clock JAGUAR XF 2009 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2009, Model line: XF, Model: JAGUAR XF 2009 1.GPages: 391, PDF Size: 19.32 MB

Page 114 of 391

Information displays

114

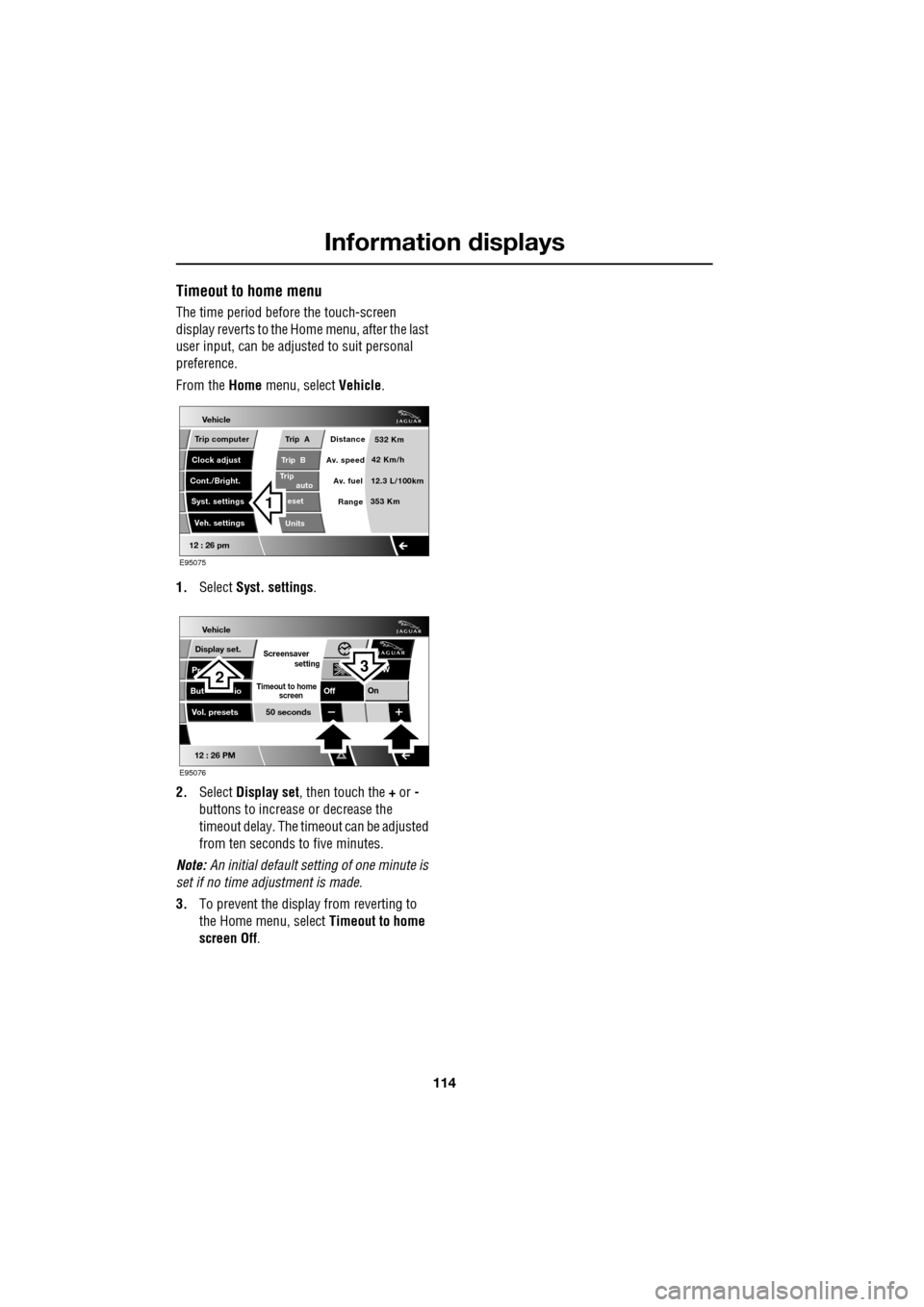

Timeout to home menu

The time period before the touch-screen

display reverts to the Home menu, after the last

user input, can be adjusted to suit personal

preference.

From the Home menu, select Vehicle.

1. Select Syst. settings .

2. Select Display set , then touch the + or -

buttons to increase or decrease the

timeout delay. The time out can be adjusted

from ten seconds to five minutes.

Note: An initial defa ult setting of one minute is

set if no time adjustment is made.

3. To prevent the display from reverting to

the Home menu, select Timeout to home

screen Off .

Vehicle

Trip B

Trip

auto eset

Units Distance

Av. speed

Av. fuel 532 Km

42 Km/h

12.3 L/100km

353 Km

RangeClock adjust

Cont./Bright. Trip computer

Syst. settings Veh. settings

Trip A

12 : 26 pm

E95075

1

Vehicle

Display set.

Pr

But io

Vol. presets

12 : 26 PM

50 seconds

OnOff

Screensaver

Timeout to home

setting

screen

W

E95076

32

Page 124 of 391

Convenience features

124

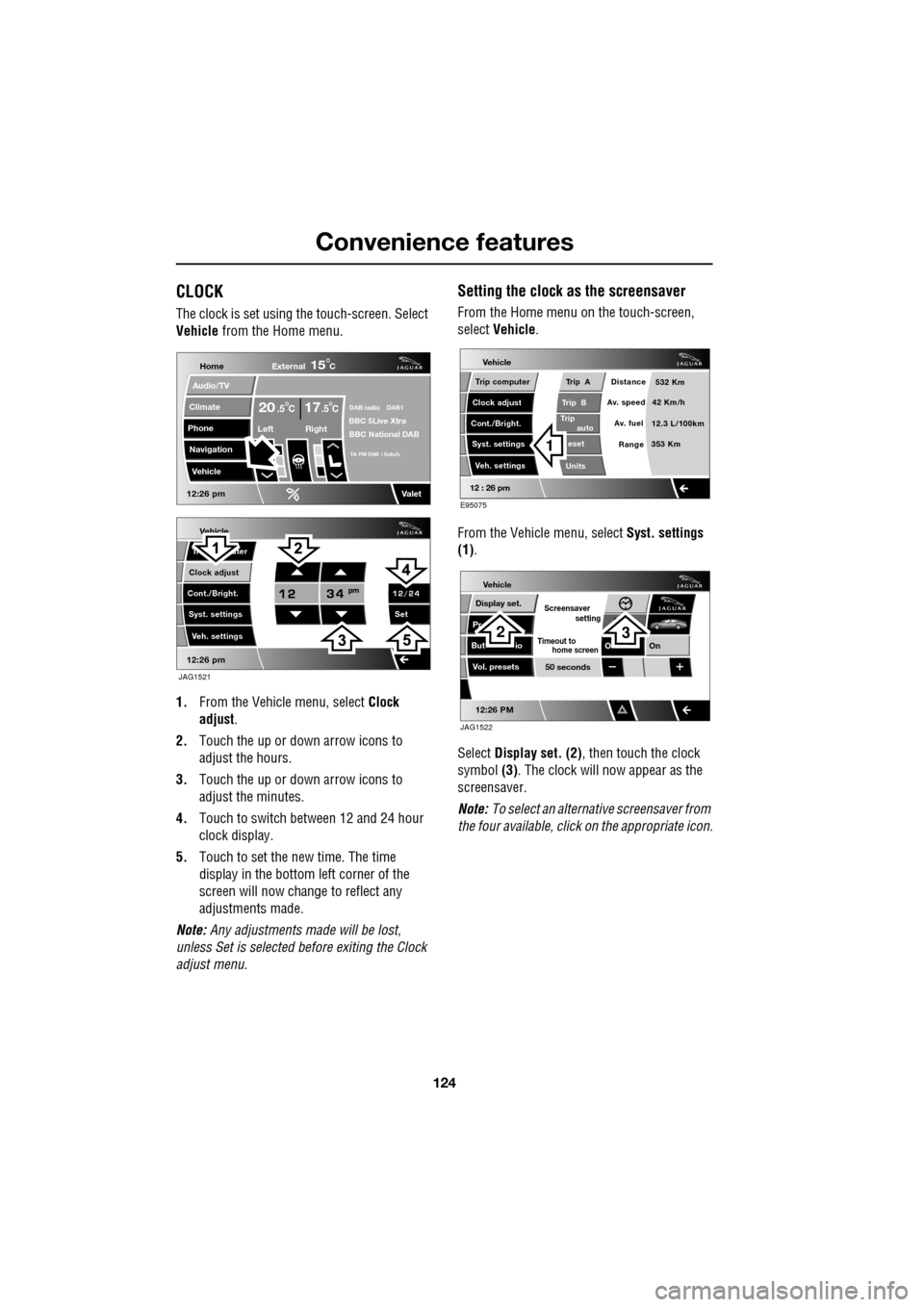

CLOCK

The clock is set using the touch-screen. Select

Vehicle from the Home menu.

1. From the Vehicl e menu, select Clock

adjust .

2. Touch the up or down arrow icons to

adjust the hours.

3. Touch the up or down arrow icons to

adjust the minutes.

4. Touch to switch between 12 and 24 hour

clock display.

5. Touch to set the new time. The time

display in the bottom left corner of the

screen will now change to reflect any

adjustments made.

Note: Any adjustments made will be lost,

unless Set is selected before exiting the Clock

adjust menu.

Setting the clock as the screensaver

From the Home menu on the touch-screen,

select Vehicle.

From the Vehicle menu, select Syst. settings

(1) .

Select Display set. (2) , then touch the clock

symbol (3). The clock will now appear as the

screensaver.

Note: To select an alternative screensaver from

the four available, click on the appropriate icon.

Vehicle

Clock adjust

Cont./Bright. Tr uter

Syst. settings Veh. settings Set

12:26 pm

JAG1521

Home

Audio/TV

Climate

Phone

Navigation

Vehicle

DAB radio DAB1BBC 5Live XtraBBC National DAB

TA FM DAB i Subch.

Va l e t12:26 pm

External15C

Left Right

20 17CC.5 .5

Vehicle

Trip B

Trip

auto eset

Units Distance

Av. speed

Av. fuel 532 Km

42 Km/h

12.3 L/100km

353 Km

RangeClock adjust

Cont./Bright. Trip computer

Syst. settings Veh. settings

Trip A

12 : 26 pm

E95075

1

Vehicle

Display set.

Pr

But io

Vol. presets

12:26 PM

50 seconds

OnO

Screensaver

Timeout to

setting

home screen

JAG1522

23

Page 178 of 391

Fuel and refuelling

178

Resetting the fuel cut-off

1.Switch the ignition off and wait for one

minute.

2. Turn the ignition on for 30 seconds.

3. Check the vehicle thor oughly for fuel leaks.

If a leak is detected switch the ignition off

immediately.

• Do not start the vehicle if a leak is

present. Seek qualified advice and have

the vehicle recovered.

4. If no leaks are detected, start the vehicle.

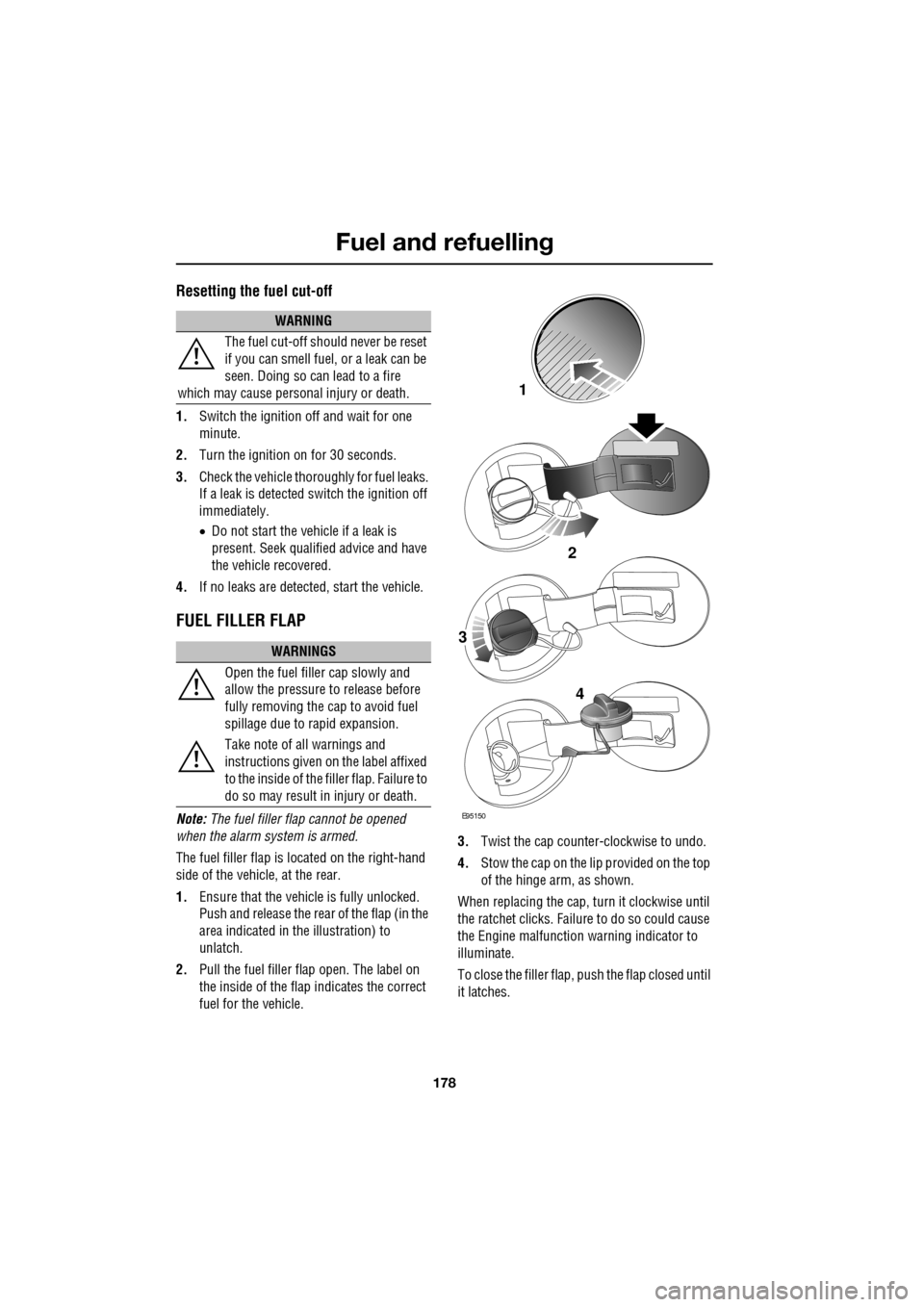

FUEL FILLER FLAP

Note: The fuel filler flap cannot be opened

when the alarm system is armed.

The fuel filler flap is located on the right-hand

side of the vehicle, at the rear.

1. Ensure that the vehicle is fully unlocked.

Push and release the rear of the flap (in the

area indicated in the illustration) to

unlatch.

2. Pull the fuel filler flap open. The label on

the inside of the flap indicates the correct

fuel for the vehicle. 3.

Twist the cap counte r-clockwise to undo.

4. Stow the cap on the lip provided on the top

of the hinge arm, as shown.

When replacing the cap, turn it clockwise until

the ratchet clicks. Failur e to do so could cause

the Engine malfunction warning indicator to

illuminate.

To close the filler flap, pus h the flap closed until

it latches.

WARNING

The fuel cut-off should never be reset

if you can smell fuel, or a leak can be

seen. Doing so can lead to a fire

which may cause persona l injury or death.

WARNINGS

Open the fuel filler cap slowly and

allow the pressure to release before

fully removing the cap to avoid fuel

spillage due to rapid expansion.

Take note of all warnings and

instructions given on the label affixed

to the inside of the fi ller flap. Failure to

do so may result in injury or death.

E95150

2

1

3

4

Page 190 of 391

Vehicle care

190

Leather

Leather is an easy to maintain natural product.

However, dust and subs tances can penetrate

the pores and crease the leather, causing

surface wear and brittleness.

To prevent ingrained dirt and staining, inspect

the seat upholstery regularly and clean every

one to two months, as follows:

• Wipe off fine dust from the seat surfaces

using a clean, damp, non-coloured cloth.

Change frequently to a clean area of cloth,

to avoid abrasive action on the leather

surface. Avoid over-wetting.

• If this is not suffic ient, use a cloth which

has been dampened with warm soapy

water and then wrung out. Use only mild

non-caustic soap.

• Use Jaguar Leather Cleaner for heavily

soiled areas. Dry off and rub with a clean

soft cloth, changing surfaces regularly.

When staining (e.g. from clothing) or spillage

occurs, clean the affected area immediately as

described above.

Use Jaguar Leather Cleaner several times a

year to maintain its appearance and

suppleness. The clea ner will nourish and

moisturise and help to improve the surface

protective film agains t dust and substances.

• Do not use solvents. Do not use

detergents, furniture polish or household

cleaners. While these products may

initially give impressi ve results, their use

will lead to rapid deterioration of the

leather and will inva lidate the warranty.

Jaguar recommend a basic set of products

that have been specially selected for the

type of leather in your vehicle.

• Dark clothing may stain leather seats just

like other upholstery products. •

Sharp objects such as belts, zip fasteners,

rivets, etc., can leave permanent scratches

and scratch marks on the leather surface.

• Unless spillages such as tea, coffee or ink

are washed away immediately, permanent

staining may have to be accepted.

If a valet service is used, ensure that the

specialist concerned is aware of, and follows,

these instructions precisely.

Cloth and fabric

Use Jaguar Upholstery Cleaner, following the

instructions. Avoid over-wetting.

Removing stains

Most stains on woollen fabric can be removed

if treatment is carried out immediately, before

the stain has a chance to dry-in.

Most stains can be treated with one of three

cleaning fluids: Jaguar U pholstery Cleaner, dry

cleaning fluid or clean water. Follow the

instructions on the package.

Instrument pack, clock, and audio

equipment

Only use a soft dry cloth to clean the

instrument pack, clock and audio equipment.

Do not use cleaning fluids or sprays.

CAUTIONS

Never use soap, ammonia, bleach or

other cleaners intended for use on hard

surfaces.

Do not use upholst ery cleaner on

electrical equipment such as fascia

switches.

When cleaning around electrical

equipment such as switches, ensure

that fluids do not leak into any gaps around the

components or between panels or trim.

Page 232 of 391

Wheels and tyres

232

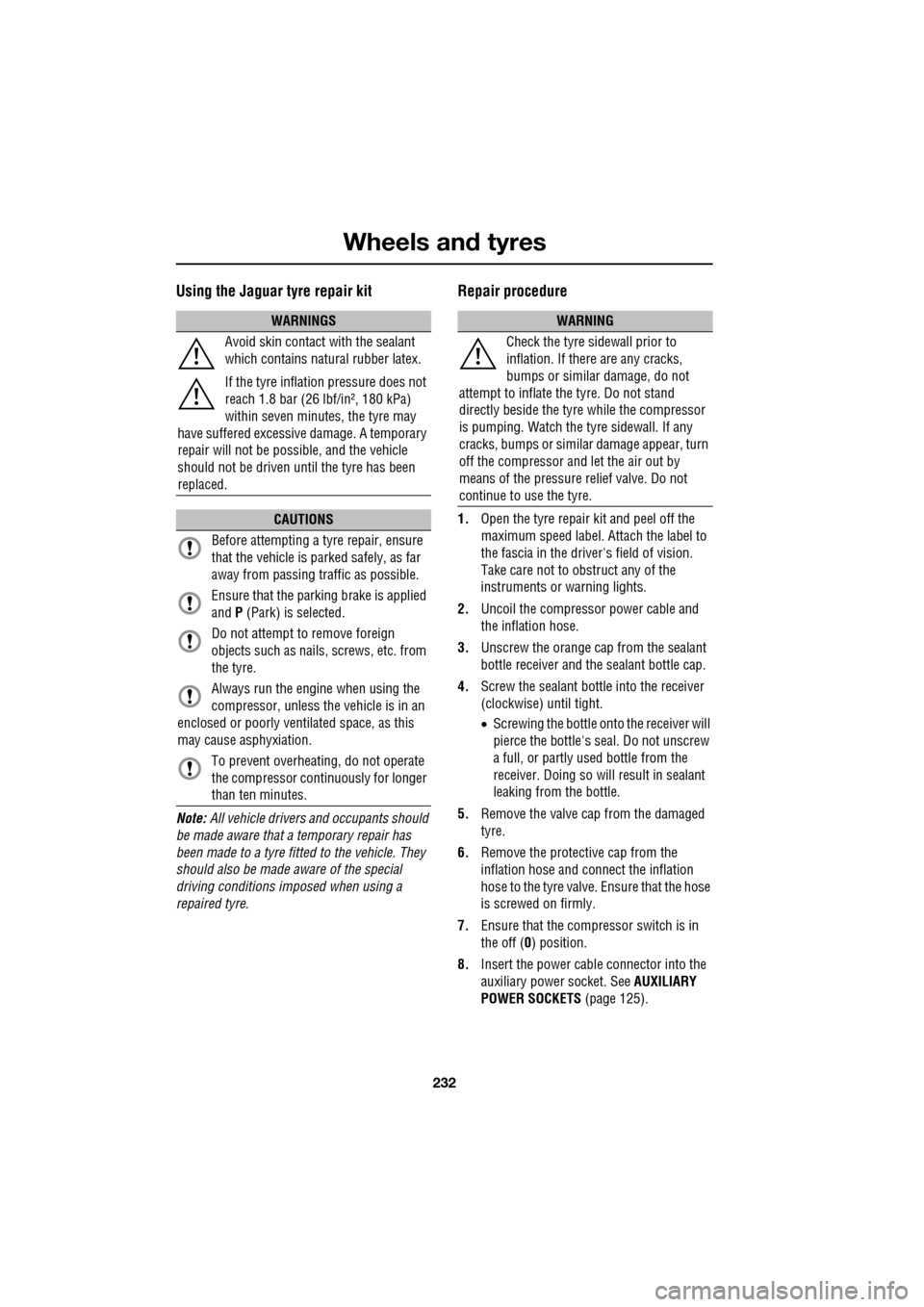

Using the Jaguar tyre repair kit

Note: All vehicle drivers and occupants should

be made aware that a temporary repair has

been made to a tyre fitted to the vehicle. They

should also be made aware of the special

driving conditions im posed when using a

repaired tyre.

Repair procedure

1. Open the tyre repair kit and peel off the

maximum speed label. Attach the label to

the fascia in the driver's field of vision.

Take care not to obstruct any of the

instruments or warning lights.

2. Uncoil the compressor power cable and

the inflation hose.

3. Unscrew the orange cap from the sealant

bottle receiver and the sealant bottle cap.

4. Screw the sealant bottle into the receiver

(clockwise) until tight.

•Screwing the bottle onto the receiver will

pierce the bottle's se al. Do not unscrew

a full, or partly us ed bottle from the

receiver. Doing so will result in sealant

leaking from the bottle.

5. Remove the valve cap from the damaged

tyre.

6. Remove the protective cap from the

inflation hose and connect the inflation

hose to the tyre valve. Ensure that the hose

is screwed on firmly.

7. Ensure that the compressor switch is in

the off (0) position.

8. Insert the power cable connector into the

auxiliary power socket. See AUXILIARY

POWER SOCKETS (page 125).

WARNINGS

Avoid skin contact with the sealant

which contains natu ral rubber latex.

If the tyre inflati on pressure does not

reach 1.8 bar (26 lbf/in², 180 kPa)

within seven minutes, the tyre may

have suffered excessive damage. A temporary

repair will not be poss ible, and the vehicle

should not be driven until the tyre has been

replaced.

CAUTIONS

Before attempting a ty re repair, ensure

that the vehicle is parked safely, as far

away from passing traffic as possible.

Ensure that the parki ng brake is applied

and P (Park) is selected.

Do not attempt to remove foreign

objects such as nails, screws, etc. from

the tyre.

Always run the engine when using the

compressor, unless the vehicle is in an

enclosed or poorly ventil ated space, as this

may cause asphyxiation.

To prevent overheating, do not operate

the compressor continuously for longer

than ten minutes.

WARNING

Check the tyre sidewall prior to

inflation. If there are any cracks,

bumps or similar damage, do not

attempt to inflate the tyre. Do not stand

directly beside the tyre while the compressor

is pumping. Watch the ty re sidewall. If any

cracks, bumps or simila r damage appear, turn

off the compressor and let the air out by

means of the pressure relief valve. Do not

continue to use the tyre.

Page 233 of 391

233

Wheels and tyres

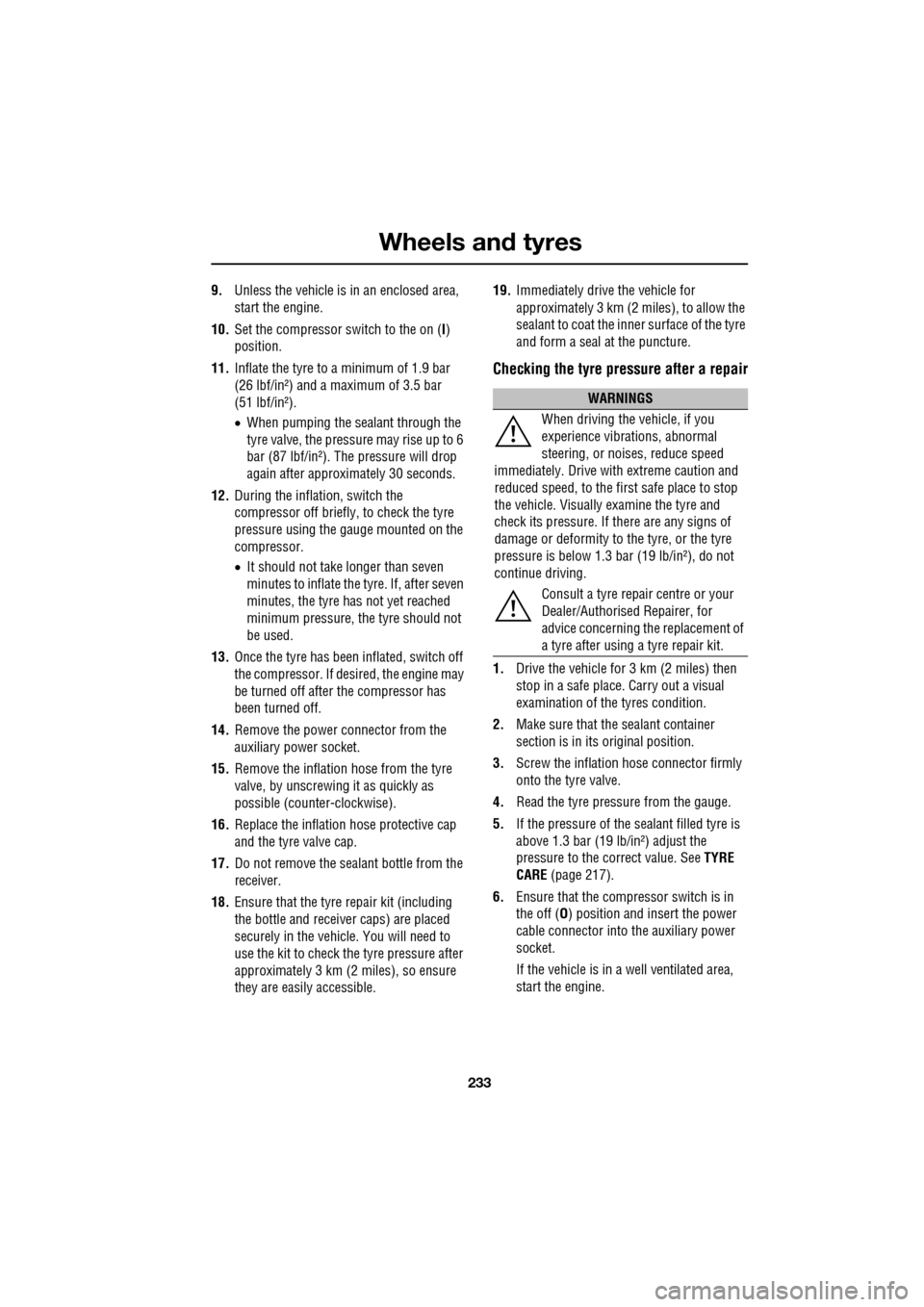

9.Unless the vehicle is in an enclosed area,

start the engine.

10. Set the compressor switch to the on ( I)

position.

11. Inflate the tyre to a minimum of 1.9 bar

(26 lbf/in²) and a maximum of 3.5 bar

(51 lbf/in²).

•When pumping the sealant through the

tyre valve, the pressure may rise up to 6

bar (87 lbf/in²). The pressure will drop

again after approximately 30 seconds.

12. During the inflation, switch the

compressor off briefly, to check the tyre

pressure using the gauge mounted on the

compressor.

• It should not take longer than seven

minutes to inflate the tyre. If, after seven

minutes, the tyre has not yet reached

minimum pressure, the tyre should not

be used.

13. Once the tyre has been inflated, switch off

the compressor. If desired, the engine may

be turned off after the compressor has

been turned off.

14. Remove the power connector from the

auxiliary power socket.

15. Remove the inflation hose from the tyre

valve, by unscrewing it as quickly as

possible (count er-clockwise).

16. Replace the inflation hose protective cap

and the tyre valve cap.

17. Do not remove the sealant bottle from the

receiver.

18. Ensure that the tyre repair kit (including

the bottle and receiver caps) are placed

securely in the vehicle. You will need to

use the kit to check the tyre pressure after

approximately 3 km (2 miles), so ensure

they are easily accessible. 19.

Immediately drive the vehicle for

approximately 3 km (2 miles), to allow the

sealant to coat the inner surface of the tyre

and form a seal at the puncture.

Checking the tyre pressure after a repair

1.Drive the vehicle for 3 km (2 miles) then

stop in a safe place. Carry out a visual

examination of the tyres condition.

2. Make sure that the sealant container

section is in its original position.

3. Screw the inflation hos e connector firmly

onto the tyre valve.

4. Read the tyre pressure from the gauge.

5. If the pressure of the sealant filled tyre is

above 1.3 bar (19 lb/in²) adjust the

pressure to the correct value. See TYRE

CARE (page 217).

6. Ensure that the compressor switch is in

the off (O ) position and insert the power

cable connector into the auxiliary power

socket.

If the vehicle is in a well ventilated area,

start the engine.

WARNINGS

When driving the vehicle, if you

experience vibr ations, abnormal

steering, or noises, reduce speed

immediately. Drive with extreme caution and

reduced speed, to the first safe place to stop

the vehicle. Visually examine the tyre and

check its pressure. If there are any signs of

damage or deformity to the tyre, or the tyre

pressure is below 1.3 bar (19 lb/in²), do not

continue driving.

Consult a tyre repair centre or your

Dealer/Authorised Repairer, for

advice concerning the replacement of

a tyre after using a tyre repair kit.

Page 253 of 391

253

Vehicle recovery

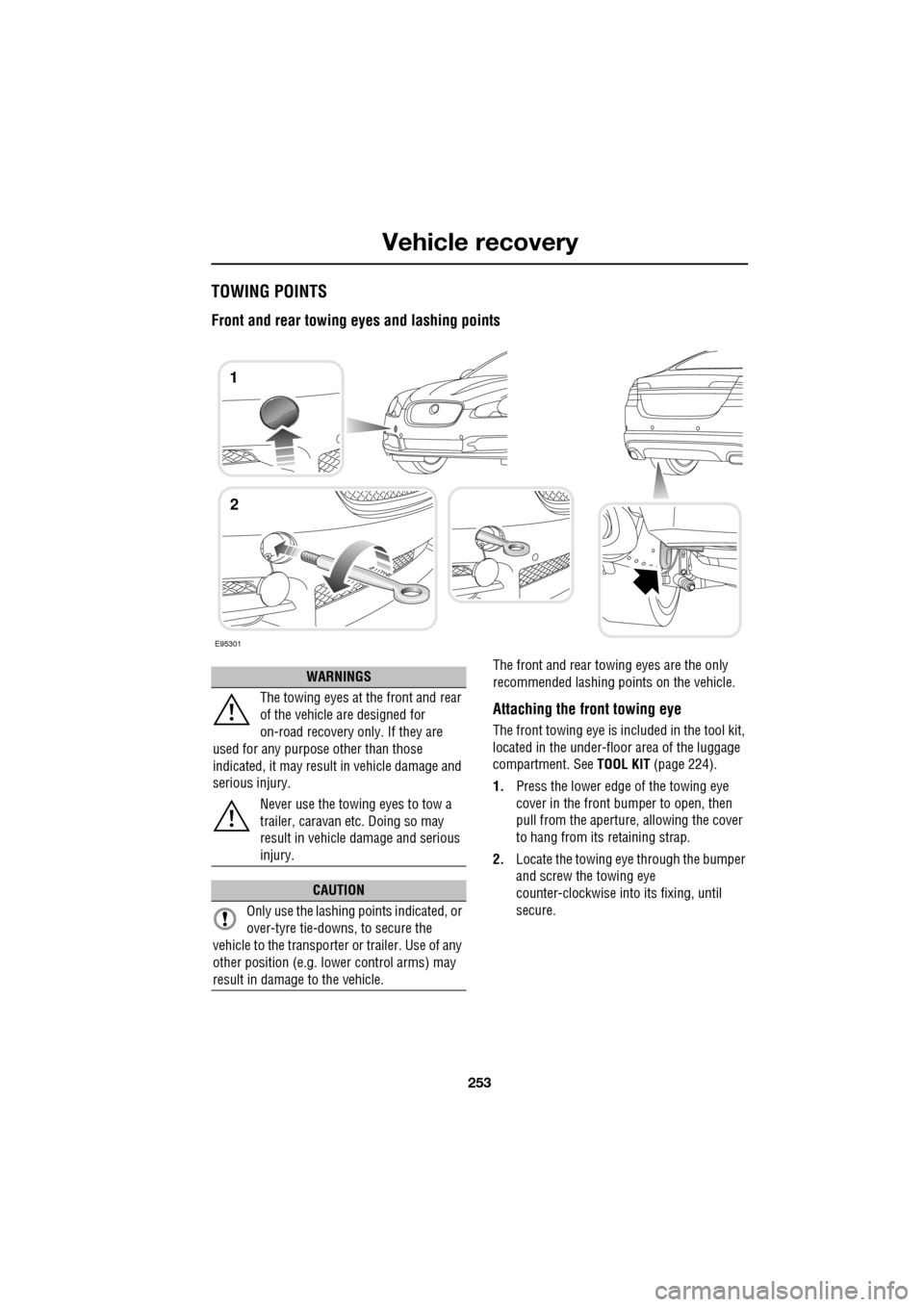

TOWING POINTS

Front and rear towing eyes and lashing points

The front and rear towing eyes are the only

recommended lashing points on the vehicle.

Attaching the front towing eye

The front towing eye is included in the tool kit,

located in the under-floor area of the luggage

compartment. See TOOL KIT (page 224).

1. Press the lower edge of the towing eye

cover in the front bumper to open, then

pull from the aperture, allowing the cover

to hang from its retaining strap.

2. Locate the towing eye through the bumper

and screw the towing eye

counter-clockwise into its fixing, until

secure.

E95301

1

2

WARNINGS

The towing eyes at the front and rear

of the vehicle are designed for

on-road recovery only. If they are

used for any purpose other than those

indicated, it may result in vehicle damage and

serious injury.

Never use the towing eyes to tow a

trailer, caravan etc. Doing so may

result in vehicle damage and serious

injury.

CAUTION

Only use the lashing points indicated, or

over-tyre tie-downs, to secure the

vehicle to the transporter or trailer. Use of any

other position (e.g. lower control arms) may

result in damage to the vehicle.

Page 255 of 391

255

Vehicle recovery

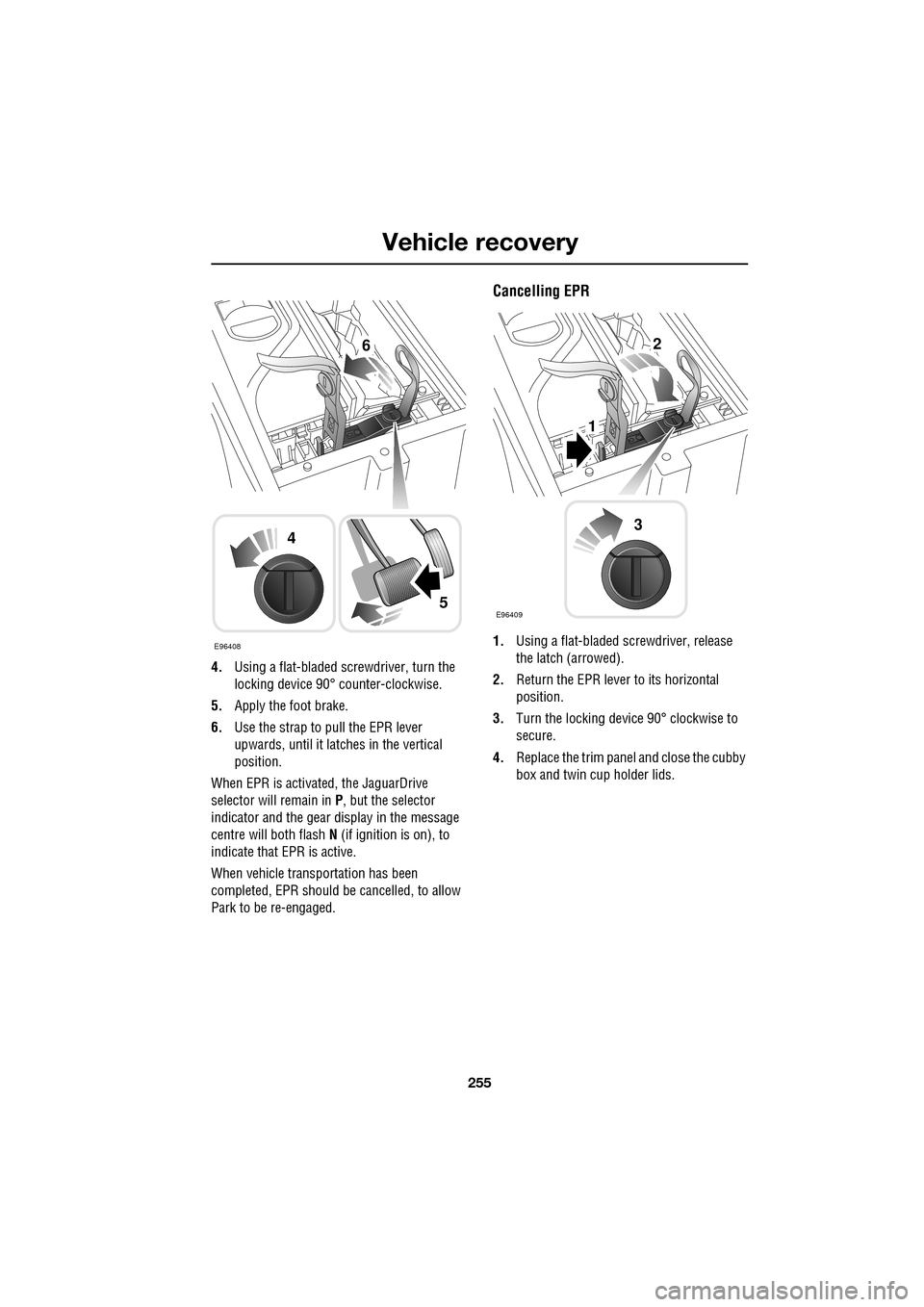

4.Using a flat-bladed screwdriver, turn the

locking device 90° counter-clockwise.

5. Apply the foot brake.

6. Use the strap to pull the EPR lever

upwards, until it latches in the vertical

position.

When EPR is activated, the JaguarDrive

selector will remain in P , but the selector

indicator and the gear display in the message

centre will both flash N (if ignition is on), to

indicate that EPR is active.

When vehicle transportation has been

completed, EPR should be cancelled, to allow

Park to be re-engaged.

Cancelling EPR

1. Using a flat-bladed sc rewdriver, release

the latch (arrowed).

2. Return the EPR lever to its horizontal

position.

3. Turn the locking device 90° clockwise to

secure.

4. Replace the trim pane l and close the cubby

box and twin cup holder lids.E96408

4

5

62

1

E96409

3

Page 382 of 391

Index

382

Bulb changing . . . . . . . . . . . . . . . . . . . . . . 83direction indicator bulb (front) . . . . . . . 84

headlamp unit bulbs . . . . . . . . . . . . . . . 83

high level brake lamp . . . . . . . . . . . . . . 86

number plate lamp bulb . . . . . . . . . . . . 86

rear lamp bulbs . . . . . . . . . . . . . . . . . . . 85

side lamp bulb . . . . . . . . . . . . . . . . . . . 85

side repeater lamp . . . . . . . . . . . . . . . . 85

Bulb specification chart . . . . . . . . . . . . . . . 87

C

Cancel guidance . . . . . . . . . . . . . . . . . . . 350

Car wash . . . . . . . . . . . . . . . . . . . . . . . . . 187

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Changing a bulb . . . . . . . . . . . . . . . . . . . . 83 general information . . . . . . . . . . . . . . . . 83

Changing a fuse. . . . . . . . . . . . . . . . . . . . 241 checking or renewing a blown fuse . . . 241

Changing a road wheel . . . . . . . . . . . . . . 225

locking wheel nuts . . . . . . . . . . . . . . . 226

spare wheel location . . . . . . . . . . . . . . 226

temporary use spare wheel . . . . . . . . . 225

tightening the wheel nuts . . . . . . . . . . 229

wheel changing procedure . . . . . . . . . 228

wheel changing safety. . . . . . . . . . . . . 227

Changing the remote cont rol battery . . . . . 24

Changing the vehicle battery . . . . . . . . . . 215

battery disposal. . . . . . . . . . . . . . . . . . 215

Changing the wiper blades . . . . . . . . . . . . 91 changing the wiper blades . . . . . . . . . . 92

service position . . . . . . . . . . . . . . . . . . . 91

Channel automatic tuning . . . . . . . . . . . . 284

Channel options. . . . . . . . . . . . . . . . . . . . 284 DAB search . . . . . . . . . . . . . . . . . . . . . 286

finding a channel. . . . . . . . . . . . . . . . . 285

finding a subchannel . . . . . . . . . . . . . . 285

finding an ensemble . . . . . . . . . . . . . . 286

Charging the vehicle battery . . . . . . . . . . 215

Checking the wiper blades . . . . . . . . . . . . . 90

Child safety locks . . . . . . . . . . . . . . . . . . . 65

Child seat anchor points . . . . . . . . . . . . . . 62 installing an ISOFIX child seat. . . . . . . . 63

ISOFIX anchor points . . . . . . . . . . . . . . 62

tether anchorage points . . . . . . . . . . . . 64

Child seat positioning . . . . . . . . . . . . . . . . 60 Child seats . . . . . . . . . . . . . . . . . . . . . . . . . 59

child restraint check list . . . . . . . . . . . . . 60

Cleaning the alloy wheels . . . . . . . . . . . . . 187

Cleaning the exterior . . . . . . . . . . . . . . . . . 187

bird droppings . . . . . . . . . . . . . . . . . . . 189

cleaning the rear screen . . . . . . . . . . . . 189

glass surfaces . . . . . . . . . . . . . . . . . . . 189

polishing . . . . . . . . . . . . . . . . . . . . . . . 189

removing grease and tar. . . . . . . . . . . . 189

underbonnet cleaning . . . . . . . . . . . . . . 188

using an automatic wash . . . . . . . . . . . 188

washing the vehicle paintwork . . . . . . . 187

Cleaning the interior . . . . . . . . . . . . . . . . . 189 airbag module covers . . . . . . . . . . . . . . 191

carpet and mats . . . . . . . . . . . . . . . . . . 191

cloth and fabric . . . . . . . . . . . . . . . . . . 190

instrument pack, clock, and audio equipment . . . . . . . . . . . . . . . . . . . . 190

leather . . . . . . . . . . . . . . . . . . . . . . . . . 190

removing stains . . . . . . . . . . . . . . . . . . 190

seat belts . . . . . . . . . . . . . . . . . . . . . . . 191

Climate seats . . . . . . . . . . . . . . . . . . . . . . . 48 backrest ventilation only. . . . . . . . . . . . . 48

cooled ventilation . . . . . . . . . . . . . . . . . . 48

heated ventilation . . . . . . . . . . . . . . . . . . 48

Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124 setting the clock as the screensaver . . . 124

Compact disc display options . . . . . . . . . . 296

Compact disc pause . . . . . . . . . . . . . . . . . 295

Compact disc player CD compatibility . . . . . . . . . . . . . . . . . . 292

loading CDs . . . . . . . . . . . . . . . . . . . . . 292

Compact disc selection . . . . . . . . . . . . . . . 294

Compass view. . . . . . . . . . . . . . . . . . . . . . 360

Condensation - lamps . . . . . . . . . . . . . . . . . 76

Controls overview . . . . . . . . . . . . . . . . . . . . 12

Coolant check . . . . . . . . . . . . . . . . . . . . . . 204

Cornering lamps . . . . . . . . . . . . . . . . . . . . . 79

Cruise control . . . . . . . . . . . . . . . . . . . 74, 156

principle of operation . . . . . . . . . . . . . . 156

Cup holders . . . . . . . . . . . . . . . . . . . . . . . 126 twin cup holder . . . . . . . . . . . . . . . . . . 127