Timing JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 861 of 3039

16 Bias spring 17 Snap ring 18 Reluctor ring 19 Center plate 20 Snap ring 21 Screw (6 off) 22 Spool valve 23 Outer plate Each VCT unit is attached to the camshaft by three bolts. A rotor assembly and a reed plate are installed inside a sprocket housing, which consists of a sprocket, an outer plate and an inner plate held together by six screws.

A reluctor ring, for the CMP (camshaft position) sensor, a center plate and a bias spring are installed at the front of the VCT unit. The ends of the bias spring locate on the center plate assembly and the sprocket housing, to give a turning moment to

the camshaft in the advance direction. A snap ring locates the reluctor ring on to a sleeve installed in the center of the rotor

assembly. The opposite end of the sleeve locates in a bore in the front face of the camshaft, which contains a filter.

A spring and spool valve are installed in the rotor assembly sleeve and retained by a snap ring. The spring keeps the spool

valve in contact with the armature of the related VCT solenoid.

Each VCT unit is supplied with engine oil from an oil gallery in the cylinder head, through the camshaft front bearing cap and a bore in the center of the camshaft.

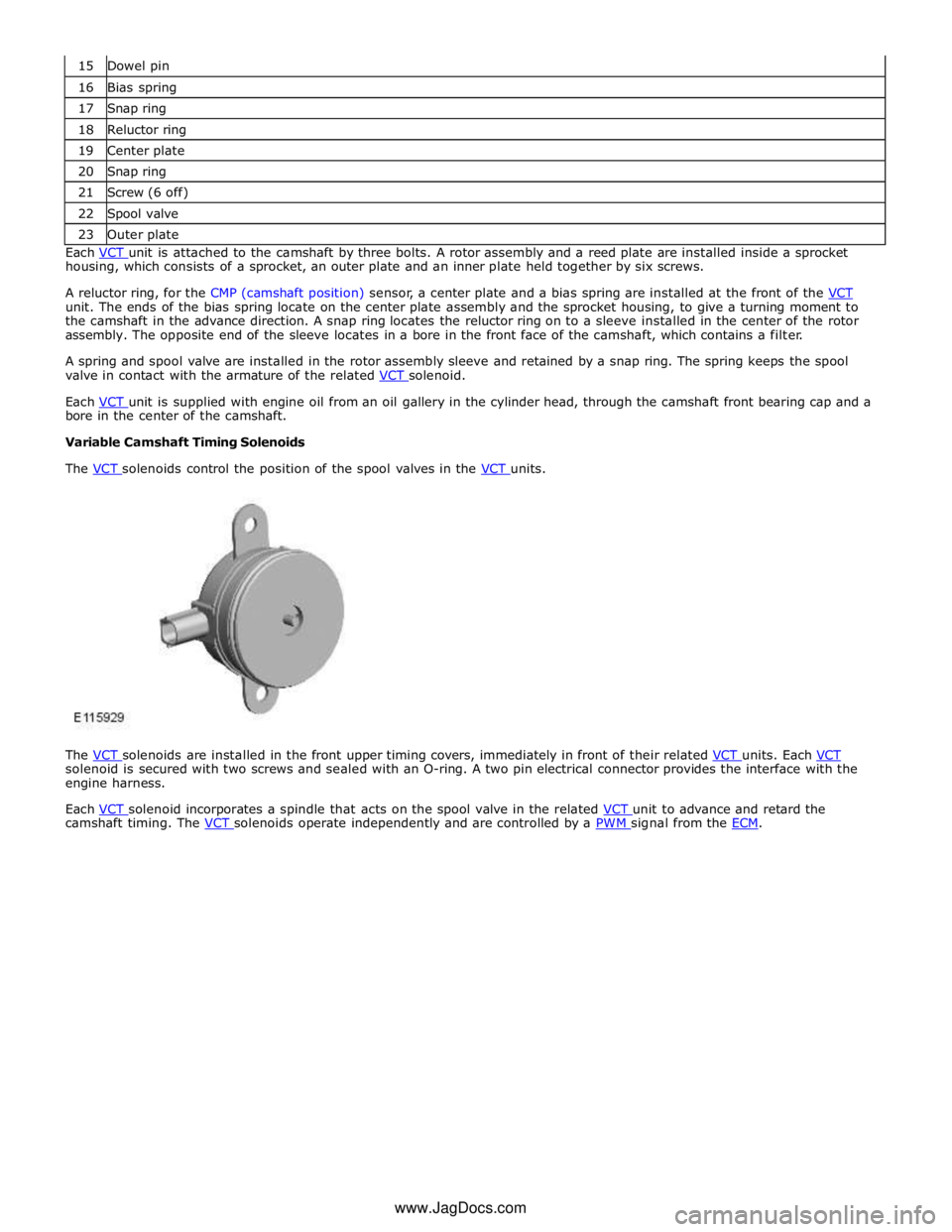

Variable Camshaft Timing Solenoids

The VCT solenoids control the position of the spool valves in the VCT units.

The VCT solenoids are installed in the front upper timing covers, immediately in front of their related VCT units. Each VCT solenoid is secured with two screws and sealed with an O-ring. A two pin electrical connector provides the interface with the

engine harness.

Each VCT solenoid incorporates a spindle that acts on the spool valve in the related VCT unit to advance and retard the camshaft timing. The VCT solenoids operate independently and are controlled by a PWM signal from the ECM. www.JagDocs.com

Page 862 of 3039

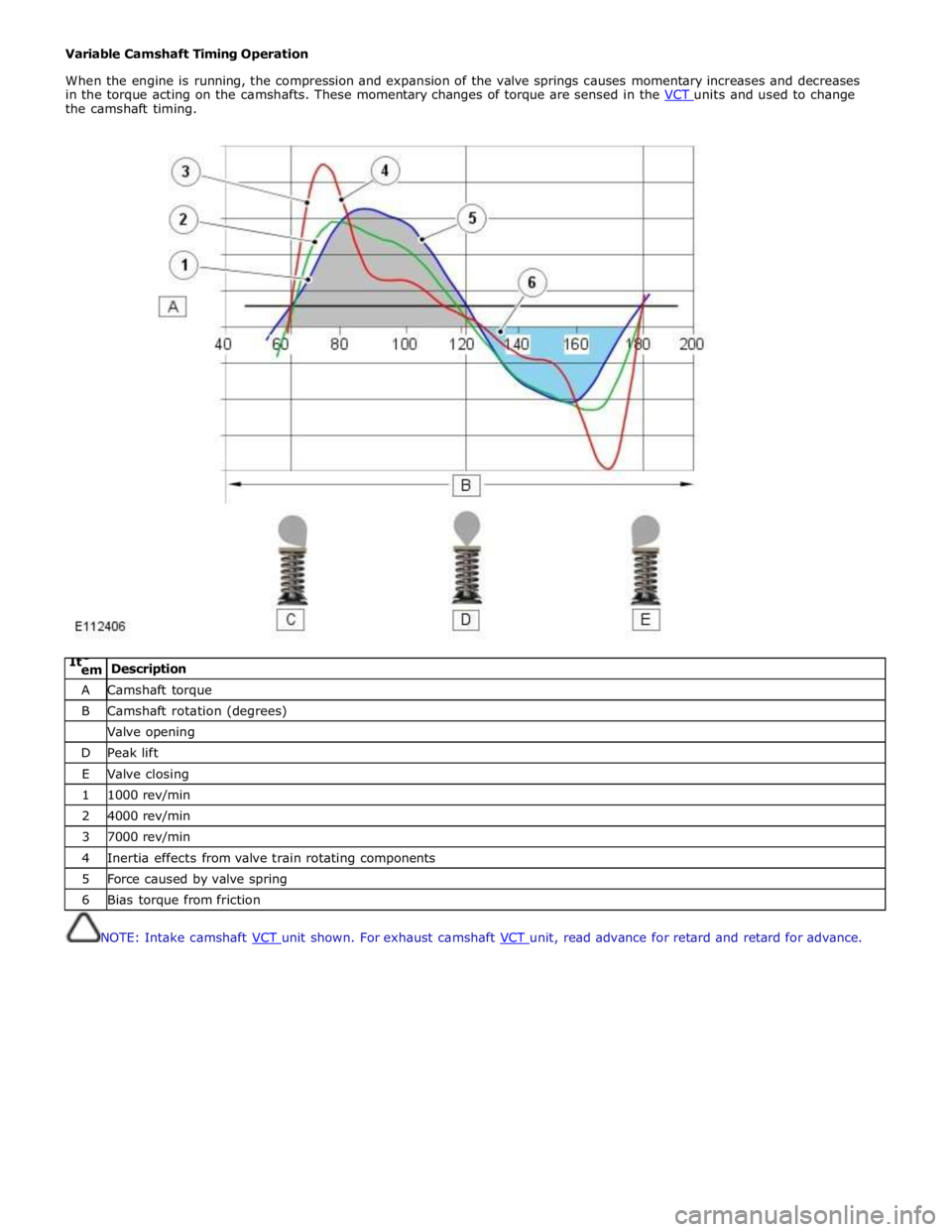

Variable Camshaft Timing Operation

When the engine is running, the compression and expansion of the valve springs causes momentary increases and decreases

in the torque acting on the camshafts. These momentary changes of torque are sensed in the VCT units and used to change the camshaft timing.

ItC

em Description A Camshaft torque B Camshaft rotation (degrees) Valve opening D Peak lift E Valve closing 1 1000 rev/min 2 4000 rev/min 3 7000 rev/min 4 Inertia effects from valve train rotating components 5 Force caused by valve spring 6 Bias torque from friction

NOTE: Intake camshaft VCT unit shown. For exhaust camshaft VCT unit, read advance for retard and retard for advance.

Page 864 of 3039

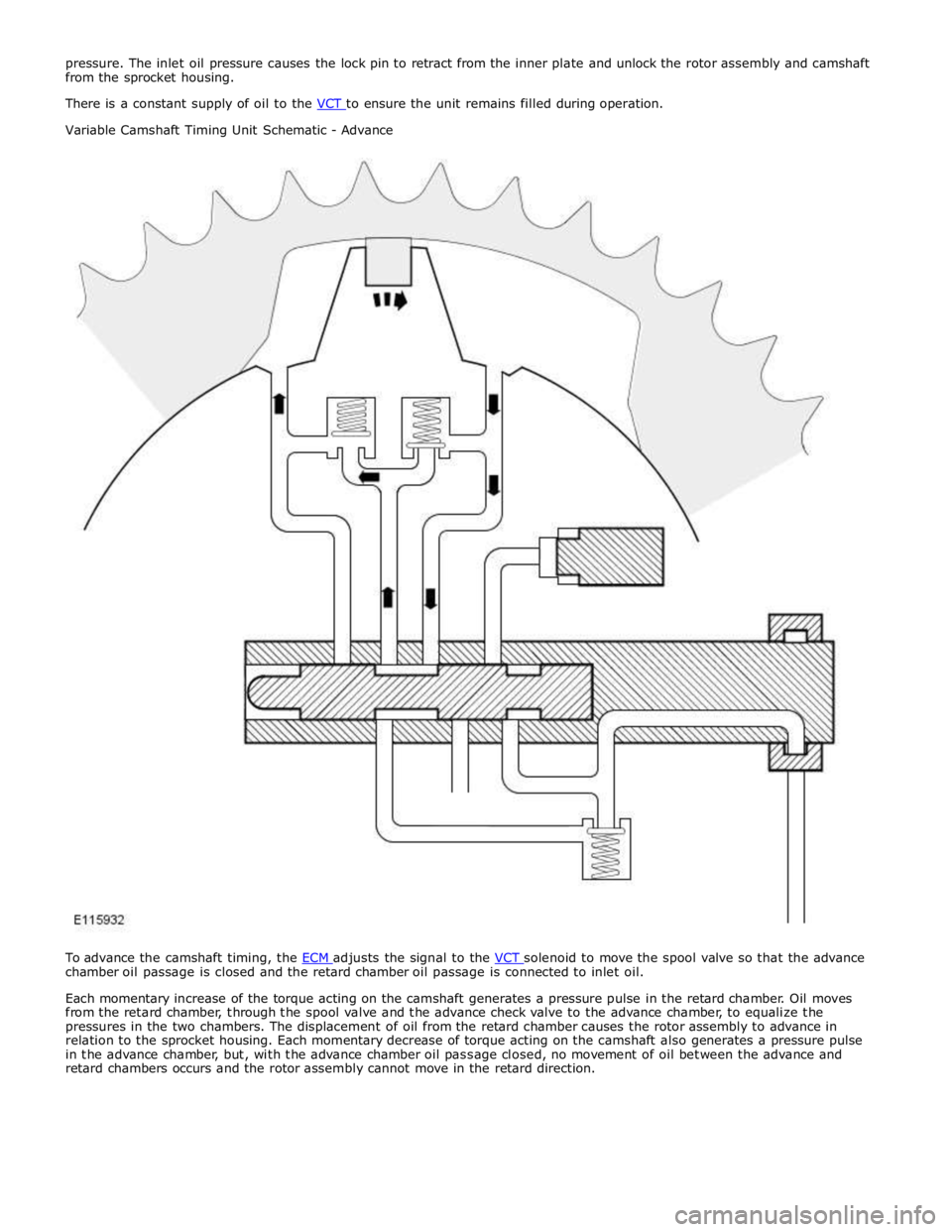

Variable Camshaft Timing Unit Schematic - Advance

To advance the camshaft timing, the ECM adjusts the signal to the VCT solenoid to move the spool valve so that the advance chamber oil passage is closed and the retard chamber oil passage is connected to inlet oil.

Each momentary increase of the torque acting on the camshaft generates a pressure pulse in the retard chamber. Oil moves

from the retard chamber, through the spool valve and the advance check valve to the advance chamber, to equalize the

pressures in the two chambers. The displacement of oil from the retard chamber causes the rotor assembly to advance in

relation to the sprocket housing. Each momentary decrease of torque acting on the camshaft also generates a pressure pulse

in the advance chamber, but, with the advance chamber oil passage closed, no movement of oil between the advance and

retard chambers occurs and the rotor assembly cannot move in the retard direction.

Page 865 of 3039

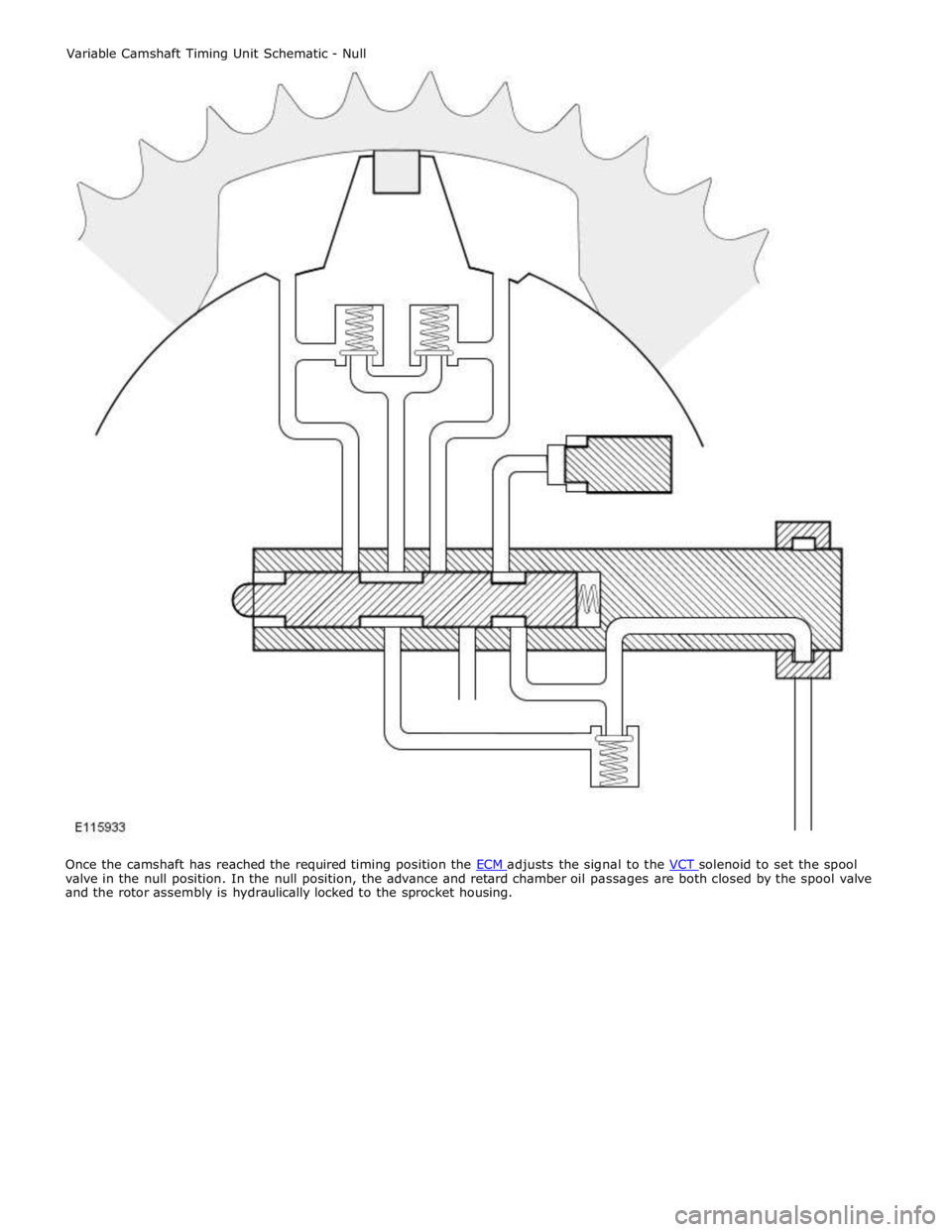

valve in the null position. In the null position, the advance and retard chamber oil passages are both closed by the spool valve

and the rotor assembly is hydraulically locked to the sprocket housing. Variable Camshaft Timing Unit Schematic - Null

Page 866 of 3039

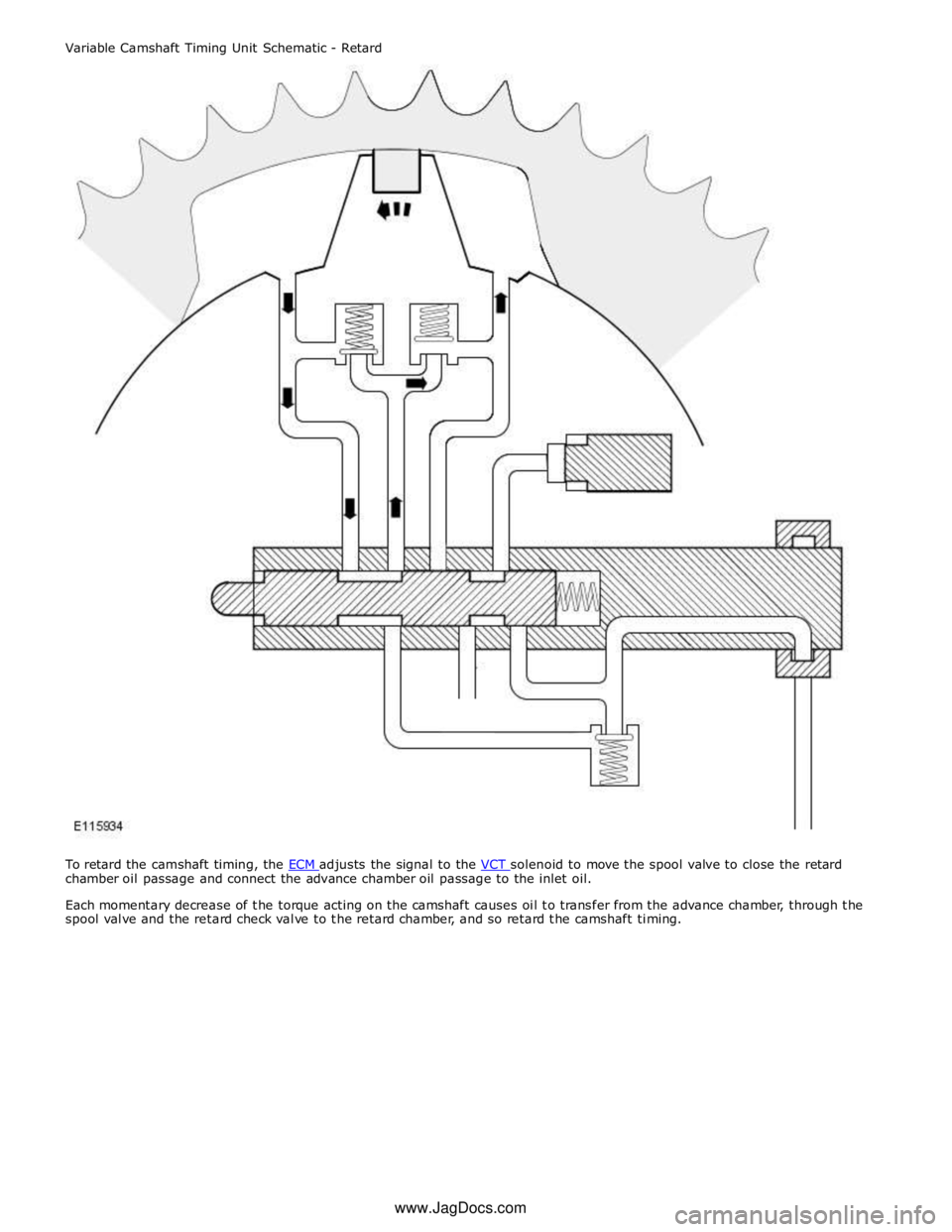

chamber oil passage and connect the advance chamber oil passage to the inlet oil.

Each momentary decrease of the torque acting on the camshaft causes oil to transfer from the advance chamber, through the

spool valve and the retard check valve to the retard chamber, and so retard the camshaft timing. www.JagDocs.com

Page 867 of 3039

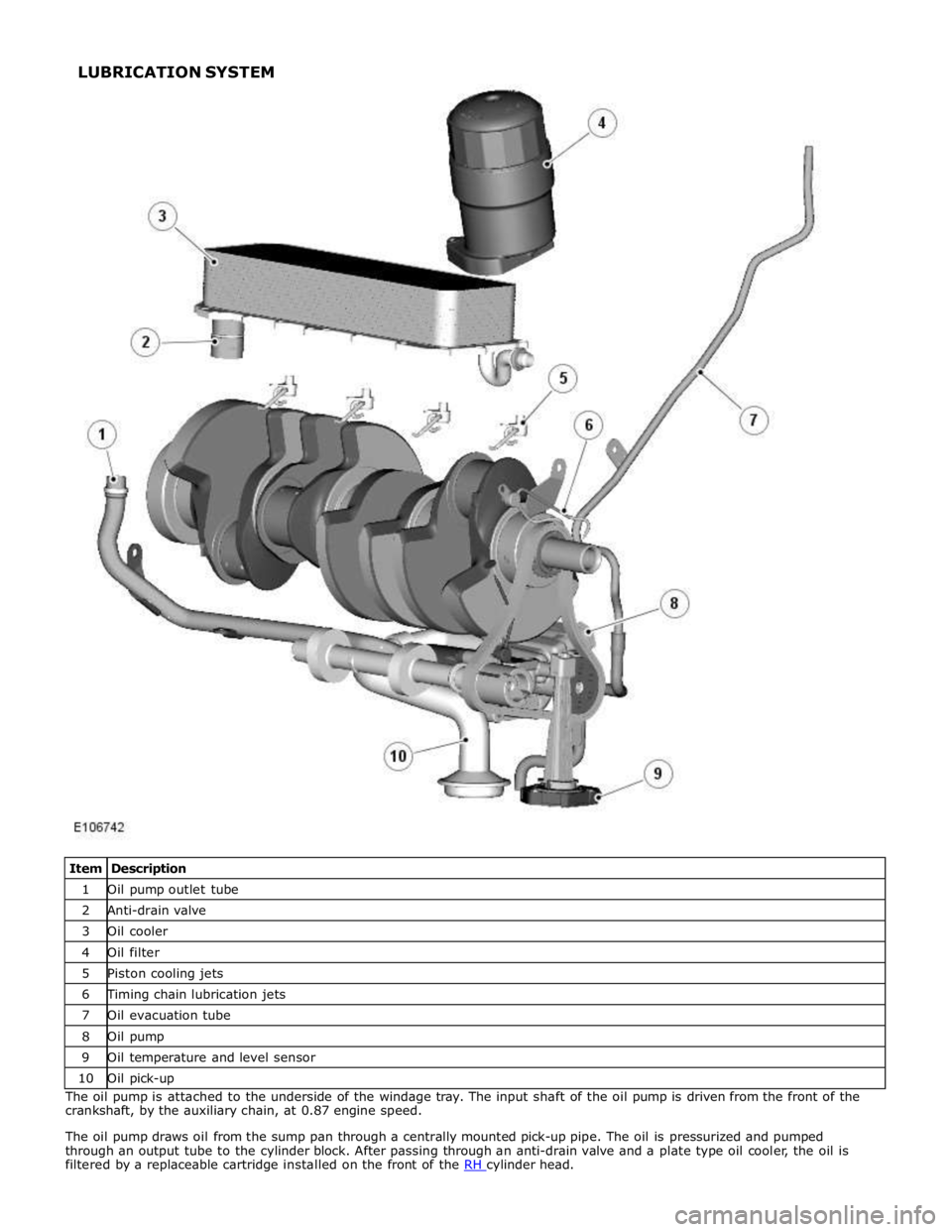

1 Oil pump outlet tube 2 Anti-drain valve 3 Oil cooler 4 Oil filter 5 Piston cooling jets 6 Timing chain lubrication jets 7 Oil evacuation tube 8 Oil pump 9 Oil temperature and level sensor 10 Oil pick-up The oil pump is attached to the underside of the windage tray. The input shaft of the oil pump is driven from the front of the

crankshaft, by the auxiliary chain, at 0.87 engine speed.

The oil pump draws oil from the sump pan through a centrally mounted pick-up pipe. The oil is pressurized and pumped

through an output tube to the cylinder block. After passing through an anti-drain valve and a plate type oil cooler, the oil is

filtered by a replaceable cartridge installed on the front of the RH cylinder head. LUBRICATION SYSTEM

Page 868 of 3039

cooling jets and the timing chain lubrication jets.

The oil returns to the oil pan under gravity. Large drain holes through the cylinder heads and cylinder block ensure the rapid

return of the oil to the sump pan. System replenishment is through the oil filler cap on the LH cylinder head cover.

An oil evacuation tube is installed to allow oil to be drawn from the sump pan. The upper end of the oil evacuation tube is

located under the oil filler cap.

An oil drain plug is installed in the RH side of the sump pan.

Oil Pump Nominal Operating Pressures

Engine Speed, rev/min Temperature, °C (°F) Pressure, bar (lbf/in2

) Idle 20 (68) 2.0 (29.0) 1500 20 (68) 6.0 (87.0) 3000 40 (104) 6.2 (90.0) 3000 110 (230) 5.0 (72.5) 3000 130 (266) 4.0 (58.0) Oil Level Monitoring

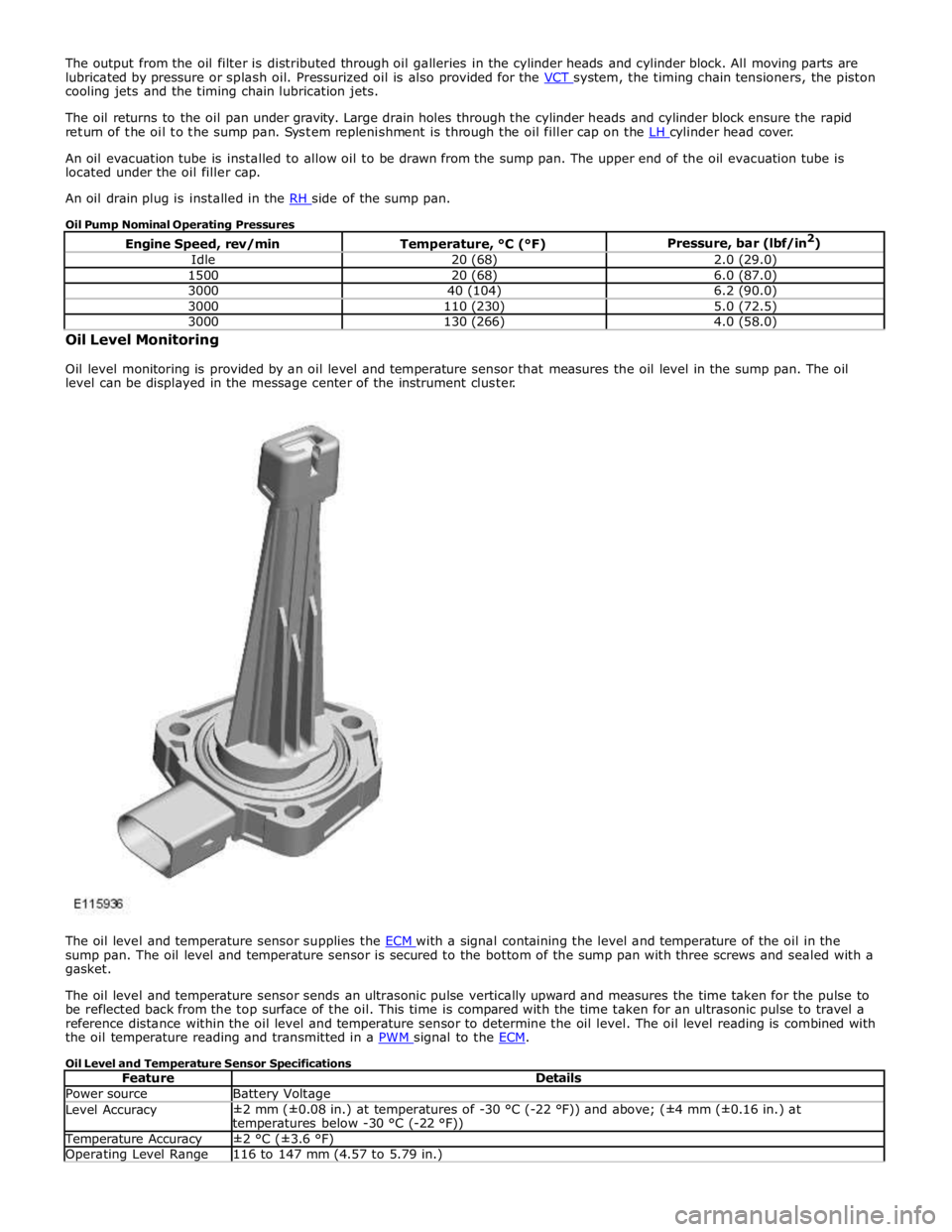

Oil level monitoring is provided by an oil level and temperature sensor that measures the oil level in the sump pan. The oil

level can be displayed in the message center of the instrument cluster.

The oil level and temperature sensor supplies the ECM with a signal containing the level and temperature of the oil in the sump pan. The oil level and temperature sensor is secured to the bottom of the sump pan with three screws and sealed with a

gasket.

The oil level and temperature sensor sends an ultrasonic pulse vertically upward and measures the time taken for the pulse to

be reflected back from the top surface of the oil. This time is compared with the time taken for an ultrasonic pulse to travel a

reference distance within the oil level and temperature sensor to determine the oil level. The oil level reading is combined with

the oil temperature reading and transmitted in a PWM signal to the ECM.

Oil Level and Temperature Sensor Specifications

Feature Details Power source Battery Voltage Level Accuracy ±2 mm (±0.08 in.) at temperatures of -30 °C (-22 °F)) and above; (±4 mm (±0.16 in.) at

temperatures below -30 °C (-22 °F)) Temperature Accuracy ±2 °C (±3.6 °F) Operating Level Range 116 to 147 mm (4.57 to 5.79 in.)

Page 885 of 3039

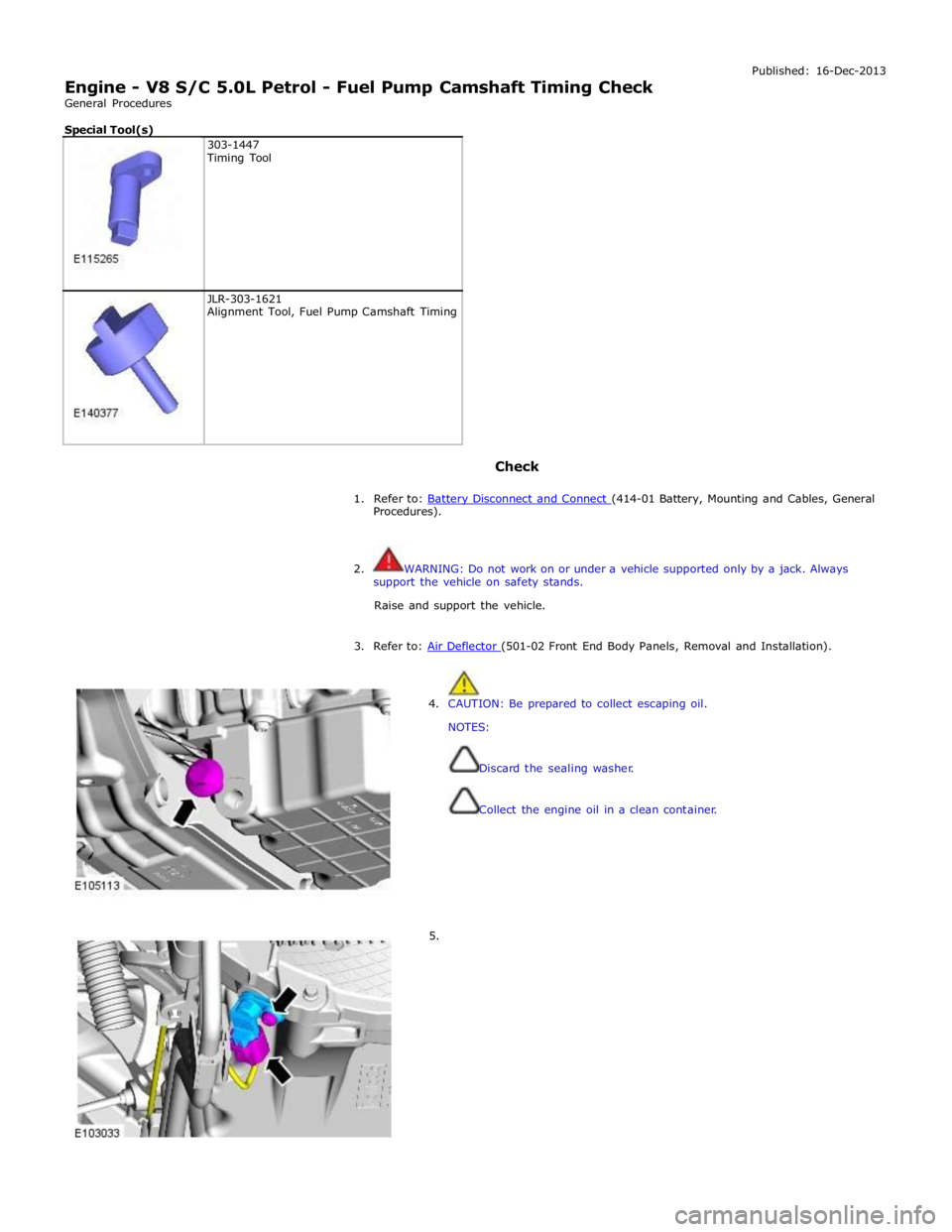

Engine - V8 S/C 5.0L Petrol - Fuel Pump Camshaft Timing Check

General Procedures

Special Tool(s)

303-1447

Timing Tool

JLR-303-1621

Alignment Tool, Fuel Pump Camshaft Timing

Check Published: 16-Dec-2013

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Do not work on or under a vehicle supported only by a jack. Always

support the vehicle on safety stands.

Raise and support the vehicle.

3. Refer to: Air Deflector (501-02 Front End Body Panels, Removal and Installation).

4. CAUTION: Be prepared to collect escaping oil.

NOTES:

Discard the sealing washer.

Collect the engine oil in a clean container.

5.

Page 887 of 3039

10. Remove the Special Tool(s): 303-1447

11.

If required,

carefully

adjust the

crankshaft

position to

allow correct

installation

of the

special tool.

Install the

Special

Tool(s):

JLR-303-1621

12.

CAUTION: Do not use excessive force when adjusting the crankshaft

position.

NOTE: If the crankshaft timing tool cannot be installed, adjustment of

the fuel pump camshaft timing will be required.

If required, carefully adjust the crankshaft position to allow correct

installation of the special tool.

Install the Special Tool(s): 303-1447 If the crankshaft timing tool cannot be installed, adjustment of the

fuel pump camshaft timing will be required.

Refer to: Fuel Pump Camshaft Timing Adjustment (303-01C Engine - V8 5.0L Petrol, General Procedures).

Page 893 of 3039

Published: 21-Dec-2011

Engine - V8 S/C 5.0L Petrol - Fuel Pump Camshaft Timing Adjustment

General Procedures

Special Tool(s)

303-1447

Timing Tool

JLR-303-1613

Alignment Tool, Fuel Pump Camshaft Timing

Adjustment

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

3. Refer to: Fuel Pump Camshaft Timing Check (303-01D Engine - V8 S/C 5.0L Petrol, General Procedures).

4. Refer to: Lower Timing Cover (303-01C Engine - V8 5.0L Petrol, Removal and Installation).

Refer to: Lower Timing Cover (303-01D Engine - V8 S/C 5.0L Petrol, Removal and Installation).