engine oil JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1361 of 3039

DIAGNOSTICS

The ECM stores each fault as a DTC (diagnostic trouble code). The DTC and associated environmental and freeze frame data can be read using Jaguar approved diagnostic equipment, which can also read real time data from each sensor, the adaption

values currently being employed and the current fueling, ignition and idle speed settings.

ENGINE CONTROL MODULE Component Description

The ECM is installed in the front passenger side of the engine compartment, on a bracket attached to the engine bulkhead. The ECM has the capability of adapting its fuel and ignition control outputs in response to several sensor inputs. The ECM receives inputs from the following:

CKP sensor. CMP (camshaft position) sensors (4 off).

ECT (engine coolant temperature) sensor.

Knock sensors (4 off).

MAP (manifold absolute pressure) sensor.

MAFT sensors (2 off). MAPT (manifold absolute pressure and temperature) sensor.

Throttle position sensor.

Heated oxygen sensors (4 off).

APP sensor. Ambient air temperature sensor.

FRP (fuel rail pressure) sensor. For additional information, refer to 303-04G Fuel Charging and Controls.

Engine cooling fan. For additional information, refer to 303-03D Engine Cooling.

Stoplamp switch. For additional information, refer to 206-09 Anti-Lock Control - Stability Assist.

Speed control cancel/suspend switch. For additional information, refer to 310-03D Speed Control.

Oil level and temperature sensor. For additional information, refer to 303-01F Engine.

Fuel LP (low pressure) sensor. For additional information, refer to 310-01D Fuel Tank and Lines.

Fuel pump driver module. For additional information, refer to 310-01D Fuel Tank and Lines.

The ECM provides outputs to the following: Electronic throttle.

Main relay.

Heater elements of the heated oxygen sensors (4 off).

Fuel injectors (8 off). For additional information, refer to 303-04G Fuel Charging and Controls. www.JagDocs.com

Page 1369 of 3039

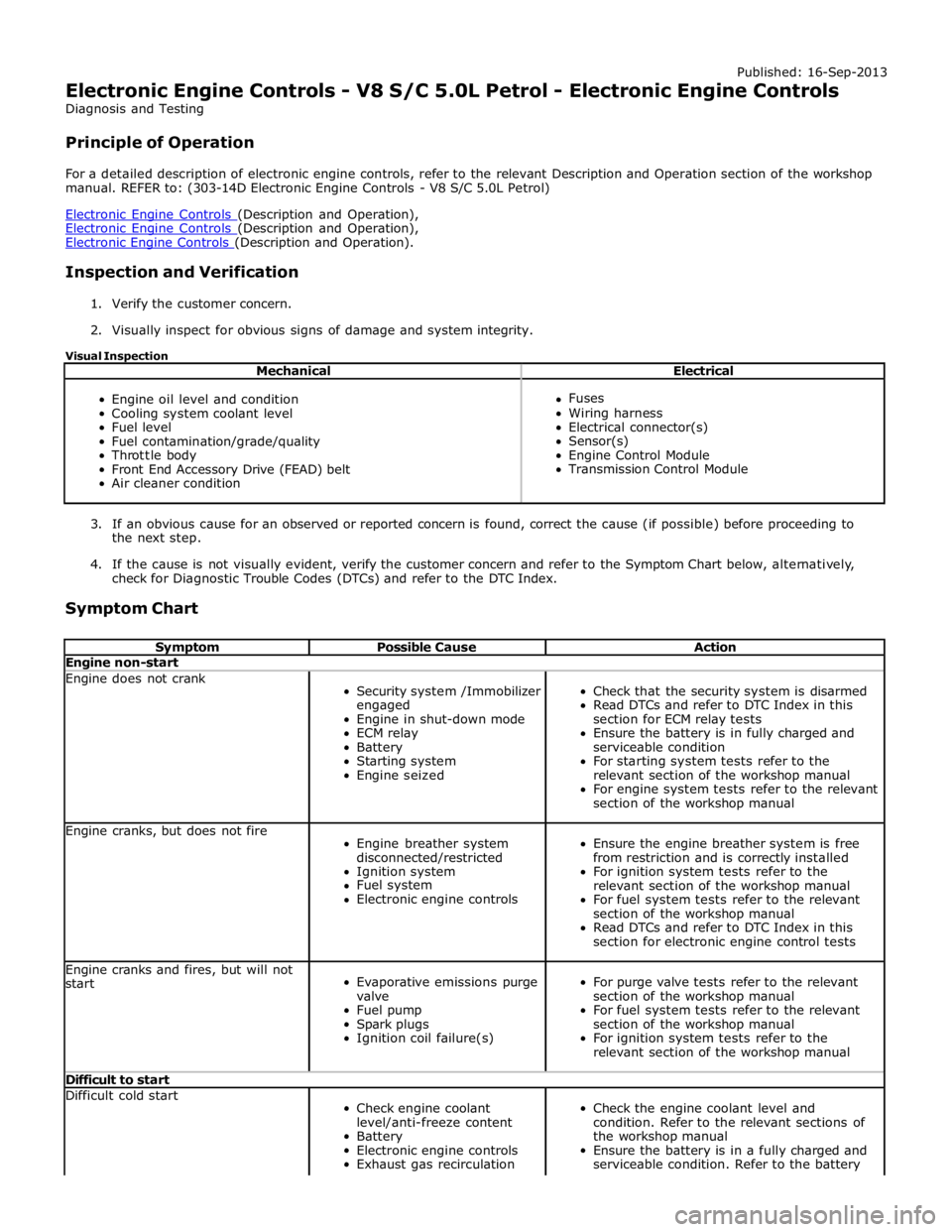

Published: 16-Sep-2013

Electronic Engine Controls - V8 S/C 5.0L Petrol - Electronic Engine Controls

Diagnosis and Testing

Principle of Operation

For a detailed description of electronic engine controls, refer to the relevant Description and Operation section of the workshop

manual. REFER to: (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol)

Electronic Engine Controls (Description and Operation), Electronic Engine Controls (Description and Operation), Electronic Engine Controls (Description and Operation).

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Engine oil level and condition

Cooling system coolant level

Fuel level

Fuel contamination/grade/quality

Throttle body

Front End Accessory Drive (FEAD) belt

Air cleaner condition

Fuses

Wiring harness

Electrical connector(s)

Sensor(s)

Engine Control Module

Transmission Control Module

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the customer concern and refer to the Symptom Chart below, alternatively,

check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Symptom Possible Cause Action Engine non-start Engine does not crank

Security system /Immobilizer

engaged

Engine in shut-down mode

ECM relay

Battery

Starting system

Engine seized

Check that the security system is disarmed

Read DTCs and refer to DTC Index in this

section for ECM relay tests

Ensure the battery is in fully charged and

serviceable condition

For starting system tests refer to the

relevant section of the workshop manual

For engine system tests refer to the relevant

section of the workshop manual Engine cranks, but does not fire

Engine breather system

disconnected/restricted

Ignition system

Fuel system

Electronic engine controls

Ensure the engine breather system is free

from restriction and is correctly installed

For ignition system tests refer to the

relevant section of the workshop manual

For fuel system tests refer to the relevant

section of the workshop manual

Read DTCs and refer to DTC Index in this

section for electronic engine control tests Engine cranks and fires, but will not

start

Evaporative emissions purge

valve

Fuel pump

Spark plugs

Ignition coil failure(s)

For purge valve tests refer to the relevant

section of the workshop manual

For fuel system tests refer to the relevant

section of the workshop manual

For ignition system tests refer to the

relevant section of the workshop manual Difficult to start Difficult cold start

Check engine coolant

level/anti-freeze content

Battery

Electronic engine controls

Exhaust gas recirculation

Check the engine coolant level and

condition. Refer to the relevant sections of

the workshop manual

Ensure the battery is in a fully charged and

serviceable condition. Refer to the battery

Page 1373 of 3039

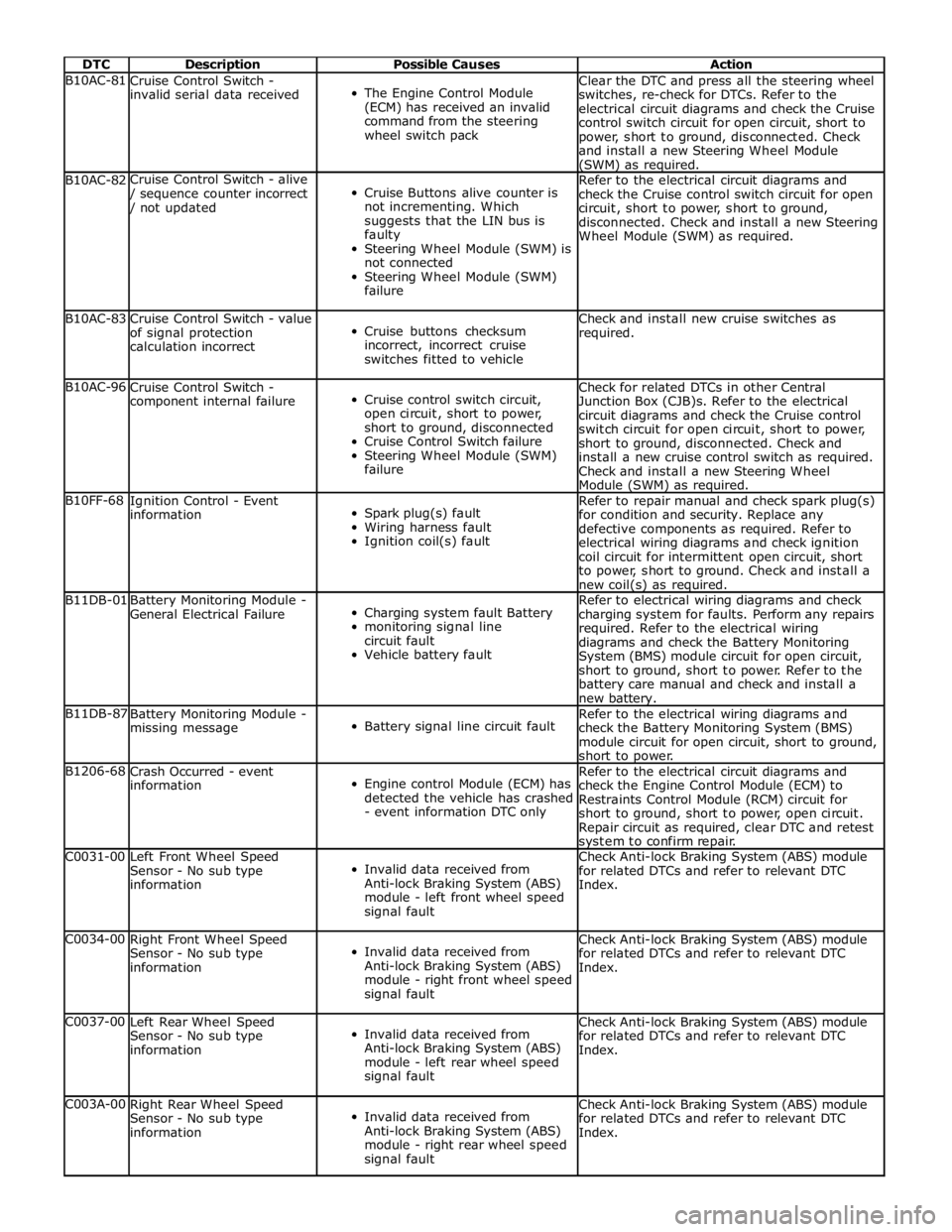

DTC Description Possible Causes Action B10AC-81

Cruise Control Switch -

invalid serial data received

The Engine Control Module

(ECM) has received an invalid

command from the steering

wheel switch pack Clear the DTC and press all the steering wheel

switches, re-check for DTCs. Refer to the

electrical circuit diagrams and check the Cruise

control switch circuit for open circuit, short to

power, short to ground, disconnected. Check

and install a new Steering Wheel Module (SWM) as required. B10AC-82 Cruise Control Switch - alive / sequence counter incorrect / not updated

Cruise Buttons alive counter is

not incrementing. Which

suggests that the LIN bus is

faulty

Steering Wheel Module (SWM) is

not connected

Steering Wheel Module (SWM)

failure Refer to the electrical circuit diagrams and

check the Cruise control switch circuit for open

circuit, short to power, short to ground,

disconnected. Check and install a new Steering

Wheel Module (SWM) as required. B10AC-83

Cruise Control Switch - value

of signal protection

calculation incorrect

Cruise buttons checksum

incorrect, incorrect cruise

switches fitted to vehicle Check and install new cruise switches as

required. B10AC-96

Cruise Control Switch -

component internal failure

Cruise control switch circuit,

open circuit, short to power,

short to ground, disconnected

Cruise Control Switch failure

Steering Wheel Module (SWM)

failure Check for related DTCs in other Central

Junction Box (CJB)s. Refer to the electrical

circuit diagrams and check the Cruise control

switch circuit for open circuit, short to power,

short to ground, disconnected. Check and

install a new cruise control switch as required.

Check and install a new Steering Wheel

Module (SWM) as required. B10FF-68

Ignition Control - Event

information

Spark plug(s) fault

Wiring harness fault

Ignition coil(s) fault Refer to repair manual and check spark plug(s)

for condition and security. Replace any

defective components as required. Refer to

electrical wiring diagrams and check ignition

coil circuit for intermittent open circuit, short

to power, short to ground. Check and install a

new coil(s) as required. B11DB-01

Battery Monitoring Module -

General Electrical Failure

Charging system fault Battery

monitoring signal line

circuit fault

Vehicle battery fault Refer to electrical wiring diagrams and check

charging system for faults. Perform any repairs

required. Refer to the electrical wiring

diagrams and check the Battery Monitoring

System (BMS) module circuit for open circuit,

short to ground, short to power. Refer to the

battery care manual and check and install a

new battery. B11DB-87

Battery Monitoring Module -

missing message

Battery signal line circuit fault Refer to the electrical wiring diagrams and

check the Battery Monitoring System (BMS)

module circuit for open circuit, short to ground,

short to power. B1206-68

Crash Occurred - event

information

Engine control Module (ECM) has

detected the vehicle has crashed

- event information DTC only Refer to the electrical circuit diagrams and

check the Engine Control Module (ECM) to

Restraints Control Module (RCM) circuit for

short to ground, short to power, open circuit.

Repair circuit as required, clear DTC and retest

system to confirm repair. C0031-00

Left Front Wheel Speed

Sensor - No sub type

information

Invalid data received from

Anti-lock Braking System (ABS)

module - left front wheel speed

signal fault Check Anti-lock Braking System (ABS) module

for related DTCs and refer to relevant DTC

Index. C0034-00

Right Front Wheel Speed

Sensor - No sub type

information

Invalid data received from

Anti-lock Braking System (ABS)

module - right front wheel speed

signal fault Check Anti-lock Braking System (ABS) module

for related DTCs and refer to relevant DTC

Index. C0037-00

Left Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from

Anti-lock Braking System (ABS)

module - left rear wheel speed

signal fault Check Anti-lock Braking System (ABS) module

for related DTCs and refer to relevant DTC

Index. C003A-00

Right Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from

Anti-lock Braking System (ABS)

module - right rear wheel speed

signal fault Check Anti-lock Braking System (ABS) module

for related DTCs and refer to relevant DTC

Index.

Page 1376 of 3039

Published: 11-May-2011

Electronic Engine Controls - V8 S/C 5.0L Petrol - Camshaft Position (CMP)

Sensor LH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Disconnect the battery ground cable.

Refer to: Specifications (414-00 Charging System - General Information,

Specifications).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Refer to: Thermostat Housing - 5.0L SC V8 - AJ133 (303-03 Engine

Cooling - 5.0L NA V8 - AJ133/5.0L SC V8 - AJ133, Removal and

Installation).

Installation

4. NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

Torque: 10 Nm

1. CAUTIONS:

Make sure that the mating faces are clean and free of foreign

material.

Make sure that the sensor tip is clean and free of foreign material.

NOTE: Lubricate the O-ring seal with clean engine oil.

To install, reverse the removal procedure. www.JagDocs.com

Page 1377 of 3039

Published: 11-May-2011

Electronic Engine Controls - V8 S/C 5.0L Petrol - Camshaft Position (CMP)

Sensor RH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Disconnect the battery ground cable.

Refer to: Specifications (414-00 Charging System - General Information,

Specifications).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Refer to: Thermostat Housing - 5.0L SC V8 - AJ133 (303-03 Engine

Cooling - 5.0L NA V8 - AJ133/5.0L SC V8 - AJ133, Removal and

Installation).

Installation

4. NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

Torque: 10 Nm

1. CAUTIONS:

Make sure that the mating faces are clean and free of foreign

material.

Make sure that the sensor tip is clean and free of foreign material.

NOTE: Lubricate the O-ring seal with clean engine oil.

To install, reverse the removal procedure.

Page 1389 of 3039

Published: 11-May-2011

Electronic Engine Controls - V8 S/C 5.0L Petrol - Engine Oil Level Sensor

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Refer to: Air Deflector (501-02 Front End Body Panels, Removal and Installation).

3. Refer to: Engine Oil Draining and Filling (303-01D Engine - V8 S/C 5.0L Petrol, General Procedures).

Installation

4. CAUTION: Be prepared to collect escaping fluids.

Torque: 11 Nm

1. CAUTION: A new O-ring seal is to be installed.

To install, reverse the removal procedure.

Page 1404 of 3039

Published: 11-May-2011

Electronic Engine Controls - V8 S/C 5.0L Petrol - Variable Valve Timing (VVT)

Oil Control Solenoid LH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Disconnect the battery ground cable.

Refer to: Specifications (414-00, Specifications).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Refer to: Thermostat Housing - Vehicles With: Supercharger (303-03,

Removal and Installation).

4. NOTE: Some variation in the illustrations may occur, but

the essential information is always correct.

Torque: 10 Nm

5. CAUTION: Evenly and progressively, remove the VVT

units from each side.

NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

Page 1405 of 3039

Installation

1. CAUTION: Make sure that the mating faces are clean and free of

foreign material.

NOTE: Lubricate the O-ring seal with clean engine oil.

To install, reverse the removal procedure.

2. NOTE: For NAS vehicles only.

If required, carry out a short drive cycle.

Refer to: Powertrain Control Module (PCM) Short Drive Cycle Self-Test (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, General

Procedures).

Page 1406 of 3039

Published: 11-May-2011

Electronic Engine Controls - V8 S/C 5.0L Petrol - Variable Valve Timing (VVT)

Oil Control Solenoid RH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Disconnect the battery ground cable.

Refer to: Specifications (414-00, Specifications).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Refer to: Thermostat Housing - Vehicles With: Supercharger (303-03,

Removal and Installation).

4. NOTE: Some variation in the illustrations may occur, but

the essential information is always correct.

5. NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

Torque: 10 Nm www.JagDocs.com

Page 1407 of 3039

Installation 6. CAUTION: Evenly and progressively, remove the VVT

units from each side.

NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

1. CAUTION: Make sure that the mating faces are clean and free of

foreign material.

NOTE: Lubricate the O-ring seal with clean engine oil.

To install, reverse the removal procedure.

2. NOTE: For NAS vehicles only.

If required, carry out a short drive cycle.

Refer to: Powertrain Control Module (PCM) Short Drive Cycle Self-Test (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, General

Procedures).