sensor JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1588 of 3039

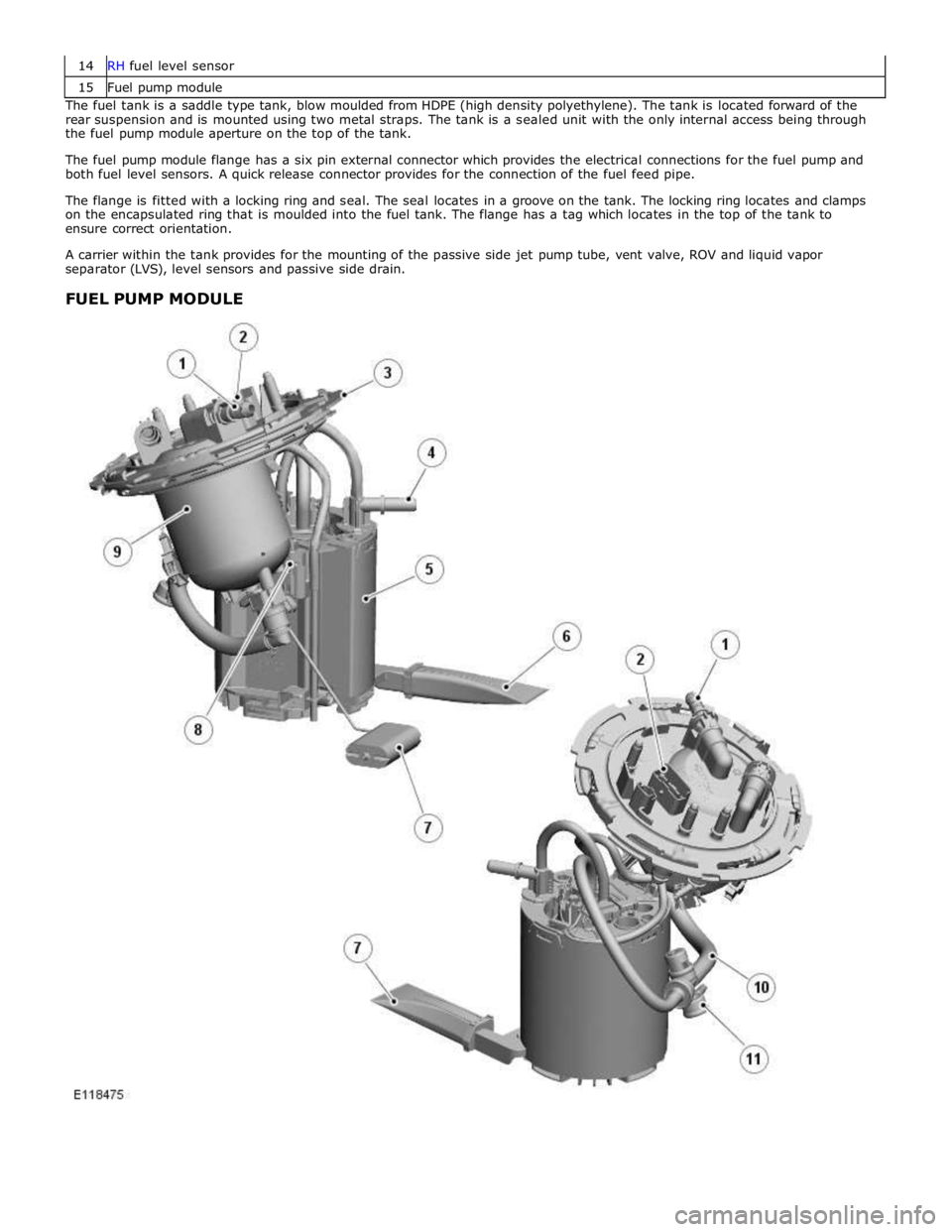

15 Fuel pump module The fuel tank is a saddle type tank, blow moulded from HDPE (high density polyethylene). The tank is located forward of the

rear suspension and is mounted using two metal straps. The tank is a sealed unit with the only internal access being through

the fuel pump module aperture on the top of the tank.

The fuel pump module flange has a six pin external connector which provides the electrical connections for the fuel pump and

both fuel level sensors. A quick release connector provides for the connection of the fuel feed pipe.

The flange is fitted with a locking ring and seal. The seal locates in a groove on the tank. The locking ring locates and clamps

on the encapsulated ring that is moulded into the fuel tank. The flange has a tag which locates in the top of the tank to

ensure correct orientation.

A carrier within the tank provides for the mounting of the passive side jet pump tube, vent valve, ROV and liquid vapor

separator (LVS), level sensors and passive side drain.

FUEL PUMP MODULE

Page 1589 of 3039

1 Fuel supply connection 2 Electrical connector 3 Flange locking ring and seal 4 Sucking jet connector 5 Fuel pump module 6 Fuel pick up filter 7 Level sensor float 8 RH level sensor 9 Fuel filter 10 Pressure relief valve 11 Pump supply to flange connection 12 The fuel pump is a variable speed rotary vane type. The pump is energized by the fuel pump relay which is located in the RJB and the FPDM which is located under the RH floor pan above the rear suspension stabilizer bar. The relay and FPDM are controlled by the ECM.

A fine mesh filter is located in the lower section of the pump module. This provides filtration to the fuel as it is drawn into the

module. There is a winged filter on the fuel pump that gives additional protection and a life time fuel filter integrated into the

flange which eliminates the need for an additional filter further downstream in the fuel system.

The RH fuel level sensor is mounted into the pump module housing.

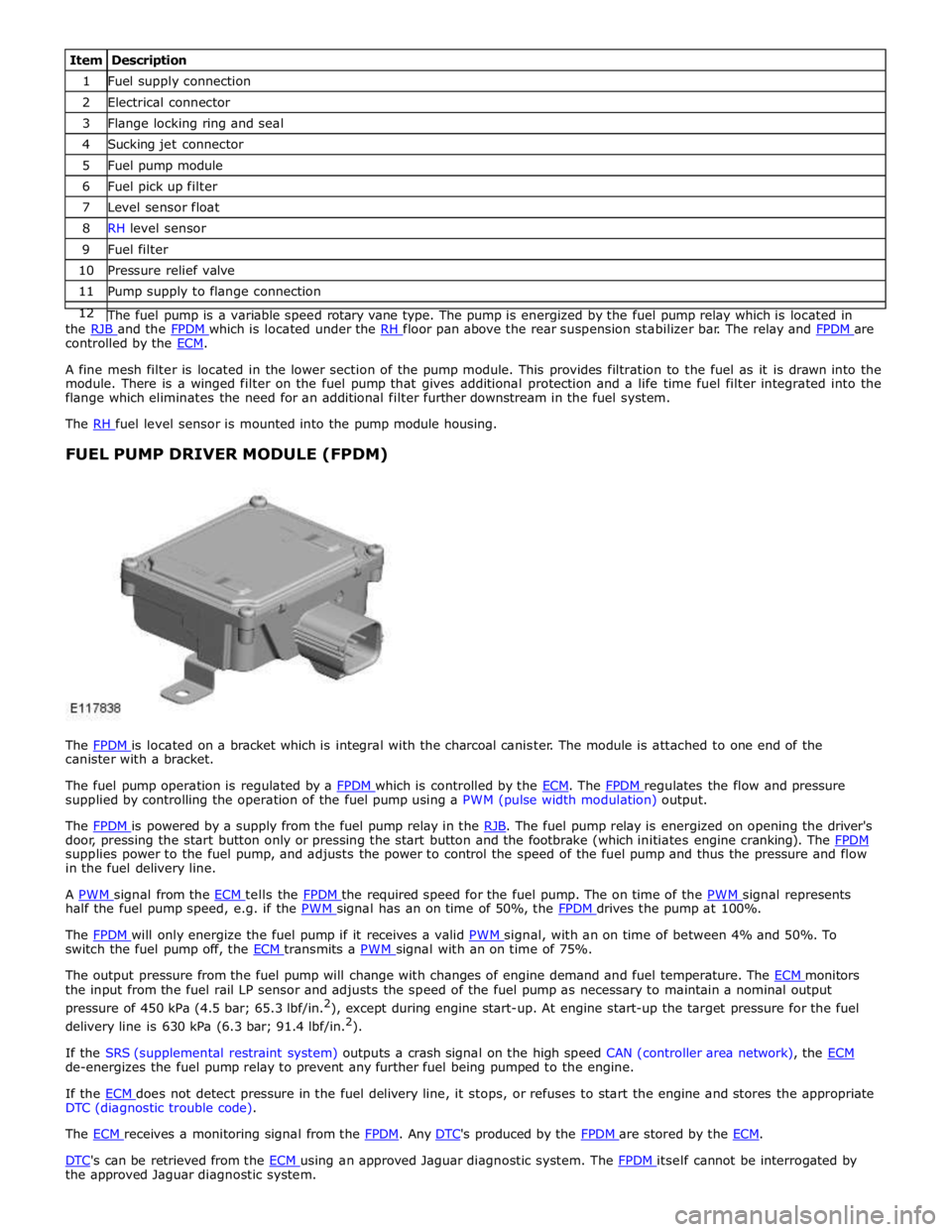

FUEL PUMP DRIVER MODULE (FPDM)

The FPDM is located on a bracket which is integral with the charcoal canister. The module is attached to one end of the canister with a bracket.

The fuel pump operation is regulated by a FPDM which is controlled by the ECM. The FPDM regulates the flow and pressure supplied by controlling the operation of the fuel pump using a PWM (pulse width modulation) output.

The FPDM is powered by a supply from the fuel pump relay in the RJB. The fuel pump relay is energized on opening the driver's door, pressing the start button only or pressing the start button and the footbrake (which initiates engine cranking). The FPDM supplies power to the fuel pump, and adjusts the power to control the speed of the fuel pump and thus the pressure and flow

in the fuel delivery line.

A PWM signal from the ECM tells the FPDM the required speed for the fuel pump. The on time of the PWM signal represents half the fuel pump speed, e.g. if the PWM signal has an on time of 50%, the FPDM drives the pump at 100%.

The FPDM will only energize the fuel pump if it receives a valid PWM signal, with an on time of between 4% and 50%. To switch the fuel pump off, the ECM transmits a PWM signal with an on time of 75%.

The output pressure from the fuel pump will change with changes of engine demand and fuel temperature. The ECM monitors the input from the fuel rail LP sensor and adjusts the speed of the fuel pump as necessary to maintain a nominal output

pressure of 450 kPa (4.5 bar; 65.3 lbf/in.2

), except during engine start-up. At engine start-up the target pressure for the fuel

delivery line is 630 kPa (6.3 bar; 91.4 lbf/in.2

).

If the SRS (supplemental restraint system) outputs a crash signal on the high speed CAN (controller area network), the ECM de-energizes the fuel pump relay to prevent any further fuel being pumped to the engine.

If the ECM does not detect pressure in the fuel delivery line, it stops, or refuses to start the engine and stores the appropriate DTC (diagnostic trouble code).

The ECM receives a monitoring signal from the FPDM. Any DTC's produced by the FPDM are stored by the ECM.

DTC's can be retrieved from the ECM using an approved Jaguar diagnostic system. The FPDM itself cannot be interrogated by the approved Jaguar diagnostic system.

Page 1590 of 3039

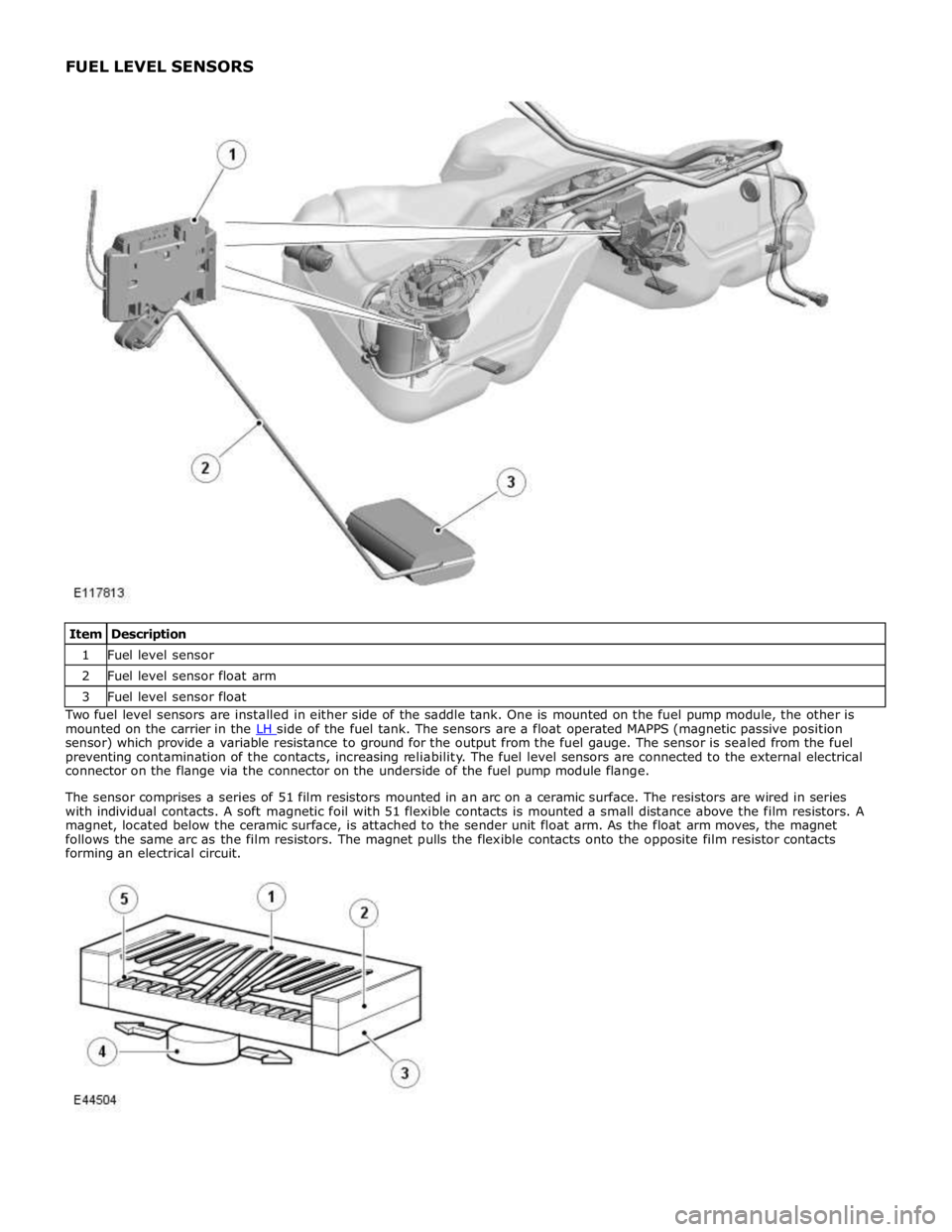

1 Fuel level sensor 2 Fuel level sensor float arm 3 Fuel level sensor float Two fuel level sensors are installed in either side of the saddle tank. One is mounted on the fuel pump module, the other is

mounted on the carrier in the LH side of the fuel tank. The sensors are a float operated MAPPS (magnetic passive position sensor) which provide a variable resistance to ground for the output from the fuel gauge. The sensor is sealed from the fuel

preventing contamination of the contacts, increasing reliability. The fuel level sensors are connected to the external electrical

connector on the flange via the connector on the underside of the fuel pump module flange.

The sensor comprises a series of 51 film resistors mounted in an arc on a ceramic surface. The resistors are wired in series

with individual contacts. A soft magnetic foil with 51 flexible contacts is mounted a small distance above the film resistors. A

magnet, located below the ceramic surface, is attached to the sender unit float arm. As the float arm moves, the magnet

follows the same arc as the film resistors. The magnet pulls the flexible contacts onto the opposite film resistor contacts

forming an electrical circuit.

Page 1596 of 3039

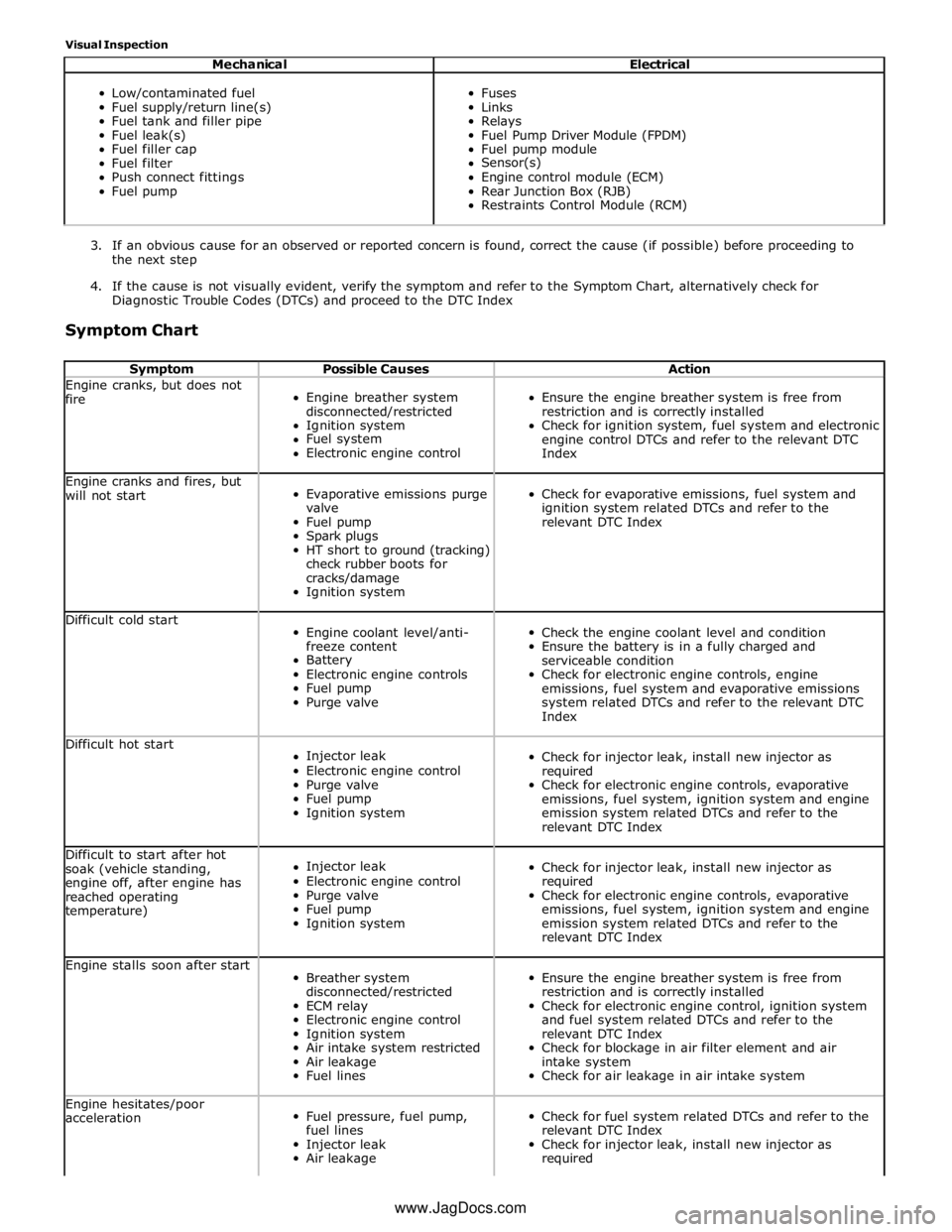

Visual Inspection

Mechanical Electrical

Low/contaminated fuel

Fuel supply/return line(s)

Fuel tank and filler pipe

Fuel leak(s)

Fuel filler cap

Fuel filter

Push connect fittings

Fuel pump

Fuses

Links

Relays

Fuel Pump Driver Module (FPDM)

Fuel pump module

Sensor(s)

Engine control module (ECM)

Rear Junction Box (RJB)

Restraints Control Module (RCM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and proceed to the DTC Index

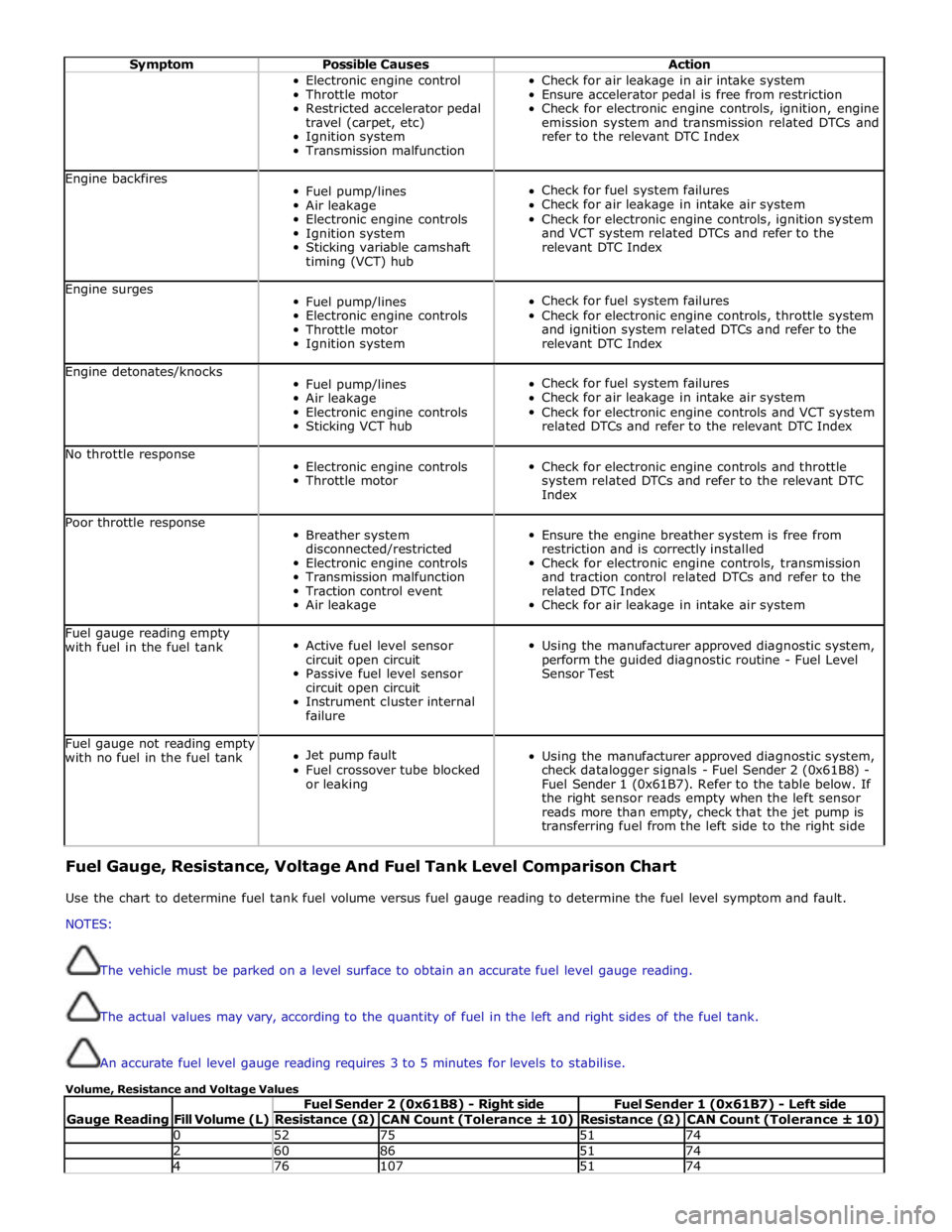

Symptom Chart

Symptom Possible Causes Action Engine cranks, but does not

fire

Engine breather system

disconnected/restricted

Ignition system

Fuel system

Electronic engine control

Ensure the engine breather system is free from

restriction and is correctly installed

Check for ignition system, fuel system and electronic

engine control DTCs and refer to the relevant DTC

Index Engine cranks and fires, but

will not start

Evaporative emissions purge

valve

Fuel pump

Spark plugs

HT short to ground (tracking)

check rubber boots for

cracks/damage

Ignition system

Check for evaporative emissions, fuel system and

ignition system related DTCs and refer to the

relevant DTC Index Difficult cold start

Engine coolant level/anti-

freeze content

Battery

Electronic engine controls

Fuel pump

Purge valve

Check the engine coolant level and condition

Ensure the battery is in a fully charged and

serviceable condition

Check for electronic engine controls, engine

emissions, fuel system and evaporative emissions

system related DTCs and refer to the relevant DTC

Index Difficult hot start

Injector leak

Electronic engine control

Purge valve

Fuel pump

Ignition system

Check for injector leak, install new injector as

required

Check for electronic engine controls, evaporative

emissions, fuel system, ignition system and engine

emission system related DTCs and refer to the

relevant DTC Index Difficult to start after hot

soak (vehicle standing,

engine off, after engine has

reached operating

temperature)

Injector leak

Electronic engine control

Purge valve

Fuel pump

Ignition system

Check for injector leak, install new injector as

required

Check for electronic engine controls, evaporative

emissions, fuel system, ignition system and engine

emission system related DTCs and refer to the

relevant DTC Index Engine stalls soon after start

Breather system

disconnected/restricted

ECM relay

Electronic engine control

Ignition system

Air intake system restricted

Air leakage

Fuel lines

Ensure the engine breather system is free from

restriction and is correctly installed

Check for electronic engine control, ignition system

and fuel system related DTCs and refer to the

relevant DTC Index

Check for blockage in air filter element and air

intake system

Check for air leakage in air intake system Engine hesitates/poor

acceleration

Fuel pressure, fuel pump,

fuel lines

Injector leak

Air leakage

Check for fuel system related DTCs and refer to the

relevant DTC Index

Check for injector leak, install new injector as

required www.JagDocs.com

Page 1597 of 3039

Symptom Possible Causes Action Electronic engine control

Throttle motor

Restricted accelerator pedal

travel (carpet, etc)

Ignition system

Transmission malfunction Check for air leakage in air intake system

Ensure accelerator pedal is free from restriction

Check for electronic engine controls, ignition, engine

emission system and transmission related DTCs and

refer to the relevant DTC Index Engine backfires

Fuel pump/lines

Air leakage

Electronic engine controls

Ignition system

Sticking variable camshaft

timing (VCT) hub

Check for fuel system failures

Check for air leakage in intake air system

Check for electronic engine controls, ignition system

and VCT system related DTCs and refer to the

relevant DTC Index Engine surges

Fuel pump/lines

Electronic engine controls

Throttle motor

Ignition system

Check for fuel system failures

Check for electronic engine controls, throttle system

and ignition system related DTCs and refer to the

relevant DTC Index Engine detonates/knocks

Fuel pump/lines

Air leakage

Electronic engine controls

Sticking VCT hub

Check for fuel system failures

Check for air leakage in intake air system

Check for electronic engine controls and VCT system

related DTCs and refer to the relevant DTC Index No throttle response

Electronic engine controls

Throttle motor

Check for electronic engine controls and throttle

system related DTCs and refer to the relevant DTC

Index Poor throttle response

Breather system

disconnected/restricted

Electronic engine controls

Transmission malfunction

Traction control event

Air leakage

Ensure the engine breather system is free from

restriction and is correctly installed

Check for electronic engine controls, transmission

and traction control related DTCs and refer to the

related DTC Index

Check for air leakage in intake air system Fuel gauge reading empty

with fuel in the fuel tank

Active fuel level sensor

circuit open circuit

Passive fuel level sensor

circuit open circuit

Instrument cluster internal

failure

Using the manufacturer approved diagnostic system,

perform the guided diagnostic routine - Fuel Level

Sensor Test Fuel gauge not reading empty

with no fuel in the fuel tank

Jet pump fault

Fuel crossover tube blocked

or leaking

Using the manufacturer approved diagnostic system,

check datalogger signals - Fuel Sender 2 (0x61B8) -

Fuel Sender 1 (0x61B7). Refer to the table below. If

the right sensor reads empty when the left sensor

reads more than empty, check that the jet pump is

transferring fuel from the left side to the right side Fuel Gauge, Resistance, Voltage And Fuel Tank Level Comparison Chart

Use the chart to determine fuel tank fuel volume versus fuel gauge reading to determine the fuel level symptom and fault.

NOTES:

The vehicle must be parked on a level surface to obtain an accurate fuel level gauge reading.

The actual values may vary, according to the quantity of fuel in the left and right sides of the fuel tank.

An accurate fuel level gauge reading requires 3 to 5 minutes for levels to stabilise.

Volume, Resistance and Voltage Values

Gauge Reading

Fill Volume (L) Fuel Sender 2 (0x61B8) - Right side Fuel Sender 1 (0x61B7) - Left side Resistance (Ω) CAN Count (Tolerance ± 10) Resistance (Ω) CAN Count (Tolerance ± 10) 0 52 75 51 74 2 60 86 51 74 4 76 107 51 74

Page 1603 of 3039

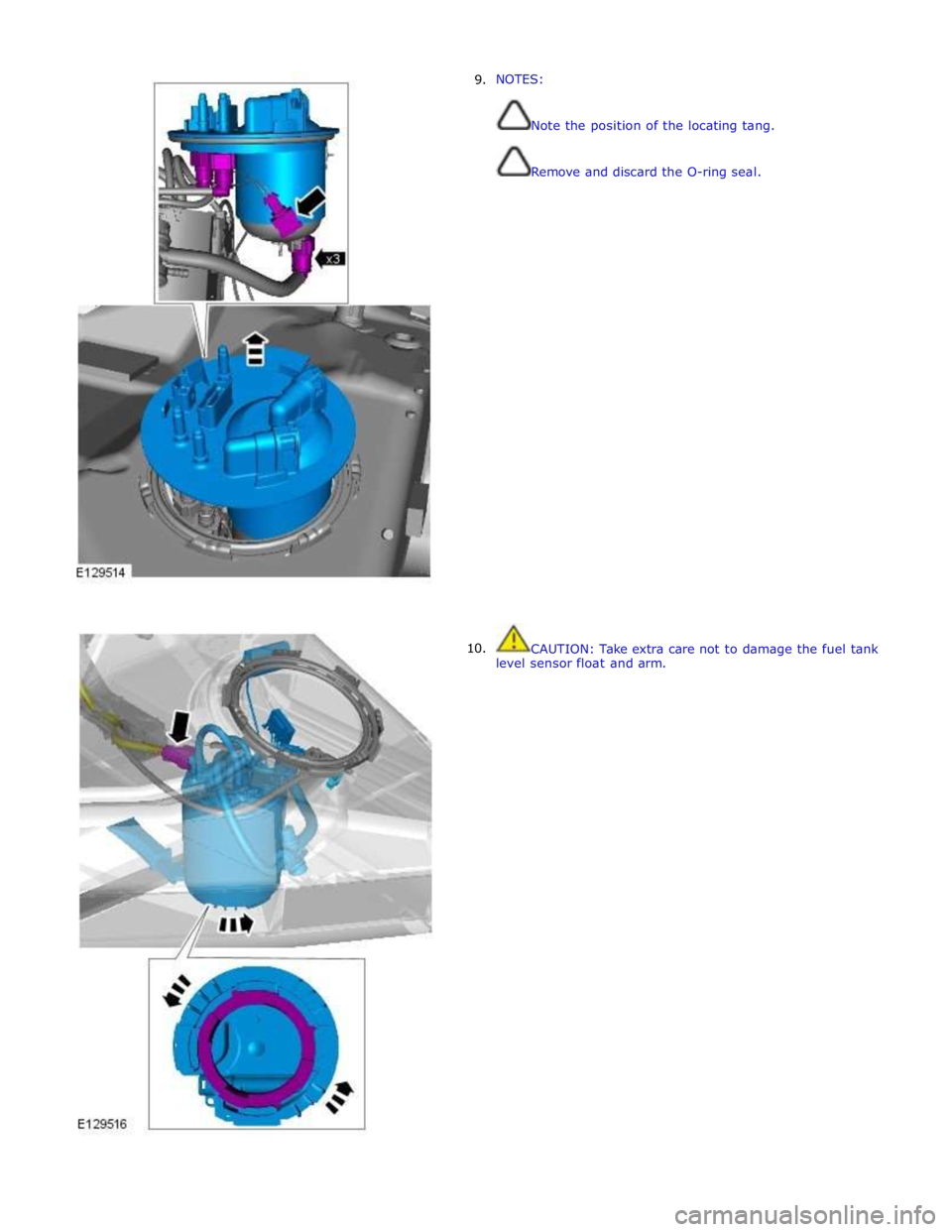

9.

10. NOTES:

Note the position of the locating tang.

Remove and discard the O-ring seal.

CAUTION: Take extra care not to damage the fuel tank

level sensor float and arm.

Page 1604 of 3039

Installation

1. CAUTIONS:

arm. Take extra care not to damage the fuel tank level sensor float and

Make sure the fuel pump and sender unit is correctly installed in to

the retaining bracket in the fuel tank.

NOTE: Make sure the locating tang is installed in the correct

position.

To install, reverse the removal procedure.

Page 1631 of 3039

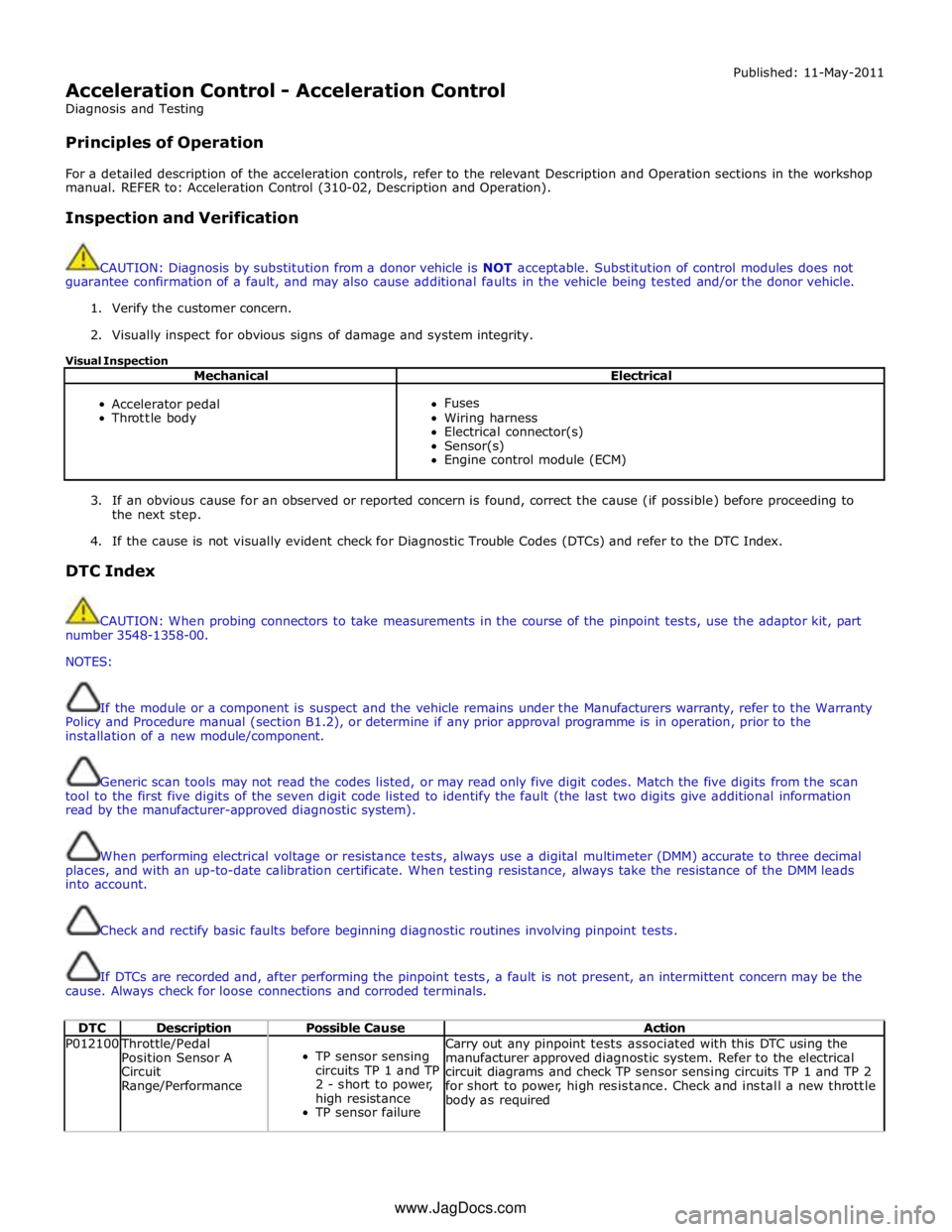

Acceleration Control - Acceleration Control

Diagnosis and Testing

Principles of Operation Published: 11-May-2011

For a detailed description of the acceleration controls, refer to the relevant Description and Operation sections in the workshop

manual. REFER to: Acceleration Control (310-02, Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Accelerator pedal

Throttle body

Fuses

Wiring harness

Electrical connector(s)

Sensor(s)

Engine control module (ECM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00.

NOTES:

If the module or a component is suspect and the vehicle remains under the Manufacturers warranty, refer to the Warranty

Policy and Procedure manual (section B1.2), or determine if any prior approval programme is in operation, prior to the

installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer-approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

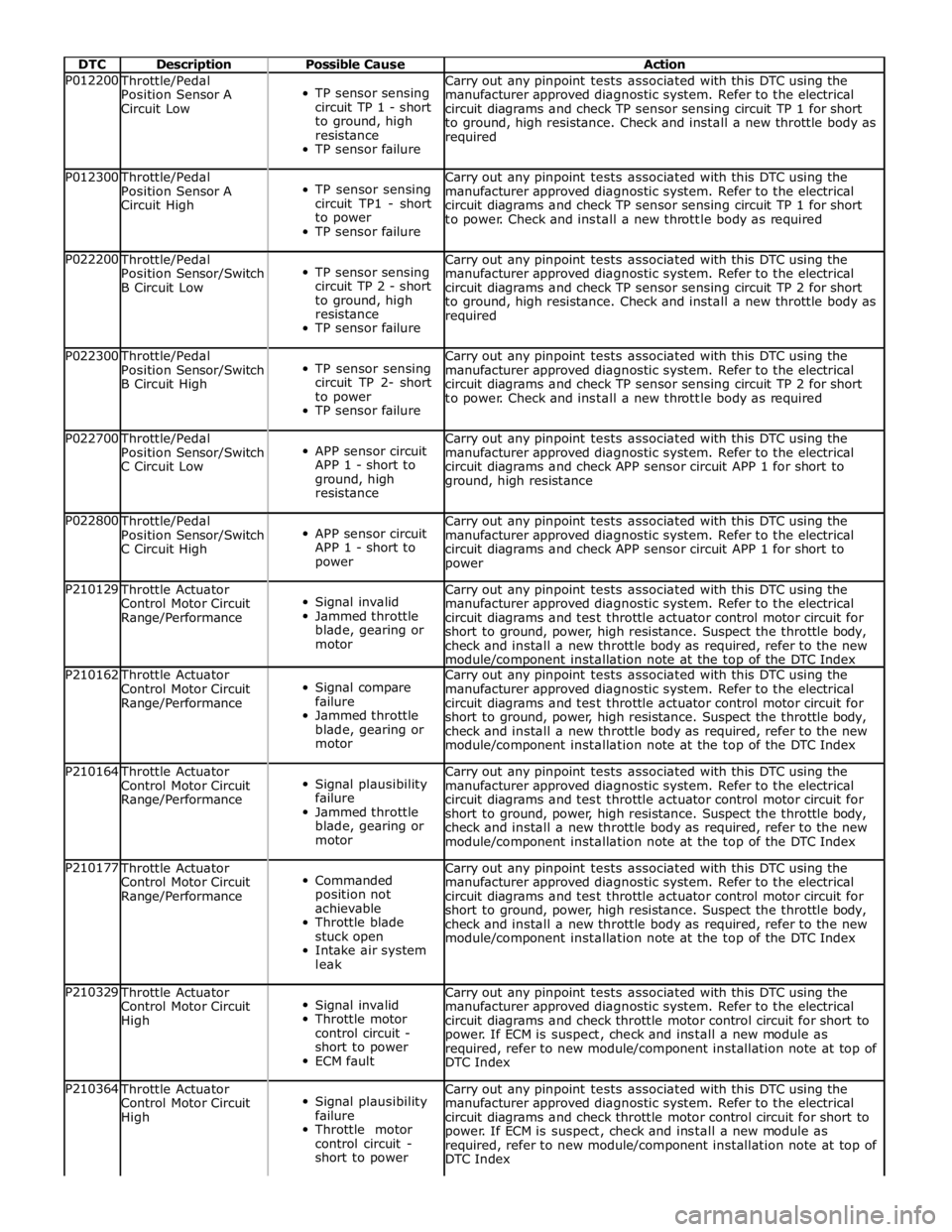

DTC Description Possible Cause Action P012100 Throttle/Pedal

Position Sensor A

Circuit

Range/Performance

TP sensor sensing

circuits TP 1 and TP

2 - short to power,

high resistance

TP sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check TP sensor sensing circuits TP 1 and TP 2

for short to power, high resistance. Check and install a new throttle

body as required www.JagDocs.com

Page 1632 of 3039

DTC Description Possible Cause Action P012200 Throttle/Pedal

Position Sensor A

Circuit Low

TP sensor sensing

circuit TP 1 - short

to ground, high

resistance

TP sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check TP sensor sensing circuit TP 1 for short

to ground, high resistance. Check and install a new throttle body as

required P012300 Throttle/Pedal

Position Sensor A

Circuit High

TP sensor sensing

circuit TP1 - short

to power

TP sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check TP sensor sensing circuit TP 1 for short

to power. Check and install a new throttle body as required P022200 Throttle/Pedal

Position Sensor/Switch

B Circuit Low

TP sensor sensing

circuit TP 2 - short

to ground, high

resistance

TP sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check TP sensor sensing circuit TP 2 for short

to ground, high resistance. Check and install a new throttle body as

required P022300 Throttle/Pedal

Position Sensor/Switch

B Circuit High

TP sensor sensing

circuit TP 2- short

to power

TP sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check TP sensor sensing circuit TP 2 for short

to power. Check and install a new throttle body as required P022700 Throttle/Pedal

Position Sensor/Switch

C Circuit Low

APP sensor circuit

APP 1 - short to

ground, high

resistance Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check APP sensor circuit APP 1 for short to

ground, high resistance P022800 Throttle/Pedal

Position Sensor/Switch

C Circuit High

APP sensor circuit

APP 1 - short to

power Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check APP sensor circuit APP 1 for short to

power P210129 Throttle Actuator

Control Motor Circuit

Range/Performance

Signal invalid

Jammed throttle

blade, gearing or

motor Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and test throttle actuator control motor circuit for

short to ground, power, high resistance. Suspect the throttle body,

check and install a new throttle body as required, refer to the new module/component installation note at the top of the DTC Index P210162 Throttle Actuator

Control Motor Circuit

Range/Performance

Signal compare

failure

Jammed throttle

blade, gearing or

motor Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and test throttle actuator control motor circuit for

short to ground, power, high resistance. Suspect the throttle body,

check and install a new throttle body as required, refer to the new

module/component installation note at the top of the DTC Index P210164 Throttle Actuator

Control Motor Circuit

Range/Performance

Signal plausibility

failure

Jammed throttle

blade, gearing or

motor Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and test throttle actuator control motor circuit for

short to ground, power, high resistance. Suspect the throttle body,

check and install a new throttle body as required, refer to the new

module/component installation note at the top of the DTC Index P210177 Throttle Actuator

Control Motor Circuit

Range/Performance

Commanded

position not

achievable

Throttle blade

stuck open

Intake air system

leak Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and test throttle actuator control motor circuit for

short to ground, power, high resistance. Suspect the throttle body,

check and install a new throttle body as required, refer to the new

module/component installation note at the top of the DTC Index P210329 Throttle Actuator

Control Motor Circuit

High

Signal invalid

Throttle motor

control circuit -

short to power

ECM fault Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check throttle motor control circuit for short to

power. If ECM is suspect, check and install a new module as

required, refer to new module/component installation note at top of

DTC Index P210364 Throttle Actuator

Control Motor Circuit

High

Signal plausibility

failure

Throttle motor

control circuit -

short to power Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check throttle motor control circuit for short to

power. If ECM is suspect, check and install a new module as

required, refer to new module/component installation note at top of

DTC Index

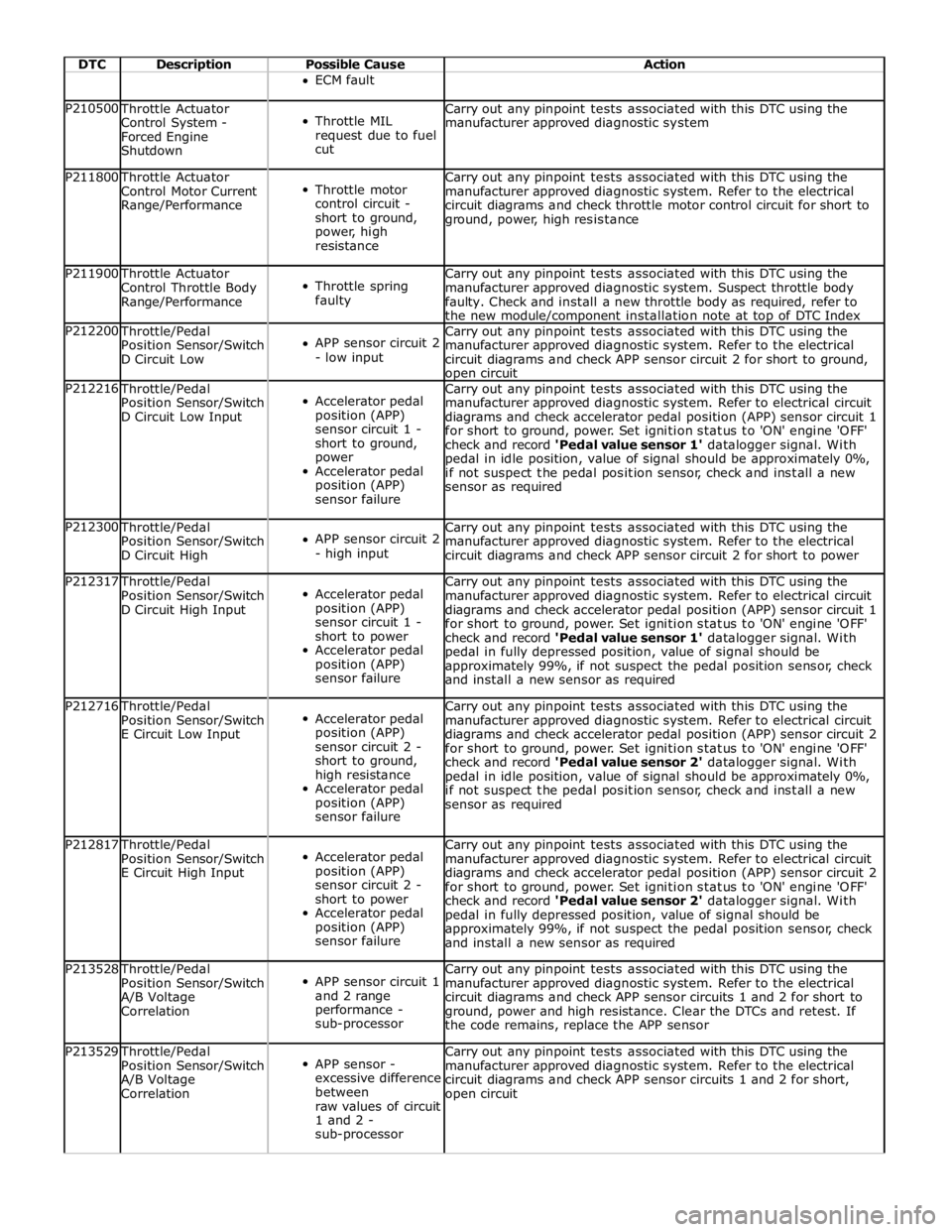

Page 1633 of 3039

DTC Description Possible Cause Action ECM fault

P210500 Throttle Actuator

Control System -

Forced Engine

Shutdown

Throttle MIL

request due to fuel

cut Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system P211800 Throttle Actuator

Control Motor Current

Range/Performance

Throttle motor

control circuit -

short to ground,

power, high

resistance Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check throttle motor control circuit for short to

ground, power, high resistance P211900 Throttle Actuator

Control Throttle Body

Range/Performance

Throttle spring

faulty Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Suspect throttle body

faulty. Check and install a new throttle body as required, refer to

the new module/component installation note at top of DTC Index P212200 Throttle/Pedal

Position Sensor/Switch

D Circuit Low

APP sensor circuit 2

- low input Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check APP sensor circuit 2 for short to ground, open circuit P212216 Throttle/Pedal

Position Sensor/Switch

D Circuit Low Input

Accelerator pedal

position (APP)

sensor circuit 1 -

short to ground,

power

Accelerator pedal

position (APP)

sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to electrical circuit

diagrams and check accelerator pedal position (APP) sensor circuit 1

for short to ground, power. Set ignition status to 'ON' engine 'OFF'

check and record 'Pedal value sensor 1' datalogger signal. With

pedal in idle position, value of signal should be approximately 0%,

if not suspect the pedal position sensor, check and install a new

sensor as required P212300 Throttle/Pedal

Position Sensor/Switch

D Circuit High

APP sensor circuit 2

- high input Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check APP sensor circuit 2 for short to power P212317 Throttle/Pedal

Position Sensor/Switch

D Circuit High Input

Accelerator pedal

position (APP)

sensor circuit 1 -

short to power

Accelerator pedal

position (APP)

sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to electrical circuit

diagrams and check accelerator pedal position (APP) sensor circuit 1

for short to ground, power. Set ignition status to 'ON' engine 'OFF'

check and record 'Pedal value sensor 1' datalogger signal. With

pedal in fully depressed position, value of signal should be

approximately 99%, if not suspect the pedal position sensor, check

and install a new sensor as required P212716 Throttle/Pedal

Position Sensor/Switch

E Circuit Low Input

Accelerator pedal

position (APP)

sensor circuit 2 -

short to ground,

high resistance

Accelerator pedal

position (APP)

sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to electrical circuit

diagrams and check accelerator pedal position (APP) sensor circuit 2

for short to ground, power. Set ignition status to 'ON' engine 'OFF'

check and record 'Pedal value sensor 2' datalogger signal. With

pedal in idle position, value of signal should be approximately 0%,

if not suspect the pedal position sensor, check and install a new

sensor as required P212817 Throttle/Pedal

Position Sensor/Switch

E Circuit High Input

Accelerator pedal

position (APP)

sensor circuit 2 -

short to power

Accelerator pedal

position (APP)

sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to electrical circuit

diagrams and check accelerator pedal position (APP) sensor circuit 2

for short to ground, power. Set ignition status to 'ON' engine 'OFF'

check and record 'Pedal value sensor 2' datalogger signal. With

pedal in fully depressed position, value of signal should be

approximately 99%, if not suspect the pedal position sensor, check

and install a new sensor as required P213528 Throttle/Pedal

Position Sensor/Switch

A/B Voltage

Correlation

APP sensor circuit 1

and 2 range

performance -

sub-processor Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check APP sensor circuits 1 and 2 for short to

ground, power and high resistance. Clear the DTCs and retest. If

the code remains, replace the APP sensor P213529 Throttle/Pedal

Position Sensor/Switch

A/B Voltage

Correlation

APP sensor -

excessive difference

between

raw values of circuit

1 and 2 -

sub-processor Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check APP sensor circuits 1 and 2 for short,

open circuit