warning JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1842 of 3039

Parking Aid - Parking Aid - Overview

Description and Operation

OVERVIEW Published: 11-May-2011

The parking aid system provides an audible warning to the driver when any obstacles are in the path of the vehicle during a

forward (if front sensors are fitted) or reversing manoeuver. The purpose of the system is to assist the driver when parking or

manoeuvring in a restricted space. It is not designed as a crash avoidance system or a replacement for visual interpretation by

the driver.

All vehicles are fitted with rear parking aid sensors. Higher specification vehicles may also be fitted with front parking aid

sensors.

A roof console mounted parking aid switch allows the driver to deactivate the parking aid system if operation is not required.

NOTE: The switch is only fitted to vehicles with front parking aid sensors.

A parking aid camera is a standard fitment on some models and optional on others. The parking aid camera supplements the

information provided by the parking aid system by providing the driver with a visual display of the area directly behind the

vehicle.

www.JagDocs.com

Page 1845 of 3039

3 RJB 4 Entertainment system control module 5 Touch Screen Display (TSD) 6 Parking aid camera

PARKING AID System Operation

Two levels of parking aid system can be fitted; a rear only system or a front and rear system.

The parking aid module receives and ignition power mode 6 supply from the RJB. The parking aid module is connected to the entertainment system control module by the medium speed CAN (controller area

network) bus and the Media Orientated System Transport (MOST). The entertainment system is used by the parking aid system

to provide the driver with an audible warning. If an obstacle is sensed by the rear parking aid sensors, the rear audio system

speakers will sound. If an obstacle is sensed by the front parking aid sensors (if fitted), the front audio system speakers will

sound.

The parking aid system operates using ultrasonic signals which are transmitted by the sensors. The reflected echo from this

output is received by the sensors and used by the parking aid module to calculate the distance from an object.

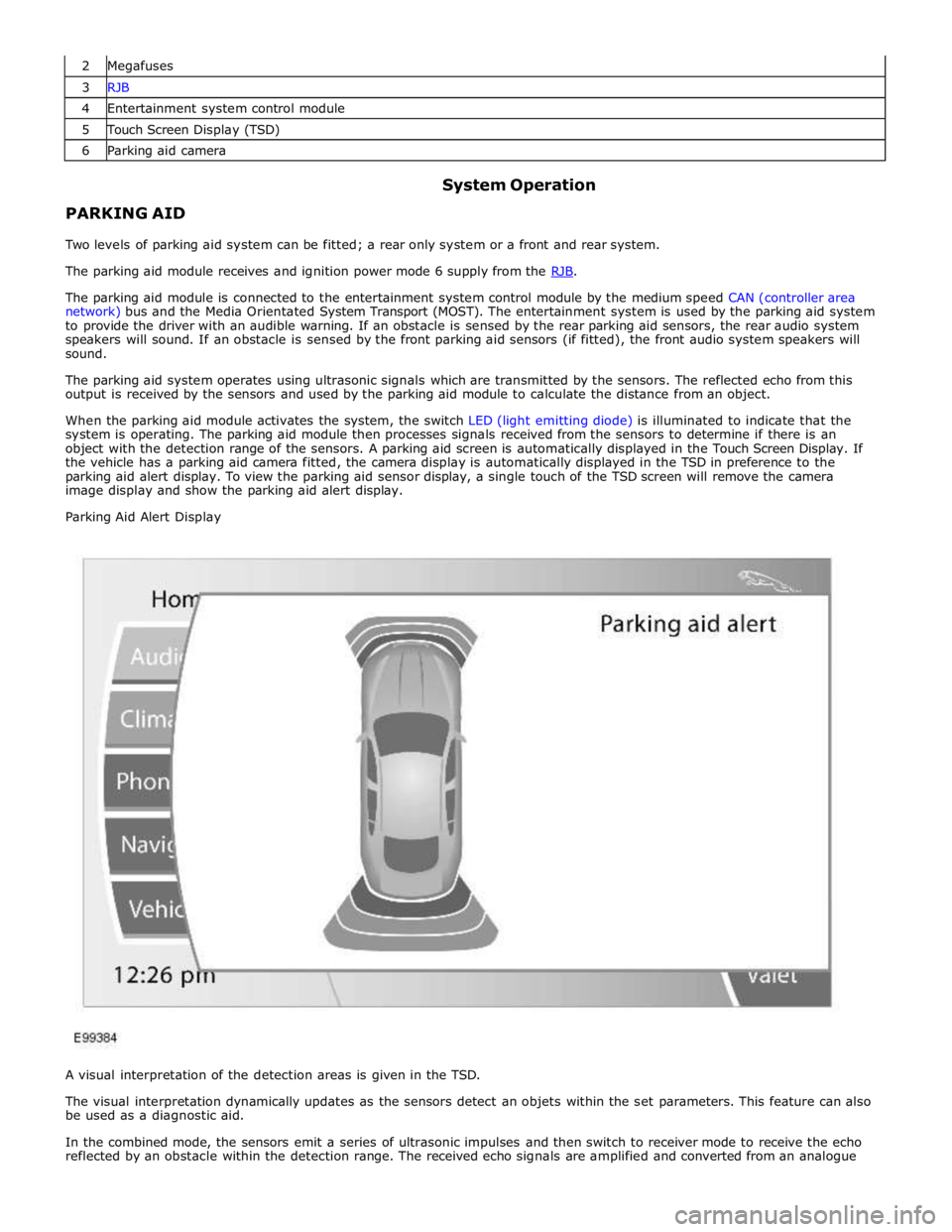

When the parking aid module activates the system, the switch LED (light emitting diode) is illuminated to indicate that the

system is operating. The parking aid module then processes signals received from the sensors to determine if there is an

object with the detection range of the sensors. A parking aid screen is automatically displayed in the Touch Screen Display. If

the vehicle has a parking aid camera fitted, the camera display is automatically displayed in the TSD in preference to the

parking aid alert display. To view the parking aid sensor display, a single touch of the TSD screen will remove the camera

image display and show the parking aid alert display.

Parking Aid Alert Display

A visual interpretation of the detection areas is given in the TSD.

The visual interpretation dynamically updates as the sensors detect an objets within the set parameters. This feature can also

be used as a diagnostic aid.

In the combined mode, the sensors emit a series of ultrasonic impulses and then switch to receiver mode to receive the echo

reflected by an obstacle within the detection range. The received echo signals are amplified and converted from an analogue

Page 1846 of 3039

signal to a digital signal by the sensor. The digital signal is passed to the parking aid module and compared with

pre-programmed data stored in an EEPROM (electrically erasable programmable read only memory) within the module. The

module receives this data via the signal line from the sensor and calculates the distance from the object using the elapsed

time between the transmitted and received impulse. The duration of the impulse duration is determined by the module, with

the sensor controlling the frequency of the impulse output.

In receiver mode, the sensor receives impulses that were emitted by adjacent sensors. The module uses this information to

precisely determine the position and distance of the object.

If no objects are detected there are no further warning tones. If an object is detected, repeated audible tones are emitted

from either the front or rear audio speakers as appropriate. The time delay between the tones decreases as the distance

between the object and the vehicle decreases, until at approximately 300 mm (12 inches), the audible tone becomes

continuous.

After the initial detection of an object, if there is no decrease in the distance between an object and the central sensors, the

time delay between the audible warnings remains constant. If an object is detected by one of the corner sensors only, the

audible warnings stop after approximately 5 seconds if there is no change in the distance between an object and the corner

sensor.

When approaching several objects within detection range, the control module recognises the distance from the vehicle to the

nearest object.

The PDC module will prioritise the objects detected, the nearest object detected will take priority and the corresponding audio

outputs will be emitted. For example if 2 objects are detected (one front one rear) the nearest detected object will take

priority and relevant audible tone will be heard.

If two objects are detected at equal distance (one front one rear) the audible tones will alternate between the front and rear

speakers.

If reverse (R) is the first gear selected after the ignition is switched on, both the front (if fitted) and rear parking aid sensors

will become operational. If a forward drive gear is subsequently selected, the front and rear parking aid sensors will remain

operational until vehicle speed increases above 16 km/h (10 mph), park (P) is selected or the PDC control switch is pressed.

If drive (D) is the first gear selected after the ignition is switched on the parking aid system will have to be activated by

pressing the PDC control switch.

NOTE: The PDC system can not be activated whilst the vehicle is in park (P).

The volume output of the parking aid audible tones can be adjusted by selecting the 'Vehicle Settings' menu and selecting

'Parking' from the menu on the TSD. The volume can be adjusted using the + or - selections on the TSD.

The system can detect when a trailer is connected to the vehicle by a message output on the medium speed CAN bus from the trailer module. When the parking aid module detects that a trailer is connected to the vehicle, the rear sensors are disabled to

prevent constant warnings due to the close proximity of the trailer.

NOTE: The ignition needs to be cycled once the trailer has been disconnected to activate the rear parking aid system.

Page 1848 of 3039

information from other systems:

ABS (anti-lock brake system) module - Road speed signal

TCM (transmission control module) - Reverse gear engaged signal

Trailer module - Trailer attached to vehicle

The module also outputs messages on the medium speed CAN bus which are received by the integrated audio module. The integrated audio module processes these messages and converts them into Media Orientated System Transport (MOST) signals

which are passed to the audio system power amplifier. These signals are then used by the power amplifier to emit the

applicable warning tones from the front or rear audio speakers when an object is detected by the front or rear parking aid

sensors. A warning tone can also be emitted to alert the driver to a fault in the parking aid system.

The control module has a diagnostic connection via the medium speed CAN bus to enable faults to be retrieved using the

Jaguar approved diagnostic equipment. Additionally an on-board diagnostic routine within the control module constantly

monitors the system and alerts the driver to a system fault by emitting a 3 second continuous tone through the rear audio

system speakers when the ignition is switched on. If front parking aid sensors are fitted, the control switch LED will also flash

6 times.

Parking Aid Sensors

Four ultrasonic sensors are located in the front (if fitted) and rear bumpers.

Each sensor has a three pin connector which mates with a bumper harness, which in turn is connected to the main body

harness. Three pins provide for power supply, ground and signal lines to and from the parking aid module.

The parking aid module controls the operation of each sensor using a digital output on the signal line. The module controls the

sensor in one of two modes; combined transmitter and receiver mode or receiver mode only.

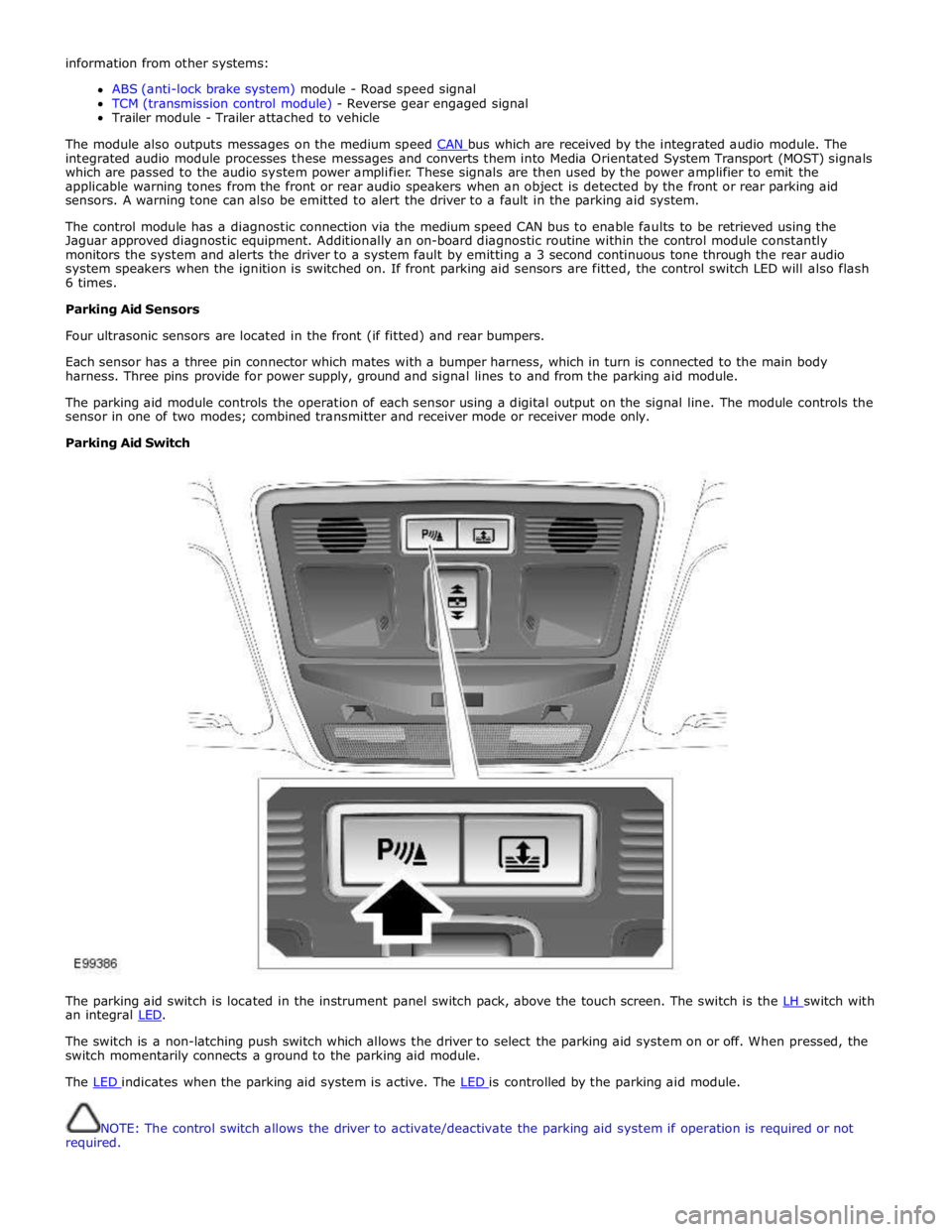

Parking Aid Switch

The parking aid switch is located in the instrument panel switch pack, above the touch screen. The switch is the LH switch with an integral LED.

The switch is a non-latching push switch which allows the driver to select the parking aid system on or off. When pressed, the

switch momentarily connects a ground to the parking aid module.

The LED indicates when the parking aid system is active. The LED is controlled by the parking aid module.

NOTE: The control switch allows the driver to activate/deactivate the parking aid system if operation is required or not

required.

Page 1850 of 3039

Parking Aid - Parking Aid

Diagnosis and Testing

Principles of Operation Published: 24-Feb-2014

For a detailed description of the parking aid system, characteristics and limitations refer to the relevant description and

operation section in the workshop manual.

REFER to: Parking Aid (413-13 Parking Aid, Description and Operation).

Parking Aid System On-Board Self-Test

As part of the strategy of the system if any DTCs are detected, a long high-pitched tone approx 3 seconds will sound and the

parking aid switch (where fitted) indicator LED will flash 6 times at ignition on

If a fault is present when the parking aid system is activated then the parking aid switch (where fitted) status LED will

flash 6 times indicating an issue with front or rear parking aid sensors, wiring switch, parking aid control module or hard

wired sounders

The rear parking aid sounder/rear audio system will emit an error tone for approx 3 seconds at ignition on if a fault is

detected with the front or rear sensors, the switch, or if there is a controller area network (CAN) bus error

(Only applicable to vehicles fitted with front parking aid and a hard wired rear parking aid sounder). If there is a fault

with the rear parking aid sounder the error tone will come from the front parking aid sounder unit (integral with the

instrument cluster)

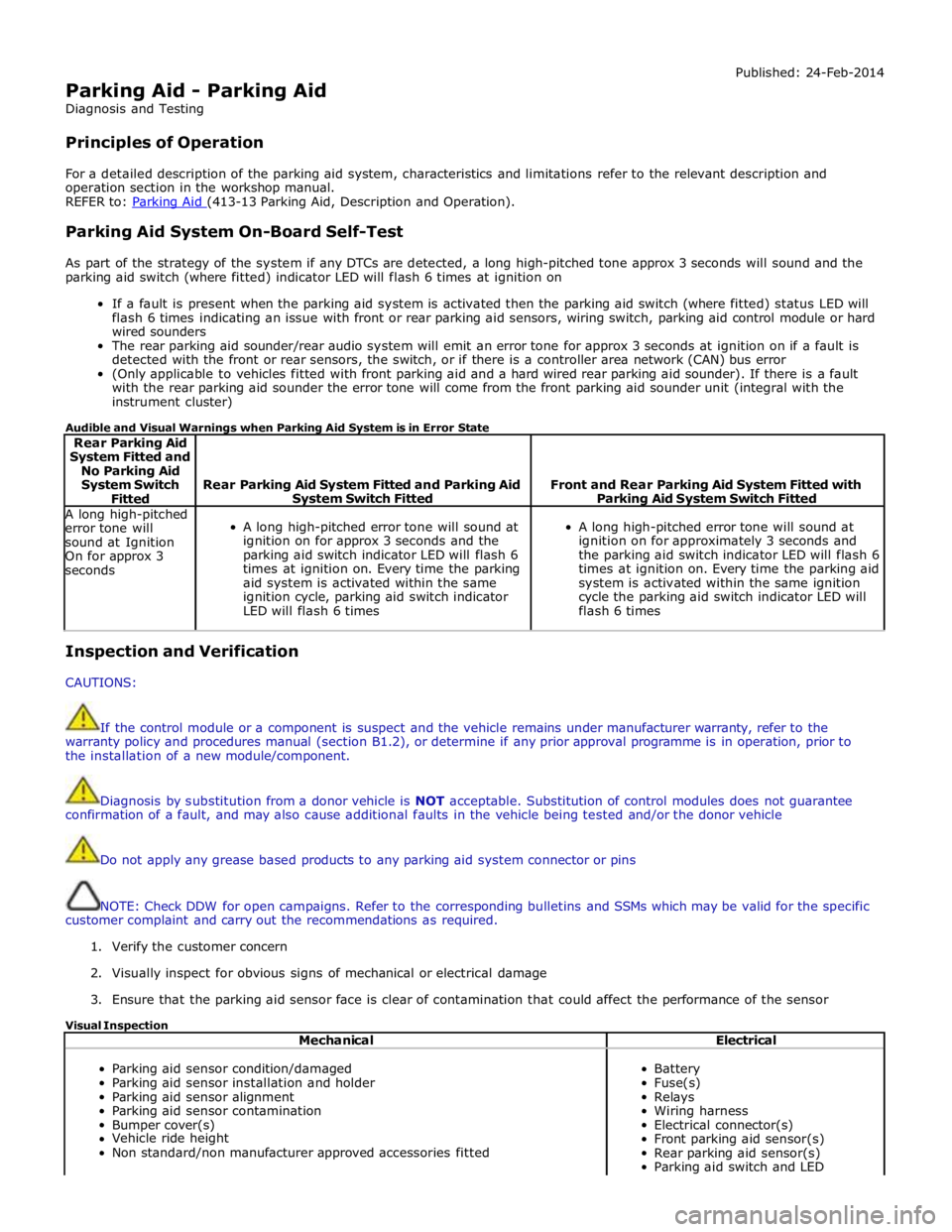

Audible and Visual Warnings when Parking Aid System is in Error State

Rear Parking Aid

System Fitted and

No Parking Aid

System Switch

Fitted

Rear Parking Aid System Fitted and Parking Aid System Switch Fitted

Front and Rear Parking Aid System Fitted with Parking Aid System Switch Fitted A long high-pitched

error tone will

sound at Ignition

On for approx 3

seconds

A long high-pitched error tone will sound at

ignition on for approx 3 seconds and the

parking aid switch indicator LED will flash 6

times at ignition on. Every time the parking

aid system is activated within the same

ignition cycle, parking aid switch indicator

LED will flash 6 times

A long high-pitched error tone will sound at

ignition on for approximately 3 seconds and

the parking aid switch indicator LED will flash 6

times at ignition on. Every time the parking aid

system is activated within the same ignition

cycle the parking aid switch indicator LED will

flash 6 times Inspection and Verification

CAUTIONS:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not guarantee

confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

Do not apply any grease based products to any parking aid system connector or pins

NOTE: Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

1. Verify the customer concern

2. Visually inspect for obvious signs of mechanical or electrical damage

3. Ensure that the parking aid sensor face is clear of contamination that could affect the performance of the sensor

Visual Inspection

Mechanical Electrical

Parking aid sensor condition/damaged

Parking aid sensor installation and holder

Parking aid sensor alignment

Parking aid sensor contamination

Bumper cover(s)

Vehicle ride height

Non standard/non manufacturer approved accessories fitted

Battery

Fuse(s)

Relays

Wiring harness

Electrical connector(s)

Front parking aid sensor(s)

Rear parking aid sensor(s)

Parking aid switch and LED

Page 1854 of 3039

PINPOINT TEST B : PARKING AID SYSTEM NOT FUNCTIONING CORRECTLY WITH NO DTCS LOGGED TEST

CONDITIONS DETAILS/RESULTS/ACTIONS B1: PARKING AID SYSTEM GIVES WARNING SIGNAL WITHOUT OBSTACLE 1 Clean the parking aid sensor face. Check for any damage to the parking aid sensor face. Rectify as required. Snow, water or ice on sensor face. Parking aid sensor face has been repainted to the incorrect

thickness. Rectify as required Parking aid system functioning correctly? Yes

No further action required

No

GO to B2. B2: PARKING AID SYSTEM GIVES WARNING SIGNAL WITHOUT OBSTACLE 1 Ensure the vehicle ride height is within manufacturer specified limits. Rectify as required Parking aid system functioning correctly? Yes

No further action required

No

GO to B3. B3: PARKING AID SYSTEM GIVES WARNING SIGNAL WITHOUT OBSTACLE 1 Check for any non standard accessories are not fitted, such as tow bar, bike rack, body kit, modified exhaust, lighting or licence plate holder Parking aid system functioning correctly? Yes

No further action required

No

GO to B4. B4: PARKING AID SYSTEM GIVES WARNING SIGNAL WITHOUT OBSTACLE 1 Limitations or characteristics of the parking aid system such as vehicle on a gradient, exhaust gas vapour, signal reflection Parking aid system functioning correctly? Yes

No further action required

No

For a detailed description of the parking aid system, refer to the relevant description and operation

section in the workshop manual.

REFER to: Parking Aid (413-13 Parking Aid, Description and Operation). DTC Index

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If the control module is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty Policy and

Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to the installation of a

new module.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places,

and with an up-to-date calibration certificate. When testing resistance always take the resistance of the DMM leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals. Parking aid system functioning correctly

Yes

No further action required

Page 1867 of 3039

procedure.

NOTE: Under no circumstances should the battery be disconnected with the engine running because under these

conditions the generator can give a very high output voltage. This high transient voltage will damage the electronic

components in the vehicle. Loose or incomplete battery connections may also cause high transient voltage.

3. HEALTH AND SAFETY PRECAUTIONS

WARNINGS:

BATTERY CELLS CONTAIN SULPHURIC ACID AND EXPLOSIVE MIXTURES OF HYDROGEN AND OXYGEN GASES. IT IS

THEREFORE ESSENTIAL THAT THE FOLLOWING SAFETY PRECAUTIONS ARE OBSERVED.

Batteries emit highly explosive hydrogen at all times, particularly during charging. To prevent any potential form of

ignition occurring when working in the vicinity of a battery:

Do not smoke when working near batteries.

Avoid sparks, short circuits or other sources of ignition in the battery vicinity.

Switch off current before making or breaking electrical connections.

Ensure battery charging area is well ventilated.

Ensure the charger is switched off when: a) connecting to a battery; b) disconnecting from the battery.

Always disconnect the ground cable from the battery terminal first and reconnect it last.

Batteries contain poisonous and highly corrosive acid. To prevent personal injury, or damage to clothing or the vehicle,

the following working practices should be followed when topping up, checking electrolyte specific gravity, removal, refitting or

carrying batteries:

Always wear suitable protective clothing (an apron or similar), safety glasses, a face mask and suitable gloves.

If acid is spilled or splashed onto clothing or the body, it must be neutralized immediately and then rinsed with clean

water. A solution of baking soda or household ammonia and water may be used as a neutralizer.

In the event of contact with the skin, drench the affected area with water. In the case of contact with the eyes, bathe

the affected area with cool clean water for approximately 15 minutes and seek urgent medical attention.

If battery acid is spilled or splashed on any surface of a vehicle, it should be neutralized and rinsed with clean water.

Heat is generated when acid is mixed with water. If it becomes necessary to prepare electrolyte of a desired specific

gravity, SLOWLY pour the concentrated acid into water (not water into acid), adding small amounts of acid while

stirring. Allow the electrolyte to cool if noticeable heat develops. With the exception of lead or lead-lined containers,

always use non-metallic receptacles or funnels. Do not store acid in excessively warm locations or in direct sunlight.

Due to their hazardous contents, the disposal of batteries is strictly controlled. When a battery is scrapped, ensure it is

disposed of safely, complying with local environmental regulations. If in doubt, contact your local authority for advice on

disposal facilities.

4. BATTERY CARE REQUIREMENTS

4.1 RECEIPT OF A NEW VEHICLE

Within 24 hours of receipt of a new vehicle, a battery condition check must be carried out in accordance with the battery test

process utilizing a JLR approved tester as outlined in the Equipment section (Section 5) of this procedure.

NOTE: The Midtronics code from the tester must be recorded on the form.

Any actions must be carried out in accordance with the table shown in the Determining Battery Condition section (Section 6)

of this procedure. The details must be recorded on the New Vehicle Storage Form which is part of the new vehicle storage

document.

For additional information, refer to: New Vehicle Storage Form (100-11 Vehicle Transportation Aids and Vehicle Storage, Description and Operation).

4.2 NEW VEHICLE STORAGE

If the vehicle is to be stored the transit relays MUST be refitted and / or the vehicle put into transport mode.

Transit relay removal / vehicle placed in normal mode should only be completed a maximum of 72 hours prior to handover to

customer

For vehicles without either a transit mode or transit relay the battery negative cable must be DISCONNECTED from the battery.

The battery must be tested and/or re-charged every 30 days and MUST be re-charged after every 90 day period.

NOTE: The Midtronics code from the tester must be recorded on the form. www.JagDocs.com

Page 1870 of 3039

system.

9 CONFIRMING ELECTROLYTE LEVEL

WARNINGS:

BEFORE CHECKING AND TOPPING-UP THE BATTERY ELECTROLYTE, REFER TO THE HEALTH AND SAFETY PRECAUTIONS

SECTION.

AGM TECHNOLOGY BATTERIES ARE FULLY SEALED FOR LIFE AND NO ATTEMPT SHOULD BE MADE TO CHECK OR TOP UP

THE ELECTROLYTE LEVEL.

On certain types of battery the electrolyte level may need to be checked.

Make sure the battery is of a type suitable for topping up. These types of batteries will have cell plugs visible on the

top face of the battery or a removable access panel to allow access to the cells.

On batteries with a clear or opaque case and level marks, check the electrolyte level by visual inspection of the

maximum level indicator mark on the battery casing indicating adequate level above the battery separators.

On batteries with black cases, remove the cell plugs or access panel and ensure the electrolyte level is level with the

indicator in the cell hole. A flashlight may be required to see the electrolyte level on this type of battery.

If the electrolyte level is low, top-up using distilled water.

NOTE: Maintenance free and Valve Regulated (AGM) batteries are sealed and therefore cannot be topped up.

CAUTION: DO NOT overfill.

Page 1873 of 3039

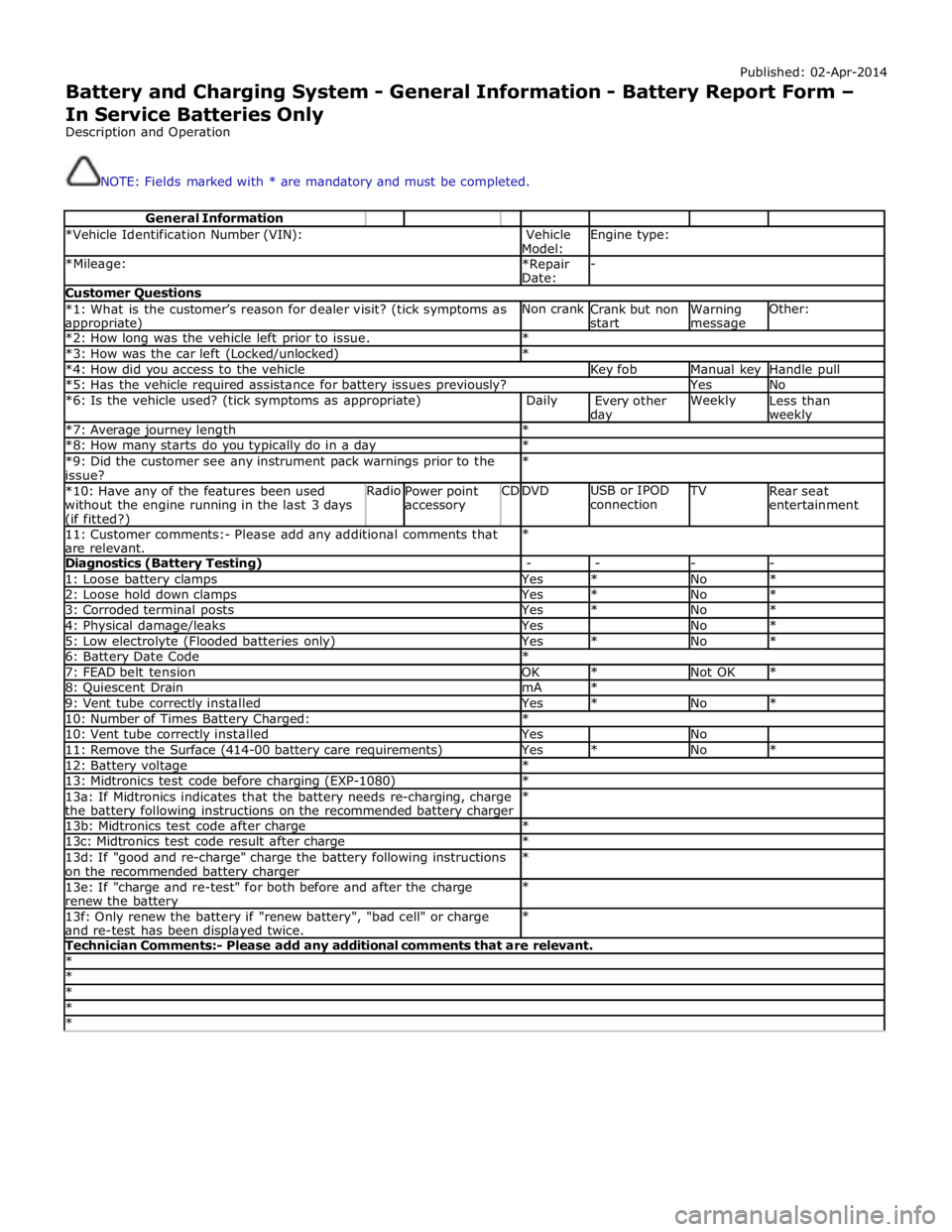

Published: 02-Apr-2014

Battery and Charging System - General Information - Battery Report Form – In Service Batteries Only

Description and Operation

NOTE: Fields marked with * are mandatory and must be completed.

General Information *Vehicle Identification Number (VIN):

Vehicle

Model: Engine type: *Mileage:

*Repair

Date: - Customer Questions *1: What is the customer’s reason for dealer visit? (tick symptoms as appropriate) Non crank

Crank but non

start Warning message Other: *2: How long was the vehicle left prior to issue. * *3: How was the car left (Locked/unlocked) * *4: How did you access to the vehicle Key fob Manual key Handle pull *5: Has the vehicle required assistance for battery issues previously? Yes No *6: Is the vehicle used? (tick symptoms as appropriate) Daily

Every other day Weekly

Less than weekly *7: Average journey length * *8: How many starts do you typically do in a day * *9: Did the customer see any instrument pack warnings prior to the

issue? * *10: Have any of the features been used

without the engine running in the last 3 days (if fitted?) Radio

Power point

accessory CD DVD USB or IPOD

connection TV

Rear seat

entertainment 11: Customer comments:- Please add any additional comments that

are relevant. * Diagnostics (Battery Testing) - - - - 1: Loose battery clamps Yes * No * 2: Loose hold down clamps Yes * No * 3: Corroded terminal posts Yes * No * 4: Physical damage/leaks Yes No * 5: Low electrolyte (Flooded batteries only) Yes * No * 6: Battery Date Code * 7: FEAD belt tension OK * Not OK * 8: Quiescent Drain mA * 9: Vent tube correctly installed Yes * No * 10: Number of Times Battery Charged: * 10: Vent tube correctly installed Yes No 11: Remove the Surface (414-00 battery care requirements) Yes * No * 12: Battery voltage * 13: Midtronics test code before charging (EXP-1080) * 13a: If Midtronics indicates that the battery needs re-charging, charge

the battery following instructions on the recommended battery charger * 13b: Midtronics test code after charge * 13c: Midtronics test code result after charge * 13d: If "good and re-charge" charge the battery following instructions

on the recommended battery charger * 13e: If "charge and re-test" for both before and after the charge

renew the battery * 13f: Only renew the battery if "renew battery", "bad cell" or charge

and re-test has been displayed twice. * Technician Comments:- Please add any additional comments that are relevant. * * * * *

Page 1882 of 3039

11 Secondary battery 12 Dual Battery Junction Box (DBJB) 13 Rear Junction Box (RJB) 14 Megafuse 15 Battery Junction box (BJB) 16 Primary battery

System Operation BATTERY MONITORING SYSTEM - TD4 2.2L DIESEL VEHICLES ONLY

Periodically the battery monitoring system module will instigate a self-calibration routine. To self calibrate, the battery

monitoring system first charges the battery to its full condition.

NOTE: If the vehicle is only driven for short periods the charging process could take a number of days to complete.

Once the battery is fully charged, the battery monitoring system will discharge the battery to approximately 75% of its full

state of charge, but never lower than 12.2 V. The time taken to complete this part of the routine is dependent on the electrical

load on the vehicle.

When the second part of the routine has been successfully completed, the battery monitoring system will return the battery to

its optimum level of charge. The optimum level of charge will be between 12.6 V and 15 V, depending on battery condition,

temperature and loading.

The battery monitoring system module also monitors the battery condition with the engine switched off. If a low voltage

condition is detected the module can request the infotainment system is switched off to protect battery voltage. Once the

infotainment system has been switched off, the vehicle must be run for at least 5 minutes to charge the battery before the

infotainment system can be operated with the engine switched off.

BATTERY MONITORING SYSTEM - SINGLE AND DUAL BATTERY SYSTEM VEHICLES

When the ignition is off (power mode 0), the BMS control module records the primary battery state of charge and begins to

monitor the battery condition from this point.

If the battery state of charge falls by 7%, the BMS control module will monitor the primary battery for 5 minutes. If after the 5

minute monitoring period, the primary battery charge has continued to fall due to the quiescent drain current being too high,

the BMS control module will determine that some control modules are still 'awake'. The BMS control module sends a shutdown

message on the LIN (local interconnect network) bus to the GWM (Gateway Module). The GWM sends a CAN (controller area

network) bus message on both the medium and high speed networks to all control modules, requesting them to shutdown.

The BMS control module will monitor the primary battery state of charge for a further 5 minutes and determine if the primary

battery state of charge is still dropping. If a quiescent drain current continues, the primary battery state of charge will

continue to drop. If the state of charge falls to 12% of the initial monitoring value, the BMS control module determines that

one or more control modules are still awake and a failure to respond to the shutdown request may indicate an error state

within the control module(s).

BMS Low Battery Warning and Energy Management Messages

The BMS continuously monitors the condition of the primary vehicle battery. If excessive battery discharge occurs, the system

will begin to shut down non-essential electrical systems in order to protect the battery.

If the BMS calculates that battery condition is not within set parameters, there are 3 messages that can be displayed, 2 on the

touch screen and 1 on the message center. These inform the user that the battery is either at a low level of charge or the

engine-off power consumption limit has been exceeded.

Low Battery - Please switch engine on or system will shutdown in 3 minutes: is displayed as a Warning on the

touch screen if the engine is not running. This indicates that the battery has fallen below a predefined threshold. As

soon as the battery is charged back above this threshold then the message will be removed.

Low Battery - Please start your engine is displayed on the message center if the engine is not running. This indicates

that the battery has fallen below a predefined threshold. As soon as the battery is charged back above this threshold

then the message will be removed or it can be manually removed by pressing 'OK'.

System will shut down in 3 minutes: is displayed as an Energy management on the touch screen if the engine is not

running, and system features are causing excessive battery discharge. After 3 minutes the BMS will begin shutting

down vehicle systems. Normal system operation will resume when the engine is started.

This is based on a percentage of battery capacity available for the customer to use with the engine off. The percentage can

change based upon several factors.

Once triggered, the resetting of this message will not occur until the vehicle is driven for 10 minutes with the engine running

(to allow the battery to recoup any lost charge). However, if the engine is run for less than 10 minutes, the message will only

be displayed after an additional 5 minutes with the ignition on but engine off.

BMS Control Module Self Calibration

Periodically the BMS control module will instigate a self-calibration routine. To self calibrate, the battery monitoring system www.JagDocs.com