steering wheel JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 309 of 3039

Removal and Installation),

Shock Absorber and Spring Assembly (204-02 Rear Suspension, Removal and Installation). Incorrect Tire Wear

* Incorrect tire pressure (rapid center rib

or inner and outer edge wear). * Check and adjust the tire pressure. Inspect the tire for

excessive wear.

REFER to: Specifications (204-04 Wheels and Tires, Specifications). * Excessive front or rear toe (rapid inner

or outer edge wear). * Check and adjust the wheel alignment. REFER to:

(204-00 Suspension System - General Information)

Front Toe Adjustment (General Procedures), Rear Toe Adjustment (General Procedures), Camber and Caster Adjustment (General Procedures). * Excessive negative or positive camber

(rapid inner or outer edge wear). * Check and adjust the wheel alignment. REFER to:

(204-00 Suspension System - General Information)

Front Toe Adjustment (General Procedures), Rear Toe Adjustment (General Procedures), Camber and Caster Adjustment (General Procedures). * Tires out of balance (tires cupped or dished). * Balance the tires. Rough ride * Spring(s)

* Check and install new spring(s) as necessary. REFER to:

Front Shock Absorber (204-01 Front Suspension, Removal and Installation),

Shock Absorber and Spring Assembly (204-02 Rear Suspension, Removal and Installation). Shimmy or Wheel Tramp * Loose wheel nut(s).

* Check and tighten the wheel nuts to specification.

REFER to: Specifications (204-04 Wheels and Tires, Specifications). * Loose front suspension fasteners.

* Check and tighten the suspension fasteners to

specification.

REFER to: Specifications (204-00 Suspension System - General Information, Specifications). * Front wheel bearing(s). * Check the wheel bearings. * Worn or damaged suspension component bushing. * Check and install new components as necessary. * Wheel/tires.

* Check the wheels/tires. Balance or install new

wheel/tires as necessary.

REFER to: Wheels and Tires (204-04 Wheels and Tires, Diagnosis and Testing). * Loose, worn or damaged ball joint(s). * Check the Ball Joint(s). * Loose, worn or damaged steering components. * Check and install new components as necessary. * Front wheel alignment.

* Check and adjust the wheel alignment. REFER to:

(204-00 Suspension System - General Information)

Front Toe Adjustment (General Procedures), Rear Toe Adjustment (General Procedures), Camber and Caster Adjustment (General Procedures). * Shock absorber(s). * Check and install new shock absorber(s) as necessary.

REFER to:

Front Shock Absorber (204-01 Front Suspension, Removal and Installation),

Shock Absorber and Spring Assembly (204-02 Rear Suspension, Removal and Installation). * Spring(s).

* Check and install new springs as necessary. REFER to:

Front Shock Absorber (204-01 Front Suspension, Removal and Installation),

Shock Absorber and Spring Assembly (204-02 Rear Suspension, Removal and Installation). Poor self center action of

the steering * Ball joints. * Check the Ball Joints. * Steering components. * Check and install new components as necessary. Steering wheel off-center * Unequal front or rear toe settings.

* Check and adjust the wheel alignment. REFER to:

(204-00 Suspension System - General Information)

Front Toe Adjustment (General Procedures), Rear Toe Adjustment (General Procedures), Camber and Caster Adjustment (General Procedures). * Steering components. * Check and install new components as necessary. Sway or roll

* Overloaded, unevenly or incorrectly

loaded vehicle. * Notify the customer of incorrect vehicle loading. * Loose wheel nut(s).

* Check and tighten the wheel nut(s) to specification.

REFER to: Specifications (204-04 Wheels and Tires, Specifications). * Coil spring(s).

* Check and install new coil springs as necessary. REFER

to:

Front Shock Absorber (204-01 Front Suspension, Removal and Installation),

Page 310 of 3039

Shock Absorber and Spring Assembly (204-02 Rear Suspension, Removal and Installation). * Loose front stabilizer bar or rear

stabilizer bar. * Check and tighten the stabilizer bar to specification.

REFER to:

Specifications (204-01 Front Suspension, Specifications), Specifications (204-02 Rear Suspension, Specifications). * Worn lower suspension arm stabilizer

bar insulators. * Install new lower suspension arm stabilizer bar as

necessary. REFER to:

Front Stabilizer Bar - 2.7L Diesel (204-01, Removal and

Installation),

Front Stabilizer Bar - V6 3.0L Petrol (204-01 Front Suspension, Removal and Installation),

Front Stabilizer Bar - 4.2L (204-01, Removal and

Installation),

Rear Stabilizer Bar (204-02 Rear Suspension, Removal and Installation). * Shock absorber(s). * Check and install new shock absorber(s) as necessary.

REFER to:

Front Shock Absorber (204-01 Front Suspension, Removal and Installation),

Shock Absorber and Spring Assembly (204-02 Rear Suspension, Removal and Installation). Vehicle Leans to One

Side * Unevenly loaded or overloaded vehicle. * Notify the customer of incorrect vehicle loading. * Front or rear suspension components.

* Inspect the front and rear suspension systems. Repair or

install new suspension components as necessary. * Shock absorber(s). * Check and install new shock absorber(s) as necessary.

REFER to:

Front Shock Absorber (204-01 Front Suspension, Removal and Installation),

Shock Absorber and Spring Assembly (204-02 Rear Suspension, Removal and Installation). * Coil spring(s).

* Check and install new spring(s) as necessary. REFER to:

Front Shock Absorber (204-01 Front Suspension, Removal and Installation),

Shock Absorber and Spring Assembly (204-02 Rear Suspension, Removal and Installation). * Incorrect ride height. Lateral tilt out of

specification. * Check the ride height. Install new spring(s) as

necessary. REFER to:

Front Shock Absorber (204-01 Front Suspension, Removal and Installation),

Shock Absorber and Spring Assembly (204-02 Rear Suspension, Removal and Installation). Vibration/Noise * Tires/wheels.

* Wheel bearings.

* Wheel hubs.

* Brake components.

* Suspension components.

* Steering components. * Check and install new components as necessary. Wander * Unevenly loaded or overloaded vehicle. * Notify the customer of incorrect vehicle loading. * Ball joint(s). * Check the Ball Joint(s). * Front wheel bearing(s). * Check the wheel bearings. * Loose, worn or damaged suspension components. * Check and install new suspension components as necessary. * Loose suspension fasteners.

* Check and tighten the suspension fasteners to

specification.

REFER to: Specifications (204-00 Suspension System - General Information, Specifications). * Steering components. * Check and install new steering components. * Wheel alignment (excessive total front

toe-out). * Check and adjust the wheel alignment. REFER to:

(204-00 Suspension System - General Information)

Front Toe Adjustment (General Procedures), Rear Toe Adjustment (General Procedures), Camber and Caster Adjustment (General Procedures). Component Tests

Ball Joint Inspection

NOTE: The front suspension is shown in the following procedures. The inspection of the rear suspension upper ball joint

is similar.

1. Raise and support the vehicle. REFER to: (100-02 Jacking and Lifting)

Jacking (Description and Operation), Lifting (Description and Operation).

2. Prior to carrying out any inspection of the ball joints, inspect the front wheel bearings.

Page 317 of 3039

Published: 16-Oct-2013

Suspension System - General Information - Four-Wheel Alignment

General Procedures

CAUTIONS:

Make sure the vehicle is on a flat level surface.

Make sure the tire pressures are within specification.

Make sure that only the manufacturers' recommended four wheel alignment equipment is used.

Make sure the steering is in the straight ahead position.

1. For wheel alignment information, refer to the suspension specification

section.

For additional information, refer to: Specifications (204-00 Suspension System - General Information, Specifications).

2. Check the tie rod ends, suspension joints, wheel bearings and wheels

and tires for damage, wear and free play.

Adjust or repair any worn, damaged or incorrectly adjusted

components.

3. Check and adjust tire pressures.

4. Position the vehicle on a calibrated, level, vehicle lift.

5. Vehicles with air suspension.

For additional information, refer to: Air Suspension Manual Tight

Tolerance Setting Mode (204-05, General Procedures).

6. Release the vehicle parking brake.

7. Using only four-wheel alignment equipment approved by Jaguar, check

the wheel alignment.

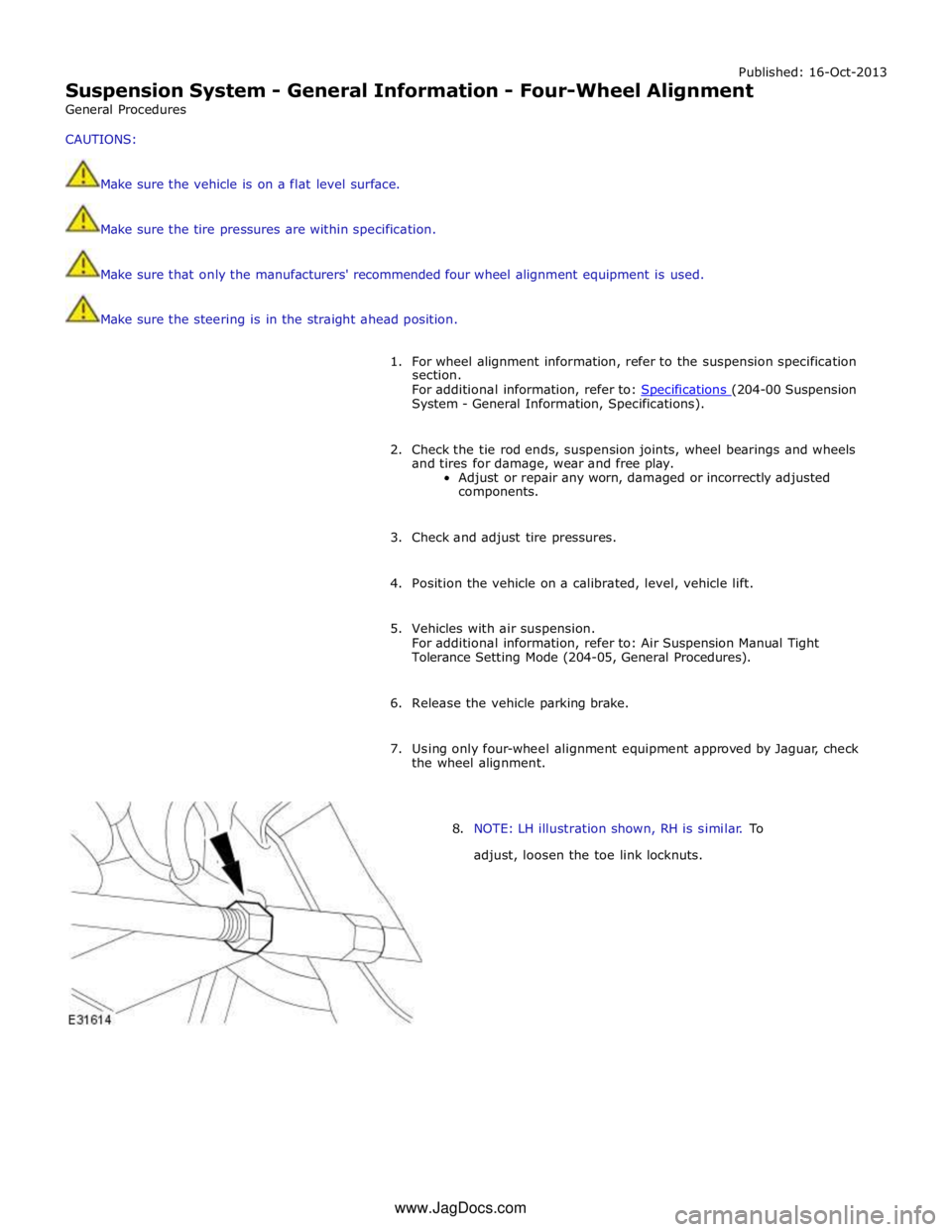

8. NOTE: LH illustration shown, RH is similar. To

adjust, loosen the toe link locknuts. www.JagDocs.com

Page 321 of 3039

Published: 16-Oct-2013

Suspension System - General Information - Front Toe Adjustment

General Procedures

CAUTIONS:

Make sure the vehicle is on a flat level surface.

Make sure the tire pressures are within specification.

Make sure that only the manufacturers' recommended four wheel alignment equipment is used.

Make sure the steering is in the straight ahead position.

1. For wheel alignment information, refer to the suspension specification

section.

For additional information, refer to: Specifications (204-00 Suspension System - General Information, Specifications).

2. Check the tie rod ends, suspension joints, wheel bearings and wheels

and tires for damage, wear and free play.

Adjust or repair any worn, damaged or incorrectly adjusted

components.

3. Check and adjust tire pressures.

4. Position the vehicle on a 4 post lift.

5. Release the vehicle parking brake.

6. Vehicles with air suspension.

For additional information, refer to: Air Suspension Manual Tight

Tolerance Setting Mode (204-05, General Procedures).

7. For additional information, refer to: Air Suspension Manual Tight

Tolerance Setting Mode (204-05, General Procedures).

8. Using only four-wheel alignment equipment approved by Jaguar, check

the wheel alignment.

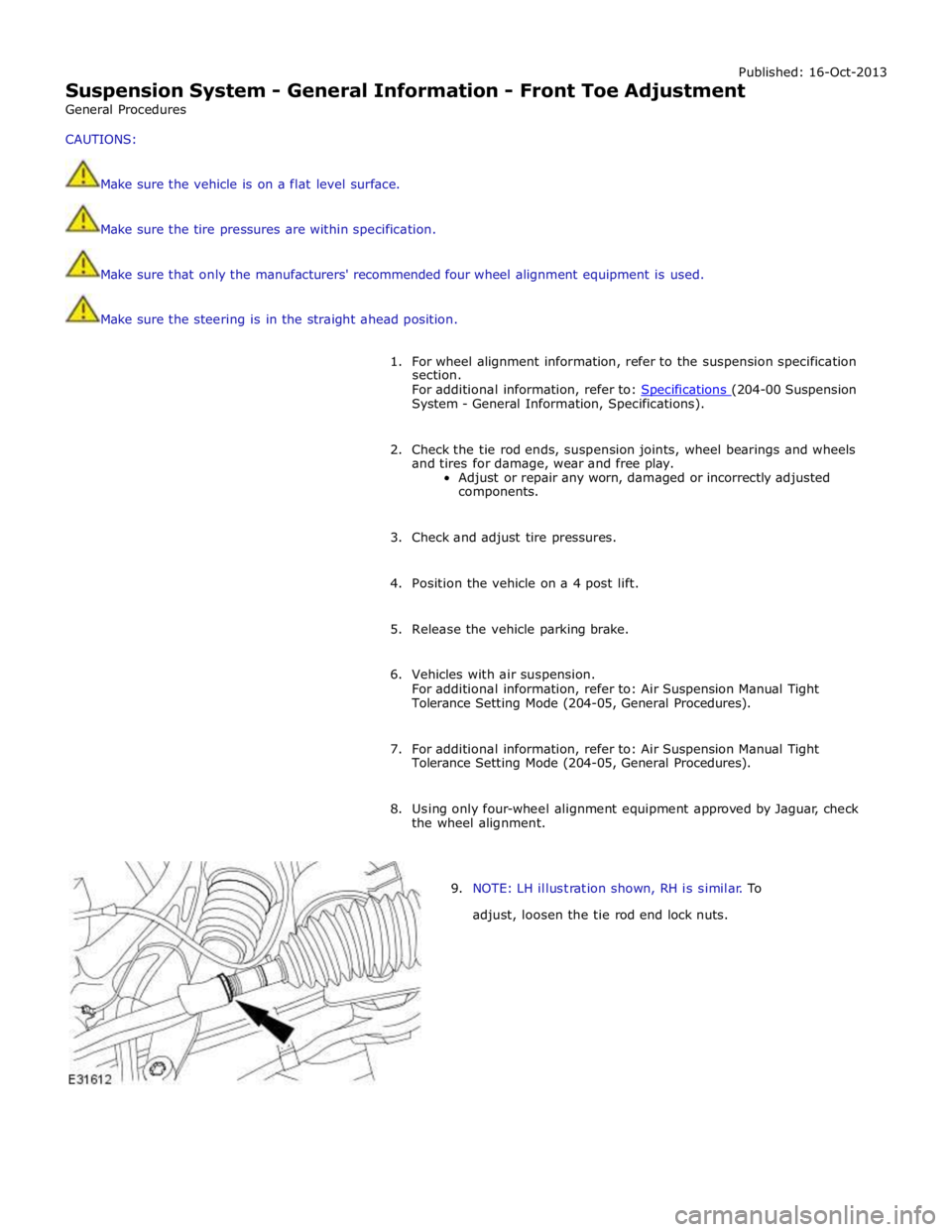

9. NOTE: LH illustration shown, RH is similar. To

adjust, loosen the tie rod end lock nuts.

Page 328 of 3039

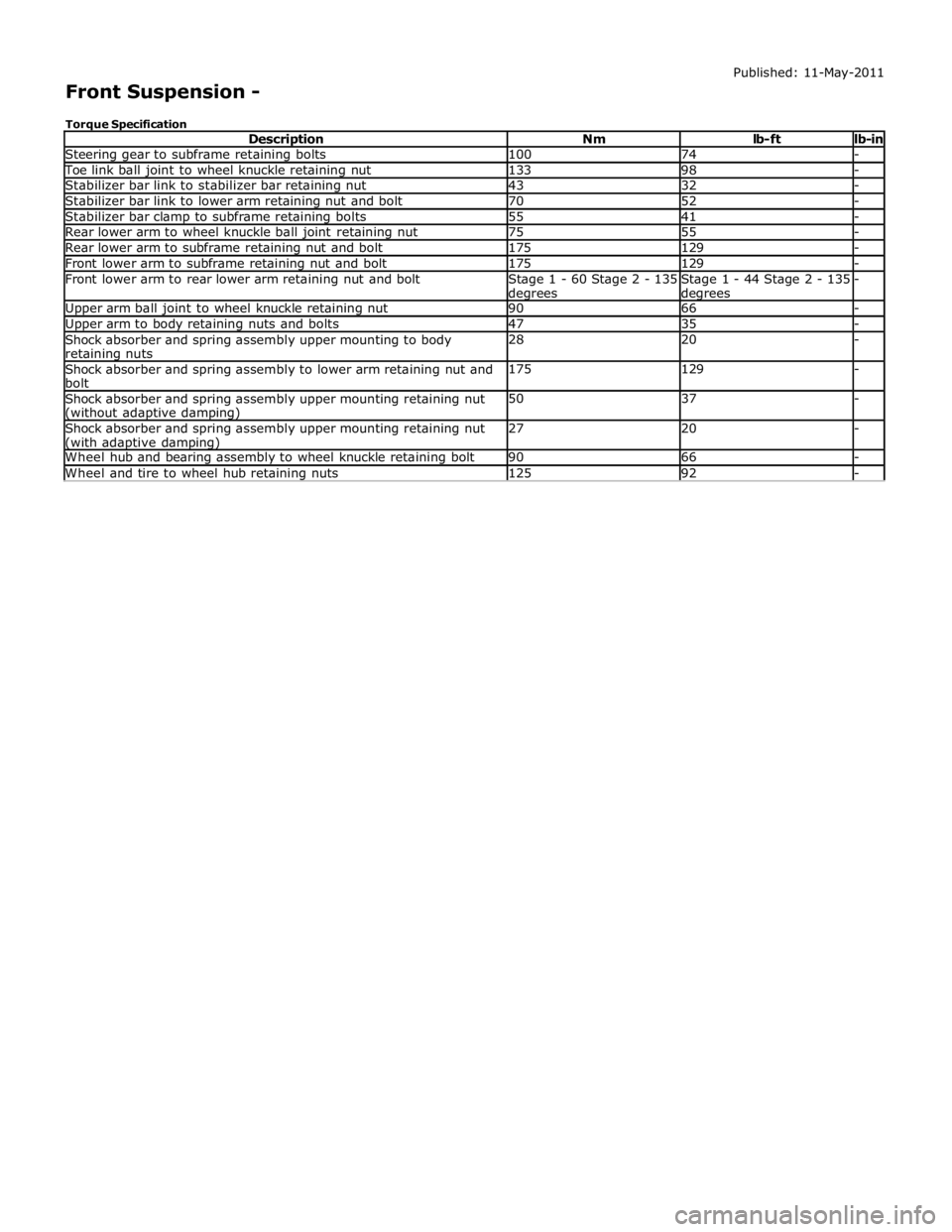

Steering gear to subframe retaining bolts 100 74 - Toe link ball joint to wheel knuckle retaining nut 133 98 - Stabilizer bar link to stabilizer bar retaining nut 43 32 - Stabilizer bar link to lower arm retaining nut and bolt 70 52 - Stabilizer bar clamp to subframe retaining bolts 55 41 - Rear lower arm to wheel knuckle ball joint retaining nut 75 55 - Rear lower arm to subframe retaining nut and bolt 175 129 - Front lower arm to subframe retaining nut and bolt 175 129 - Front lower arm to rear lower arm retaining nut and bolt

Stage 1 - 60 Stage 2 - 135 degrees Stage 1 - 44 Stage 2 - 135 degrees - Upper arm ball joint to wheel knuckle retaining nut 90 66 - Upper arm to body retaining nuts and bolts 47 35 - Shock absorber and spring assembly upper mounting to body retaining nuts 28 20 - Shock absorber and spring assembly to lower arm retaining nut and

bolt 175 129 - Shock absorber and spring assembly upper mounting retaining nut (without adaptive damping) 50 37 - Shock absorber and spring assembly upper mounting retaining nut (with adaptive damping) 27 20 - Wheel hub and bearing assembly to wheel knuckle retaining bolt 90 66 - Wheel and tire to wheel hub retaining nuts 125 92 -

Page 332 of 3039

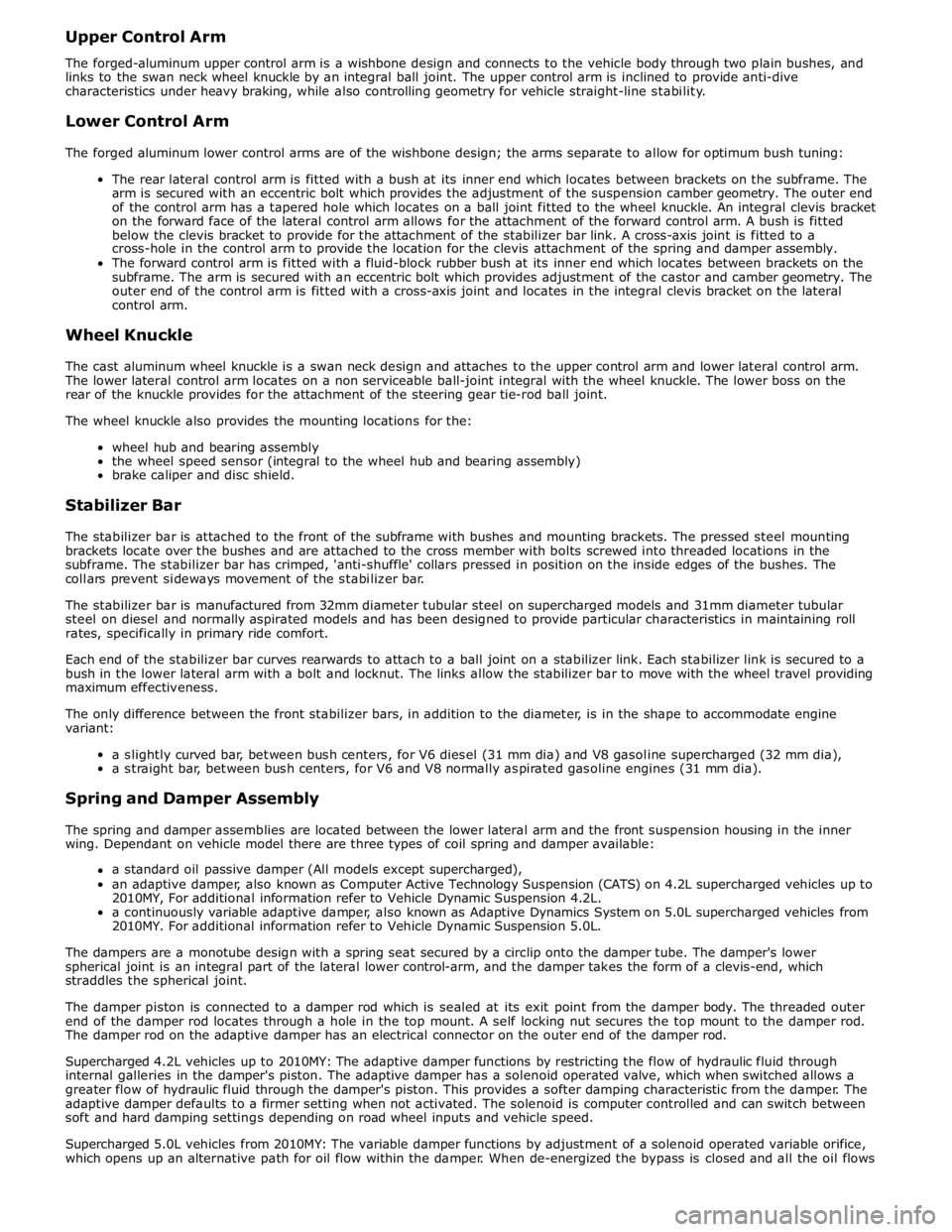

Upper Control Arm

The forged-aluminum upper control arm is a wishbone design and connects to the vehicle body through two plain bushes, and

links to the swan neck wheel knuckle by an integral ball joint. The upper control arm is inclined to provide anti-dive

characteristics under heavy braking, while also controlling geometry for vehicle straight-line stability.

Lower Control Arm

The forged aluminum lower control arms are of the wishbone design; the arms separate to allow for optimum bush tuning:

The rear lateral control arm is fitted with a bush at its inner end which locates between brackets on the subframe. The

arm is secured with an eccentric bolt which provides the adjustment of the suspension camber geometry. The outer end

of the control arm has a tapered hole which locates on a ball joint fitted to the wheel knuckle. An integral clevis bracket

on the forward face of the lateral control arm allows for the attachment of the forward control arm. A bush is fitted

below the clevis bracket to provide for the attachment of the stabilizer bar link. A cross-axis joint is fitted to a

cross-hole in the control arm to provide the location for the clevis attachment of the spring and damper assembly.

The forward control arm is fitted with a fluid-block rubber bush at its inner end which locates between brackets on the

subframe. The arm is secured with an eccentric bolt which provides adjustment of the castor and camber geometry. The

outer end of the control arm is fitted with a cross-axis joint and locates in the integral clevis bracket on the lateral

control arm.

Wheel Knuckle

The cast aluminum wheel knuckle is a swan neck design and attaches to the upper control arm and lower lateral control arm.

The lower lateral control arm locates on a non serviceable ball-joint integral with the wheel knuckle. The lower boss on the

rear of the knuckle provides for the attachment of the steering gear tie-rod ball joint.

The wheel knuckle also provides the mounting locations for the:

wheel hub and bearing assembly

the wheel speed sensor (integral to the wheel hub and bearing assembly)

brake caliper and disc shield.

Stabilizer Bar

The stabilizer bar is attached to the front of the subframe with bushes and mounting brackets. The pressed steel mounting

brackets locate over the bushes and are attached to the cross member with bolts screwed into threaded locations in the

subframe. The stabilizer bar has crimped, 'anti-shuffle' collars pressed in position on the inside edges of the bushes. The

collars prevent sideways movement of the stabilizer bar.

The stabilizer bar is manufactured from 32mm diameter tubular steel on supercharged models and 31mm diameter tubular

steel on diesel and normally aspirated models and has been designed to provide particular characteristics in maintaining roll

rates, specifically in primary ride comfort.

Each end of the stabilizer bar curves rearwards to attach to a ball joint on a stabilizer link. Each stabilizer link is secured to a

bush in the lower lateral arm with a bolt and locknut. The links allow the stabilizer bar to move with the wheel travel providing

maximum effectiveness.

The only difference between the front stabilizer bars, in addition to the diameter, is in the shape to accommodate engine

variant:

a slightly curved bar, between bush centers, for V6 diesel (31 mm dia) and V8 gasoline supercharged (32 mm dia),

a straight bar, between bush centers, for V6 and V8 normally aspirated gasoline engines (31 mm dia).

Spring and Damper Assembly

The spring and damper assemblies are located between the lower lateral arm and the front suspension housing in the inner

wing. Dependant on vehicle model there are three types of coil spring and damper available:

a standard oil passive damper (All models except supercharged),

an adaptive damper, also known as Computer Active Technology Suspension (CATS) on 4.2L supercharged vehicles up to

2010MY, For additional information refer to Vehicle Dynamic Suspension 4.2L.

a continuously variable adaptive damper, also known as Adaptive Dynamics System on 5.0L supercharged vehicles from

2010MY. For additional information refer to Vehicle Dynamic Suspension 5.0L.

The dampers are a monotube design with a spring seat secured by a circlip onto the damper tube. The damper's lower

spherical joint is an integral part of the lateral lower control-arm, and the damper takes the form of a clevis-end, which

straddles the spherical joint.

The damper piston is connected to a damper rod which is sealed at its exit point from the damper body. The threaded outer

end of the damper rod locates through a hole in the top mount. A self locking nut secures the top mount to the damper rod.

The damper rod on the adaptive damper has an electrical connector on the outer end of the damper rod.

Supercharged 4.2L vehicles up to 2010MY: The adaptive damper functions by restricting the flow of hydraulic fluid through

internal galleries in the damper's piston. The adaptive damper has a solenoid operated valve, which when switched allows a

greater flow of hydraulic fluid through the damper's piston. This provides a softer damping characteristic from the damper. The

adaptive damper defaults to a firmer setting when not activated. The solenoid is computer controlled and can switch between

soft and hard damping settings depending on road wheel inputs and vehicle speed.

Supercharged 5.0L vehicles from 2010MY: The variable damper functions by adjustment of a solenoid operated variable orifice,

which opens up an alternative path for oil flow within the damper. When de-energized the bypass is closed and all the oil flows

Page 349 of 3039

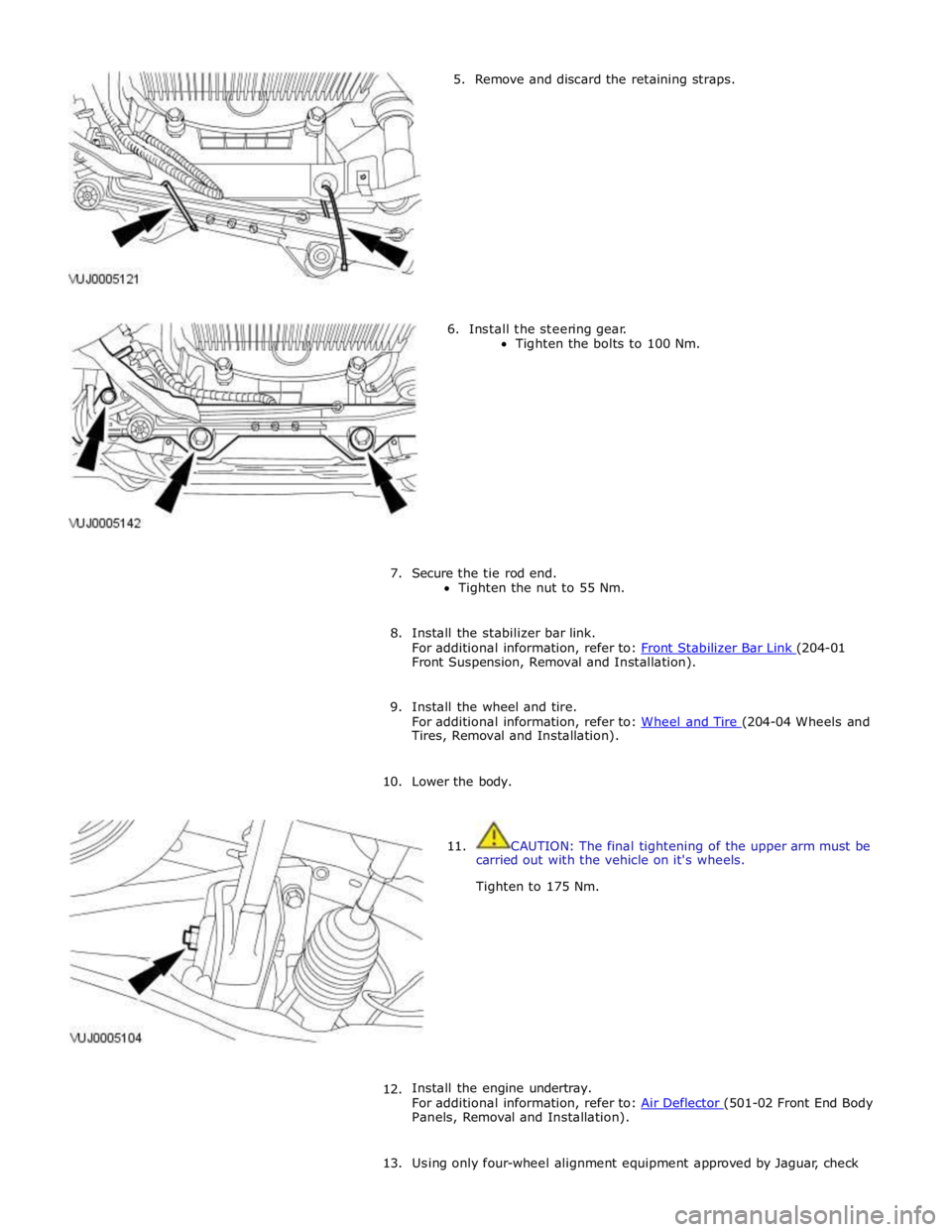

5. Remove and discard the retaining straps.

6. Install the steering gear.

Tighten the bolts to 100 Nm.

7. Secure the tie rod end.

Tighten the nut to 55 Nm.

8. Install the stabilizer bar link.

For additional information, refer to: Front Stabilizer Bar Link (204-01 Front Suspension, Removal and Installation).

9. Install the wheel and tire.

For additional information, refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

10. Lower the body.

11. CAUTION: The final tightening of the upper arm must be

carried out with the vehicle on it's wheels.

Tighten to 175 Nm.

12.

Install the engine undertray.

For additional information, refer to: Air Deflector (501-02 Front End Body Panels, Removal and Installation).

13. Using only four-wheel alignment equipment approved by Jaguar, check

Page 376 of 3039

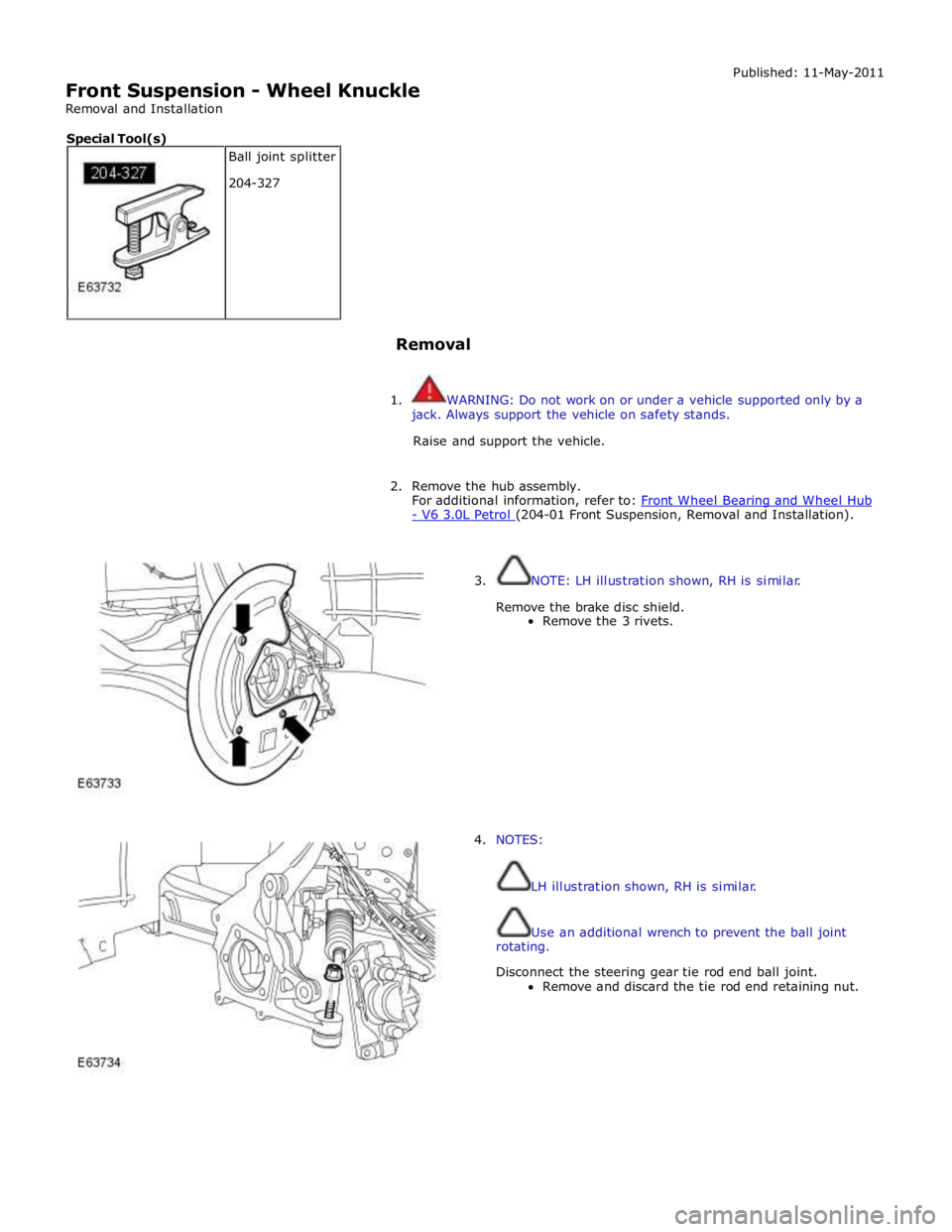

Front Suspension - Wheel Knuckle

Removal and Installation Published: 11-May-2011

Removal

1. WARNING: Do not work on or under a vehicle supported only by a

jack. Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Remove the hub assembly.

For additional information, refer to: Front Wheel Bearing and Wheel Hub - V6 3.0L Petrol (204-01 Front Suspension, Removal and Installation).

3. NOTE: LH illustration shown, RH is similar.

Remove the brake disc shield.

Remove the 3 rivets.

4. NOTES:

LH illustration shown, RH is similar.

Use an additional wrench to prevent the ball joint

rotating.

Disconnect the steering gear tie rod end ball joint.

Remove and discard the tie rod end retaining nut. Ball joint splitter

204-327 Special Tool(s)

Page 483 of 3039

7 Rear accelerometer 8 Instrument cluster 9 JaguarDrive selector module 10 ABS (anti-lock brake system) module 11 TCM (transmission control module) 12 ECM (engine control module) 13 RH (right-hand) rear damper 14 RH front damper 15 LH (left-hand) front damper 16 LH rear damper 17 LH rear suspension height sensor 18 RH rear suspension height sensor 19 LH front suspension height sensor 20 RH front accelerometer 21 RH front suspension height sensor 22 Adaptive damping module 23 LH front accelerometer

PRINCIPLES OF OPERATION System Operation

The adaptive damping module uses a combination of information from other system modules and data from the accelerometers

and suspension height sensors to measure the vehicle and suspension states and driver inputs. Using this information, the

adaptive damping module applies algorithms to control the dampers for the current driving conditions.

The adaptive damping module receives signals on the high speed CAN bus from the following system components: Brake Pressure - ABS module. Brake Pressure Quality Factor - ABS module. Car Configuration Parameters - AJB. Center Differential Range Actual - ECM. Engine Speed - ECM. Engine Speed Quality Factor - ECM. Engine Torque Flywheel Actual - ECM. Engine Torque Flywheel Actual Quality Factor - ECM. Gear Position Target - TCM. Lateral Acceleration - ABS module. Power Mode (Ignition Signal) - CJB. Power Mode Quality Factor - CJB. Roll Stability Control Mode - ABS module. Steering Wheel Angle - ABS module. Steering Wheel Angle Speed - ABS module. Steering Wheel Angle Status - ABS module. Terrain Mode Requested - JaguarDrive selector.

Torque Converter Slip - TCM. Vehicle Information Parameters HS - AJB Vehicle Speed - ABS module. Vehicle Speed Quality Factor - ABS module. Front Left Wheel Speed - ABS module. Front Left Wheel Speed Quality Factor - ABS module. Front Right Wheel Speed - ABS module. Front Right Wheel Speed Quality Factor - ABS module. Rear Left Wheel Speed - ABS module. Rear Left Wheel Speed Quality Factor - ABS module. Rear Right Wheel Speed Quality Factor - ABS module. Rear Right Wheel Speed - ABS module. The adaptive damping module also outputs information on the high speed CAN bus for use by other systems as follows: Fault Message - instrument cluster.

Terrain Mode Change Status - JaguarDrive selector.

Terrain Mode - JaguarDrive selector.

The adaptive damping module monitors the input signals and operates the damper solenoids. The input signals are used in

control modes and a force required for each damper for that mode is calculated. An arbitration mode monitors the force

requirements from each mode and apportions a force to a damper. The force is converted to the appropriate current and sent to

the damper.

The control modes are as follows:

Page 484 of 3039

each damper to the appropriate level to maintain a flat and level body.

Roll Rate Control – Uses CAN inputs. Predicts vehicle roll rate due to driver steering inputs 100 times a second and increases damping to reduce roll rate.

Pitch Rate Control – Uses CAN inputs. Predicts vehicle pitch rate due to driver throttle and braking inputs 100 times a second and increases damping to reduce pitch rate.

Bump Rebound Control – Uses suspension height sensor and CAN inputs. Monitors the position of the wheel 500 times a second and increases the damping rate as the damper approaches the end of its travel.

Wheel Hop Control – Uses suspension height sensor and CAN inputs. Monitors the position of the wheel 500 times a second and detects when the wheel is at its natural frequency and increases the dampingto reduce vertical wheel

motion.

Under normal road conditions when the vehicle is stationary with the engine running, the dampers are set to the firm condition

to reduce power consumption.

The adaptive damping module receives its power supply via a relay and fuse in the CJB. The relay remains energized for a period of time after the ignition is off. This allows the adaptive damping module to record and store any DTC (diagnostic

trouble code) relating to adaptive dynamics system faults.

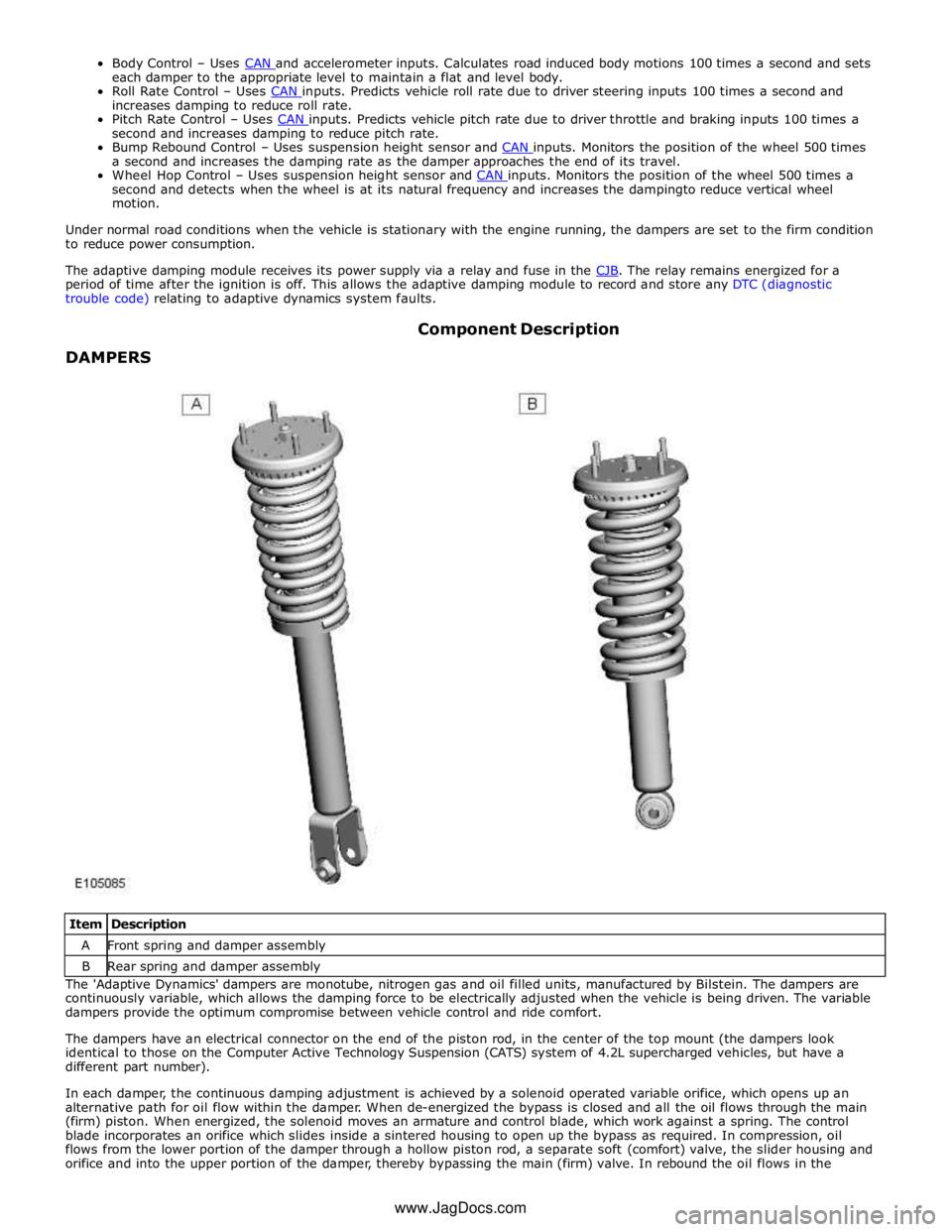

DAMPERS Component Description

Item Description A Front spring and damper assembly B Rear spring and damper assembly The 'Adaptive Dynamics' dampers are monotube, nitrogen gas and oil filled units, manufactured by Bilstein. The dampers are

continuously variable, which allows the damping force to be electrically adjusted when the vehicle is being driven. The variable

dampers provide the optimum compromise between vehicle control and ride comfort.

The dampers have an electrical connector on the end of the piston rod, in the center of the top mount (the dampers look

identical to those on the Computer Active Technology Suspension (CATS) system of 4.2L supercharged vehicles, but have a

different part number).

In each damper, the continuous damping adjustment is achieved by a solenoid operated variable orifice, which opens up an

alternative path for oil flow within the damper. When de-energized the bypass is closed and all the oil flows through the main

(firm) piston. When energized, the solenoid moves an armature and control blade, which work against a spring. The control

blade incorporates an orifice which slides inside a sintered housing to open up the bypass as required. In compression, oil

flows from the lower portion of the damper through a hollow piston rod, a separate soft (comfort) valve, the slider housing and

orifice and into the upper portion of the damper, thereby bypassing the main (firm) valve. In rebound the oil flows in the www.JagDocs.com