authorisation JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2094 of 3039

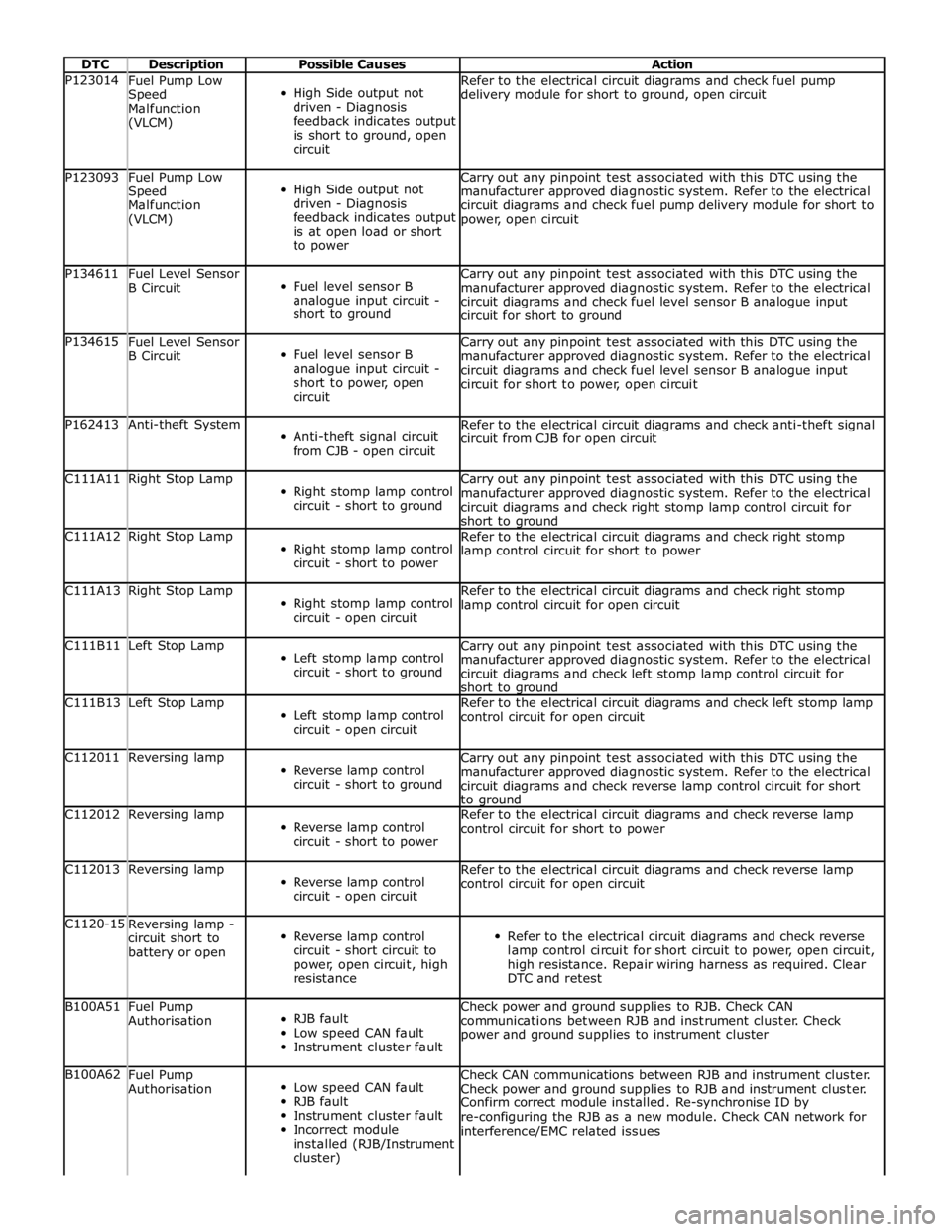

DTC Description Possible Causes Action P123014

Fuel Pump Low

Speed

Malfunction

(VLCM)

High Side output not

driven - Diagnosis

feedback indicates output

is short to ground, open

circuit Refer to the electrical circuit diagrams and check fuel pump

delivery module for short to ground, open circuit P123093

Fuel Pump Low

Speed

Malfunction

(VLCM)

High Side output not

driven - Diagnosis

feedback indicates output

is at open load or short

to power Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check fuel pump delivery module for short to

power, open circuit P134611

Fuel Level Sensor

B Circuit

Fuel level sensor B

analogue input circuit -

short to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check fuel level sensor B analogue input

circuit for short to ground P134615

Fuel Level Sensor

B Circuit

Fuel level sensor B

analogue input circuit -

short to power, open

circuit Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check fuel level sensor B analogue input

circuit for short to power, open circuit P162413 Anti-theft System

Anti-theft signal circuit

from CJB - open circuit Refer to the electrical circuit diagrams and check anti-theft signal

circuit from CJB for open circuit C111A11 Right Stop Lamp

Right stomp lamp control

circuit - short to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check right stomp lamp control circuit for

short to ground C111A12 Right Stop Lamp

Right stomp lamp control

circuit - short to power Refer to the electrical circuit diagrams and check right stomp

lamp control circuit for short to power C111A13 Right Stop Lamp

Right stomp lamp control

circuit - open circuit Refer to the electrical circuit diagrams and check right stomp

lamp control circuit for open circuit C111B11 Left Stop Lamp

Left stomp lamp control

circuit - short to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check left stomp lamp control circuit for

short to ground C111B13 Left Stop Lamp

Left stomp lamp control

circuit - open circuit Refer to the electrical circuit diagrams and check left stomp lamp

control circuit for open circuit C112011 Reversing lamp

Reverse lamp control

circuit - short to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check reverse lamp control circuit for short

to ground C112012 Reversing lamp

Reverse lamp control

circuit - short to power Refer to the electrical circuit diagrams and check reverse lamp

control circuit for short to power C112013 Reversing lamp

Reverse lamp control

circuit - open circuit Refer to the electrical circuit diagrams and check reverse lamp

control circuit for open circuit C1120-15

Reversing lamp -

circuit short to

battery or open

Reverse lamp control

circuit - short circuit to

power, open circuit, high

resistance

Refer to the electrical circuit diagrams and check reverse

lamp control circuit for short circuit to power, open circuit,

high resistance. Repair wiring harness as required. Clear

DTC and retest B100A51

Fuel Pump

Authorisation

RJB fault

Low speed CAN fault

Instrument cluster fault Check power and ground supplies to RJB. Check CAN

communications between RJB and instrument cluster. Check

power and ground supplies to instrument cluster B100A62

Fuel Pump

Authorisation

Low speed CAN fault

RJB fault

Instrument cluster fault

Incorrect module

installed (RJB/Instrument

cluster) Check CAN communications between RJB and instrument cluster.

Check power and ground supplies to RJB and instrument cluster.

Confirm correct module installed. Re-synchronise ID by

re-configuring the RJB as a new module. Check CAN network for

interference/EMC related issues

Page 2095 of 3039

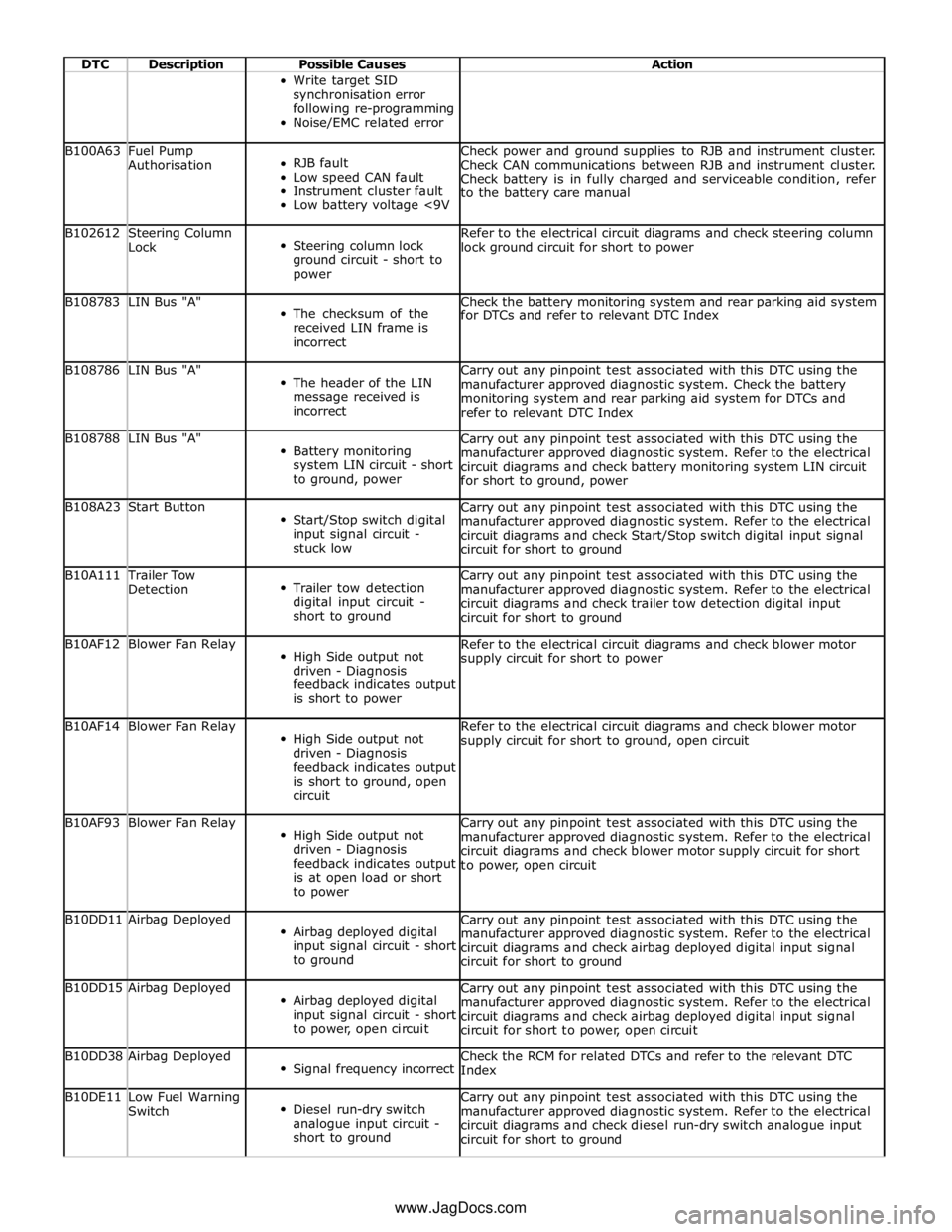

DTC Description Possible Causes Action Write target SID

synchronisation error

following re-programming

Noise/EMC related error B100A63

Fuel Pump

Authorisation

RJB fault

Low speed CAN fault

Instrument cluster fault

Low battery voltage <9V Check power and ground supplies to RJB and instrument cluster.

Check CAN communications between RJB and instrument cluster.

Check battery is in fully charged and serviceable condition, refer

to the battery care manual B102612

Steering Column

Lock

Steering column lock

ground circuit - short to

power Refer to the electrical circuit diagrams and check steering column

lock ground circuit for short to power B108783 LIN Bus "A"

The checksum of the

received LIN frame is

incorrect Check the battery monitoring system and rear parking aid system

for DTCs and refer to relevant DTC Index B108786 LIN Bus "A"

The header of the LIN

message received is

incorrect Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Check the battery

monitoring system and rear parking aid system for DTCs and

refer to relevant DTC Index B108788 LIN Bus "A"

Battery monitoring

system LIN circuit - short

to ground, power Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check battery monitoring system LIN circuit

for short to ground, power B108A23 Start Button

Start/Stop switch digital

input signal circuit -

stuck low Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check Start/Stop switch digital input signal

circuit for short to ground B10A111 Trailer Tow

Detection

Trailer tow detection

digital input circuit -

short to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check trailer tow detection digital input

circuit for short to ground B10AF12 Blower Fan Relay

High Side output not

driven - Diagnosis

feedback indicates output

is short to power Refer to the electrical circuit diagrams and check blower motor

supply circuit for short to power B10AF14 Blower Fan Relay

High Side output not

driven - Diagnosis

feedback indicates output

is short to ground, open

circuit Refer to the electrical circuit diagrams and check blower motor

supply circuit for short to ground, open circuit B10AF93 Blower Fan Relay

High Side output not

driven - Diagnosis

feedback indicates output

is at open load or short

to power Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check blower motor supply circuit for short

to power, open circuit B10DD11 Airbag Deployed

Airbag deployed digital

input signal circuit - short

to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check airbag deployed digital input signal

circuit for short to ground B10DD15 Airbag Deployed

Airbag deployed digital

input signal circuit - short

to power, open circuit Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check airbag deployed digital input signal

circuit for short to power, open circuit B10DD38 Airbag Deployed

Signal frequency incorrect Check the RCM for related DTCs and refer to the relevant DTC

Index B10DE11

Low Fuel Warning

Switch

Diesel run-dry switch

analogue input circuit -

short to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check diesel run-dry switch analogue input

circuit for short to ground www.JagDocs.com

Page 2146 of 3039

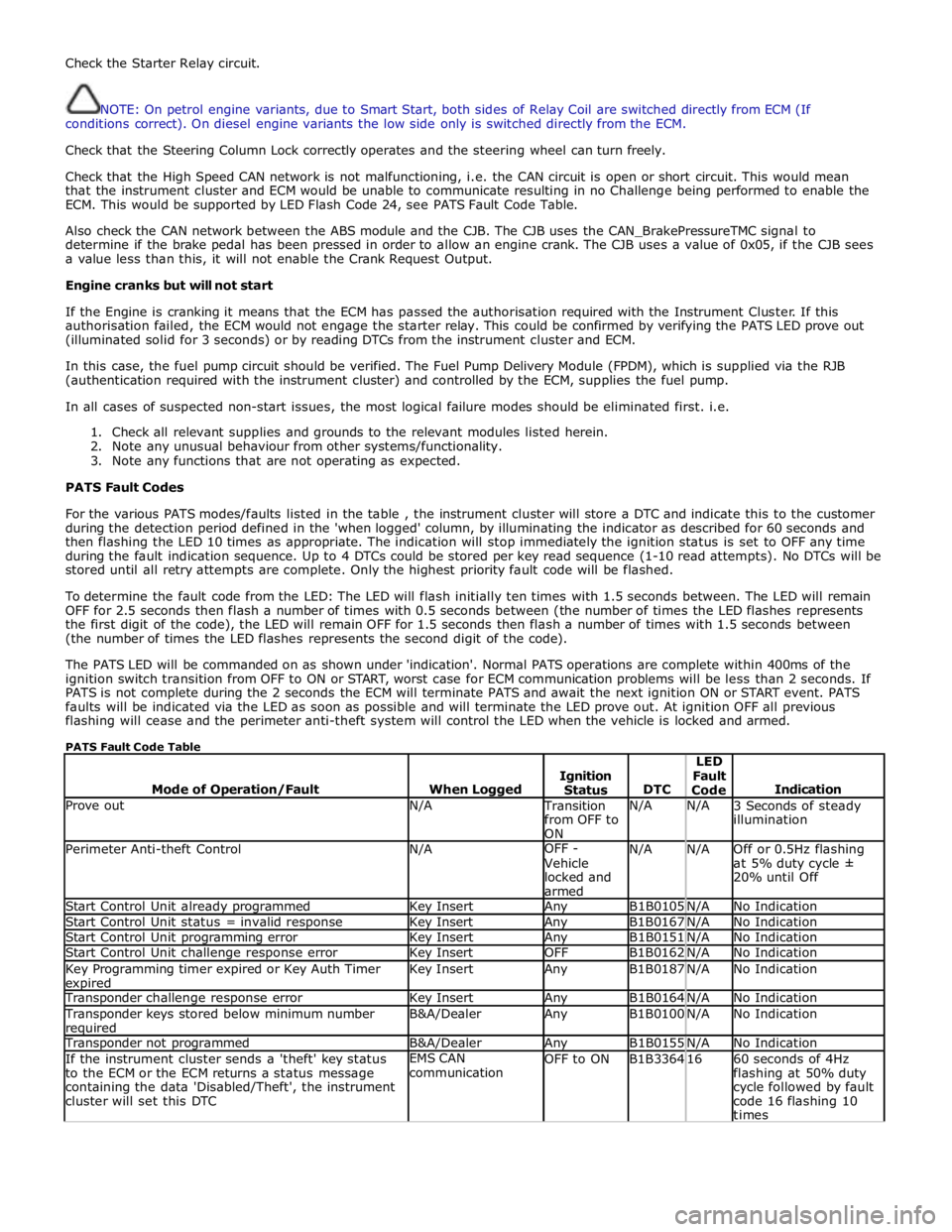

Check the Starter Relay circuit.

NOTE: On petrol engine variants, due to Smart Start, both sides of Relay Coil are switched directly from ECM (If

conditions correct). On diesel engine variants the low side only is switched directly from the ECM.

Check that the Steering Column Lock correctly operates and the steering wheel can turn freely.

Check that the High Speed CAN network is not malfunctioning, i.e. the CAN circuit is open or short circuit. This would mean

that the instrument cluster and ECM would be unable to communicate resulting in no Challenge being performed to enable the

ECM. This would be supported by LED Flash Code 24, see PATS Fault Code Table.

Also check the CAN network between the ABS module and the CJB. The CJB uses the CAN_BrakePressureTMC signal to

determine if the brake pedal has been pressed in order to allow an engine crank. The CJB uses a value of 0x05, if the CJB sees

a value less than this, it will not enable the Crank Request Output.

Engine cranks but will not start

If the Engine is cranking it means that the ECM has passed the authorisation required with the Instrument Cluster. If this

authorisation failed, the ECM would not engage the starter relay. This could be confirmed by verifying the PATS LED prove out

(illuminated solid for 3 seconds) or by reading DTCs from the instrument cluster and ECM.

In this case, the fuel pump circuit should be verified. The Fuel Pump Delivery Module (FPDM), which is supplied via the RJB

(authentication required with the instrument cluster) and controlled by the ECM, supplies the fuel pump.

In all cases of suspected non-start issues, the most logical failure modes should be eliminated first. i.e.

1. Check all relevant supplies and grounds to the relevant modules listed herein.

2. Note any unusual behaviour from other systems/functionality.

3. Note any functions that are not operating as expected.

PATS Fault Codes

For the various PATS modes/faults listed in the table , the instrument cluster will store a DTC and indicate this to the customer

during the detection period defined in the 'when logged' column, by illuminating the indicator as described for 60 seconds and

then flashing the LED 10 times as appropriate. The indication will stop immediately the ignition status is set to OFF any time

during the fault indication sequence. Up to 4 DTCs could be stored per key read sequence (1-10 read attempts). No DTCs will be

stored until all retry attempts are complete. Only the highest priority fault code will be flashed.

To determine the fault code from the LED: The LED will flash initially ten times with 1.5 seconds between. The LED will remain

OFF for 2.5 seconds then flash a number of times with 0.5 seconds between (the number of times the LED flashes represents

the first digit of the code), the LED will remain OFF for 1.5 seconds then flash a number of times with 1.5 seconds between

(the number of times the LED flashes represents the second digit of the code).

The PATS LED will be commanded on as shown under 'indication'. Normal PATS operations are complete within 400ms of the

ignition switch transition from OFF to ON or START, worst case for ECM communication problems will be less than 2 seconds. If

PATS is not complete during the 2 seconds the ECM will terminate PATS and await the next ignition ON or START event. PATS

faults will be indicated via the LED as soon as possible and will terminate the LED prove out. At ignition OFF all previous

flashing will cease and the perimeter anti-theft system will control the LED when the vehicle is locked and armed.

PATS Fault Code Table

Mode of Operation/Fault

When Logged

Ignition

Status

DTC LED

Fault

Code

Indication Prove out N/A Transition

from OFF to

ON N/A N/A

3 Seconds of steady

illumination Perimeter Anti-theft Control N/A OFF -

Vehicle

locked and

armed N/A N/A

Off or 0.5Hz flashing

at 5% duty cycle ±

20% until Off Start Control Unit already programmed Key Insert Any B1B0105 N/A No Indication Start Control Unit status = invalid response Key Insert Any B1B0167 N/A No Indication Start Control Unit programming error Key Insert Any B1B0151 N/A No Indication Start Control Unit challenge response error Key Insert OFF B1B0162 N/A No Indication Key Programming timer expired or Key Auth Timer expired Key Insert Any B1B0187 N/A No Indication Transponder challenge response error Key Insert Any B1B0164 N/A No Indication Transponder keys stored below minimum number required B&A/Dealer Any B1B0100 N/A No Indication Transponder not programmed B&A/Dealer Any B1B0155 N/A No Indication If the instrument cluster sends a 'theft' key status

to the ECM or the ECM returns a status message

containing the data 'Disabled/Theft', the instrument

cluster will set this DTC EMS CAN

communication OFF to ON B1B3364 16

60 seconds of 4Hz

flashing at 50% duty

cycle followed by fault

code 16 flashing 10

times