature Sensor

EGRT Sen s

or

Exhaus

t G

as Recirculation

Valve

EGRV

F

F a

n Control

FCEngine

cooling fan control

F

e

deral Motor Vehicle

Safety Standard (US)

FMV S

S

Fi

gur

e

Fi

g.Illustrati

on reference

Flash

E

lectrically Erasable

Programmable Read-Only

Memory

FEE PR

OM

Flash

E

rasable

Programmable Read-Only

Memory

FEP R

OM

Flywhee

l

Sensor

CKFSSens

or moun

ted so as to be

triggered by each flywheel ring gear tooth to give

an engine speed signal

Fue l

Injectors

FISol

e

noid operated devices that spray a metered quantity of fuel into the inlet

ports

F u

el Pressure Regulator

Control

FP RCControls fuel pressure regu l

ator; used primarily to

give extra fuel at cold

start-up

Fue l

Pump

FP

Fue

l

Pump Monitor

FP

MMonitors operation of fuel pump

Fue l

Pump Relay

FP

R

Fu

el rich/lean

Q

u

alitative evaluation

of air/fuel ratio based on a ratio known as

stoichiometry, or 14.7:1 (Lambda)

F u

ll Scale Deflection

FSDTh

e

maximum indication point on

an analogue meter or gauge

G

Gene

rator

GENRot

a

ting machine which converts mechanical energy into electrical energy

G

r

amme centimeter

gcm

Gramm

e

(force)

gf

Gramm

e

(mass)

g

GroundGNDEle

c

trical conductor used

as a common return for an electrical circuit or

circuits, and with a relative zero potential

H

Hard f a

ult

A

fau

lt currently present in the system

HeadlampHL

Heat

ed Oxygen

Sensor

HO2SElectrically

h

eated oxygen sensor which induces fueling corrections

Hertz (frequency)HzFrequ

e

ncy, one cycle per second

High

Moun

ted Stoplamp

HMSL

Page 58 of 2490

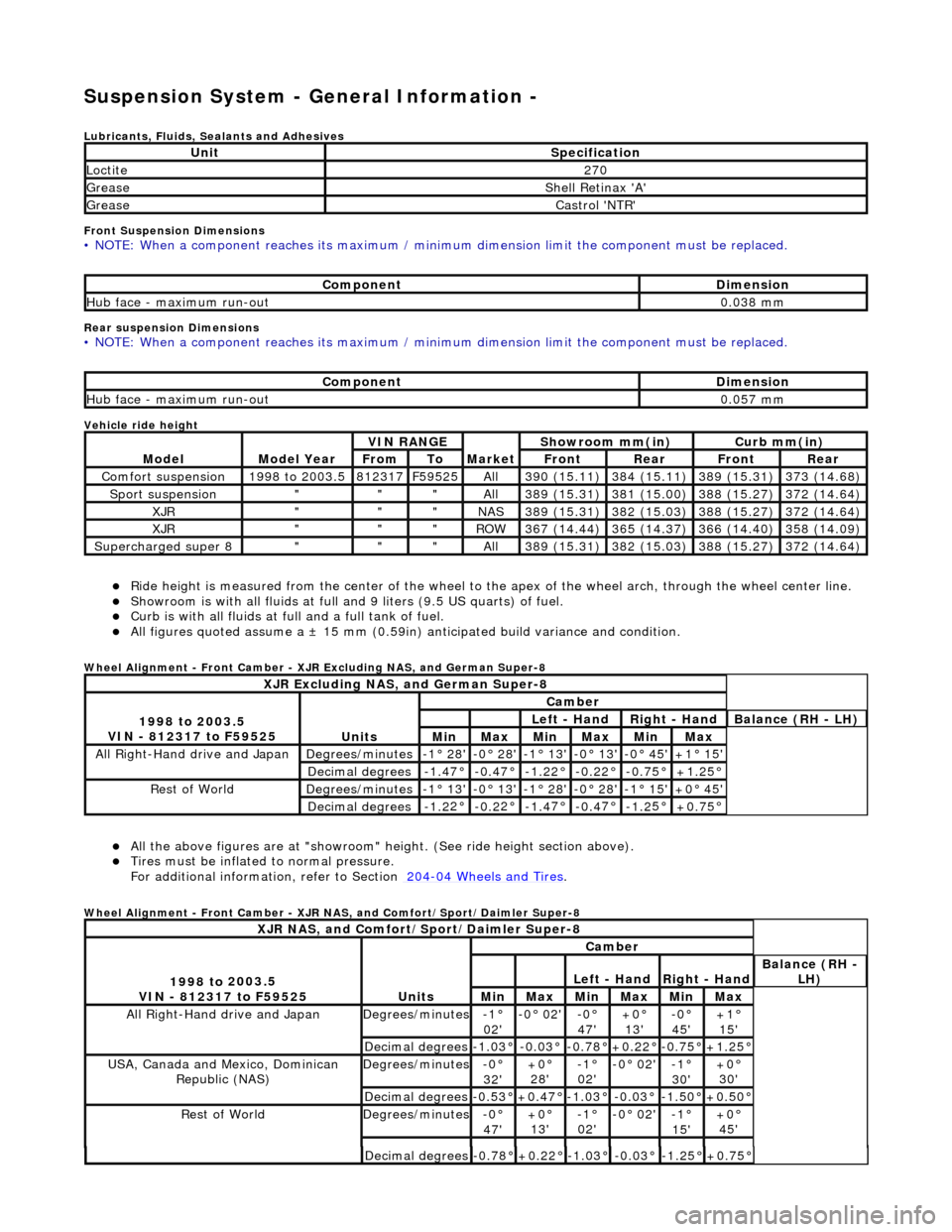

Suspension System - General Informatio

n -

Lubric

ants, Fluids, Sealants and Adhesives

Front Suspension Dimensions

• NO

TE: When a component reaches its maximum / minimum dimension limit the component must be replaced.

Rear sus

p

ension Dimensions

•

NO

TE: When a component reaches its maximum / minimum dimension limit the component must be replaced.

Vehicle ride

height

R i

de height is measured from

the center of the wheel to the apex of the wheel arch, through the wheel center line.

Showroom is with a

ll fluids at full an

d 9 liters (9.5 US quarts) of fuel.

Curb is

with all fluids at full and a full tank of fuel.

All f

i

gures quoted assume a ±

15 mm (0.59in) anticipated bu ild variance and condition.

Whee

l Alignment - Front Camber - XJR Excluding NAS, and German Super-8

Al l the above fi

gures

are at "showroom" height. (See ride height section above).

Tires must be infl

ated

to normal pressure.

For additional informat ion, refer to Section 204

-04

Wheels and Tires

.

Whe

e

l Alignment - Front Camber - XJR NAS, and Comfort/Sport/Daimler Super-8

UnitSp

ecification

Loctite27

0

Greas eShell Retin a

x 'A'

Greas

eCastro l 'NT

R'

Com

p

onent

Di

mensi

on

Hub face

-

maximum run-out

0.

03

8 mm

Com

p

onent

Di

mensi

on

Hub face

-

maximum run-out

0.

05

7 mm

Mod

e

l

Mod

e

l Year

V

I

N RANGE

Mark

et

Sh

owroom mm(in)

Curb mm(i

n)

FromToFron

t

RearFr

on

t

Rear

Com

f

ort suspension

1

998

to 2003.5

8

123

17

F

595

25

All3

90 (

15.11)

3

84 (

15.11)

3

89 (

15.31)

3

73 (

14.68)

Sport su

spe

nsion

"""All3

89 (

15.31)

3

81 (

15.00)

3

88 (

15.27)

3

72 (

14.64)

XJR"""NAS3

89 (

15.31)

3

82 (

15.03)

3

88 (

15.27)

3

72 (

14.64)

XJR"""RO

W367 (

14.44)

3

65 (

14.37)

3

66 (

14.40)

3

58 (

14.09)

Supercharged super 8"""All3

89 (

15.31)

3

82 (

15.03)

3

88 (

15.27)

3

72 (

14.64)

XJR

Excluding NAS, and German Super-8

1998 to

2003.5

VIN - 812317 to F59525

Units

Cambe r

Left

- Hand

Rig

h

t - Hand

Bal

a

nce (RH - LH)

MinMaxMinMaxMinMax

All Right-Hand driv

e and JapanDegrees

/minutes

-

1

° 28'

-0

°

28'

-

1

° 13'

-

0

° 13'

-0

° 45'+1 °

15'

Decimal degrees-1.

4

7°

-0

.4

7°

-1

.2

2°

-0.

2

2°

-0

.7

5°

+1

.25

°

R

e

st of World

De

grees

/minutes

-

1

° 13'

-0

°

13'

-

1

° 28'

-

0

° 28'

-1

° 15'+0 °

45'

Decimal degrees-1.

2

2°

-0

.2

2°

-1

.4

7°

-0.

4

7°

-1

.2

5°

+0

.75

°

XJR

NAS, and Comfort/Sport/Daimler Super-8

1

998 to

2003.5

VIN - 812317 to F59525

Units

Cambe r

Left

- Hand

Rig

h

t - Hand

Bal

a

nce (RH -

LH)

MinMaxMinMaxMinMax

All Right-Hand drive and JapanDegrees

/minutes

-1°

02'-0

° 02'

-0°

47'

+0°

13'

-0° 45'+1°

15'

Decimal degrees-1.0

3°

-0.0

3°

-0.7

8°

+0.22

°

-0.7

5°

+1.25

°

USA, Canada an

d Mexico,

Dominican

Republic (NAS)

De grees

/minutes

-0°

32 '+0 °

28'

-1 °

02'

-0 °

02'

-1°

30 '+0 °

30'

Decimal degrees-0. 5

3°

+0

.47

°

-1

.0

3°

-0

.0

3°

-1.

5

0°

+0

.50

°

R

e

st of World

De

grees

/minutes

-0°

47 '+0 °

13'

-1 °

02'

-0 °

02'

-1°

15 '+0 °

45'

Decimal degrees-0. 7

8°

+0

.22

°

-1

.0

3°

-0

.0

3°

-1.

2

5°

+0

.75

°

Page 59 of 2490

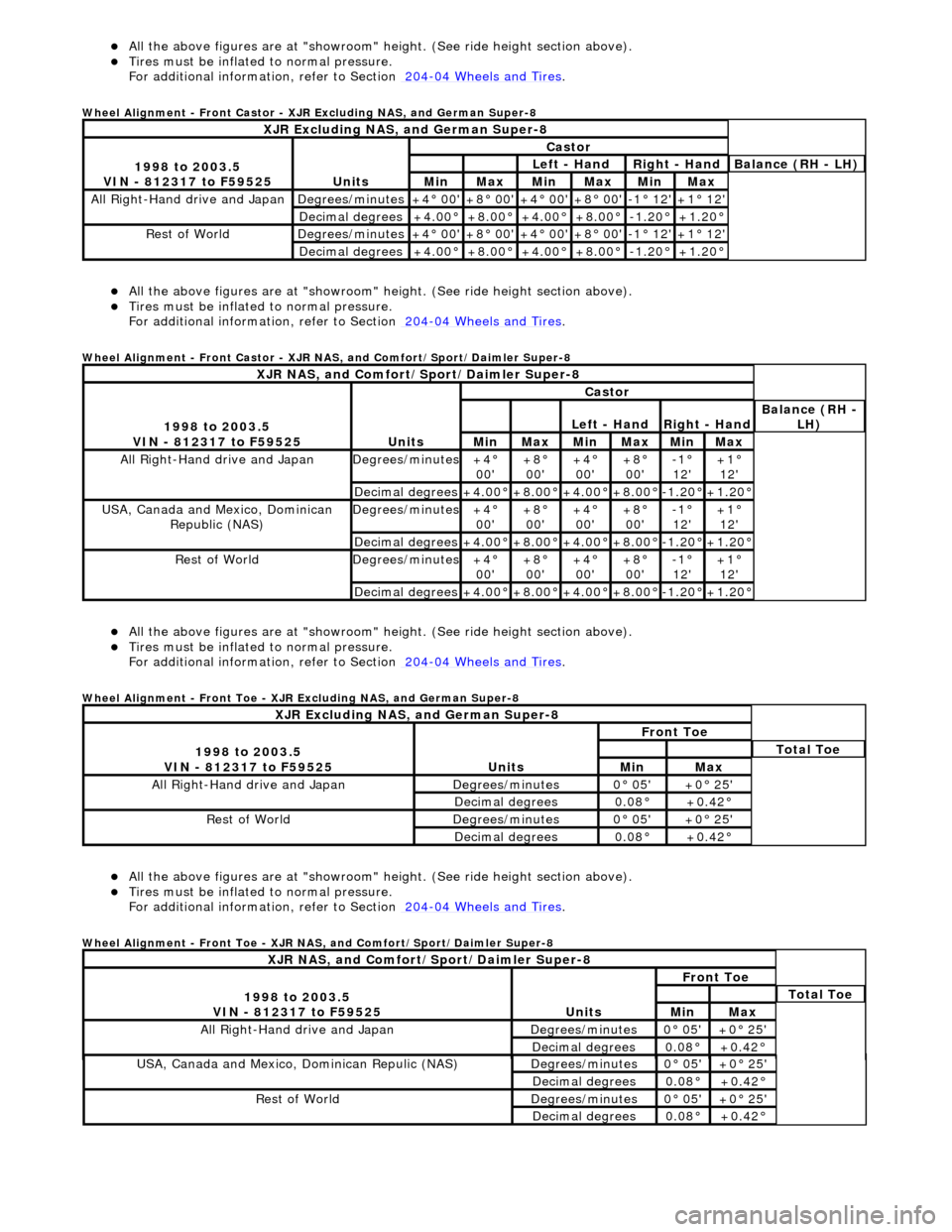

Al

l the above figures

are at "showroom" height. (See ride height section above).

Ti

res must be inflated

to normal pressure.

For additional informat ion, refer to Section 204

-0

4 Wheels and Tires

.

Whe

el Alignment - Front Castor - XJR Excluding NAS, and German Super-8

Al

l the above figures

are at "showroom" height. (See ride height section above).

Ti

res must be inflated

to normal pressure.

For additional informat ion, refer to Section 204

-0

4 Wheels and Tires

.

Whe

el Alignment - Front Castor - XJR NAS, and Comfort/Sport/Daimler Super-8

Al

l the above figures

are at "showroom" height. (See ride height section above).

Ti

res must be inflated

to normal pressure.

For additional informat ion, refer to Section 204

-0

4 Wheels and Tires

.

Whe

el Alignment - Front Toe - XJR Excluding NAS, and German Super-8

Al

l the above figures

are at "showroom" height. (See ride height section above).

Ti

res must be inflated

to normal pressure.

For additional informat ion, refer to Section 204

-0

4 Wheels and Tires

.

Whe

el Alignment - Front Toe - XJR NAS, and Comfort/Sport/Daimler Super-8

XJR

Excluding NAS, and German Super-8

1

998 to 2003.5

VIN - 812317 to F59525

Units

Castor

Le

ft - Hand

Rig

ht - Hand

Bal

ance (RH - LH)

MinMaxMinMaxMinMax

All Right

-Hand drive and Japan

De

grees/minutes

+4

° 00'

+8

° 00'

+4

° 00'

+8

° 00'

-1

° 12'

+1

° 12'

Decimal degrees+4

.00°

+8

.00°

+4

.00°

+8

.00°

-1.

20°

+1

.20°

R

est of World

De

grees/minutes

+4

° 00'

+8

° 00'

+4

° 00'

+8

° 00'

-1

° 12'

+1

° 12'

Decimal degrees+4

.00°

+8

.00°

+4

.00°

+8

.00°

-1.

20°

+1

.20°

XJR

NAS, and Comfort/Sport/Daimler Super-8

1

998 to 2003.5

VIN - 812317 to F59525

Units

Castor

Le

ft - Hand

Rig

ht - Hand

Bal

ance (RH -

LH)

MinMaxMinMaxMinMax

All Right

-Hand drive and Japan

De

grees/minutes

+4

°

00'

+8

°

00'

+4

°

00'

+8

°

00'

-1

°

12'

+1

°

12'

Decimal degrees+4

.00°

+8

.00°

+4

.00°

+8

.00°

-1.

20°

+1

.20°

USA, Canada an

d Mexico, Dominican

Republic (NAS)

De

grees/minutes

+4

°

00'

+8

°

00'

+4

°

00'

+8

°

00'

-1

°

12'

+1

°

12'

Decimal degrees+4

.00°

+8

.00°

+4

.00°

+8

.00°

-1.

20°

+1

.20°

R

est of World

De

grees/minutes

+4

°

00'

+8

°

00'

+4

°

00'

+8

°

00'

-1

°

12'

+1

°

12'

Decimal degrees+4

.00°

+8

.00°

+4

.00°

+8

.00°

-1.

20°

+1

.20°

XJR

Excluding NAS, and German Super-8

1

998 to 2003.5

VIN - 812317 to F59525

Units

Fr

ont Toe

To

tal Toe

MinMax

All Right-Hand driv

e and Japan

De

grees/minutes

0

° 05'

+0

° 25'

Decimal degrees0.

08°

+0

.42°

R

est of World

De

grees/minutes

0

° 05'

+0

° 25'

Decimal degrees0.

08°

+0

.42°

XJR

NAS, and Comfort/Sport/Daimler Super-8

1

998 to 2003.5

VIN - 812317 to F59525

Units

Fr

ont Toe

To

tal Toe

MinMax

All Right-Hand driv

e and Japan

De

grees/minutes

0

° 05'

+0

° 25'

Decimal degrees0.

08°

+0

.42°

USA, Canada an

d Mexico

, Dominican Repulic (NAS)

De

grees/minutes

0

° 05'

+0

° 25'

Decimal degrees0.

08°

+0

.42°

R

est of World

De

grees/minutes

0

° 05'

+0

° 25'

Decimal degrees0.

08°

+0

.42°

Page 60 of 2490

All the above fi

gures

are at "showroom" height. (See ride height section above).

Tires must be infl

ated

to normal pressure.

For additional informat ion, refer to Section 204

-04

Wheels and Tires

.

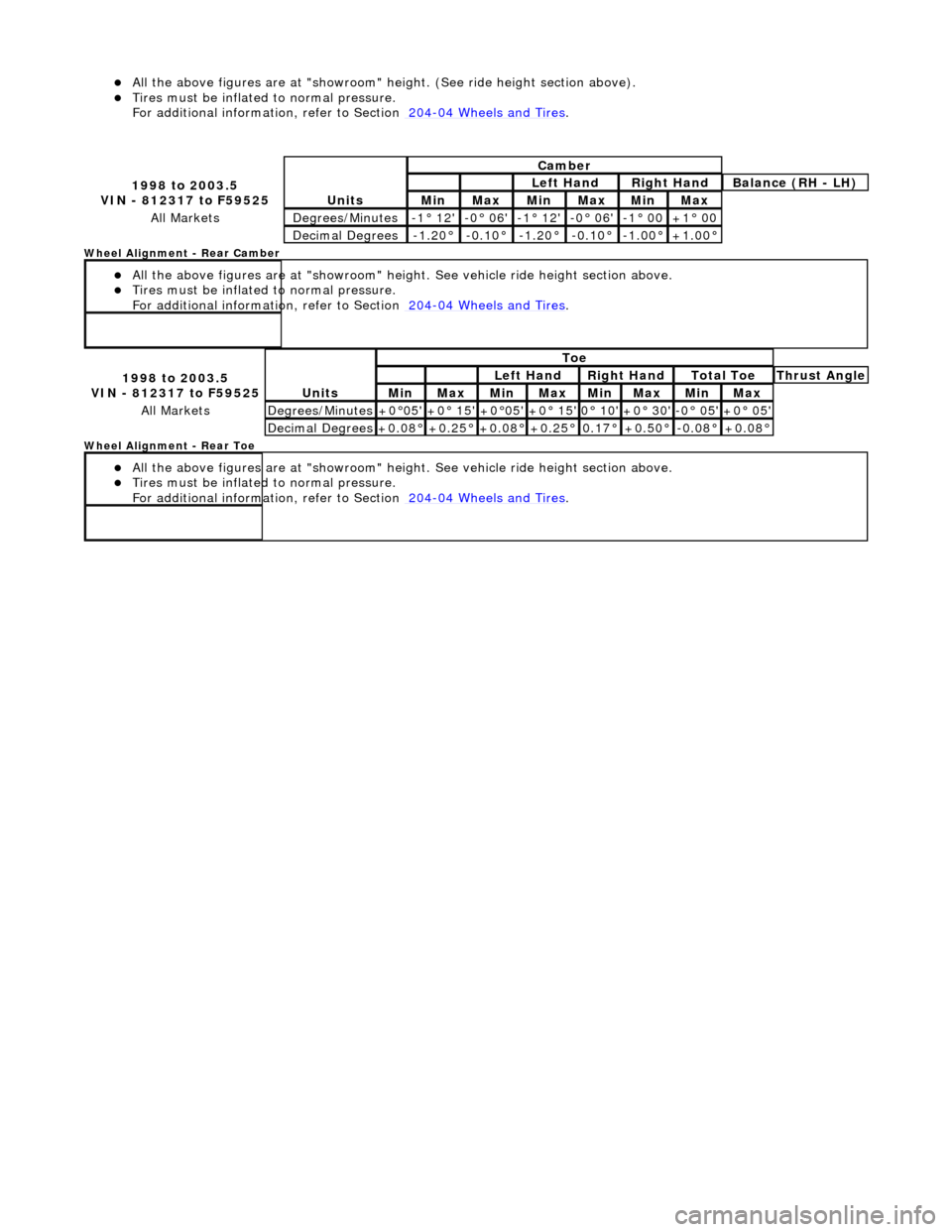

Wh

eel Alignment - Rear Camber

All the above figu res

are at "s

howroom" height. See vehicle ride height section above.

Tires must be infl

ated

to normal pressure.

For additional informat ion, refer to Section 204

-04

Wheels and Tires

.

W

h

eel Alignment - Rear Toe

All the above figu res

are at "s

howroom" height. See vehicle ride height section above.

Tires must be infl

ated

to normal pressure.

For additional informat ion, refer to Section 204

-04

Wheels and Tires

.

1 998 to

2003.5

VIN - 812317 to F59525

Units

Cambe r

Left

Hand

Rig

h

t Hand

Bal

a

nce (RH - LH)

Min MaxMin MaxMinMax

All MarketsDe

grees

/Minutes

-

1

° 12'

-0

° 06'-1° 12'-0

° 06'

-1

°

00

+1

°

00

De

ci

mal Degrees

-1.

2

0°

-0

.1

0°

-1.

2

0°

-0.

1

0°

-1.

0

0°

+1

.00

°

1

998 to

2003.5

VIN - 812317 to F59525

Units

To e

Left

Hand

Rig

h

t Hand

To

t

al Toe

Thr

u

st Angle

MinMaxMinMaxMin MaxMin Max

All MarketsDe

grees

/Minutes

+0

°

05'

+0

° 15'+0°

05'

+0

° 15'0°

10'

+0

° 30'-0° 05'+0 °

05'

De

ci

mal Degrees

+0

.08

°

+0

.25

°

+0

.08

°

+0

.25

°

0.

17

°

+0

.50

°

-0.

0

8°

+0

.08

°

Page 61 of 2490

Suspension System - General Information - Front Camber and Caster

Adjust

ment

Gen

eral Procedures

• NOTE: Before any work is commenced, th e vehicle must be checked to establish that it conforms to the Jaguar original

specification, e.g. wheels, ti res, tire pressures, etc.

• NOTE: The vehicle must be unladen and the fuel tank full when measuring suspension geometry.

1.

Road test the vehicle to establish the exact nature of the

complaint, e.g. pulling to one side, wander.

2. Measure the suspension geometry, fill in the 'Suspension

Geometry Record Form', and co ntact Jaguar Technical Support

for assistance.

3. Technical Support will give advice on the course of action to be

taken to rectify the problem.

4. Each lower wishbone pivots on and is secured to the front

crossbeam by two fulcrum bolts. A circular eccentric flange

formed under the hexagonal head of each fulcrum bolt, has

raised graduation marks to indicate radial position. A washer

with a 'D' shaped hole locates on a flat on the threaded section

of each bolt. This ensures that the washer rotates with the bolt,

maintaining an eccentric position corresponding with the

flanged head. The outer face of the washer is punch marked,

ensuring correct instal lation with the chamfered face inwards.

This permits the washer to rotate freely in the crossbeam cam

reaction plate during a djustm ent. Each fulcrum bolt and

washer are secured by a self locking nut.

On rotation of the bolt, lateral movement of the eccentric flange

and washer is restricted by the cam plate faces, forcing the bolt

shank to move laterally in the crossbeam slots. Lateral

movement of the bolt shank re sults in corresponding inward

and outward movement of th e wishbone arm, effecting

adjustment of wh eel alignment.

Rotation of the front fulcrum bolt principally adjusts wheel

caster angle, with a small amount of camber angle change.

Adjustment of the rear fulcrum bo lt mainly alters wheel camber

angle with a small amount of caster angle change.

On vehicles with VIN up to 833124, fulcrum bolt eccentric

flanges have raised graduation marks representing 15 degree

increments of bolt rotati on from 0 to 90 degrees.

On vehicles with VIN from 833125, the fulcrum bolt graduation

marks represent bolt shank ho rizontal movement in 1mm

increments from 0 to 3mm.

The upper wishbone and fulcrum shaft are not adjustable and

play no part in steering geometry adjustment.