warning JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1664 of 3039

Published: 11-Jul-2014

Climate Control System - General Information - Climate Control System

Diagnosis and Testing

Principles of Operation

For a detailed description of the Climate Control System, refer to the relevant Description and Operation sections in the

Workshop Manual. REFER to:

Air Distribution and Filtering (412-01 Climate Control, Description and Operation), Air Distribution and Filtering (412-01 Climate Control, Description and Operation), Air Distribution and Filtering (412-01 Climate Control, Description and Operation), Heating and Ventilation (412-01 Climate Control, Description and Operation), Heating and Ventilation (412-01 Climate Control, Description and Operation), Heating and Ventilation (412-01 Climate Control, Description and Operation), Air Conditioning (412-01 Climate Control, Description and Operation), Air Conditioning (412-01 Climate Control, Description and Operation), Air Conditioning (412-01 Climate Control, Description and Operation), Control Components (412-01 Climate Control, Description and Operation), Control Components (412-01 Climate Control, Description and Operation), Control Components (412-01 Climate Control, Description and Operation), Electric Booster Heater (412-02 Auxiliary Climate Control, Description and Operation), Electric Booster Heater (412-02 Auxiliary Climate Control, Description and Operation), Electric Booster Heater (412-02 Auxiliary Climate Control, Description and Operation).

Inspection and Verification

WARNING: Servicing must be carried out by personnel familiar with both vehicle system and the charging and testing

equipment. All operations must be carried out in a well ventilated area away from open flame and heat sources.

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern

2. Visually inspect for obvious signs of damage and system integrity

Visual Inspection

Mechanical Electrical

Coolant level

Hose(s)

Coolant pump

Control flap(s)

Duct(s)

Vent(s)

Cabin air filter

Drive belt

Air conditioning compressor

Thermostatic expansion valve

Evaporator

Receiver drier

Air conditioning condenser

Refrigerant pipes Auxiliary

drive belt

Fuel fired booster heater

Fuel fired booster heater fuel pump

Fuel fired booster heater fuel pipes

Fuse(s)

Wiring harness

Electrical connectors

Blower

Air conditioning compressor

Electric cooling fan

Automatic Temperature Control Module (ATCM)

Refrigerant pressure sensor

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index

5. Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

Page 1668 of 3039

Published: 11-May-2011

Climate Control System - General Information - Air Conditioning (A/C) System

Recovery, Evacuation and Charging

General Procedures

1. WARNING: Servicing must be carried out by personnel familliar with both

vehicle system and the charging and testing equipment. All operations

must be carried out in a well ventilated area away from open flame and

heat sources.

NOTE: The receiver drier need only be changed under the following

circumstances: There is dirt in the refrigerant circuit ( eg. compressor

seizure ), the system is leaking and refrigerant has been lost to

atmosphere, or the refrigerant circuit has been open more than 24 hours,

due to repair.

Refrigerant recovery.

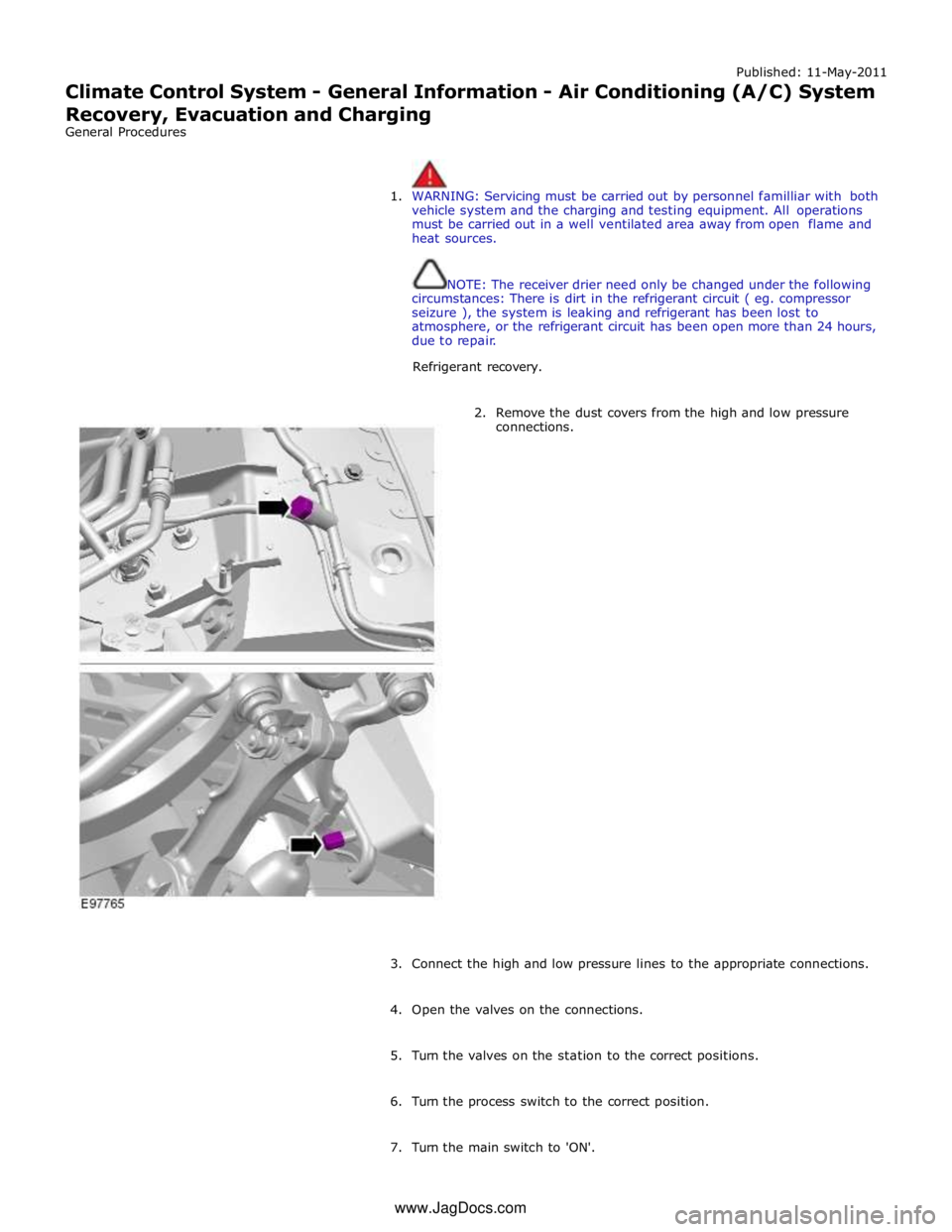

2. Remove the dust covers from the high and low pressure

connections.

3. Connect the high and low pressure lines to the appropriate connections.

4. Open the valves on the connections.

5. Turn the valves on the station to the correct positions.

6. Turn the process switch to the correct position.

7. Turn the main switch to 'ON'. www.JagDocs.com

Page 1669 of 3039

8. WARNING: Refrigerant must always be recycled before re-use to ensure

that the purity of the refrigerantis high enough for safe use in the air

conditioning system. Recycling should always be carried out with

equipment which is design certified by Underwriter Laboratory Inc. for

compliance with SEA J1991. Other equipment may not recycle refrigerant

to the required level of purity. R143a Refrigerant Recover Recycling

Recharging station must not be used with any other type of

refrigerant.Refrigerant R134a from domestic and comercial sources must

not be used in motor vehicles air conditioning systems.

Allow the system to recover the refrigerant from the system.

9. Close the valves on the refrigerant station.

10. Turn the main switch 'OFF'.

11. Close the valves on the connections.

12. Disconnect the high and low pressure connections.

13. Install the dust covers to the connectors.

14. Open the tap at the rear of the station to drain the refrigerant oil.

15. Measure and record the quantity of refrigerant oil recovered from the

system.

16. Close the tap at the rear of the station.

17. Evacuation.

18. Remove the dust covers from the high and low pressure connections.

19. Connect the high and low pressure lines to the appropriate connections.

20. Open the valves on the connections.

21. Turn the valves on the station to the correct positions.

22. Turn the process switch to the correct position.

23. Turn the main switch to 'ON'.

24. Allow the station to evacuate the A/C system.

25. CAUTION: The system must be evacuated immediatley before

recharging commences. Delay between evacuation and recharging is not

permitted

Recharging

26. Close the valves on the refrigerant station.

Page 1671 of 3039

Published: 11-May-2011

Climate Control System - General Information - Air Conditioning (A/C) System

Flushing

General Procedures

1. WARNINGS:

Use extreme care and observe all safety precautions related to the

use of refrigerants. Due to refrigerant hazards, always wear safety

goggles and non-penetrable gloves when working on or flushing air

conditioning (A/C) systems. Failure to follow this instruction may result

in personal injury.

When flushing the A/C system, refer to the manufacturers

equipment instructions for additional information. Failure to do so may

result in system damage or personal injury.

The A/C refrigerant analyzer must be used before the recovery of

any vehicle's A/C refrigerant. Failure to do so puts shop bulk refrigerant

at risk of contamination. If the vehicle A/C refrigerant is contaminated,

refer the customer to return to the repair facility that performed the last

A/C repair. If the customer wishes to pay the additional cost, use the

A/C recovery equipment that is designated for recovering contaminated

A/C refrigerant. All contaminated A/C refrigerant must be disposed of as

hazardous waste. For additional information, refer to the manufacturers

equipment instructions. Failure to follow this instruction may result in

personal injury.

Prior to using the A/C flushing equipment for the first time, follow

the operating instructions. Failure to follow this instruction may result in

personal injury.

CAUTION: Prior to flushing, remove and discard the desiccant sack.

Depending on the equipment used, other A/C components may have to

be removed prior to flushing. For additional information, refer to the

manufacturers equipment instructions before flushing the A/C system.

Recover the refrigerant.

For additional information, refer to Air conditioning (A/C) System Recovery, Evacuation and Charging in this section.

2. Remove the desiccant sack.

For additional information, refer to Section 412-03 Air Conditioning.

3. Flush the system. For additional information, refer to the manufacturers

equipment instructions.

4. Install new refrigerant lines if blocked with debris.

5. Install a new desiccant sack.

For additional information, refer to Section 412-03 Air Conditioning.

6. Add the required amount of oil to the A/C system depending on the

repair procedure.

For additional information, refer to Refrigerant Oil Adding in this section.

7. Evacuate and charge the A/C system.

For additional information, refer to Air conditioning (A/C) System Recovery, Evacuation and Charging in this section.

8. Carry out fluorescent dye leak detection test.

Page 1674 of 3039

Published: 11-May-2011

Climate Control System - General Information - Electronic Leak Detection

General Procedures

1. WARNING: Good ventilation is necessary in the area where A/C leak

testing is to be carried out. If the surrounding air is contaminated with

refrigerant gas, the leak detector will indicate this gas all the time.

Odors from other chemicals such as antifreeze, diesel fuel, disc brake

cleaner, or other cleaning solvents can cause the same problem. A fan,

even in a well ventilated area, is very helpful in removing small traces of

contamination from the air that might affect the leak detector. Failure to

follow this instruction may result in personal injury.

Attach an R-134a manifold gauge set or use a UL-approved

recovery/recycling device such as an R-134a A/C refrigerant center (which

meets SAE Standard J 1991). For additional information, refer to the

manufacturers equipment instructions.

Both gauges should indicate 413-551 kPa (60-80 psi) at 24°C

(75°F) with the engine off.

If little or no pressure is indicated, carry out the air conditioning

(A/C) system recovery, evacuation and charging procedure.

For additional information, refer to Air Conditioning (AC) System Recovery, Evacuation and Charging in this section.

2. Use an R134-a Automatic calibration halogen leak detector to leak test

the refrigerant system. For additional information, refer to the

manufacturers equipment instructions.

3. If a leak is found, carry out the air conditioning (A/C) system recovery

procedure.

For additional information, refer to Air Conditioning (AC) System Recovery, Evacuation and Charging in this section.

Page 1675 of 3039

Published: 11-May-2011

Climate Control System - General Information - Fluorescent Dye Leak Detection

General Procedures

1. WARNING: Eye protection glasses supplied with the ultraviolet (UV)

lamp should be used to protect eyesight from harm.

NOTE: The air conditioning (A/C) system has an R-134a leak trace

dye wafer incorporated into the desiccant bag. The exact location of

leaks can be pinpointed by the bright yellow/green glow of the tracer

dye. Since more than one leak may exist, always inspect each

component. If it is necessary to add dye (due to a severe leakage for

example) use proprietary tracer dye injection equipment.

Check for leaks using ultraviolet (UV) lamp.

2. Check all components, fittings and lines of the A/C system.

3. Carry out the repair. For additional information, refer to Section 412-03 Air Conditioning.

4. After the leak is repaired, remove any traces of leak trace dye with a

general purpose oil solvent.

5. Check the A/C system for correct operation.

6. Verify the repair by operating the system for a short time and inspecting

with the (UV) lamp.

Page 1677 of 3039

Published: 11-May-2011

Climate Control System - General Information - Manifold Gauge Set Connection

General Procedures

1. WARNINGS:

Use extreme care and observe all safety precautions related to the

use of refrigerants. Failure to follow this instruction may result in

personal injury.

For additional information, refer to the manufacturers equipment

instructions. Failure to follow this instruction may result in personal

injury and system damage.

Install the manifold gauge set. For additional information, refer to the

manufacturers equipment instructions.

2. Carry out the repair.

3. Remove the manifold gauge set. For additional information, refer to the

manufacturers equipment instructions.

4. Carry out flourescent dye leak detection test.

For additional information, refer to Flourescent Dye Leak Detection in this section.

5. Check air conditioning (A/C) system for correct operation.

Page 1680 of 3039

Published: 28-Dec-2012

Climate Control System - General Information - Refrigerant System Tests

General Procedures

1. WARNINGS:

Use extreme care and observe all safety precautions related to the

use of refrigerants. Failure to follow this instruction may result in

personal injury.

The A/C refrigerant analyzer must be used before the recovery of

any vehicle's A/C refrigerant. Failure to do so puts shop bulk refrigerant

at risk of contamination. If the vehicle A/C refrigerant is contaminated,

refer the customer to return to the repair facility that carried out the last

A/C repair. If the customer wishes to pay the additional cost, use the A/C

recovery equipment that is designated for recovering contaminated A/C

refrigerant. All contaminated A/C refrigerant must be disposed of as

hazardous waste. For all equipment, follow the equipment manufacturers

procedures and instructions. Failure to follow this instruction may result

in personal injury.

NOTE: Jaguar Land Rover Limited supports the efficient usage,

recovery and recycling of the refrigerant used in passenger car air

conditioners. Jaguar Land Rover Limited recommends the use of

UL-approved recovery/recycling device such as R-134a A/C refrigerant

center (which meets SAE Standard J 1991) during any A/C system repair

and recharge procedure which requires that the system be evacuated.

Use R-134a A/C Refrigerant Centre to evacuate and recover the A/C

system.

Follow the equipment manufactures procedures and instructions

for use of equipment.

Page 1725 of 3039

Climate Control - Climate Control Assembly

Removal and Installation

Removal

NOTES:

Removal steps in this procedure may contain installation details.

RHD illustration shown, LHD is similar. Published: 11-May-2011

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Refer to: Instrument Panel Console (501-12 Instrument Panel and Console, Removal and Installation).

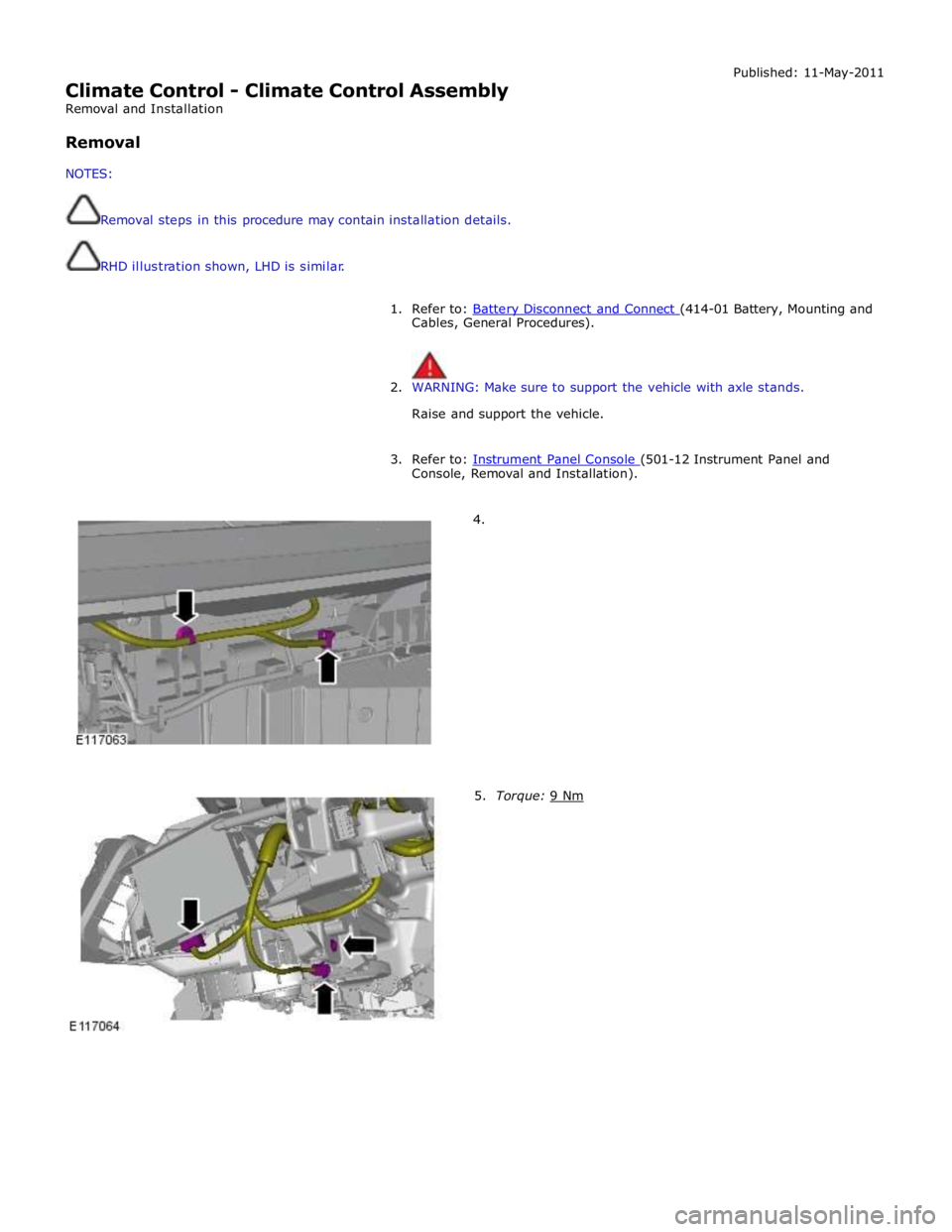

4.

5. Torque: 9 Nm

Page 1736 of 3039

Installation

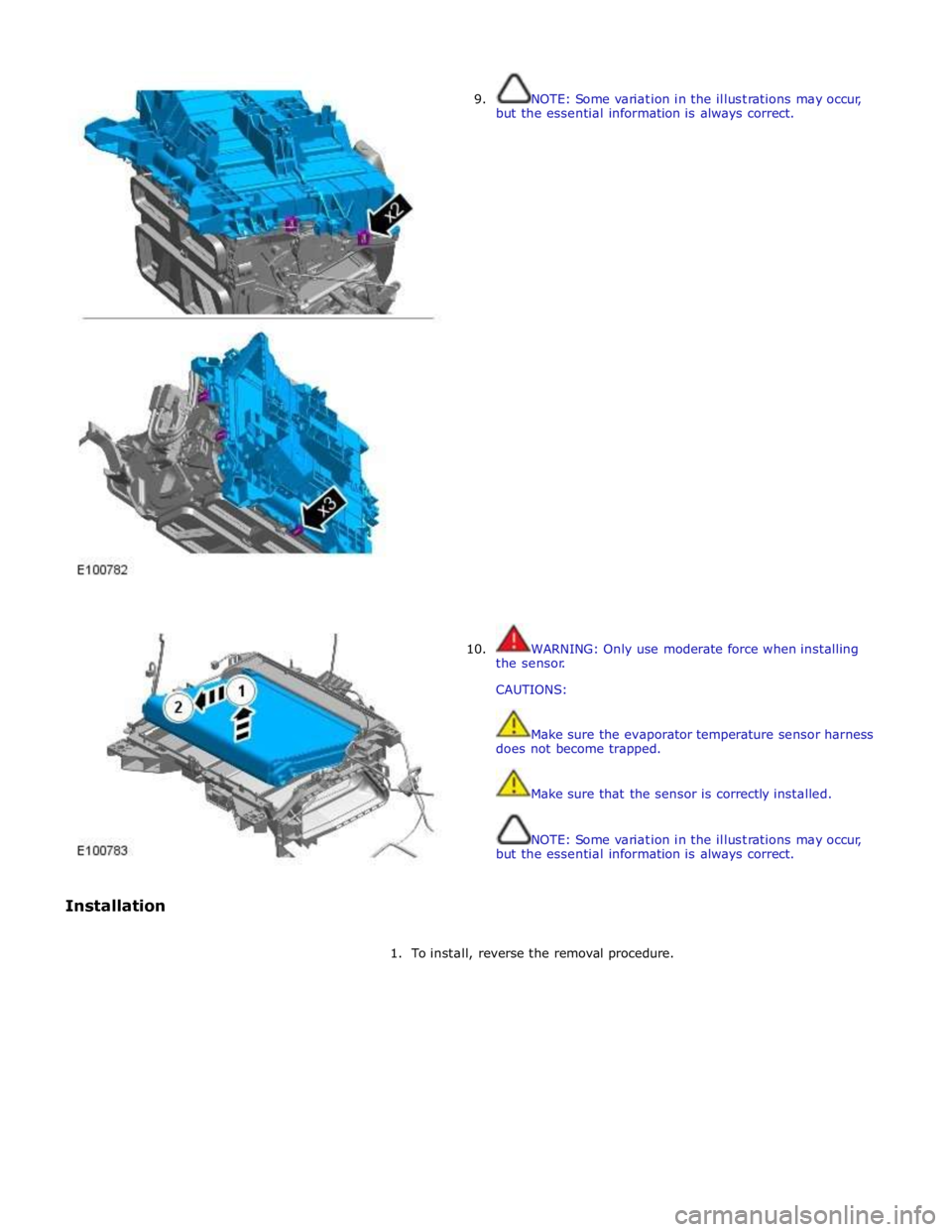

9.

10.

NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

WARNING: Only use moderate force when installing

the sensor.

CAUTIONS:

Make sure the evaporator temperature sensor harness

does not become trapped.

Make sure that the sensor is correctly installed.

NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

1. To install, reverse the removal procedure.