JAGUAR XFR 2010 1.G Workshop Manual

XFR 2010 1.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7642/w960_7642-0.png

JAGUAR XFR 2010 1.G Workshop Manual

Trending: check oil, B100d-64, spark plug replacement, coolant capacity, snow chains, Drc, lug pattern

Page 421 of 3039

System - V6 3.0L Petrol, Removal and Installation).

19. Refill the fuel tank.

For additional information, refer to: Fuel Tank Draining (310-00 Fuel System - General Information, General Procedures).

20. Bleed the brake system.

For additional information, refer to: Brake System Bleeding (206-00 Brake System - General Information, General Procedures).

21. Install the rear wheels and tires.

For additional information, refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

22. Connect the battery ground cable.

For additional information, refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

23. Using only four-wheel alignment equipment approved by Jaguar, check

and adjust the wheel alignment.

For additional information, refer to: Camber and Caster Adjustment (204-00 Suspension System - General Information, General Procedures).

Page 422 of 3039

204-269

Flange remover forcing screw

204-305

Remover, Wheel Bearing

204-725

Support Tool, Wheel Hub

204-726

Remover/Installer, Wheel Bearing

204-727A

Installer, Wheel Bearing

Page 423 of 3039

205-491

Hub puller

205-491-1

Adapter nuts Removal

1. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

2. Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

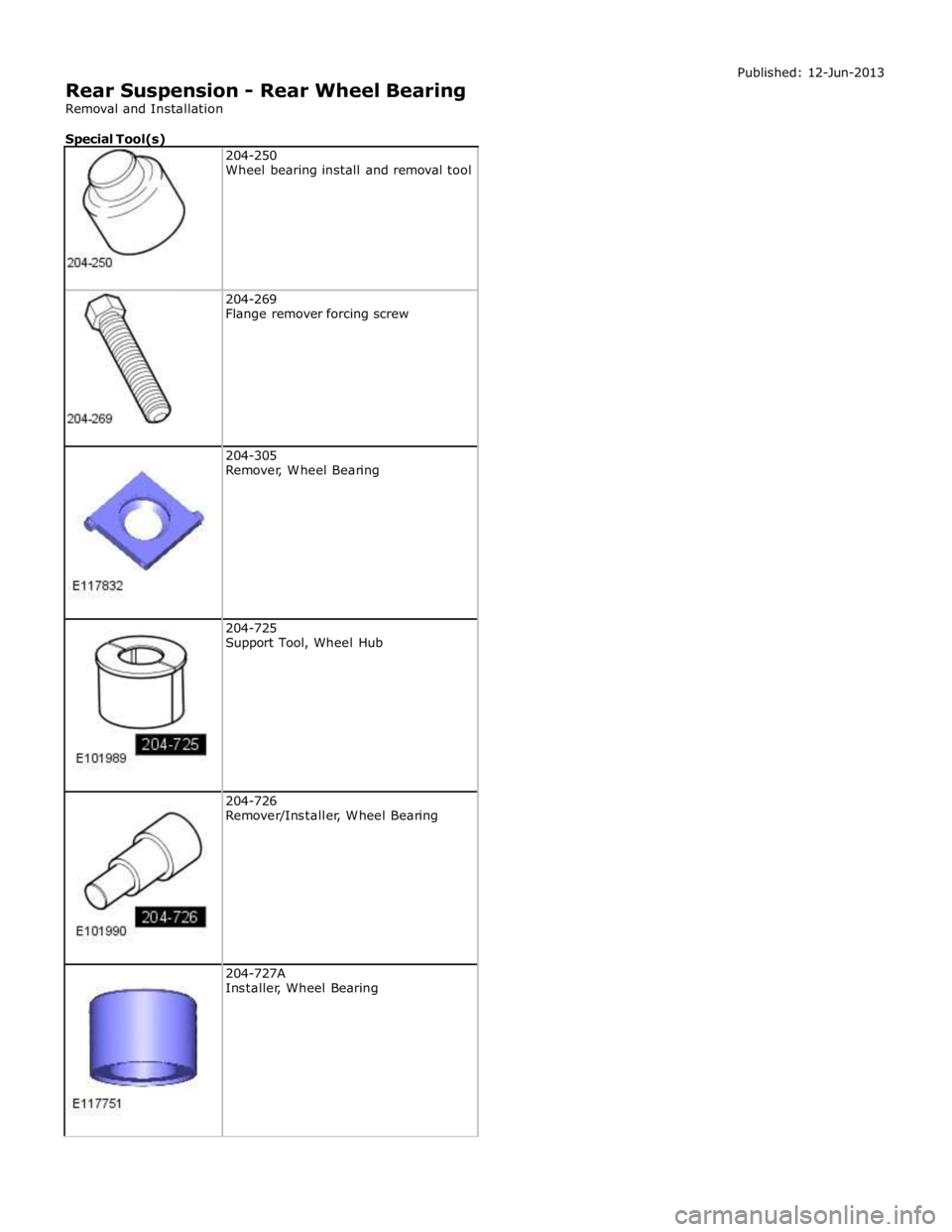

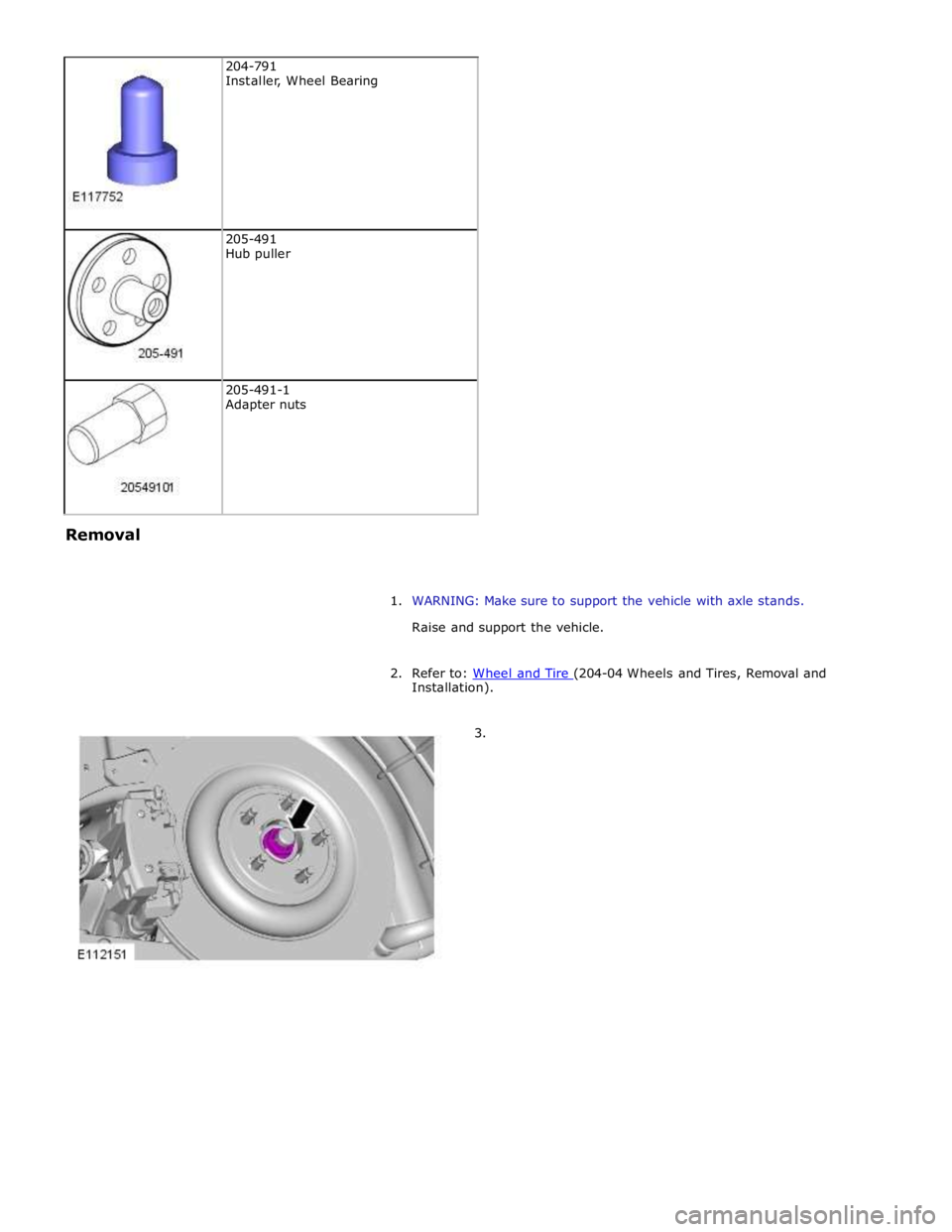

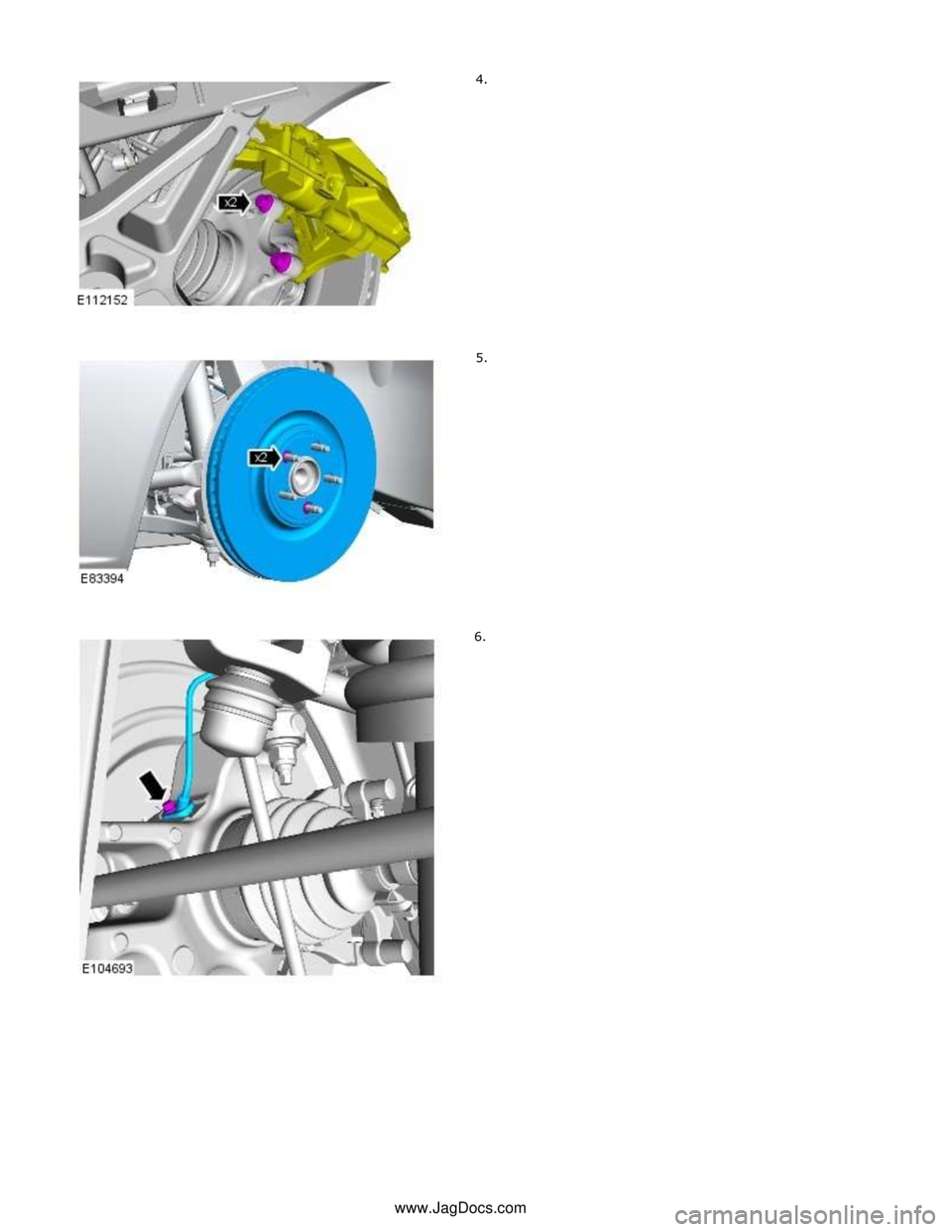

3.

Page 424 of 3039

Page 425 of 3039

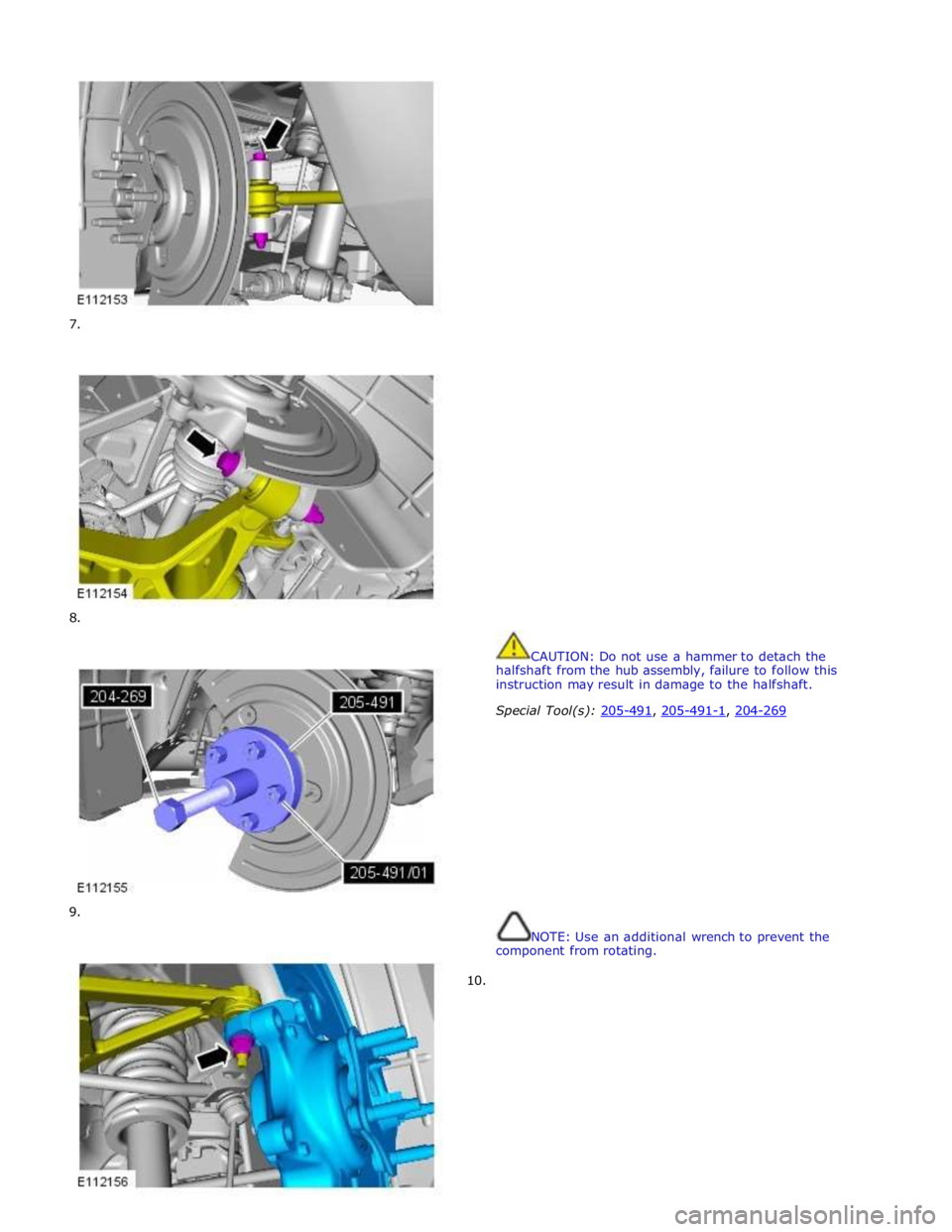

7.

8.

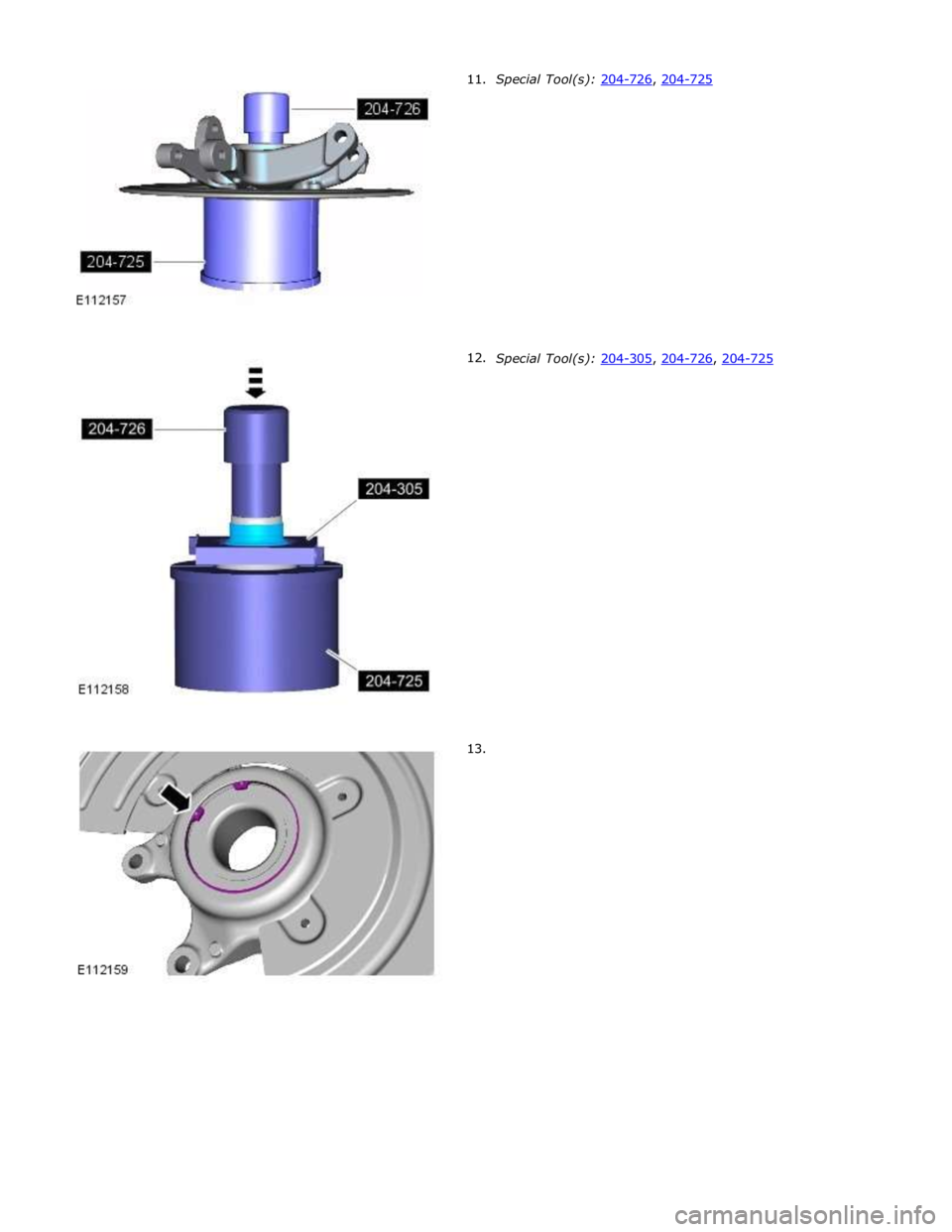

9.

10.

CAUTION: Do not use a hammer to detach the

halfshaft from the hub assembly, failure to follow this

instruction may result in damage to the halfshaft.

Special Tool(s): 205-491, 205-491-1, 204-269

NOTE: Use an additional wrench to prevent the

component from rotating.

Page 426 of 3039

Special Tool(s): 204-305, 204-726, 204-725

Page 427 of 3039

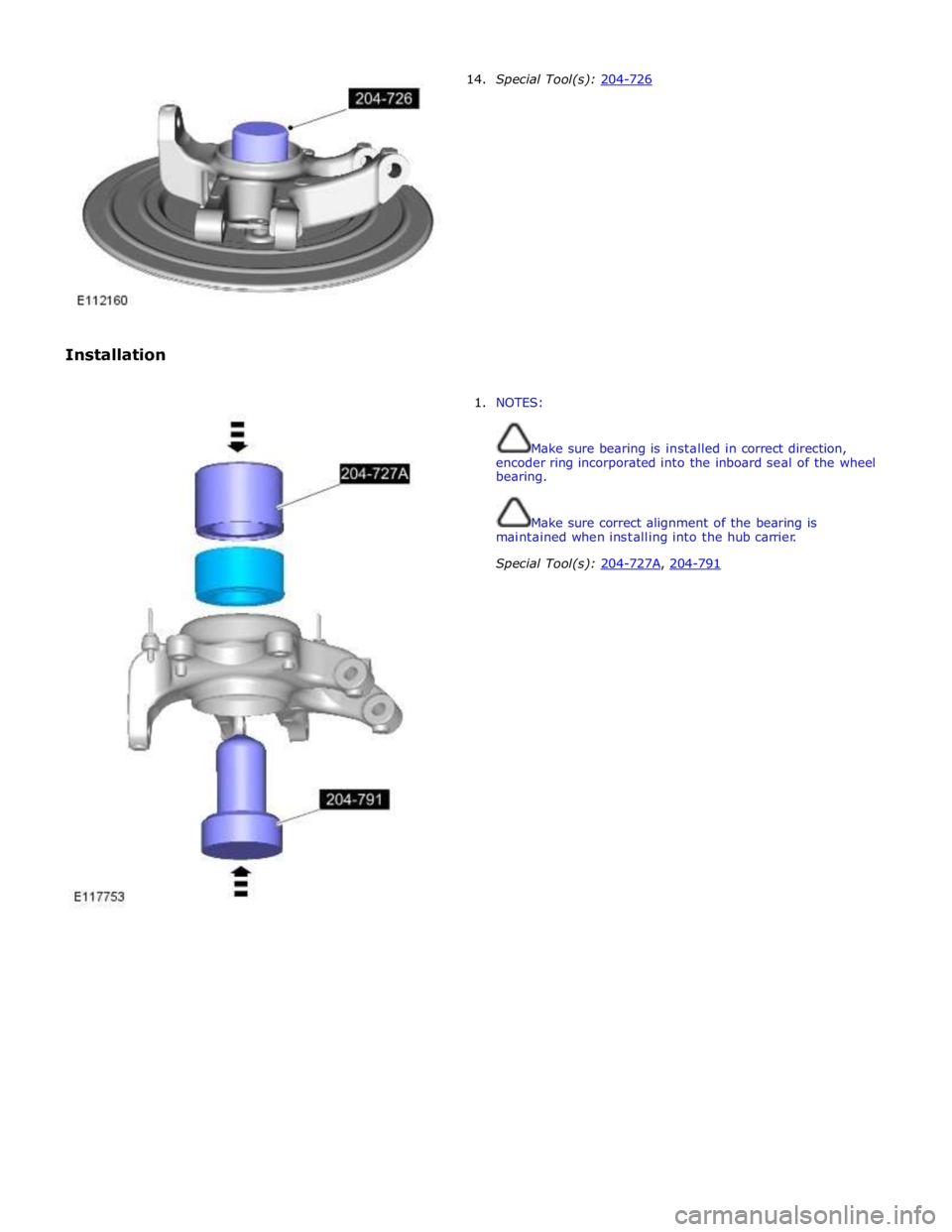

Installation 14. Special Tool(s): 204-726

1. NOTES:

Make sure bearing is installed in correct direction,

encoder ring incorporated into the inboard seal of the wheel

bearing.

Make sure correct alignment of the bearing is

maintained when installing into the hub carrier.

Special Tool(s): 204-727A, 204-791

Page 428 of 3039

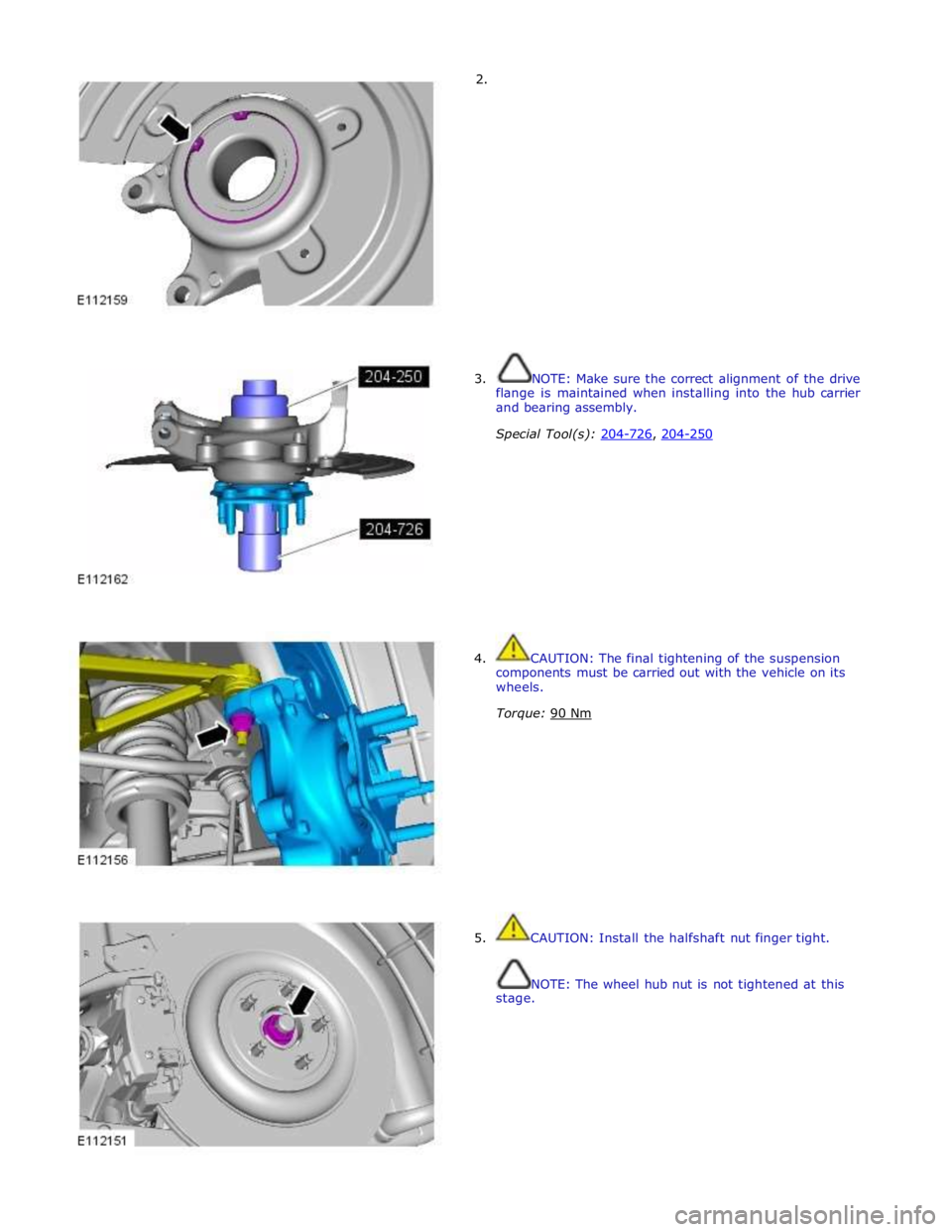

2.

3. NOTE: Make sure the correct alignment of the drive

flange is maintained when installing into the hub carrier

and bearing assembly.

Special Tool(s): 204-726, 204-250

4. CAUTION: The final tightening of the suspension

components must be carried out with the vehicle on its

wheels.

Torque: 90 Nm

5. CAUTION: Install the halfshaft nut finger tight.

NOTE: The wheel hub nut is not tightened at this

stage.

Page 429 of 3039

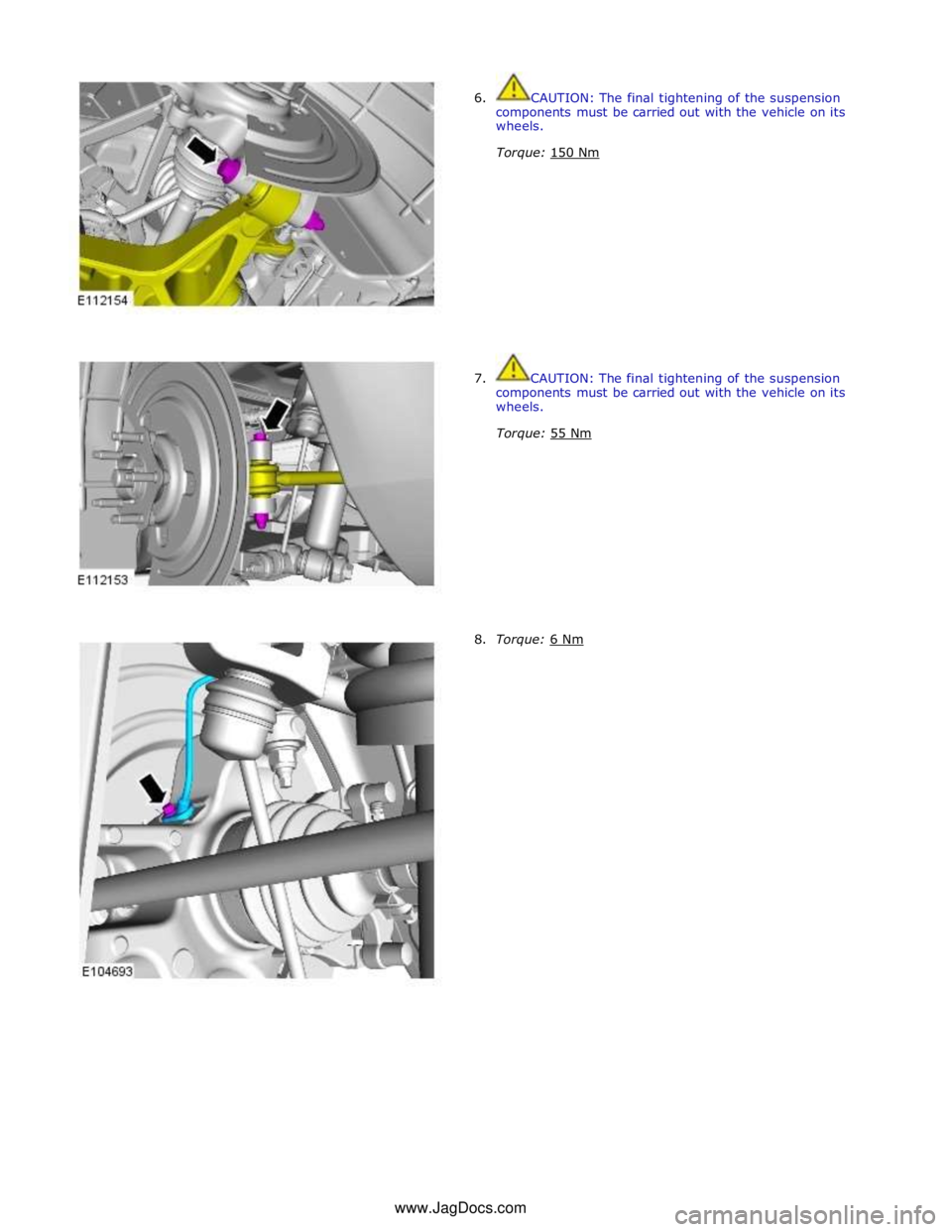

6. CAUTION: The final tightening of the suspension

components must be carried out with the vehicle on its

wheels.

Torque: 150 Nm

7. CAUTION: The final tightening of the suspension

components must be carried out with the vehicle on its

wheels.

Torque: 55 Nm

8. Torque: 6 Nm www.JagDocs.com

Page 430 of 3039

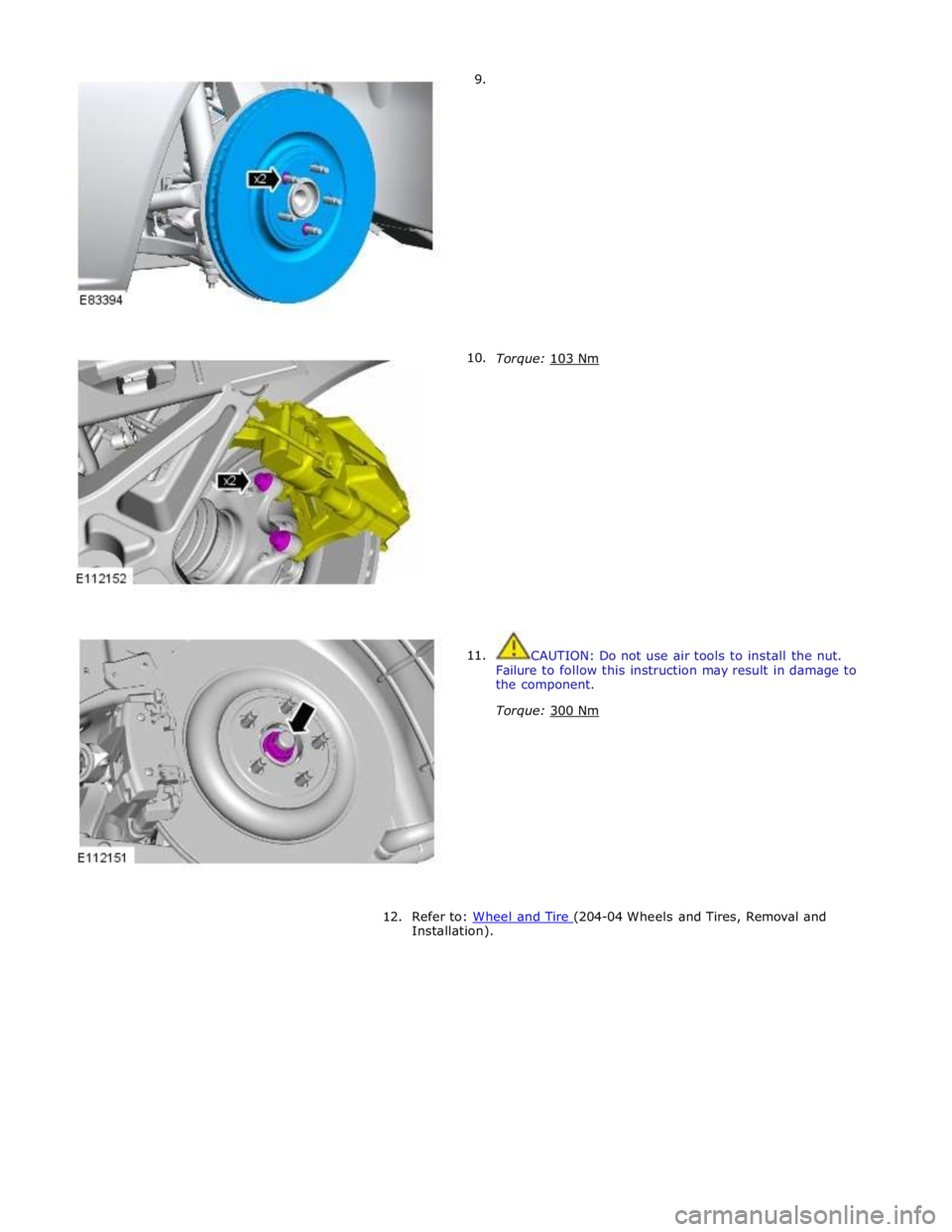

9.

10.

11.

Torque: 103 Nm

CAUTION: Do not use air tools to install the nut.

Failure to follow this instruction may result in damage to

the component.

Torque: 300 Nm

12. Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

Trending: tire pressure reset, B111E-15, coolant pump, heater, B102B, manual transmission, auxiliary battery