battery JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1885 of 3039

is operated to crank the engine. The GWM is connected to the ABS (Anti-lock Brake System) control module via the high speed

CAN bus. With the vehicle stationary and the engine off after an ECO engine stop, when the driver releases the brake pedal

the ABS control module senses the reduction in brake pressure. This change of brake pressure state is sent as a high speed

CAN message which is received by the GWM and the ECM. The GWM reacts within 105ms to instruct the DBM via the LIN bus

to operate the two contactors in the DBJB to supply the sensitive loads from the secondary battery and supply the TSS motor

direct from the primary battery.

When the engine is running and the generator is supplying power to the vehicle systems, the GWM again instructs the DBM to

operate the two contactors in the DBJB to supply all vehicle systems from the primary battery and the generator and to isolate

the secondary battery.

Secondary Battery Charging

The DBM also controls the charging of the secondary battery. The GWM contains electrical load management software and

monitors both batteries for their state of charge. The primary battery is monitored by the BMS control module which is

connected to the DBM via the LIN bus. The DBM communicates the primary battery condition to the GWM via a LIN bus

connection. The GWM sends a signal to the DBM via the LIN bus to instruct it to apply charging from the generator to the

secondary battery when required. The contactor 2 is closed by the DBJB to complete the secondary battery circuit, and the

generator output is applied to the secondary battery to charge it.

The generator output is controlled by the GWM which monitors and controls the electrical load management system. The

generator is connected to the GWM by a LIN bus allowing the GWM to control the output of the generator to maintain electrical

system load requirements and battery charging.

Electrical Load Management

The electrical load management is controlled by the GWM and the BMS control module.

The GWM will monitor the vehicle system power loads before and during an ECO engine stop.

Before an ECO engine stop, the GWM will transmit a signal to system control modules on the CAN bus to request a power save

on all electrical loads and set a minimum electrical value override. The GWM monitors the vehicle electrical loads and will

inhibit a ECO engine stop until the load current is at a value low enough to be supported by the secondary battery.

If the electrical loads cannot be reduced sufficiently, the GWM will inhibit the ECO engine stop.

When the engine is stopped after an ECO engine stop, the GWM will continue to monitor the primary battery state of charge.

If the primary or secondary battery voltage falls below 11.0V, a level which will result in degraded starting performance or

possible primary battery damage, the GWM will initiate an engine start.

System Inhibits

The ECO stop/start system is inhibited if the dual battery system is not be capable of preventing electrical loads on the

vehicle being subject to unacceptably low voltage levels during ECO stop/start operations due to a fault.

ECO stop/start inhibit monitoring of the primary battery is performed by the BMS control module. If the primary battery voltage

is too low to support an ECO stop/start, then the BMS control module will send a message to the GWM on the LIN bus to

suspend ECO stop/start.

The GWM monitors the secondary battery and the dual battery system components. Any fault found will cause the GWM to

inhibit ECO stop/start and the GWM will record a DTC (diagnostic trouble code).

Fault Diagnosis

The GWM performs passive and active diagnostics on the dual battery system to determine the status of the system

components.

Passive diagnostics can detect faults in the DBJB and can check for stuck open or closed contactors and failure of DBM

contactor command signals.

Active diagnostics is a routine to test the capability of the contactors to respond to open or close command signals sent from

the GWM to the DBM. This routine also checks the FET's (Field Effect Transistors) activate as required. (Refer to Dual Battery

Junction Box below for description of FET operation)

The GWM will also check the dual battery system components for faults in a controlled environment when the generator is

providing a charging output. This will ensure that the detection of a fault will not result in sensitive electrical loads being

subjected to low voltage which may occur during an ECO stop/start with a fault present.

The GWM will illuminate the charge warning indicator in the instrument cluster if fault is detected in the dual battery system

which will result in a degraded power supply.

If a fault is detected the GWM transmits a CAN message to inhibit ECO stop/start operation. In some cases it will record a

DTC, display a warning message in instrument cluster and also illuminate charge warning indicator.

PRIMARY BATTERY - ALL VEHICLES Component Description

The primary battery is located in a plastic tray under the luggage compartment floor in the right side of the luggage

compartment, adjacent to the spare wheel. The battery is vented via a tube which is connected with a T piece to the vent from

Page 1886 of 3039

the secondary battery (if fitted) and passes through a grommet in the floorpan.

On new vehicles the primary battery positive terminal is fitted with a transit relay. The transit relay must removed using the

correct process detailed in the Pre Delivery Inspection (PDI) manual.

The battery negative terminal is fitted with a BMS control module. The control module is integral with the battery negative

cable and communicates with the GWM via a LIN bus connection. The battery condition information is passed to the GWM

which controls the generator output accordingly.

CAUTION: To avoid damage to the BMS control module, always use the body ground point in the engine compartment and

not the battery negative terminal when connecting a slave power supply.

Failure to use the recommended ground point will lead to the setting of a DTC. Incorrect information of battery condition will

be retained by the BMS control module due to the unmonitored current flow into the battery. The system will however,

recognize and compensate for the change in battery status after a period of time.

If a new battery is fitted, the BMS control module will require re-calibration using a Jaguar approved diagnostic system.

Replacement of the BMS control module requires no action as the control module will re-calibrate automatically.

SECONDARY BATTERY - DUAL BATTERY VEHICLES ONLY

The secondary battery is located in a tray on the next of the primary battery and is secured to the DBJB with a bracket. The

battery negative (-) terminal is connected via a cable to the vehicle body. The positive (+) terminal is connected by a cable to

the DBJB. The battery is vented via a tube which is connected with a T piece to the vent from the primary battery and passes

through a grommet in the floorpan.

The state of charge of the secondary battery is monitored by the Gateway Module (GWM).

BATTERY MONITORING SYSTEM (BMS)

The BMS (battery monitoring system) control module is located on the primary battery negative (-) terminal. The module is

located on the battery post and is clamped to the post with a bolt and nut.

The primary battery negative ground cable is connected to the BMS control module and is attached to a ground stud on the

vehicle body.

The BMS control module is connected into the vehicle wiring harness via a multiplug. The BMS control module receives a 12V

power supply direct from the primary battery positive terminal. A LIN (local interconnect network) bus connection provides

communication between the BMS control module and the ECM for control and monitoring of the primary battery current drain and state of charge.

The BMS control module measures battery current and voltage, which it communicates to ECM.

CAUTION: Due to the self-calibration routine, it is recommended that all power supply diagnostic testing is carried out

using the Jaguar approved diagnostic system rather than a digital multimeter.

The BMS control module is able to generate DTC (diagnostic trouble code)'s to help diagnose primary battery or generator

power supply issues. These DTC's can be read using the Jaguar approved diagnostic system. The Jaguar approved diagnostic

system can also be used to implement a primary battery and generator self test routine. For additional information, refer to

the Diagnosis and Testing section of the workshop manual.

If a fault is detected, the GWM (gateway module) will override the BMS control module.

The BMS control module DTC's can be used to help diagnose battery or generator power supply faults. The DTC's are stored in

GWM. The Jaguar approved diagnostic system has a process for an automated power supply diagnostic procedure. The

procedure provides a menu driven process to locate a fault in a logical sequence. The procedure uses the capability of the BMS

control module and generator LIN bus controlled functions to provide current flow information and will detect if the BMS control

module or generator are functioning correctly.

Page 1887 of 3039

DUAL BATTERY MODULE (DBM)

The DBM (dual battery module) is located at the rear of the right wheel arch in the luggage compartment, adjacent to the

GWM (gateway module) and the RJB (rear junction box). The DBM is attached to a bracket, which is attached to a second

bracket secured to the vehicle body.

The DBM is connected by two hardwired connections to the DBJB (dual battery junction box). The DBM uses these two

connections to apply battery voltage to the contactor coils in the DBJB. A LIN bus connection from the GWM passes contactor operation signals to the DBM which operates the contactors as applicable.

The GWM will also instruct the DBM to apply charging to the secondary battery via a LIN bus message. The GWM instructs the

DBM of the charging current required for the secondary battery and the DBM applies the requested stabilized current to the

secondary battery via a dedicated connection direct to the secondary battery.

The DBM diagnoses the coils of the contactors and will report a fault via the LIN bus to the GWM.

The DBM receives a fused power supply from the RJB. www.JagDocs.com

Page 1889 of 3039

Battery, Mounting and Cables - Battery

Diagnosis and Testing

Principles of Operation Published: 10-Mar-2014

For a detailed description of the battery system and operation, refer to the relevant Description and Operation section of the

workshop manual. REFER to: Battery and Cables (414-01 Battery, Mounting and Cables, Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTES:

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer-approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

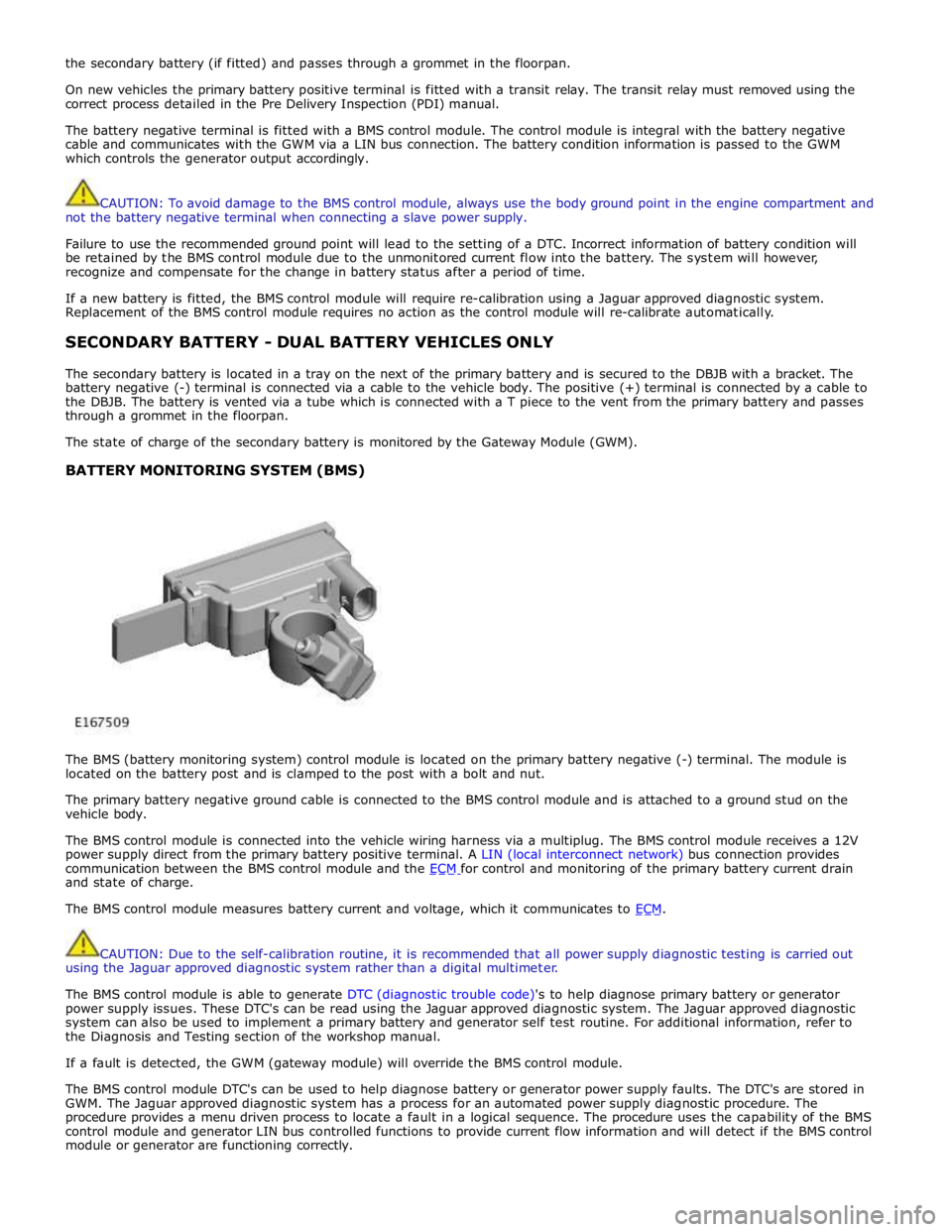

Visual Inspection

Mechanical Electrical

Generator

Drive belt

Drive belt tensioner

Generator pulley

Check the security of the generator fixings

Generator

Battery

Battery connections

Starter motor

Harnesses and connectors

Fuses

Charge warning lamp function

Engine Control Module (ECM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

5. Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

Symptom Chart

Symptom Possible Causes Action

Battery power to vehicle

interrupted

High resistance between battery terminals and

clamps

GO to Pinpoint Test

A. Midtronics EXP-1080 User Guide

Carry out the following: -

Surface Voltage Removal Process

A vehicle which has had its battery charged or been driven in a 24 hour period before the test, must have its surface charge

removed

Page 1890 of 3039

1. Turn on the ignition but do not start the vehicle

2. Switch on the headlamps on high beam for a minimum 3 minutes

3. Switch off the headlamps

4. Wait a minimum of 5 minutes before recording test results for any battery measurements

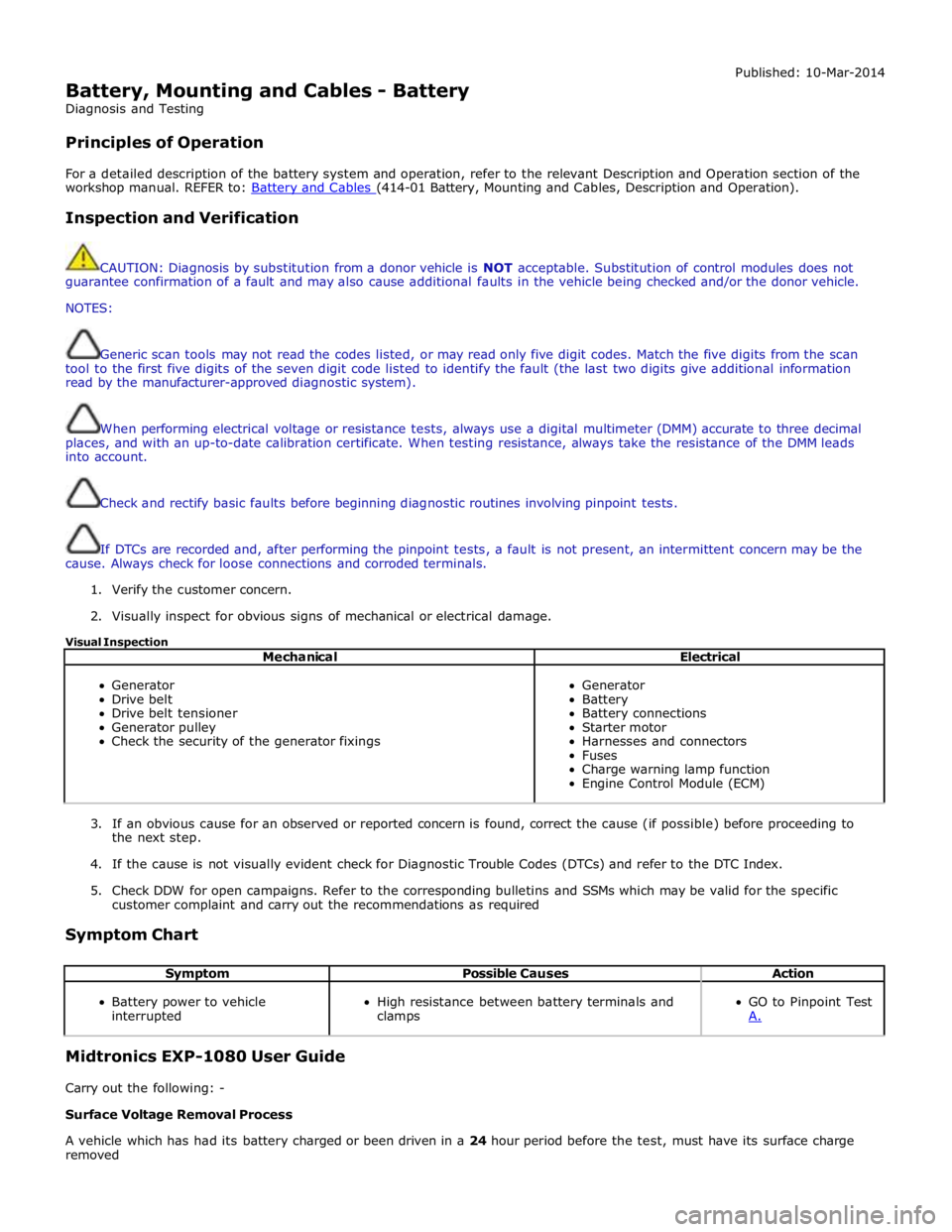

PINPOINT TEST A : VOLTAGE DROP TEST CONDITIONS DETAILS/RESULTS/ACTIONS A1: GROUND CIRCUIT

NOTE: This test checks for high resistance between the battery terminal and the battery clamp 1 Start the engine, turn on the following: (1) ) Air conditioning

(2) ) Blower fan on full speed

(3) Headlights on main beam

(4) Heated screen - rear

(5) Heated screen - front (if installed)

(6) Heated seats (if installed) 2 Connect the multimeter between the battery negative terminal and the battery clamp as shown in picture below (do not

disconnect the battery at this stage) 3 Set the multimeter to read DC voltage and record the reading Is reading equal to or below 0.1 volts? Yes

GO to A2. No

Switch all electrical loads and engine off, return the vehicle to

an ignition off condition. Disconnect the battery negative

clamp, clean clamp and terminal then reconnect and repeat test

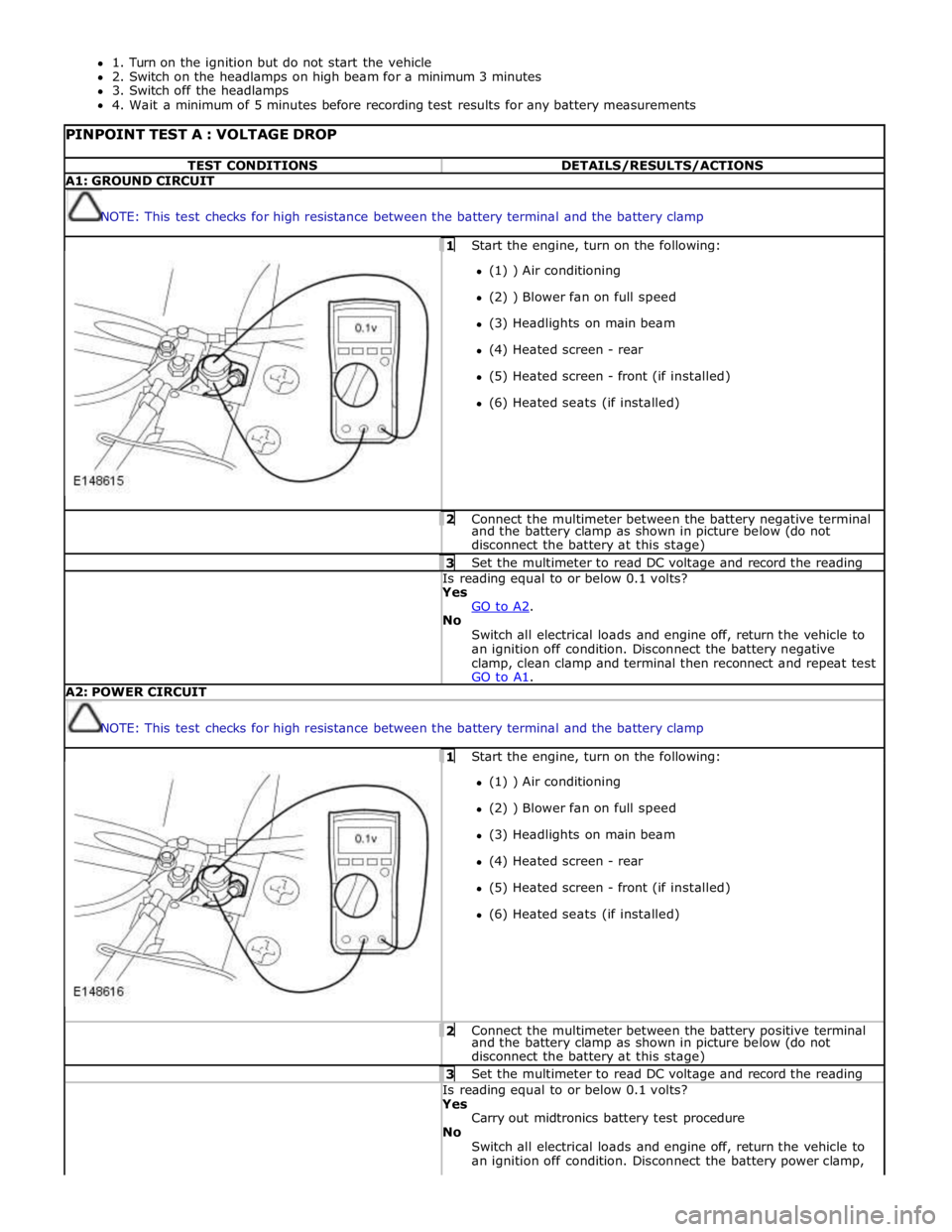

GO to A1. A2: POWER CIRCUIT

NOTE: This test checks for high resistance between the battery terminal and the battery clamp 1 Start the engine, turn on the following: (1) ) Air conditioning

(2) ) Blower fan on full speed

(3) Headlights on main beam

(4) Heated screen - rear

(5) Heated screen - front (if installed)

(6) Heated seats (if installed) 2 Connect the multimeter between the battery positive terminal and the battery clamp as shown in picture below (do not

disconnect the battery at this stage) 3 Set the multimeter to read DC voltage and record the reading Is reading equal to or below 0.1 volts? Yes

Carry out midtronics battery test procedure

No

Switch all electrical loads and engine off, return the vehicle to

an ignition off condition. Disconnect the battery power clamp,

Page 1891 of 3039

1 LCD screen with main menu 2 Control panel (key board and power button) 3 Positive and negative fly leads 4 Fly leads connection 5 Temperature sensor 6 Infra-red sensor (data transfer for printer) 7 Amp hour 8 Battery rating (CCA) 9 Rating units 10 Battery type

clean clamp and terminal then reconnect and repeat test GO to A2.

Page 1892 of 3039

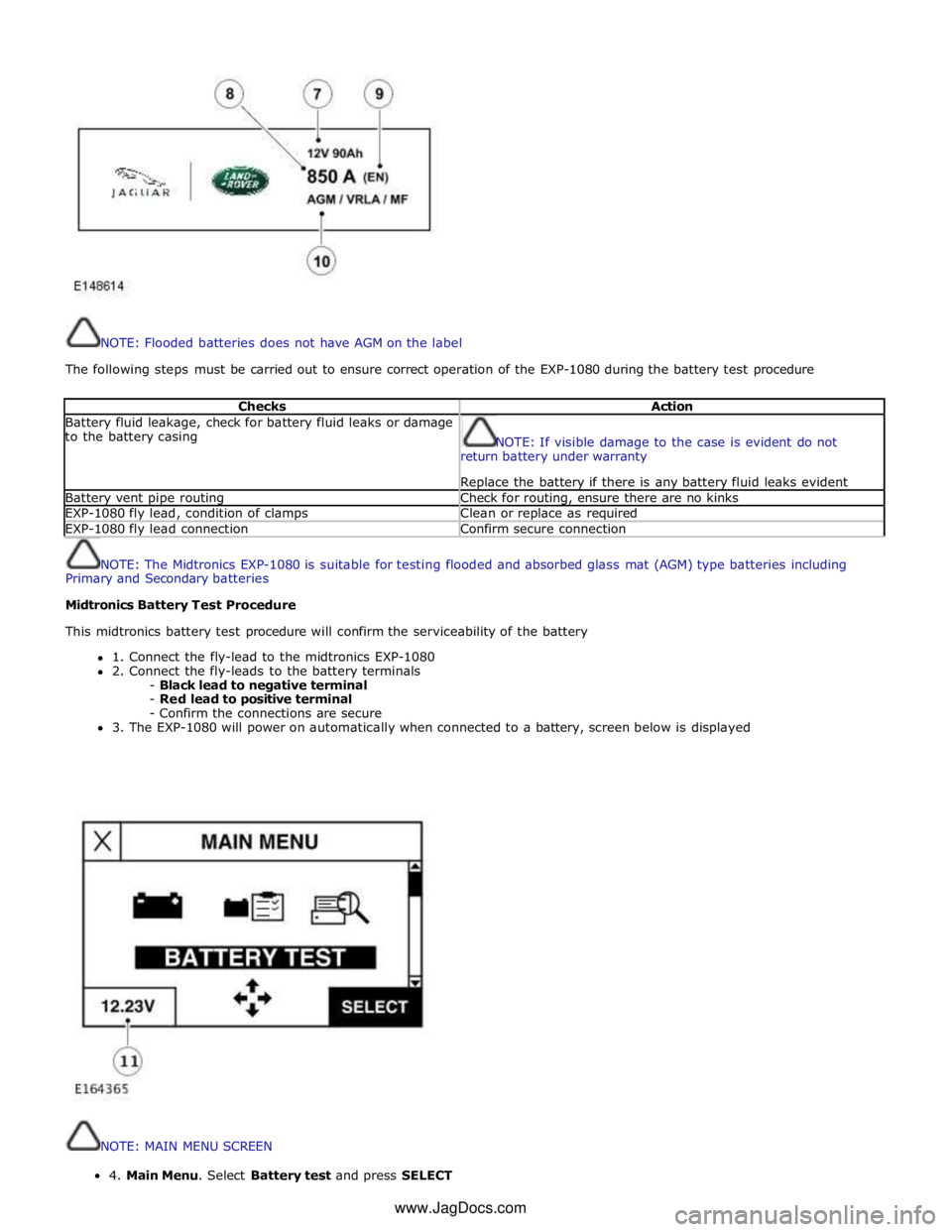

NOTE: Flooded batteries does not have AGM on the label

The following steps must be carried out to ensure correct operation of the EXP-1080 during the battery test procedure

Checks Action Battery fluid leakage, check for battery fluid leaks or damage

to the battery casing

NOTE: If visible damage to the case is evident do not

return battery under warranty

Replace the battery if there is any battery fluid leaks evident Battery vent pipe routing Check for routing, ensure there are no kinks EXP-1080 fly lead, condition of clamps Clean or replace as required EXP-1080 fly lead connection Confirm secure connection

NOTE: The Midtronics EXP-1080 is suitable for testing flooded and absorbed glass mat (AGM) type batteries including

Primary and Secondary batteries

Midtronics Battery Test Procedure

This midtronics battery test procedure will confirm the serviceability of the battery

1. Connect the fly-lead to the midtronics EXP-1080

2. Connect the fly-leads to the battery terminals

- Black lead to negative terminal

- Red lead to positive terminal

- Confirm the connections are secure

3. The EXP-1080 will power on automatically when connected to a battery, screen below is displayed

NOTE: MAIN MENU SCREEN 4.MainMenu.SelectBatterytestandpressSELECT

www.JagDocs.com

Page 1893 of 3039

NOTE: BATTERY LOCATION

5. Battery Location

Select Next

6. VIN. When IN VEHICLE selected, enter the last six of the VIN using the key pad

Page 1894 of 3039

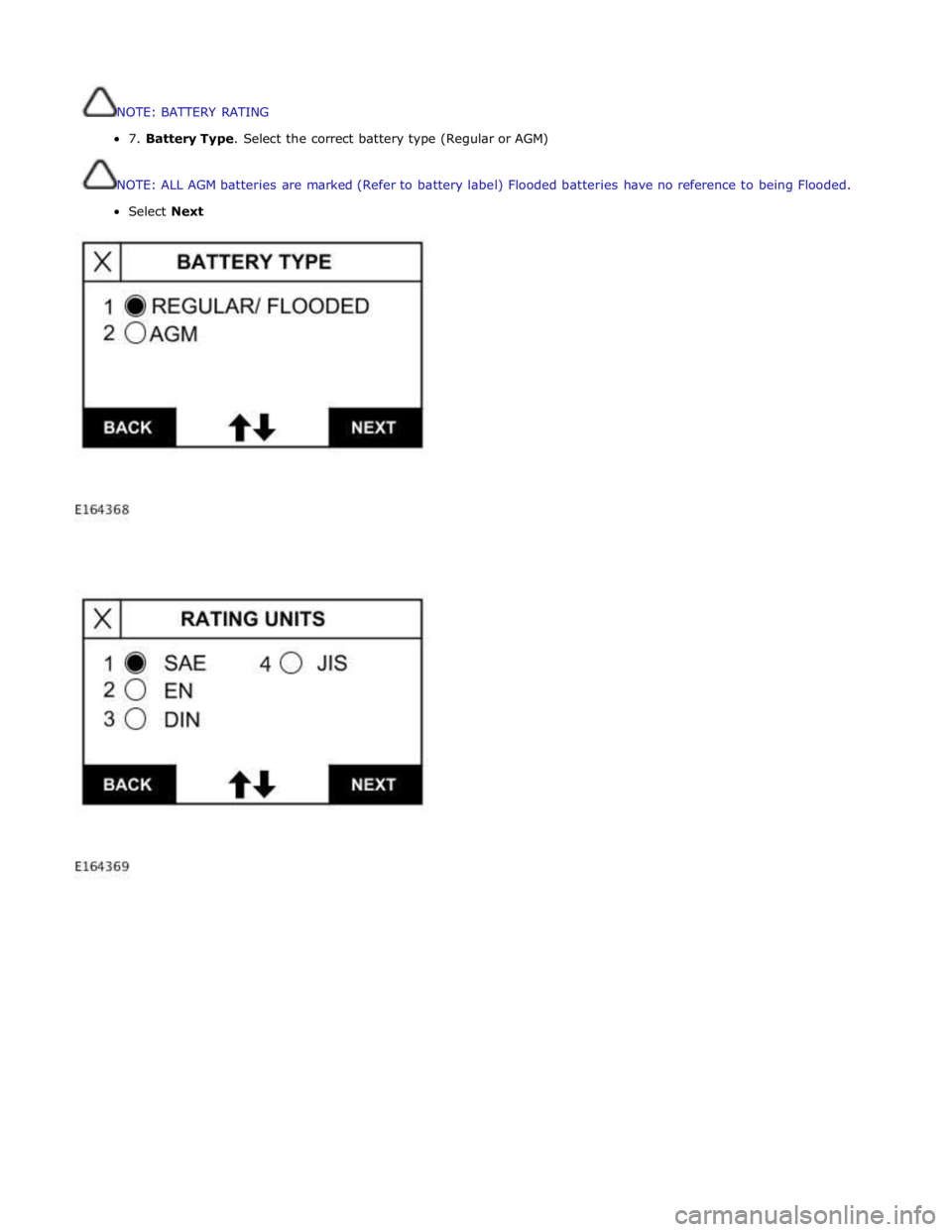

NOTE:BATTERYRATING

7.BatteryType.Selectthecorrectbatterytype(RegularorAGM)

NOTE:ALLAGMbatteriesaremarked(Refertobatterylabel) Flooded batterieshavenoreferencetobeing Flooded.

SelectNext

Page 1895 of 3039

NOTE:

BATTERY

RATING

9.

BATTERY

RATING.

Scroll

using

the

arrow

keys

on

the

midtronics

panel,

select

the

correct

CCA

rating

(For

CCA

refer

to

battery

label)

Select

Next

NOTE:BATTERYTYPE

8.BatteryUnits.Selectthecorrectbatteryratingfromthebatterylabelinbrackets(number9).Scrollusingthearrow

ontheMidtronicspanelandselectNext

NOTE:UNITS