egr JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 480 of 2490

The steering rack assembly :

Is mounted on the

rear face of the

front suspension crossbeam by two forg ed mounting brackets with resilient

bushes. The bushes are handed (pinion side and non-pinion side) and are orientated according to the vehicle range

application.

Convert s

the rotary motion of the steering wheel, via the steering gear pinion, to the lateral motion of the rack.

F

e

atures a variable ratio steering

rack with integral hydraulic po wer steering cylinder and piston.

Has a hydrauli

c control valve with Servotronic co

ntrol and positive center feel torsion bar.

The basic steering rack assembly is not serviceable. The following components are serviceable items:

Transfer pipework

.

Servotronic valve. Cent

ralizing cap.

O

u

ter ball joint.

Rac

k

gaiter.

Clips and

fittings.

Steering Rack Components

It e

m

Par

t

Number

De

scr

iption

1—Front

su

spension crossbeam

2—Steeri

ng rack housi

ng

3—Hydraulic

control valve housing

4—Moun

ting bracke

t

5—Gait

er

6—Tie

rod

7—O

u

ter ball joint

Steering R

a

ck Assembly

Page 483 of 2490

P

arts List

The positive center-feel torsion bar improves the straight ahead feel of the steering in the region where very small amounts

of hydraulic pressure, and hence re action pressure, are generated.

The torsion bar assembly forms part of the hydraulic control valve assembly , and includes an axially pre-loaded metal

bellows spring, which is arranged co-axially with the torsion bar. The torsion bar is positively connected between the end

piece and the input shaft. One end of the bellows spring is attached to the input shaft, while the other end is attached to a

centering device. The centering device has two prism-shaped recesses with ca ged, guided, ball bearings arranged between

the recesses, and determines the zero-torsion position of the bellows spring.

On turning the steering wheel from the straight ahead position, the spring fo rces of the torsion bar assembly must be

overcome. Initially, the bellows spring produces substantial additional torsional resistance. However, after an angular

movement of approximately 0.2 degrees the torsional rigidity decreases and becomes similar to a conventional torsion bar.

It

em

Par

t Number

De

scription

1—End piece

2—Torsio

n bar

3—Caged ball bearing

s

4—Centering device

5—Bel

lows spring

6—In

put shaft

Positive Center-Feel Torsion Bar

Torsio

n Bar Components

Page 485 of 2490

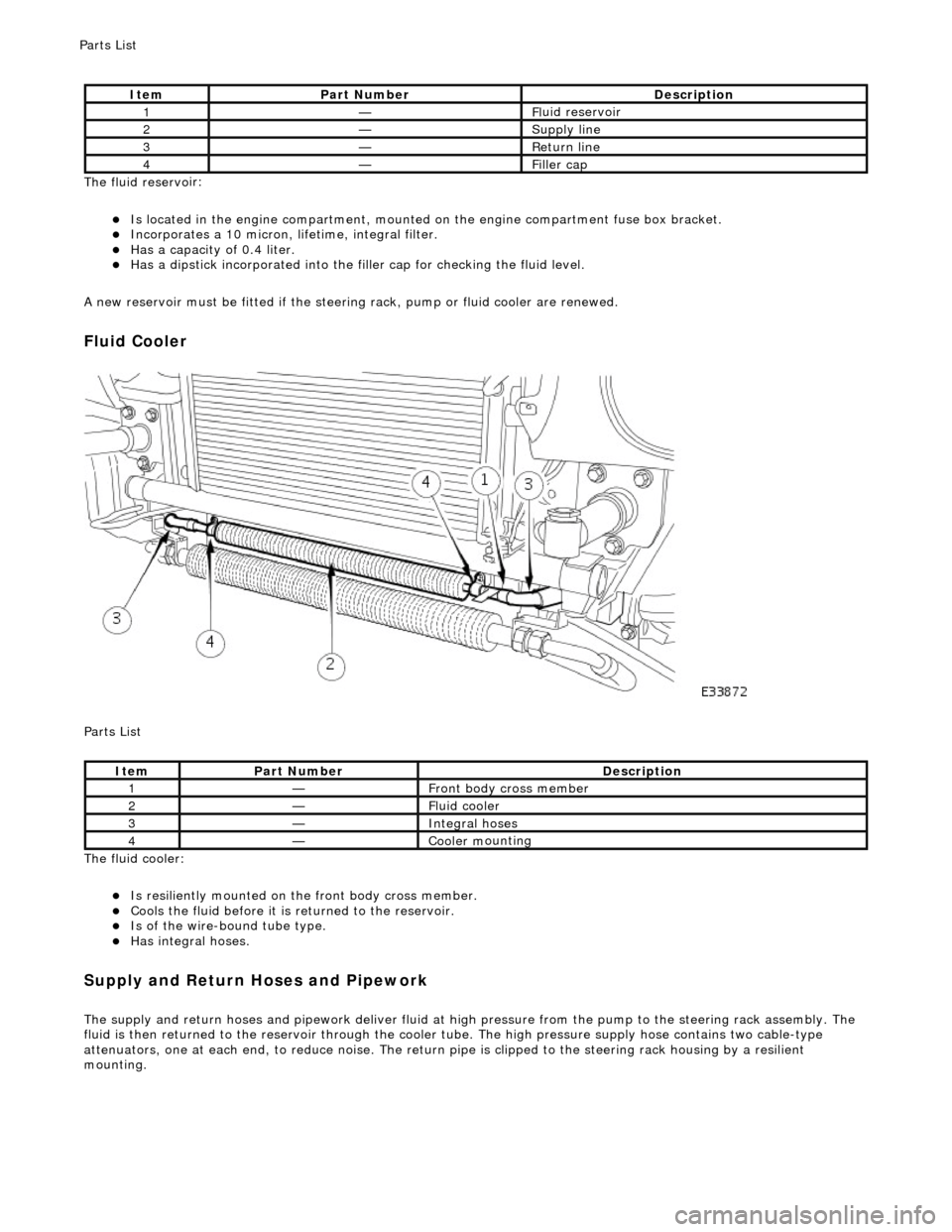

The fluid reservo

ir:

Is lo

cated in the engine compartment, mounted on the engine compartment fuse box bracket.

Incorporates

a 10 micron, li

fetime, integral filter.

Has a cap

acity of 0.4 liter.

Has a dipsti

ck incorporated into the filler cap for checking the fluid level.

A new reservoir must be fitted if the steering rack, pump or fluid cooler are renewed.

Fluid C

ooler

P

arts List

The fluid cooler:

Is

resiliently mounted on th

e front body cross member.

Coo

ls the fluid before it is

returned to the reservoir.

Is

of the wire-bound tube type.

Has i

ntegral hoses.

Supply and Return Hoses a

nd Pipework

The supply and return h

oses and

pipework deliver fluid at high pressure from the pump to th e steering rack assembly. The

fluid is then returned to th e reservoir through the cooler tube. The high pressure supply hose contains two cable-type

attenuators, one at each end, to reduce nois e. The return pipe is clipped to the steering rack housing by a resilient

mounting.

It

em

Par

t Number

De

scription

1—Fl

uid reservoir

2—Supply line

3—R

eturn line

4—Fi

ller cap

It

em

Par

t Number

De

scription

1—Front body cross member

2—F

luid cooler

3—Inte

gral hoses

4—Cooler m

ounting

P

arts List

Page 503 of 2490

Steering

Linkage - Steering Linkage

Descriptio

n and Operation

Parts List

The left- and right-hand tie rod assemblies:

T

ransmit steering forces from the steering rack to the st

eering arms which are integral with the vertical links.

Comprise the tie rod, inner

ball joint,

outer tie rod end and outer ball joint.

P

rovide front road wheel toe setting by adju

stment of the threaded outer tie rod ends.

• NOTE: Steering geometry adjustments must only be carried out wi th the vehicle on turn plates to allow the wheels to move

during adjustment.

The left- and right-hand steering rack gaiters:

Are

installed between the steering rack and the tie bars.

Are

of the concertina type.

R

etain lubricant and prevent th

e ingress of foreign matter.

P

ermit movement of the steering rack and tie rods.

ItemPa

rt Number

Descript

ion

1—St

eering rack assembly

2—St

eering rack gaiter

3—I

nner ball joint

4—Tie

rod

5—O

uter tie rod end

6—Lo

ck-nut

7—Oute

r ball joint

8—O

uter ball joint nut

Page 521 of 2490

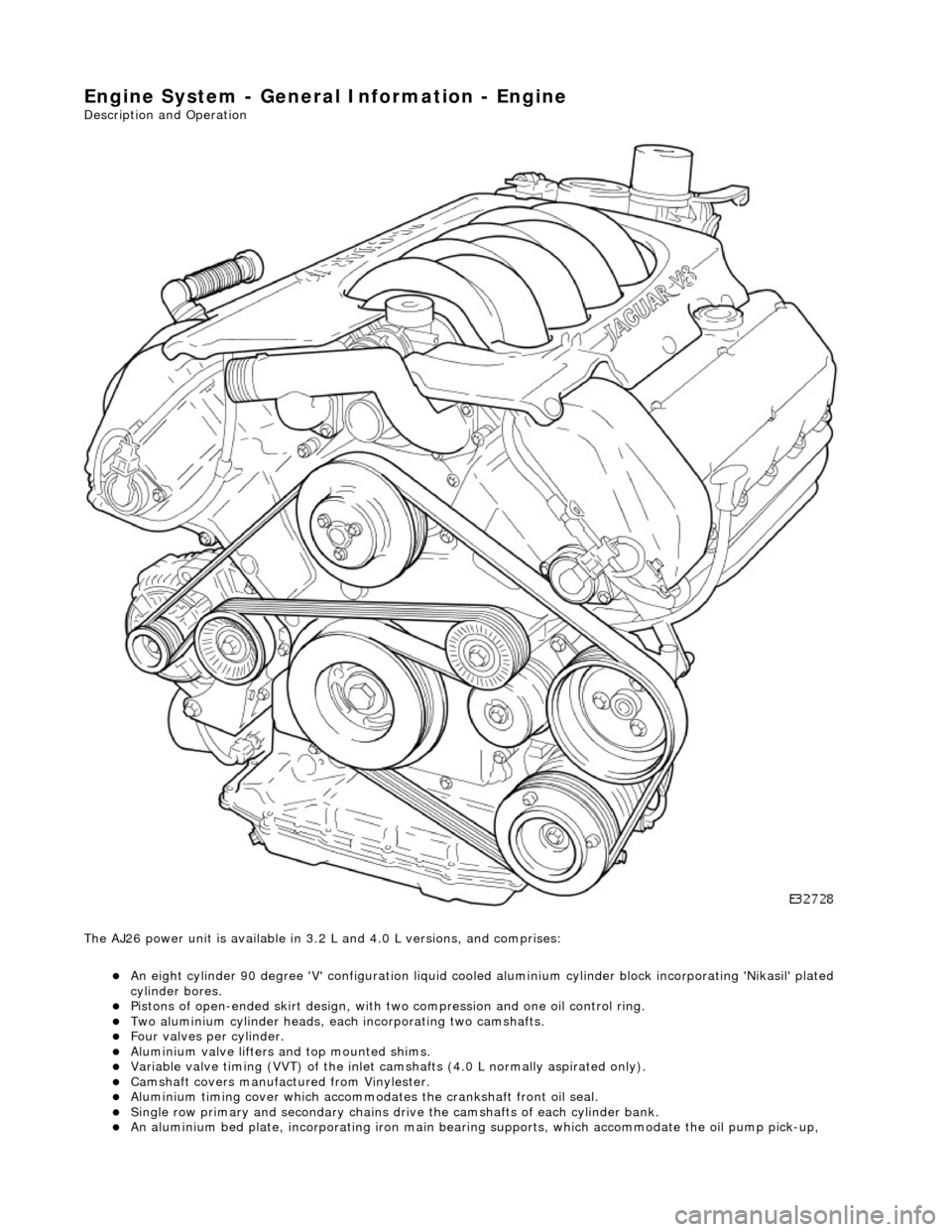

Engine System - General Infor

mation - Engine

Description an

d Operation

The AJ26 power unit is available in 3.2 L and 4.0 L versions, and comprises:

An eight cylinder 9

0 degree 'V' config

uration liquid cooled aluminium cylinder block incorporating 'Nikasil' plated

cylinder bores.

Pi

stons of open-ended skirt design, with

two compression and one oil control ring.

Two al

uminium cylinder heads, each

incorporating two camshafts.

F

our valves per cylinder.

Al

uminium valve lifters and top mounted shims.

Vari

able valve timing (VVT) of the inlet camshafts (4.0 L normally aspirated only).

Camshaft

covers manufactured from Vinylester.

Al

uminium timing cover which accommodat

es the crankshaft front oil seal.

Sin

gle row primary and secondary chains dr

ive the camshafts of each cylinder bank.

An alu

minium bed pl

ate, incorporating iron main bearing supports, which accomm odate the oil pump pick-up,

Page 528 of 2490

Speed an

d load

Coo

l

ant temperature

Ti

me el

apsed from start up

Cl

osed l

oop fuelling

Determination of the vapour concentration is made by stepped opening of the EVAP valve and subsequent monitoring of the

fuelling correction. This function is performed prior to purging, so that at the onse t of purging the EVAP valve can be set to

the optimum position. Should the ECM be unable to determine the concentration before purging, a default value is

employed, which is then modified whilst purging is in progress.

When the purging process is operational th e ECM modifies the basic fuelling calculation to maintain the correct air / fuel

ratio.

Purging is inhibited during fuel cut-off and stability / traction control intervention.

Coolant Temperature Sen

sor

Th

e

sensor outputs a voltage to the ECM which decreases as temperature increases.

Cooling Fans

In response to engi

ne coolant temperat

u

re and climate control system demand, the ECM will energize the cooling fans.

Climate Control Compressor

The E

C

M will allow the compressor clutch to be engaged if th

e engine temperature and load demand are normal. Should the

driver require maximum engine powe r or the coolant temperature be high, the request will be denied.

Cranking Signal

The ECM reacts to a signal fr

om th

e Body Processor Module (BPM) when the starter motor relay is energi

zed. This signal is

used to trigger starting, fu el and ignition strategies.

Engine Speed and Cranksh

aft Position

Engine

speed and cran

k position are moni

tored by a sensor which is mounted on the cylinder block (flywheel housing)

behind the crankshaft drive plat e. It indicates rotational speed to the ECM in the form of 12 pulses per crank revolution.

Engine speed is used for synchronization of fuel an d ignition systems, as well as other functions.

Camshaft Position

The ca

mshaft position sensor is mounted at

the rear of Bank 2 cylinder head on the inlet side and provides one signal every

720 degrees of crankshaft rotation. The signal, in conjunction with the signal from the crankshaft position sensor, indicates

to the ECM that the piston of cylinder 1A is approaching TDC on the compression stroke.

Variable Valve

Timing (Where Fitted)

By energi

si

ng a solenoid to allow the pass

age of pressurized oil on each of the inle t camshaft drives, the ECM can vary by a

single stepped amount, the relati ve timing of the inlet valves.

Ign

ition

Ignit

i

on spark is produced by

individual on-plug coil units.

There are two ignition amplifiers; module #1 drives coils 1A, 2B, 3B and 4A, whilst module #2 drives coils 1B, 2A, 3A and

4B. The ECM controls the amplifiers.

Page 529 of 2490

Thi

s sensor uses a piezo-electric sensing element to detect kn

ock which may occur under acceleration at critical conditions.

Should detonation be present the ECM will retard ignition timing of individual cylinders.

Exhaust G

as Recirculation

The EGR

valve (where fitted) reduces NOx

emissions by recirculating a portion of the exhaust gases back into the inlet

manifold.

Heated Oxyg

en Sensors

The h

eated oxygen sensors, one per bank, are situated upstream of the catalysts. Integral

to the sensors are heaters

(under ECM control) which allow the sensor s to reach their operating temperature as soon as possible after engine start. A

comparison between the level of oxygen in the exhaust gas to that in the atmosphere produces an output signal. This signal

is used by the engine closed loop fuel strategy to make fuelling corrections and so control overall emission levels.

Oxygen Sensors

Thes

e sensors, one per bank, are situated downstream of the

catalyst. The comparison of upstream and downstream signals

allows determination of cata lyst conversion efficiency.

Knock Sensor

Page 683 of 2490

Engine - Exhaust Manifold RH

In-vehicle Repair

Removal

1. Open the engine compartment and fit paintwork protection

sheets.

2. Remove the air cleaner assemb ly. Refer to Section 303-12.

3. Remove the front silencer. Refer to Section 309-00.

4. Remove the downpipe catalytic converter, right hand side.

Refer to Section 309-00.

5. From above the vehicle, disconnect the EGR pipe from the

exhaust manifold.

1. Remove the two nuts whic h secure the EGR flange to

the right hand exhaust manifold.

2. Reposition the EGR pipe from the manifold.

6. Remove the bolts which secure th e front section of the exhaust

manifold to the cylinder head.

7. If working on a right hand drive vehicle; reposition the steering rack for access.

1. Remove the two bolts which secure the steering rack at the passenger side.

2. Loosen, but do not remove, the two bolts which secure the steering rack at the driver's side.

Reposition the steering rack for access.

8. Working from below the vehicle, remove the manifold bolts.

1. Remove the bolts which secu re the rear section of the

exhaust manifold to the cylinder head.

Page 684 of 2490

Installation

9. Remove the manifold.

1. Remove the manifold and the manifold gasket from the cylinder head.

2. Remove the gasket from the EGR flange.

10. If fitting a new manifold, remove the two studs from the EGR

flange of the manifold. and transfer them to the new manifold.

11. Clean the manifold faces (if refi tting) and the mating faces on

the cylinder head.

12. Use a thread tap (plug) to clean out the threads of the

manifold securing bolt holes, in the cylinder head.

1. Fit a spacer to each new manifo ld securing bolt (8 bolts).

2. Fit the manifold and manifold gasket.

1. Fit and align the new gasket to the cylinder head.

2. Fit and align the manifo ld to the cylinder head.

3. Fit the rear four bolts wh ich secure the manifold, but

do not tighten.

3. Working from above the vehicle, fit and tighten the remaining

manifold securing bolts.

4. Working from below the vehicle, fu lly tighten the rear bolts on

each manifold.

5. Refit the steering rack (if removed for access).

1. Reposition th e steering rack.

2. Fit and tighten the rack mounting bolts on the passenger side.

Page 685 of 2490

3. Tighten the rack mounting bolts on the driver's side.

6. From above the vehicle, connect the EGR pipe to the exhaust

manifold.

1. Fit a new EGR gasket to the manifold.

2. Reposition the EGR pipe to the manifold.

3. Fit the two nuts which secure the EGR flange to the exhaust manifold.

7. Fit the downpipe catalytic converter, right hand side. Refer to

Section 309-00.

8. Fit the front silencer. Refer to Section 309-00.

9. Fit the air cleaner assembly . Refer to Section 303-12.

10. Remove paintwork protection sheets and close the engine

compartment.