tow JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 694 of 3039

7 Brake fluid level switch 8 LH rear wheel speed sensor 9 RH rear wheel speed sensor 10 RJB (rear junction box) 11 High mounted stop lamp 12 LH stop lamp 13 RH stop lamp 14 Diagnostic socket 15 TCM (transmission control module) 16 Electronic parking brake module 17 ECM (engine control module) 18 Instrument cluster 19 ABS (anti-lock brake system) module 20 JaguarDrive selector module 21 Adaptive damping control module 22 Adaptive speed control module 23 Yaw rate and lateral acceleration sensor 24 Roof opening panel motor/module 25 Brake booster vacuum sensor (3.0L vehicles only) 26 Steering angle sensor

Anti-Lock Brake System System Operation

ABS controls the speed of all road wheels to ensure optimum wheel slip when braking at the adhesion limit. The wheels are prevented from locking to retain effective steering control of the vehicle.

The brake pressures are modulated separately for each wheel. Rear brake pressures are controlled to maintain rear stability on

split friction surfaces.

Dynamic Stability Control

DSC (dynamic stability control) uses brakes and powertrain torque control to assist in maintaining the yaw stability of the

vehicle. While the ignition is energized the DSC function is permanently enabled, unless selected off using the DSC switch.

DSC enhances driving safety in abrupt maneuvers and in under-steer or over-steer situations that may occur in a bend. The

ABS module monitors the yaw rate and lateral acceleration of the vehicle, steering input and individual wheel speeds, then selectively applies individual brakes and signals for powertrain torque adjustments to reduce under-steer or over-steer

conditions.

In general:

In an under-steer situation the inner wheels are braked to counteract the yaw movement towards the outer edge of the

bend.

In an over-steer situation the outer wheels are braked to prevent the rear end of the vehicle from pushing towards the

outer edge of the bend.

The ABS module monitors the tracking stability of the vehicle using inputs from the wheel speed sensors, the steering angle sensor, and the yaw rate and lateral acceleration sensor. The tracking stability is compared with stored target data. Whenever

the tracking stability deviates from the target data, the ABS module intervenes by applying the appropriate control strategy. The following interactions occur in an intervention situation:

High speed CAN signal to the ECM, to reduce engine torque. Application of braking to the appropriate corner of the vehicle.

Trac DSC

TracDSC is an alternative setting of DSC with reduced system interventions. With TracDSC engaged, traction may be somewhat

increased, although stability may be reduced compared to normal DSC. TracDSC is intended for use only on dry tarmac, by

suitably experienced drivers and should not be selected for other surfaces or by drivers with insufficient skill and training to

operate the vehicle safely with the TracDSC function engaged.

The less restrictive TracDSC setting may be preferred, for example, by expert drivers engaged in high performance driving on

dry Tarmac surfaces such as tracks and circuits.

Switching between DSC and Trac DSC:

Page 814 of 3039

engine oil).

Oil Consumption Test

The amount of oil an engine uses will vary with the way the vehicle is driven in addition to normal engine-to-engine variation.

This is especially true during the first 16,100 km (10,000 miles) when a new engine is being broken in or until certain internal

components become conditioned. Vehicles used in heavy-duty operation may use more oil. The following are examples of

heavy-duty operation:

Trailer towing applications

Severe loading applications

Sustained high speed operation

Engines need oil to lubricate the following internal components:

Cylinder block cylinder walls

Pistons and piston rings

Intake and exhaust valve stems

Intake and exhaust valve guides

All internal engine components

When the pistons move downward, a thin film of oil is left on the cylinder walls. As the vehicle is operated, some oil is also

drawn into the combustion chambers past the intake and exhaust valve stem seals and burned.

The following are examples of conditions that can affect oil consumption rates:

Engine size

Operator driving habits

Ambient temperatures

Quality and viscosity of oil

Engine is being run in an overfilled condition (check the oil level at least five minutes after a hot shutdown with the

vehicle parked on a level surface. The oil level should not be above the top of the cross-hatched area and the letter "F"

in FULL).

Operation under varying conditions can frequently be misleading. A vehicle that has been run for several thousand miles on

short trips or in below-freezing ambient temperatures may have consumed a "normal" amount of oil. However, when checking

the engine oil level, it may measure up to the full mark on the oil level indicator due to dilution (condensation and fuel) in the

engine crankcase. The vehicle then might be driven at high speeds on the highway where the condensation and fuel boil off.

The next time the engine oil is checked it may appear that a liter of oil was used in about 160 km (100 miles). Oil

consumption rate is about one liter per 2,400 km (1,500 miles).

Make sure the selected engine oil meets Jaguar specification and the recommended API performance category "SG" and SAE

viscosity grade as shown in the vehicle Owner's Guide. It is also important that the engine oil is changed at the intervals

specified for the typical operating conditions.

The following diagnostic procedure is used to determine the source of excessive oil consumption.

NOTE: Oil use is normally greater during the first 16,100 km (10,000 miles) of service. As mileage increases, oil use

decreases. High speed driving, towing, high ambient temperature and other factors may result in greater oil use.

1. Define excessive consumption, such as the number of miles driven per liter of oil used. Also determine customers

driving habits, such as sustained high speed operation, towing, extended idle and other considerations.

2. Verify that the engine has no external oil leaks as described under Engine Oil Leaks in this section.

3. Carry out an oil consumption test:

Run the engine to normal operating temperature. Switch engine OFF and allow oil to drain back for at least five

minutes .

With vehicle parked on level surface, check the engine oil level.

If required, add engine oil to set level exactly to the FULL mark.

Record the vehicle mileage.

Instruct the customer to return for a level check after driving the vehicle as usual for 1,610 km (1000 miles).

Check the oil level under the same conditions and at the same location as the initial check.

NOTE: If the oil consumption rate is unacceptable go to Step 4.

4. Check the Positive Crankcase Ventilation (PCV) system. Make sure the system is not plugged.

5. Check for plugged oil drain-back holes in the cylinder head and cylinder block.

6. If the condition still exists after carrying out the above tests go to step 9.

7. Carry out a cylinder compression test. Refer to the Compression Test procedure in this section. This can help determine

the source of oil consumption such as valves, piston rings or other areas.

8. Check valve guides for excessive guide clearance. Install new valve stem seals after verifying valve guide clearance.

9. Worn or damaged internal engine components can cause excessive oil consumption. Small deposits of oil on the tips of

the spark plugs can be a clue to internal oil consumption.

Page 1586 of 3039

8 LH (left-hand) fuel level sensor 9 RH (right-hand) fuel level sensor and fuel pump module 10 RCM (restraints control module)

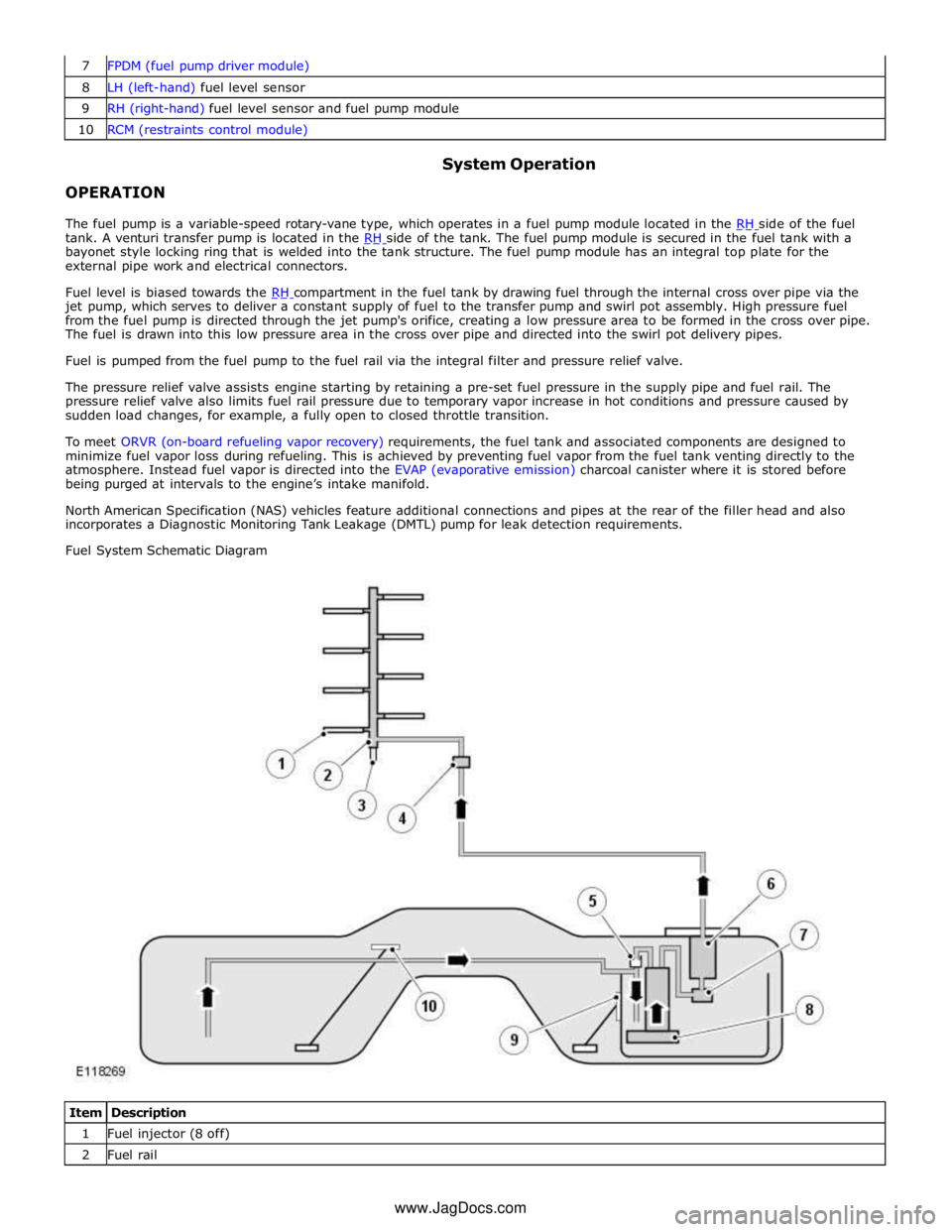

OPERATION System Operation

The fuel pump is a variable-speed rotary-vane type, which operates in a fuel pump module located in the RH side of the fuel tank. A venturi transfer pump is located in the RH side of the tank. The fuel pump module is secured in the fuel tank with a bayonet style locking ring that is welded into the tank structure. The fuel pump module has an integral top plate for the

external pipe work and electrical connectors.

Fuel level is biased towards the RH compartment in the fuel tank by drawing fuel through the internal cross over pipe via the jet pump, which serves to deliver a constant supply of fuel to the transfer pump and swirl pot assembly. High pressure fuel

from the fuel pump is directed through the jet pump's orifice, creating a low pressure area to be formed in the cross over pipe.

The fuel is drawn into this low pressure area in the cross over pipe and directed into the swirl pot delivery pipes.

Fuel is pumped from the fuel pump to the fuel rail via the integral filter and pressure relief valve.

The pressure relief valve assists engine starting by retaining a pre-set fuel pressure in the supply pipe and fuel rail. The

pressure relief valve also limits fuel rail pressure due to temporary vapor increase in hot conditions and pressure caused by

sudden load changes, for example, a fully open to closed throttle transition.

To meet ORVR (on-board refueling vapor recovery) requirements, the fuel tank and associated components are designed to

minimize fuel vapor loss during refueling. This is achieved by preventing fuel vapor from the fuel tank venting directly to the

atmosphere. Instead fuel vapor is directed into the EVAP (evaporative emission) charcoal canister where it is stored before

being purged at intervals to the engine’s intake manifold.

North American Specification (NAS) vehicles feature additional connections and pipes at the rear of the filler head and also

incorporates a Diagnostic Monitoring Tank Leakage (DMTL) pump for leak detection requirements.

Fuel System Schematic Diagram

Item Description 1 Fuel injector (8 off) 2 Fuel rail www.JagDocs.com

Page 1834 of 3039

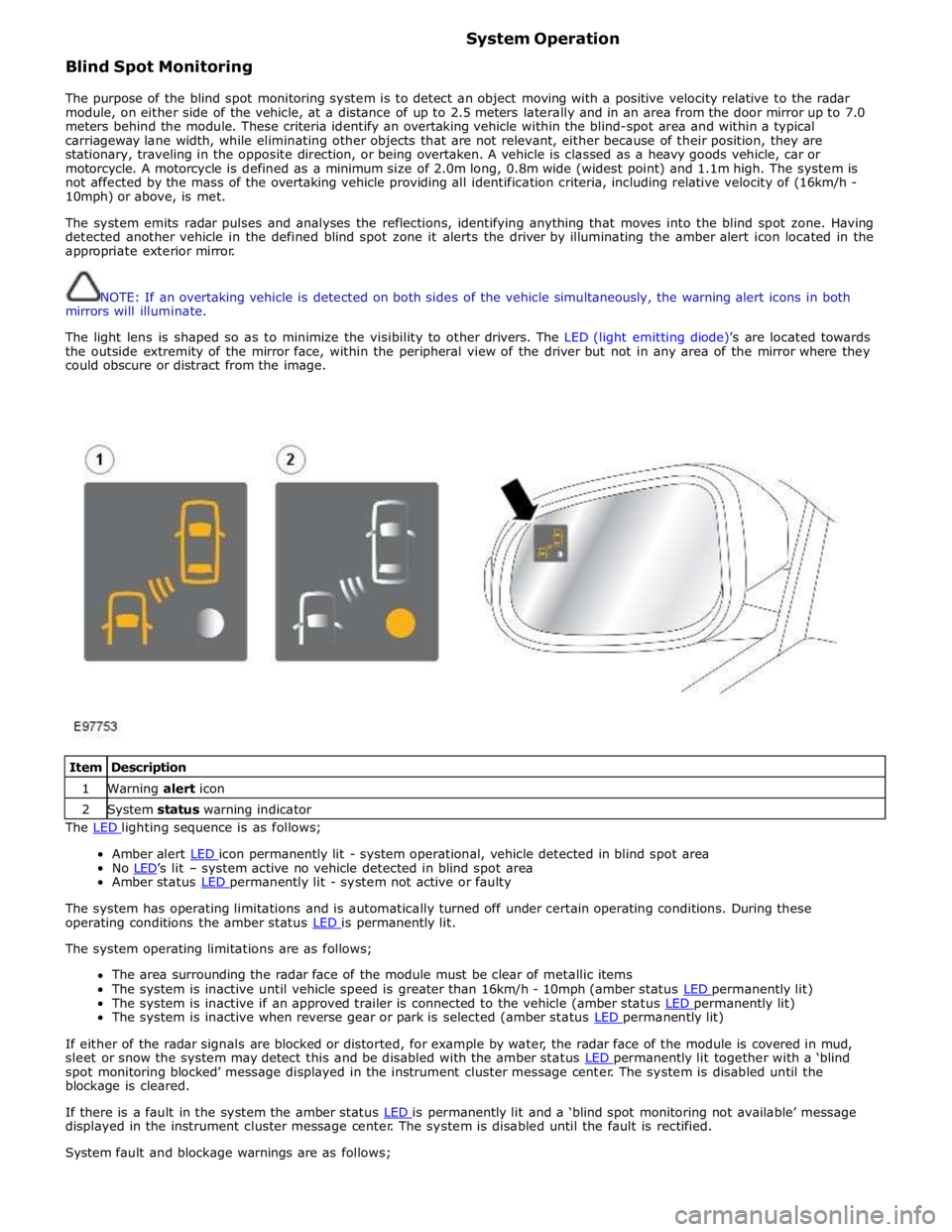

Blind Spot Monitoring System Operation

The purpose of the blind spot monitoring system is to detect an object moving with a positive velocity relative to the radar

module, on either side of the vehicle, at a distance of up to 2.5 meters laterally and in an area from the door mirror up to 7.0

meters behind the module. These criteria identify an overtaking vehicle within the blind-spot area and within a typical

carriageway lane width, while eliminating other objects that are not relevant, either because of their position, they are

stationary, traveling in the opposite direction, or being overtaken. A vehicle is classed as a heavy goods vehicle, car or

motorcycle. A motorcycle is defined as a minimum size of 2.0m long, 0.8m wide (widest point) and 1.1m high. The system is

not affected by the mass of the overtaking vehicle providing all identification criteria, including relative velocity of (16km/h -

10mph) or above, is met.

The system emits radar pulses and analyses the reflections, identifying anything that moves into the blind spot zone. Having

detected another vehicle in the defined blind spot zone it alerts the driver by illuminating the amber alert icon located in the

appropriate exterior mirror.

NOTE: If an overtaking vehicle is detected on both sides of the vehicle simultaneously, the warning alert icons in both

mirrors will illuminate.

The light lens is shaped so as to minimize the visibility to other drivers. The LED (light emitting diode)’s are located towards

the outside extremity of the mirror face, within the peripheral view of the driver but not in any area of the mirror where they

could obscure or distract from the image.

Item Description 1 Warning alert icon 2 System status warning indicator The LED lighting sequence is as follows;

Amber alert LED icon permanently lit - system operational, vehicle detected in blind spot area No LED’s lit – system active no vehicle detected in blind spot area Amber status LED permanently lit - system not active or faulty

The system has operating limitations and is automatically turned off under certain operating conditions. During these

operating conditions the amber status LED is permanently lit. The system operating limitations are as follows;

The area surrounding the radar face of the module must be clear of metallic items

The system is inactive until vehicle speed is greater than 16km/h - 10mph (amber status LED permanently lit) The system is inactive if an approved trailer is connected to the vehicle (amber status LED permanently lit) The system is inactive when reverse gear or park is selected (amber status LED permanently lit)

If either of the radar signals are blocked or distorted, for example by water, the radar face of the module is covered in mud,

sleet or snow the system may detect this and be disabled with the amber status LED permanently lit together with a ‘blind spot monitoring blocked’ message displayed in the instrument cluster message center. The system is disabled until the

blockage is cleared.

If there is a fault in the system the amber status LED is permanently lit and a ‘blind spot monitoring not available’ message displayed in the instrument cluster message center. The system is disabled until the fault is rectified.

System fault and blockage warnings are as follows;

Page 1851 of 3039

Mechanical Electrical Parking aid control module

Parking aid sounder

Audio system

4. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

5. If the cause is not visually evident, check for diagnostic trouble codes (DTCs) and refer to the DTC index

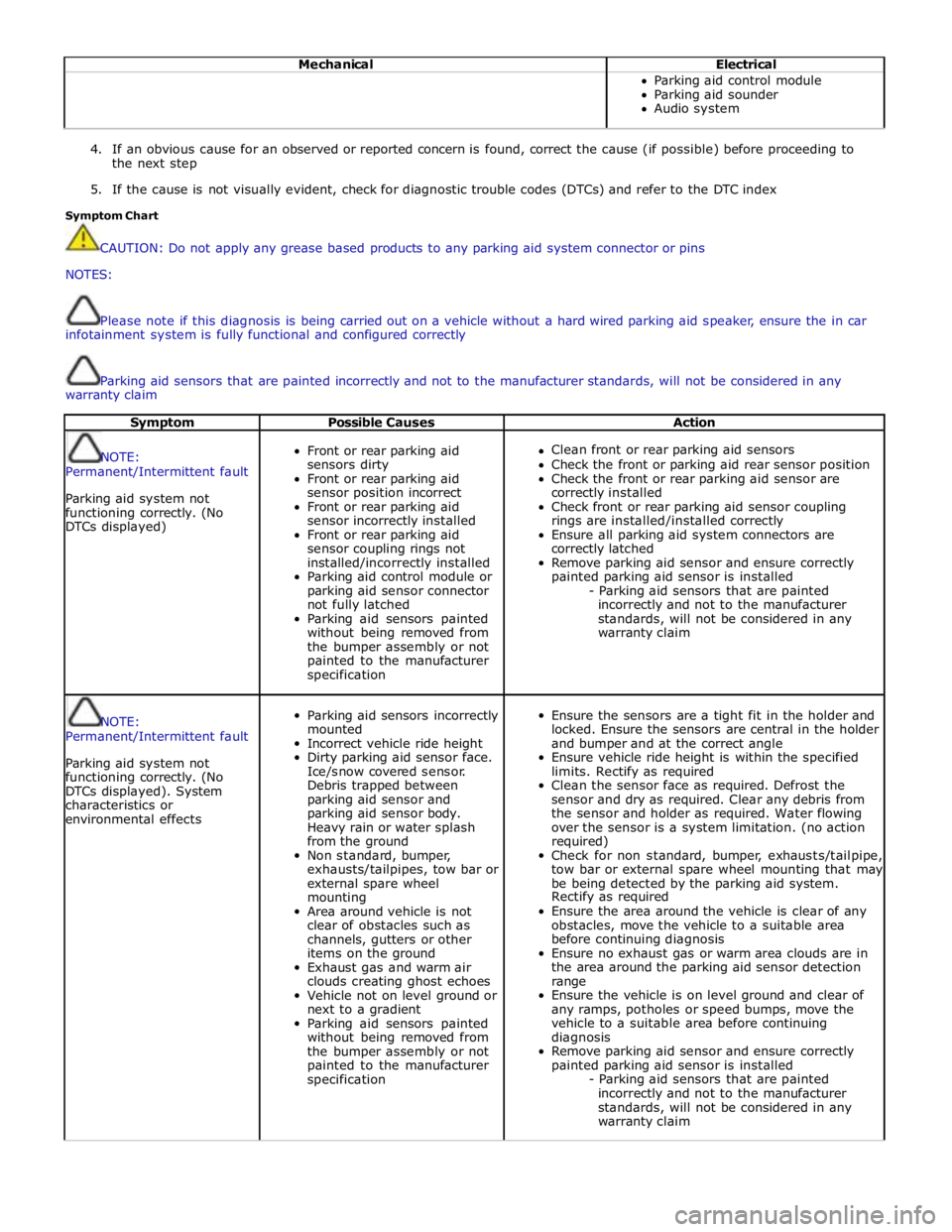

Symptom Chart

CAUTION: Do not apply any grease based products to any parking aid system connector or pins

NOTES:

Please note if this diagnosis is being carried out on a vehicle without a hard wired parking aid speaker, ensure the in car

infotainment system is fully functional and configured correctly

Parking aid sensors that are painted incorrectly and not to the manufacturer standards, will not be considered in any

warranty claim

Symptom Possible Causes Action

NOTE:

Permanent/Intermittent fault

Parking aid system not

functioning correctly. (No

DTCs displayed)

Front or rear parking aid

sensors dirty

Front or rear parking aid

sensor position incorrect

Front or rear parking aid

sensor incorrectly installed

Front or rear parking aid

sensor coupling rings not

installed/incorrectly installed

Parking aid control module or

parking aid sensor connector

not fully latched

Parking aid sensors painted

without being removed from

the bumper assembly or not

painted to the manufacturer

specification

Clean front or rear parking aid sensors

Check the front or parking aid rear sensor position

Check the front or rear parking aid sensor are

correctly installed

Check front or rear parking aid sensor coupling

rings are installed/installed correctly

Ensure all parking aid system connectors are

correctly latched

Remove parking aid sensor and ensure correctly

painted parking aid sensor is installed

- Parking aid sensors that are painted

incorrectly and not to the manufacturer

standards, will not be considered in any

warranty claim

NOTE:

Permanent/Intermittent fault

Parking aid system not

functioning correctly. (No

DTCs displayed). System

characteristics or

environmental effects

Parking aid sensors incorrectly

mounted

Incorrect vehicle ride height

Dirty parking aid sensor face.

Ice/snow covered sensor.

Debris trapped between

parking aid sensor and

parking aid sensor body.

Heavy rain or water splash

from the ground

Non standard, bumper,

exhausts/tailpipes, tow bar or

external spare wheel

mounting

Area around vehicle is not

clear of obstacles such as

channels, gutters or other

items on the ground

Exhaust gas and warm air

clouds creating ghost echoes

Vehicle not on level ground or

next to a gradient

Parking aid sensors painted

without being removed from

the bumper assembly or not

painted to the manufacturer

specification

Ensure the sensors are a tight fit in the holder and

locked. Ensure the sensors are central in the holder

and bumper and at the correct angle

Ensure vehicle ride height is within the specified

limits. Rectify as required

Clean the sensor face as required. Defrost the

sensor and dry as required. Clear any debris from

the sensor and holder as required. Water flowing

over the sensor is a system limitation. (no action

required)

Check for non standard, bumper, exhausts/tailpipe,

tow bar or external spare wheel mounting that may

be being detected by the parking aid system.

Rectify as required

Ensure the area around the vehicle is clear of any

obstacles, move the vehicle to a suitable area

before continuing diagnosis

Ensure no exhaust gas or warm area clouds are in

the area around the parking aid sensor detection

range

Ensure the vehicle is on level ground and clear of

any ramps, potholes or speed bumps, move the

vehicle to a suitable area before continuing

diagnosis

Remove parking aid sensor and ensure correctly

painted parking aid sensor is installed

- Parking aid sensors that are painted

incorrectly and not to the manufacturer

standards, will not be considered in any

warranty claim

Page 1854 of 3039

PINPOINT TEST B : PARKING AID SYSTEM NOT FUNCTIONING CORRECTLY WITH NO DTCS LOGGED TEST

CONDITIONS DETAILS/RESULTS/ACTIONS B1: PARKING AID SYSTEM GIVES WARNING SIGNAL WITHOUT OBSTACLE 1 Clean the parking aid sensor face. Check for any damage to the parking aid sensor face. Rectify as required. Snow, water or ice on sensor face. Parking aid sensor face has been repainted to the incorrect

thickness. Rectify as required Parking aid system functioning correctly? Yes

No further action required

No

GO to B2. B2: PARKING AID SYSTEM GIVES WARNING SIGNAL WITHOUT OBSTACLE 1 Ensure the vehicle ride height is within manufacturer specified limits. Rectify as required Parking aid system functioning correctly? Yes

No further action required

No

GO to B3. B3: PARKING AID SYSTEM GIVES WARNING SIGNAL WITHOUT OBSTACLE 1 Check for any non standard accessories are not fitted, such as tow bar, bike rack, body kit, modified exhaust, lighting or licence plate holder Parking aid system functioning correctly? Yes

No further action required

No

GO to B4. B4: PARKING AID SYSTEM GIVES WARNING SIGNAL WITHOUT OBSTACLE 1 Limitations or characteristics of the parking aid system such as vehicle on a gradient, exhaust gas vapour, signal reflection Parking aid system functioning correctly? Yes

No further action required

No

For a detailed description of the parking aid system, refer to the relevant description and operation

section in the workshop manual.

REFER to: Parking Aid (413-13 Parking Aid, Description and Operation). DTC Index

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If the control module is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty Policy and

Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to the installation of a

new module.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places,

and with an up-to-date calibration certificate. When testing resistance always take the resistance of the DMM leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals. Parking aid system functioning correctly

Yes

No further action required

Page 1896 of 3039

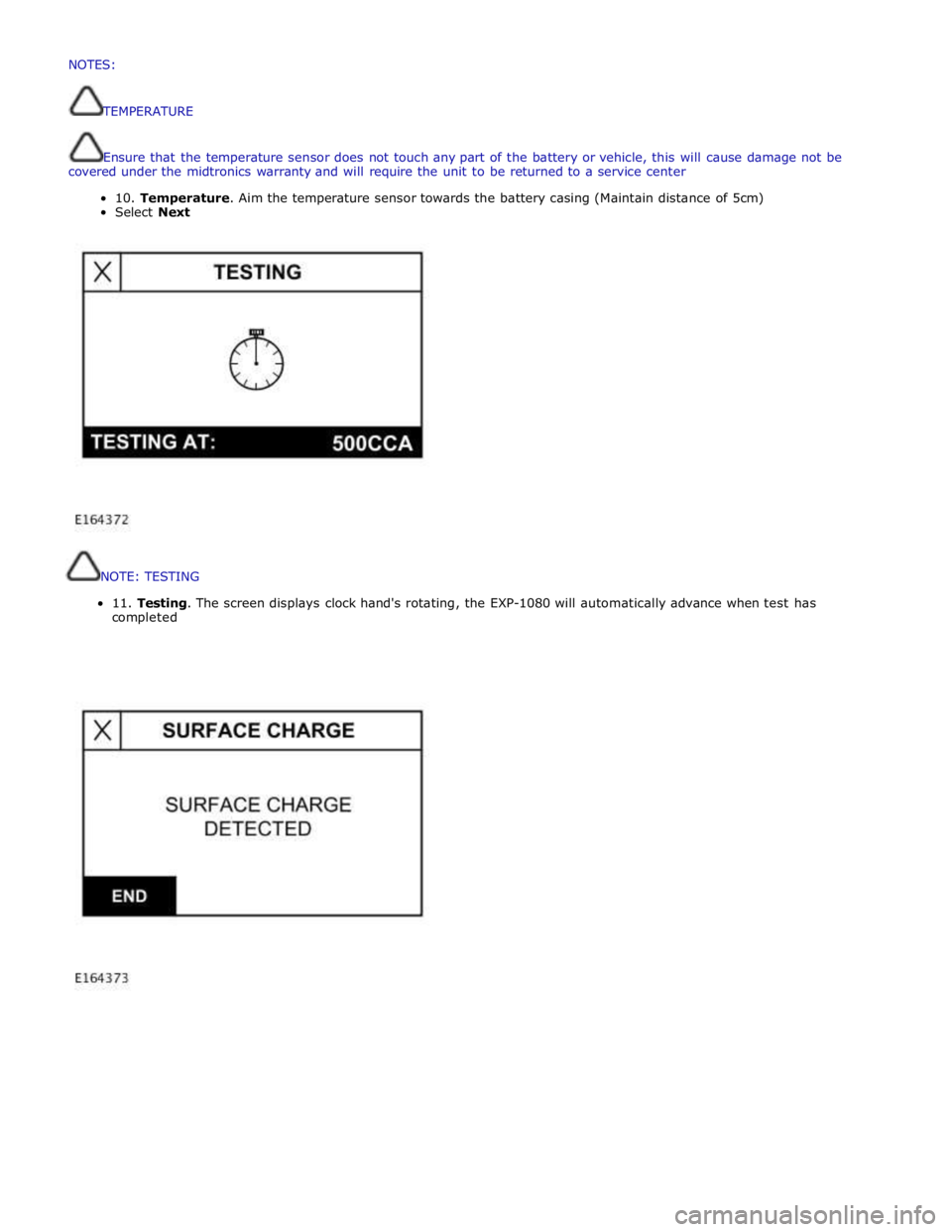

NOTE:

TESTING

11.

Testing.

The

screen

displays

clock

hand's

rotating,

the

EXP-1080

will

automatically

advance

when

test

has

completed

NOTES:

TEMPERATURE

Ensurethatthetemperaturesensordoesnottouchanypartofthebatteryorvehicle,thiswillcausedamagenotbe

coveredunderthemidtronicswarrantyand willrequiretheunittobereturnedtoaservicecenter

10.Temperature.Aimthetemperaturesensortowardsthebatterycasing (Maintaindistanceof5cm)

SelectNext

Page 1958 of 3039

The digital radio format adopted for NAS vehicles is satellite radio. Satellite service providers transmit a signal from their

up-link facility (which is the original point of transmission of data, voice or other information through an antenna system) to a

satellite where the signal is then down linked to both the terrestrial repeater network and the individual satellite car radios.

The radio switches between the satellite signal and the repeater network signal depending on the strength of the signal at any

given time.

The Sirius satellite system comprises:

Satellites

Ground repeaters

Up-link ground stations

Radio receiver systems

The Sirius satellite radio system uses three satellites on an inclined elliptical orbit. This ensures that each satellite spends

approximately 16 hours a day over the continent of the USA, with at least one satellite over the country at any one time.

The satellites beam their signals down to the ground where the signal is picked up by receivers or is transmitted to repeater

stations to cover built up areas where the signal is obscured. The satellite service comprises over 100 channels of digital

entertainment which is provided by subscription requiring a monthly payment.

Operation of the satellite radio system is the same as the radio operations with selections made through the Touch-screen and

ICP to access and navigate the system functions.

The satellite radio receiver is a dedicated tuner which is controlled by the ICM on the MOST ring. The receiver filters the

signals from the satellite radio antenna. Information is transmitted on the MOST ring and processed by the ICM. The processed

information is sent out to the power amplifier or IAM (with internal amplifier) and broadcast through the speaker system.

No configuration procedure is required if the satellite radio receiver is replaced. Calibration of the satellite radio receiver using

the Jaguar approved diagnostic equipment enables updates to be downloaded as new technology becomes available or any

fault concerns require software updates.

Satellite Radio Antenna

The satellite radio antenna is located in the roof pod and is shared with the navigation system GPS (global positioning system)

antenna where fitted. The roof pod is located externally in a central position towards the rear of the roof.

Similar to the DAB system the satellite radio antenna is designed with 50 ohm output impedance. The satellite radio receiver

is fitted with 50 ohm fakra II connectors to ensure compatibility with the antenna. For optimum performance 50 ohm low loss

coaxial cable is used between the antenna and receiver.

The antenna is designed to receive one of two signals, using the strongest signal with the least distortion to process for audio

output. For example, if the vehicle drives into a tunnel, the signal received will change from a satellite signal to a repeater

station signal maintaining the strongest signal. SATELLITE RADIO (NAS VEHICLES ONLY)

Page 1980 of 3039

the roof pod and is shared with the DAB (digital audio broadcasting) band L antenna or satellite radio antenna where fitted.

The roof pod is located externally in a central position towards the rear of the roof.

The GPS antenna is designed with 50 ohm output impedance. The navigation computer is fitted with 50 ohm fakra II connectors to ensure compatibility with the antenna. For optimum performance 50 ohm low loss coaxial cable is used between

the antenna and navigation computer.

It is possible for the GPS antenna to lose the signal from the GPS satellites; In hilly or tree lined areas

Built up areas with tall buildings

In multi storey car parks

In garages

In tunnels

On bridges

During heavy rain or thunderstorms

When the signal is lost the navigation computer will continue to give guidance using memory mapped data from the DVD map until the signal is restored.

TMC/VICS FM Antenna

Data messages for both TMC (traffic message channel) and VICS (vehicle information and communication system) are received

through the FM antennas and diversity antenna module located in the heated rear window.

VICS Beacon Antenna (Japan Only)

The VICS (vehicle information and communication system) beacon antenna receives infra red and RF (radio frequency) traffic

data signals from road side transmitters. The antenna is connected to the navigation computer which incorporates a VICS

(vehicle information and communication system) receiver.

Touch Screen Display

The Touch-screen is the control interface for the following vehicle systems;

System Functions Audio Radio display AM/FM or DAB (digital audio broadcast), auxiliary and portable audio, digital TV or CD Climate

control Air conditioning, distribution, seats, heated steering wheel, automatic air recirculation Telephone Digit dialer, phone book, last ten calls (made, received, missed) www.JagDocs.com

Page 2087 of 3039

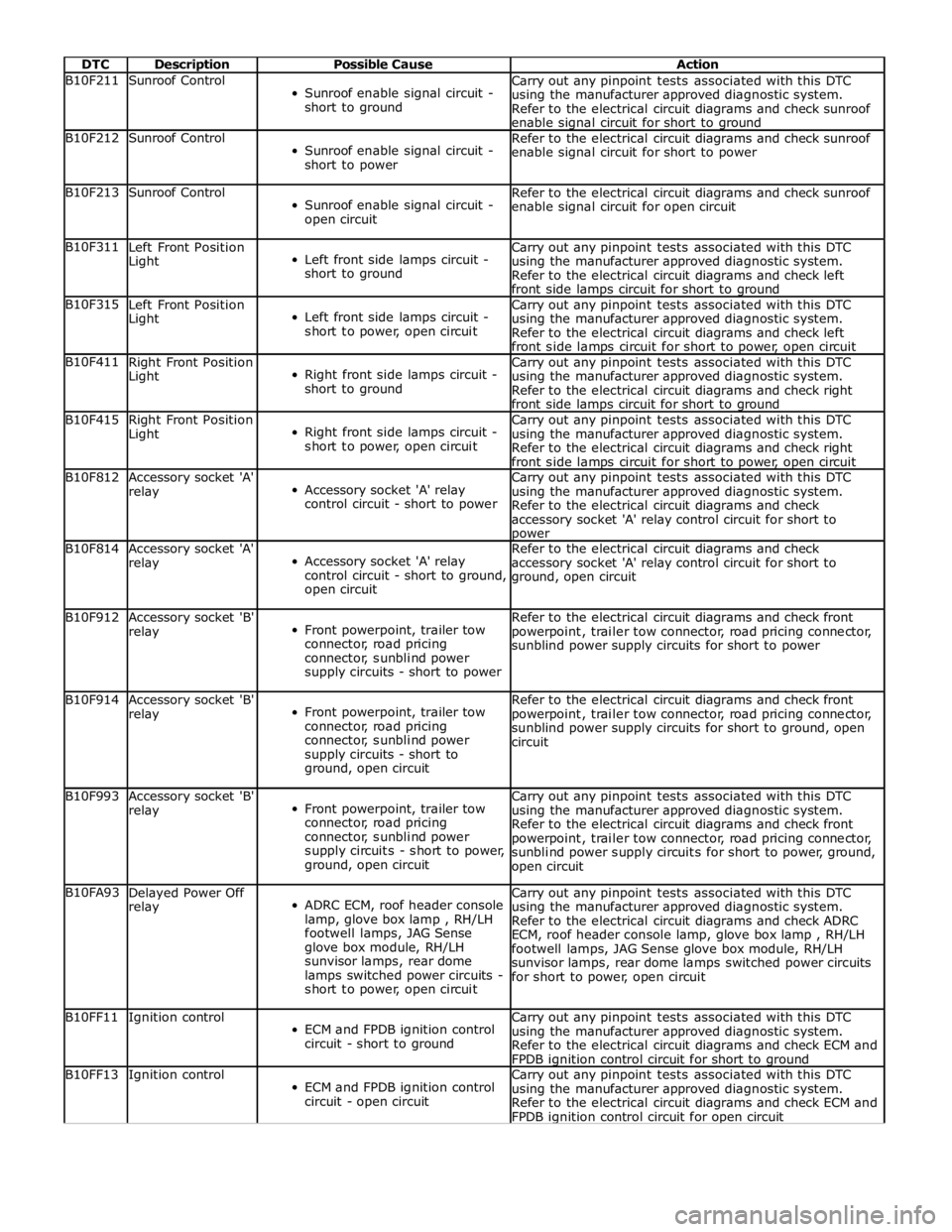

DTC Description Possible Cause Action B10F211 Sunroof Control

Sunroof enable signal circuit -

short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check sunroof

enable signal circuit for short to ground B10F212 Sunroof Control

Sunroof enable signal circuit -

short to power Refer to the electrical circuit diagrams and check sunroof

enable signal circuit for short to power B10F213 Sunroof Control

Sunroof enable signal circuit -

open circuit Refer to the electrical circuit diagrams and check sunroof

enable signal circuit for open circuit B10F311

Left Front Position

Light

Left front side lamps circuit -

short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check left

front side lamps circuit for short to ground B10F315

Left Front Position

Light

Left front side lamps circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check left

front side lamps circuit for short to power, open circuit B10F411

Right Front Position

Light

Right front side lamps circuit -

short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check right

front side lamps circuit for short to ground B10F415

Right Front Position

Light

Right front side lamps circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check right

front side lamps circuit for short to power, open circuit B10F812

Accessory socket 'A'

relay

Accessory socket 'A' relay

control circuit - short to power Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

accessory socket 'A' relay control circuit for short to power B10F814

Accessory socket 'A'

relay

Accessory socket 'A' relay

control circuit - short to ground,

open circuit Refer to the electrical circuit diagrams and check

accessory socket 'A' relay control circuit for short to

ground, open circuit B10F912

Accessory socket 'B'

relay

Front powerpoint, trailer tow

connector, road pricing

connector, sunblind power

supply circuits - short to power Refer to the electrical circuit diagrams and check front

powerpoint, trailer tow connector, road pricing connector,

sunblind power supply circuits for short to power B10F914

Accessory socket 'B'

relay

Front powerpoint, trailer tow

connector, road pricing

connector, sunblind power

supply circuits - short to

ground, open circuit Refer to the electrical circuit diagrams and check front

powerpoint, trailer tow connector, road pricing connector,

sunblind power supply circuits for short to ground, open

circuit B10F993

Accessory socket 'B'

relay

Front powerpoint, trailer tow

connector, road pricing

connector, sunblind power

supply circuits - short to power,

ground, open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check front

powerpoint, trailer tow connector, road pricing connector,

sunblind power supply circuits for short to power, ground,

open circuit B10FA93

Delayed Power Off

relay

ADRC ECM, roof header console

lamp, glove box lamp , RH/LH

footwell lamps, JAG Sense

glove box module, RH/LH

sunvisor lamps, rear dome

lamps switched power circuits -

short to power, open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check ADRC

ECM, roof header console lamp, glove box lamp , RH/LH

footwell lamps, JAG Sense glove box module, RH/LH

sunvisor lamps, rear dome lamps switched power circuits

for short to power, open circuit B10FF11 Ignition control

ECM and FPDB ignition control

circuit - short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check ECM and

FPDB ignition control circuit for short to ground B10FF13 Ignition control

ECM and FPDB ignition control

circuit - open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check ECM and

FPDB ignition control circuit for open circuit