power JAGUAR XF 2009 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2009, Model line: XF, Model: JAGUAR XF 2009 1.GPages: 391, PDF Size: 19.32 MB

Page 193 of 391

193

Maintenance

Weekly checks

•Engine oil level (non- electronic dipstick

vehicles). See ENGINE OIL CHECK - V6

Petrol engines (page 197).

• Engine coolant check. See ENGINE

COOLANT CHECK (page 204).

• Brake fluid level. See BRAKE FLUID

CHECK (page 206).

• Power steering fluid level. See POWER

STEERING FLUID CHECK (page 208).

• Screen washer fluid level. See WASHER

FLUID CHECK (page 209).

• Tyre pressures and condition. See TYRE

CARE (page 217).

• Operate air conditioning. See AUTOMATIC

CLIMATE CONTROL (page 116).

Note: The engine oil level on V6 petrol engines,

should be checked more frequently if the

vehicle is driven for prolonged periods at high

speeds. The engine oil level on diesel and V8

petrol engines is checked automatically at all

times by the electronic dipstick.

Severe driving conditions

When a vehicle is operated in severe

conditions, more frequent attention must be

paid to servicing requirements.

Severe driving conditions include:

• Driving in dusty and/or sandy conditions.

• Driving on rough and/or muddy roads

and/or wading. •

Driving in extremely hot or cold

conditions.

• Driving in areas using road salt or other

corrosive materials.

• Towing a trailer or driving in mountainous

conditions.

Contact your Dealer/Authorised Repairer for

advice.

Emission control

Your vehicle is fitted with various items of

emission and evaporati ve control equipment,

designed to meet specific territorial

requirements. You should be aware that

unauthorised replacemen t, modification or

tampering with this equipment by an owner or

repair shop, may be unlawful and subject to

legal penalties.

In addition, engine se ttings must not be

tampered with. These have been established to

ensure that your vehicle complies with

stringent exhaust em ission regulations.

Incorrect engine settings may adversely affect

exhaust emissi ons, engine performance and

fuel consumption. The y may also cause high

temperatures, which will result in damage to

the catalytic converter and the vehicle.

Road testing dynamometers (rolling

roads)

Because your vehicle is equipped with anti-lock

brakes, it is essential that any dynamometer

testing is carried out only by a qualified person,

familiar with the dynamometer testing and

safety procedures practised by

Dealers/Authorised Repairers.

CAUTION

Ensure that you take notice of any

message centre information and

warnings relating to engi ne oil level (V8 petrol

and diesel engines only). Top-up the level

when advised to do so. See ENGINE OIL

CHECK - V8 Petrol engines (page 199).

Page 194 of 391

Maintenance

194

Safety in the garageFuel system

Poisonous fluids

Fluids used in motor vehicles are poisonous

and should not be consumed or brought into

contact with open wounds. These include;

battery acid, antifreeze, brake, clutch and

power steering fluid, petrol, diesel, engine oil

and windscreen washer additives.

For your own safety, always read and obey all

instructions printed on labels and containers.

Used engine oil

Prolonged contact with engine oil may cause

serious skin disorders, including dermatitis

and cancer of the skin. Always wash

thoroughly after contact.

It is illegal to pollute drains, water

courses or soil. Use authorised

waste disposal site s to dispose of

used oil and toxic chemicals.

WARNINGS

If the vehicle has been driven

recently, do not touch exhaust and

cooling system components until the

engine has cooled.

Never leave the engi ne running in an

unventilated area - exhaust gases are

poisonous and extremely dangerous.

Do not work beneath the vehicle with

the wheel changing jack as the only

means of support.

Keep your hands and clothing away

from drive belts, pulleys and fans.

Some fans may continue to operate

after the engi ne has stopped.

Remove metal wrist bands and

jewellery, before working in the

engine compartment.

Do not touch electrical leads or

components while the engine is

running, or with the starter switch

turned on.

Do not allow tools or metal parts of

the vehicle to make contact with the

battery leads or terminals.WARNINGS

Under no circumstances should any

part of the fuel system be dismantled

or replaced by anyone other than a

suitably qualified vehicle technician. Failure to

comply with this instruct ion, may result in fuel

spillage with a consequent serious risk of fire.

Ensure sparks and naked lights are

kept away from the engine

compartment.

Wear protective cl othing, including,

where practicable, gloves made from

an impervious material.

Page 196 of 391

Maintenance

196

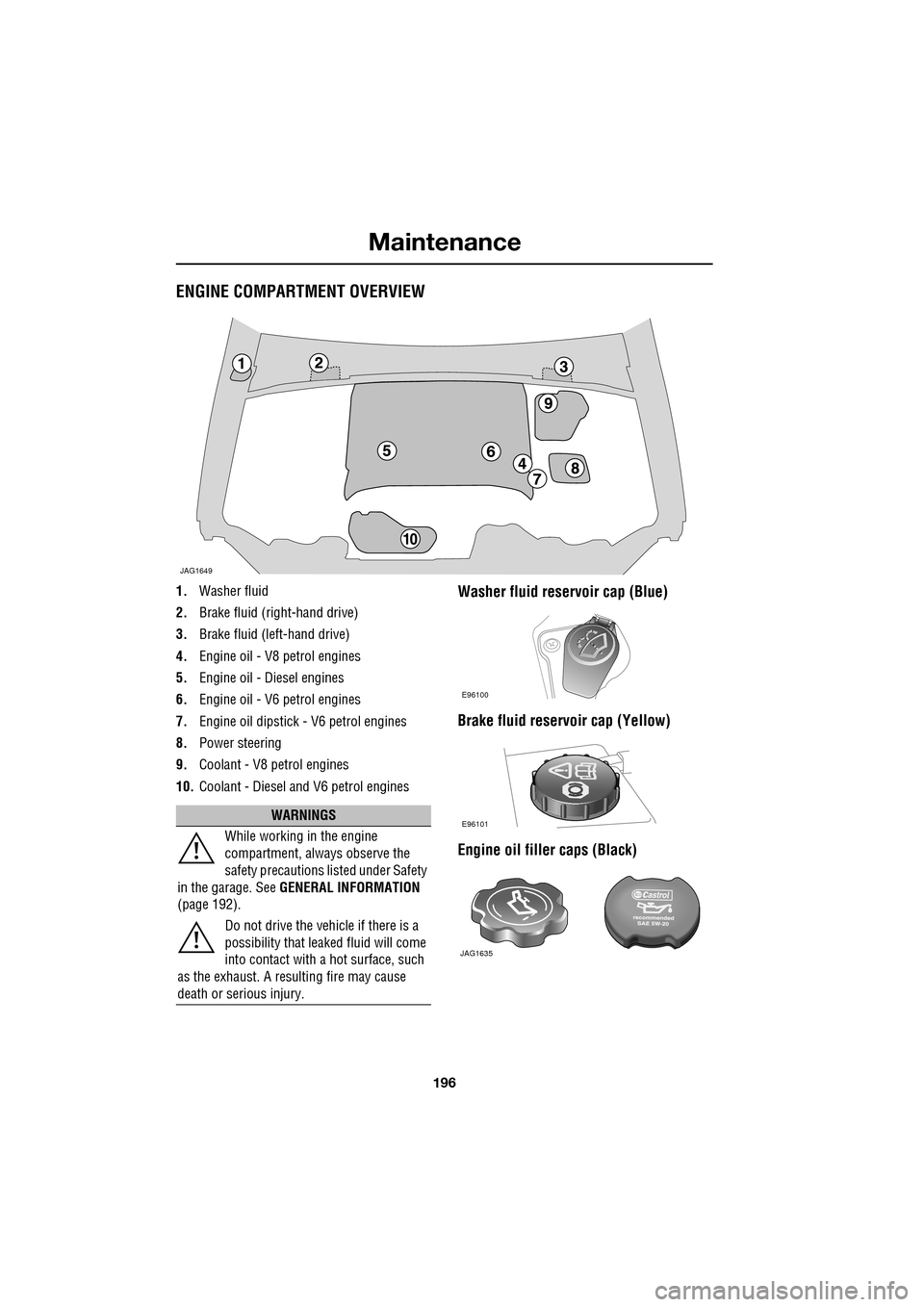

ENGINE COMPARTMENT OVERVIEW

1.Washer fluid

2. Brake fluid (right-hand drive)

3. Brake fluid (left-hand drive)

4. Engine oil - V8 petrol engines

5. Engine oil - Diesel engines

6. Engine oil - V6 petrol engines

7. Engine oil dipstick - V6 petrol engines

8. Power steering

9. Coolant - V8 petrol engines

10. Coolant - Diesel and V6 petrol enginesWasher fluid reservoir cap (Blue)

Brake fluid reservoir cap (Yellow)

Engine oil filler caps (Black)

JAG1649

WARNINGS

While working in the engine

compartment, always observe the

safety precautions listed under Safety

in the garage. See GENERAL INFORMATION

(page 192).

Do not drive the vehicle if there is a

possibility that leaked fluid will come

into contact with a hot surface, such

as the exhaust. A resulting fire may cause

death or serious injury.

E96100

E96101

JAG1635

Page 197 of 391

197

Maintenance

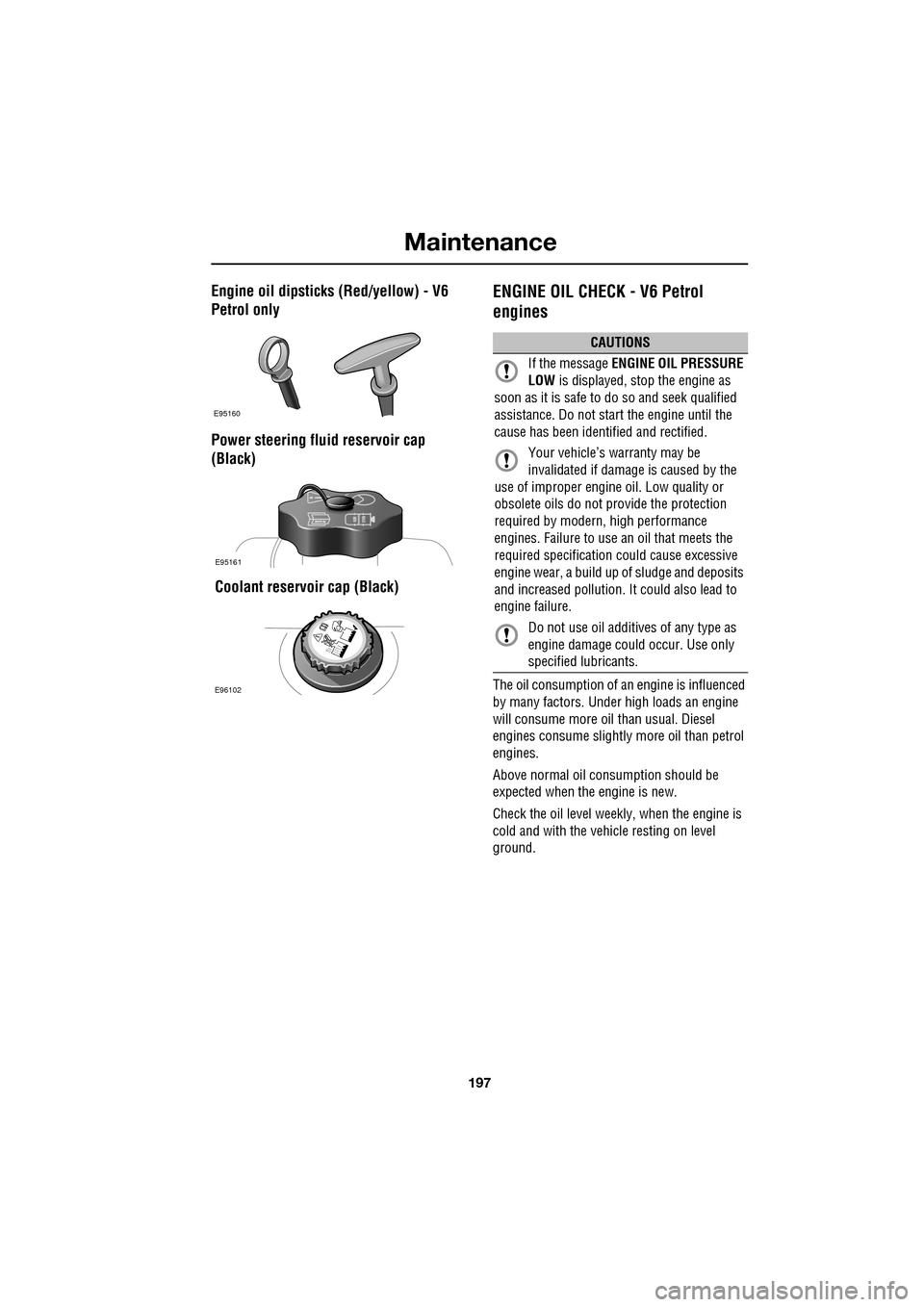

Engine oil dipsticks (Red/yellow) - V6

Petrol only

Power steering fluid reservoir cap

(Black)

Coolant reservoir cap (Black)ENGINE OIL CHECK - V6 Petrol

engines

The oil consumption of an engine is influenced

by many factors. Unde r high loads an engine

will consume more oil than usual. Diesel

engines consume slightly more oil than petrol

engines.

Above normal oil consumption should be

expected when the engine is new.

Check the oil level weekly , when the engine is

cold and with the vehicle resting on level

ground.

E95160

E95161

E96102

CAUTIONS

If the message ENGINE OIL PRESSURE

LOW is displayed, st op the engine as

soon as it is safe to do so and seek qualified

assistance. Do not start the engine until the

cause has been identified and rectified.

Your vehicle’s warranty may be

invalidated if damage is caused by the

use of improper engine oil. Low quality or

obsolete oils do not pr ovide the protection

required by modern, high performance

engines. Failure to use an oil that meets the

required specification could cause excessive

engine wear, a build up of sludge and deposits

and increased pollution. It could also lead to

engine failure.

Do not use oil additi ves of any type as

engine damage coul d occur. Use only

specified lubricants.

Page 208 of 391

Maintenance

208

POWER STEERING FLUID CHECK

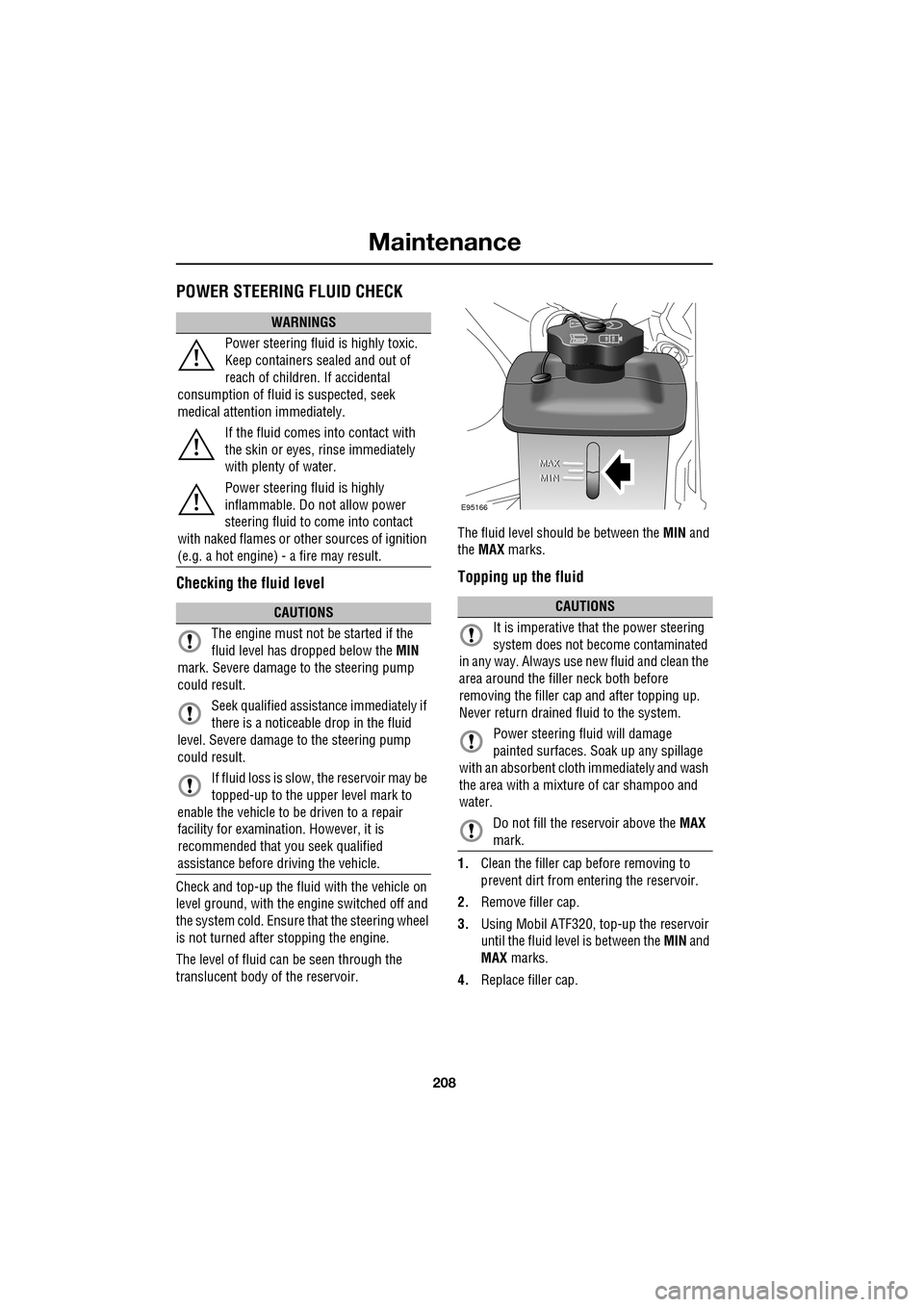

Checking the fluid level

Check and top-up the fluid with the vehicle on

level ground, with the e ngine switched off and

the system cold. Ensure that the steering wheel

is not turned after stopping the engine.

The level of fluid can be seen through the

translucent body of the reservoir. The fluid level shoul

d be between the MIN and

the MAX marks.

Topping up the fluid

1.Clean the filler cap before removing to

prevent dirt from entering the reservoir.

2. Remove filler cap.

3. Using Mobil ATF320, top-up the reservoir

until the fluid level is between the MIN and

MAX marks.

4. Replace filler cap.

WARNINGS

Power steering fluid is highly toxic.

Keep containers sealed and out of

reach of children. If accidental

consumption of fluid is suspected, seek

medical attenti on immediately.

If the fluid comes into contact with

the skin or eyes, rinse immediately

with plenty of water.

Power steering fluid is highly

inflammable. Do not allow power

steering fluid to come into contact

with naked flames or other sources of ignition

(e.g. a hot engine) - a fire may result.

CAUTIONS

The engine must not be started if the

fluid level has dropped below the MIN

mark. Severe damage to the steering pump

could result.

Seek qualified assistance immediately if

there is a noticeable drop in the fluid

level. Severe damage to the steering pump

could result.

If fluid loss is slow, the reservoir may be

topped-up to the upper level mark to

enable the vehicle to be driven to a repair

facility for examination. However, it is

recommended that you seek qualified

assistance before driving the vehicle.CAUTIONS

It is imperative that the power steering

system does not beco me contaminated

in any way. Always use new fluid and clean the

area around the filler neck both before

removing the filler ca p and after topping up.

Never return drained fluid to the system.

Power steering fluid will damage

painted surfaces. So ak up any spillage

with an absorbent cloth immediately and wash

the area with a mixture of car shampoo and

water.

Do not fill the reservoir above the MAX

mark.

E95166

Page 210 of 391

Maintenance

210

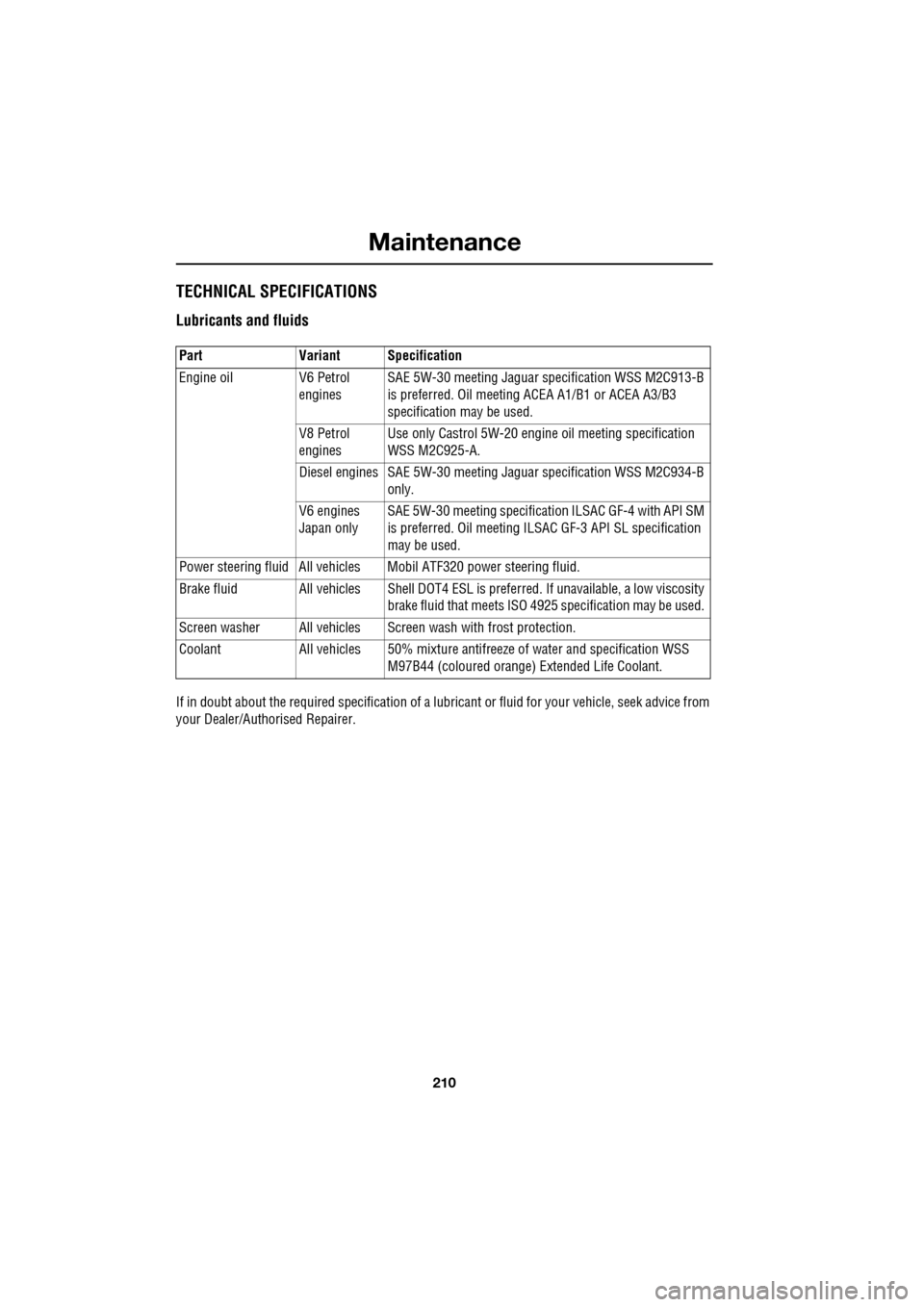

TECHNICAL SPECIFICATIONS

Lubricants and fluids

If in doubt about the required specification of a lubricant or fluid for your vehicle, seek advice from

your Dealer/Authorised Repairer. Part Variant Specification

Engine oil V6 Petrol

enginesSAE 5W-30 meeting Jaguar specification WSS M2C913-B

is preferred. Oil meeting

ACEA A1/B1 or ACEA A3/B3

specification may be used.

V8 Petrol

engines Use only Castrol 5W-20 engine

oil meeting specification

WSS M2C925-A.

Diesel engines SAE 5W-30 meeting Jaguar specification WSS M2C934-B

only.

V6 engines

Japan only SAE 5W-30 meeting specification ILSAC GF-4 with API SM

is preferred. Oil meeting ILSA

C GF-3 API SL specification

may be used.

Power steering fluid All vehicles M obil ATF320 power steering fluid.

Brake fluid All vehicles Shell DOT4 ESL is pr eferred. If unavailable, a low viscosity

brake fluid that meets ISO 4925 specification may be used.

Screen washer All vehicles Screen wash with frost protection.

Coolant All vehicles 50% mixture antifreeze of water and specification WSS M97B44 (coloured orange) Extended Life Coolant.

Page 213 of 391

213

Vehicle battery

Your vehicle is fitted with a low maintenance

battery, which is located under the floor of the

luggage compartment.

In hot climates more frequent checks of the

battery electrolyte level and condition are

required. If necessary, the battery cells can be

topped up using di stilled water.

When the ignition is switched on, but without

the engine running, BATTERY NOT CHARGING

is displayed in the mess age centre. The battery

will only charge when the engine is running.

Note: Do not connect any 12 volt equipment

(e.g. a 12 volt inspection lamp), directly to the

battery terminals. Use the accessory socket

located in the cubby box, for connecting Jaguar

approved accessories.

Battery Monitoring System (BMS)

Your vehicle is equipped with a Battery

Monitoring System (BMS) which manages the

battery charging system and, if excessive

battery discharge is o ccurring when the engine

isn't running, shuts down non-essential

electrical systems to protect battery power.

In the event that too many electrical systems

are operational when the engine is not running,

and the battery charge is insufficient, the audio

and entertainment systems (if active) and

climate control system will be switched off.

This will be confirmed by a low battery warning

message displayed on the touch-screen. If this

occurs, switch on and run the engine for at

least five minutes, preferably with all auxiliary

electrical systems switched off (e.g. lights,

wipers, climate control, seat heaters etc.).

Note: The audio system can be operated

during this five minute period when the engine

is running.

If the engine is switched off before the five

minute period ends and the audio system is

switched on, the warning message will

re-appear on the touch-sc reen and the audio,

entertainment and climate control systems will

switch off again. For this reason, it is important

that the engine is left running for the full five

minute period.

Charging faults

If there is a fault in the battery charging system,

CHARGING FAULT is displayed with red

backlighting in the mess age centre. If this

occurs, switch off all non-essential electrical

systems and seek qualified assistance at the

earliest opportunity.

CAUTION

Do not allow battery electrolyte to come

into contact with fabrics or painted

surfaces. If battery electrolyte comes into

contact with any surfac e, the surface should

be washed down immedi ately with copious

amounts of clean water. Battery electrolyte is

both corrosive and toxic, and can damage a

wide range of materials if left.

Page 231 of 391

231

Wheels and tyres

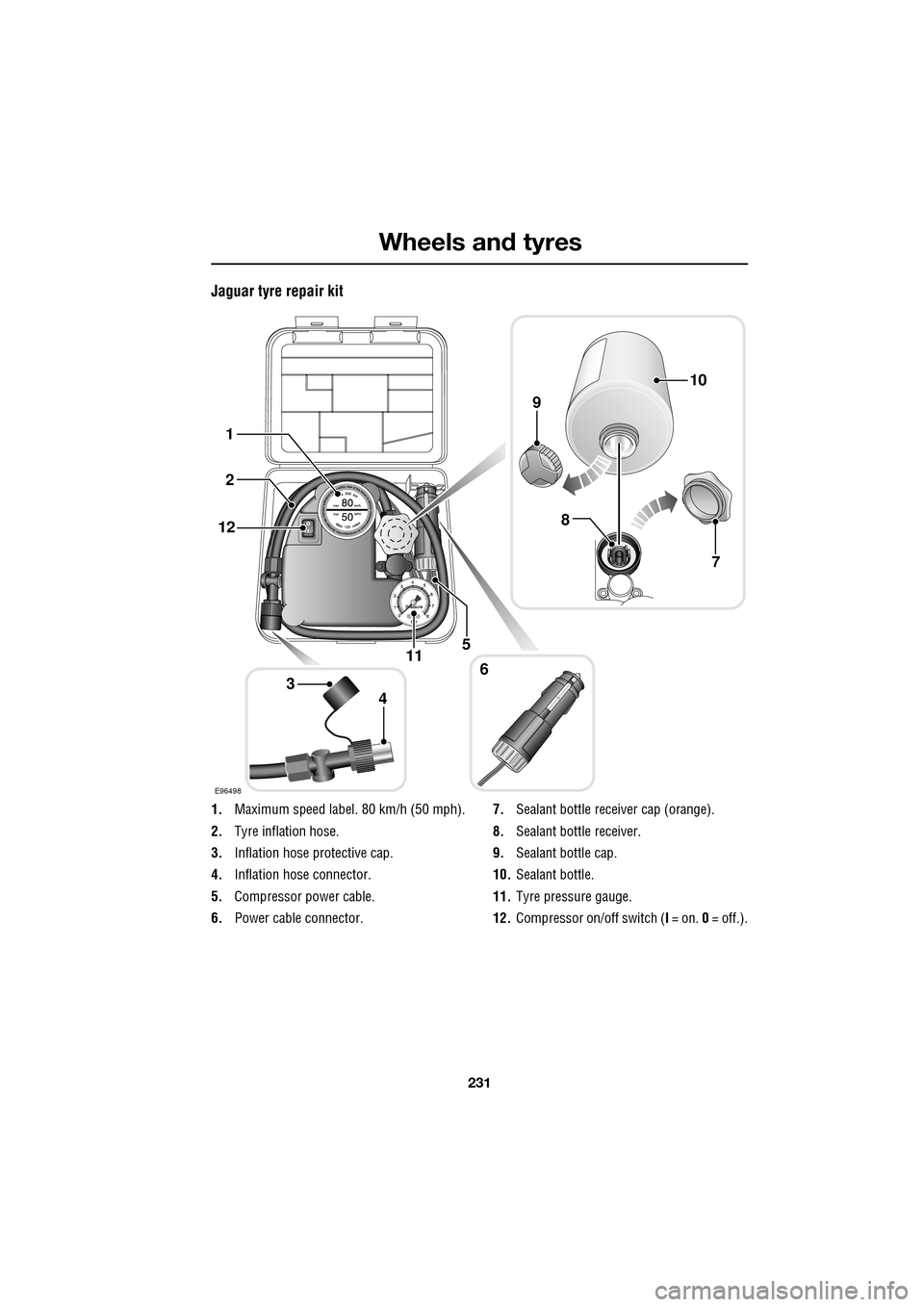

Jaguar tyre repair kit

1.Maximum speed label. 80 km/h (50 mph).

2. Tyre inflation hose.

3. Inflation hose protective cap.

4. Inflation hose connector.

5. Compressor power cable.

6. Power cable connector. 7.

Sealant bottle receiver cap (orange).

8. Sealant bottle receiver.

9. Sealant bottle cap.

10. Sealant bottle.

11. Tyre pressure gauge.

12. Compressor on/off switch ( I = on. 0 = off.).

E96498

34

2

6

5

1

12

11

8

9

10

7

Page 232 of 391

Wheels and tyres

232

Using the Jaguar tyre repair kit

Note: All vehicle drivers and occupants should

be made aware that a temporary repair has

been made to a tyre fitted to the vehicle. They

should also be made aware of the special

driving conditions im posed when using a

repaired tyre.

Repair procedure

1. Open the tyre repair kit and peel off the

maximum speed label. Attach the label to

the fascia in the driver's field of vision.

Take care not to obstruct any of the

instruments or warning lights.

2. Uncoil the compressor power cable and

the inflation hose.

3. Unscrew the orange cap from the sealant

bottle receiver and the sealant bottle cap.

4. Screw the sealant bottle into the receiver

(clockwise) until tight.

•Screwing the bottle onto the receiver will

pierce the bottle's se al. Do not unscrew

a full, or partly us ed bottle from the

receiver. Doing so will result in sealant

leaking from the bottle.

5. Remove the valve cap from the damaged

tyre.

6. Remove the protective cap from the

inflation hose and connect the inflation

hose to the tyre valve. Ensure that the hose

is screwed on firmly.

7. Ensure that the compressor switch is in

the off (0) position.

8. Insert the power cable connector into the

auxiliary power socket. See AUXILIARY

POWER SOCKETS (page 125).

WARNINGS

Avoid skin contact with the sealant

which contains natu ral rubber latex.

If the tyre inflati on pressure does not

reach 1.8 bar (26 lbf/in², 180 kPa)

within seven minutes, the tyre may

have suffered excessive damage. A temporary

repair will not be poss ible, and the vehicle

should not be driven until the tyre has been

replaced.

CAUTIONS

Before attempting a ty re repair, ensure

that the vehicle is parked safely, as far

away from passing traffic as possible.

Ensure that the parki ng brake is applied

and P (Park) is selected.

Do not attempt to remove foreign

objects such as nails, screws, etc. from

the tyre.

Always run the engine when using the

compressor, unless the vehicle is in an

enclosed or poorly ventil ated space, as this

may cause asphyxiation.

To prevent overheating, do not operate

the compressor continuously for longer

than ten minutes.

WARNING

Check the tyre sidewall prior to

inflation. If there are any cracks,

bumps or similar damage, do not

attempt to inflate the tyre. Do not stand

directly beside the tyre while the compressor

is pumping. Watch the ty re sidewall. If any

cracks, bumps or simila r damage appear, turn

off the compressor and let the air out by

means of the pressure relief valve. Do not

continue to use the tyre.

Page 233 of 391

233

Wheels and tyres

9.Unless the vehicle is in an enclosed area,

start the engine.

10. Set the compressor switch to the on ( I)

position.

11. Inflate the tyre to a minimum of 1.9 bar

(26 lbf/in²) and a maximum of 3.5 bar

(51 lbf/in²).

•When pumping the sealant through the

tyre valve, the pressure may rise up to 6

bar (87 lbf/in²). The pressure will drop

again after approximately 30 seconds.

12. During the inflation, switch the

compressor off briefly, to check the tyre

pressure using the gauge mounted on the

compressor.

• It should not take longer than seven

minutes to inflate the tyre. If, after seven

minutes, the tyre has not yet reached

minimum pressure, the tyre should not

be used.

13. Once the tyre has been inflated, switch off

the compressor. If desired, the engine may

be turned off after the compressor has

been turned off.

14. Remove the power connector from the

auxiliary power socket.

15. Remove the inflation hose from the tyre

valve, by unscrewing it as quickly as

possible (count er-clockwise).

16. Replace the inflation hose protective cap

and the tyre valve cap.

17. Do not remove the sealant bottle from the

receiver.

18. Ensure that the tyre repair kit (including

the bottle and receiver caps) are placed

securely in the vehicle. You will need to

use the kit to check the tyre pressure after

approximately 3 km (2 miles), so ensure

they are easily accessible. 19.

Immediately drive the vehicle for

approximately 3 km (2 miles), to allow the

sealant to coat the inner surface of the tyre

and form a seal at the puncture.

Checking the tyre pressure after a repair

1.Drive the vehicle for 3 km (2 miles) then

stop in a safe place. Carry out a visual

examination of the tyres condition.

2. Make sure that the sealant container

section is in its original position.

3. Screw the inflation hos e connector firmly

onto the tyre valve.

4. Read the tyre pressure from the gauge.

5. If the pressure of the sealant filled tyre is

above 1.3 bar (19 lb/in²) adjust the

pressure to the correct value. See TYRE

CARE (page 217).

6. Ensure that the compressor switch is in

the off (O ) position and insert the power

cable connector into the auxiliary power

socket.

If the vehicle is in a well ventilated area,

start the engine.

WARNINGS

When driving the vehicle, if you

experience vibr ations, abnormal

steering, or noises, reduce speed

immediately. Drive with extreme caution and

reduced speed, to the first safe place to stop

the vehicle. Visually examine the tyre and

check its pressure. If there are any signs of

damage or deformity to the tyre, or the tyre

pressure is below 1.3 bar (19 lb/in²), do not

continue driving.

Consult a tyre repair centre or your

Dealer/Authorised Repairer, for

advice concerning the replacement of

a tyre after using a tyre repair kit.