differential JAGUAR XFR 2010 1.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 563 of 3039

Published: 11-May-2011

Rear Drive Halfshafts - Rear Drive Halfshafts - System Operation and

Component Description

Description and Operation

System Operation

Rear Drive Halfshafts Component Description

The solid-steel halfshafts are of unequal length, with each halfshaft comprising inner and outer CV (constant velocity) joints.

The CV joints are the 'ball and socket' type packed with grease and protected by gaiters.

The outer CV joint is an interference fit into the wheel hub and secured by a locking nut. The inner CV joint is a slide fit and is

retained in the differential with a spring clip.

www.JagDocs.com

Page 568 of 3039

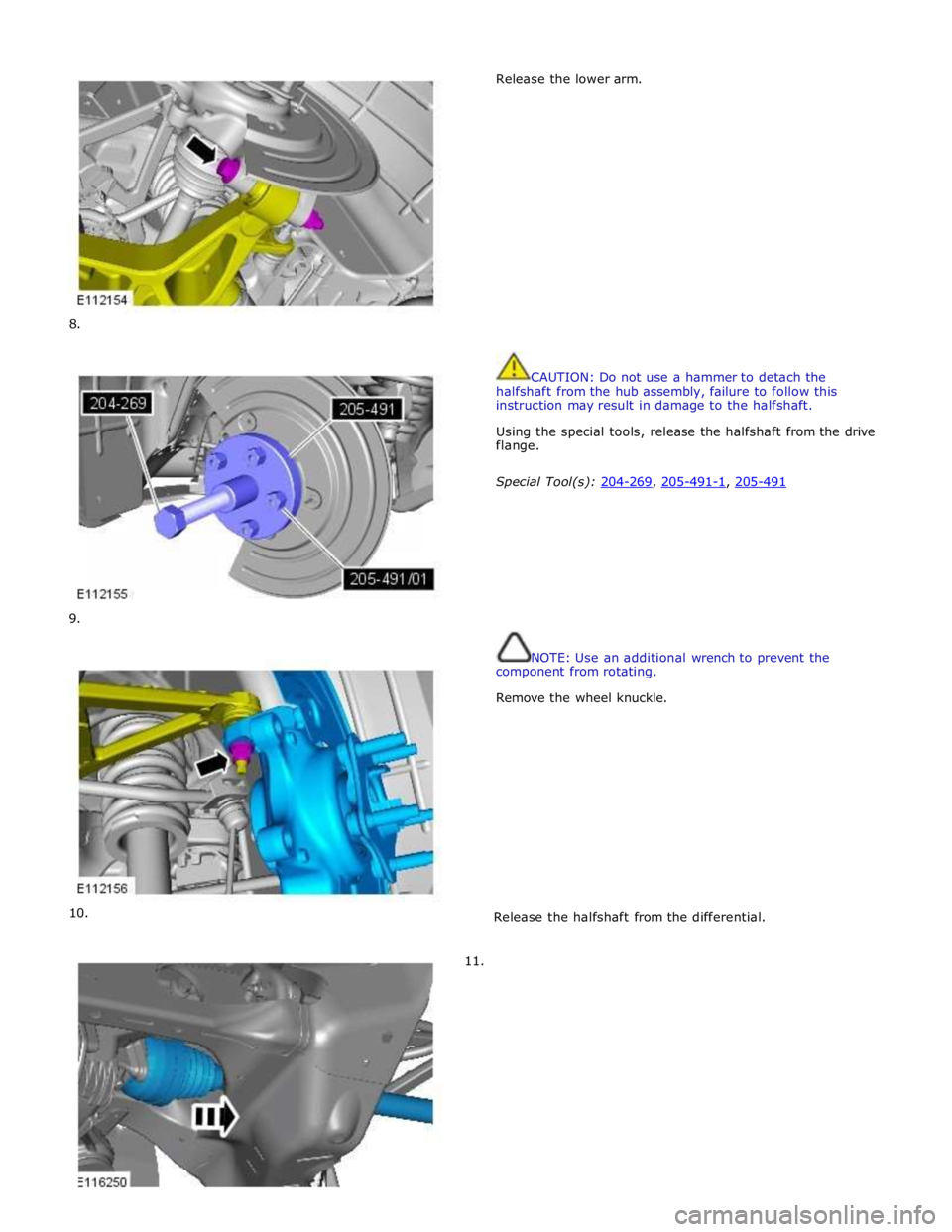

8.

9.

10.

11. Release the lower arm.

CAUTION: Do not use a hammer to detach the

halfshaft from the hub assembly, failure to follow this

instruction may result in damage to the halfshaft.

Using the special tools, release the halfshaft from the drive

flange.

Special Tool(s): 204-269, 205-491-1, 205-491

NOTE: Use an additional wrench to prevent the

component from rotating.

Remove the wheel knuckle.

Release the halfshaft from the differential.

Page 574 of 3039

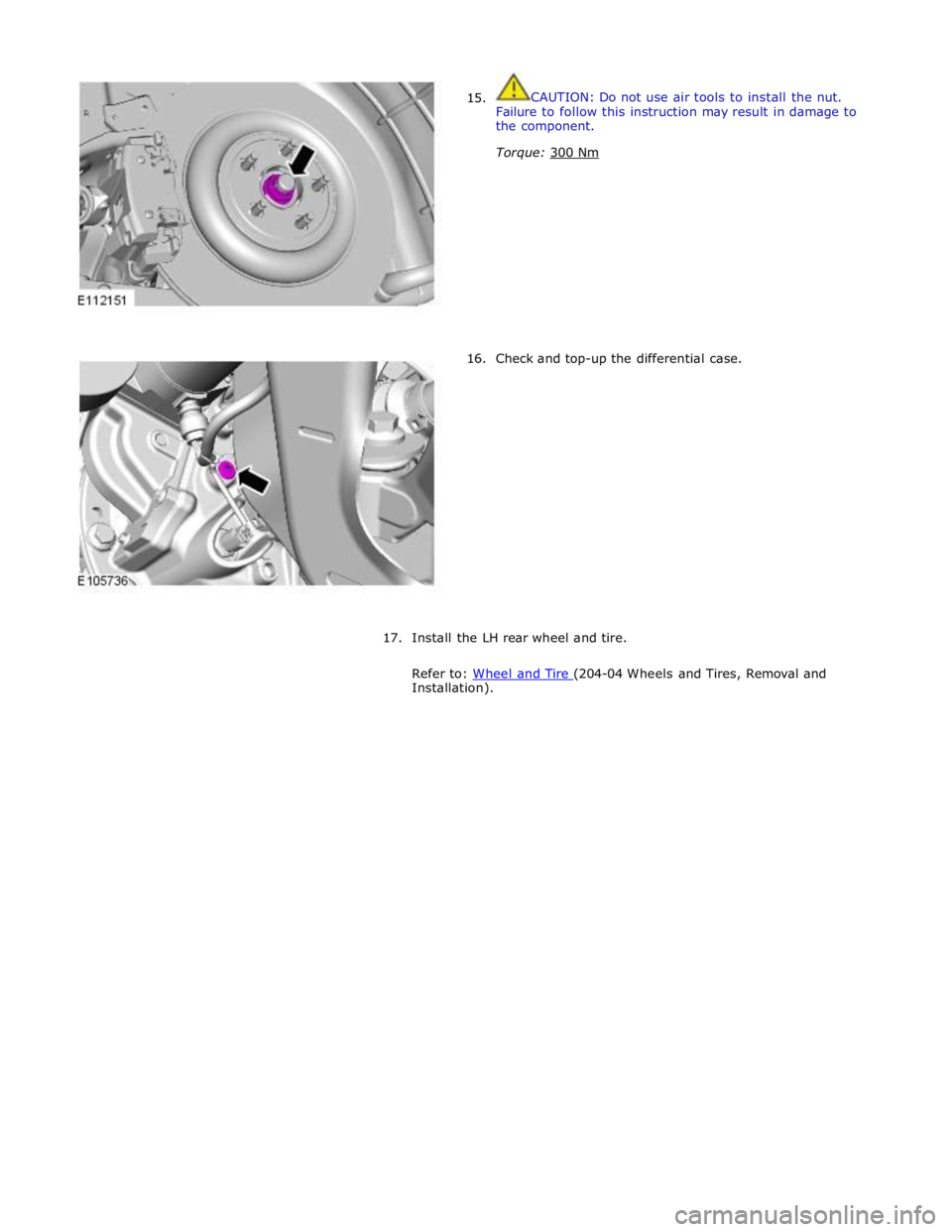

15.

16. CAUTION: Do not use air tools to install the nut.

Failure to follow this instruction may result in damage to

the component.

Torque: 300 Nm

Check and top-up the differential case.

17.

Install the LH rear wheel and tire.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

Page 664 of 3039

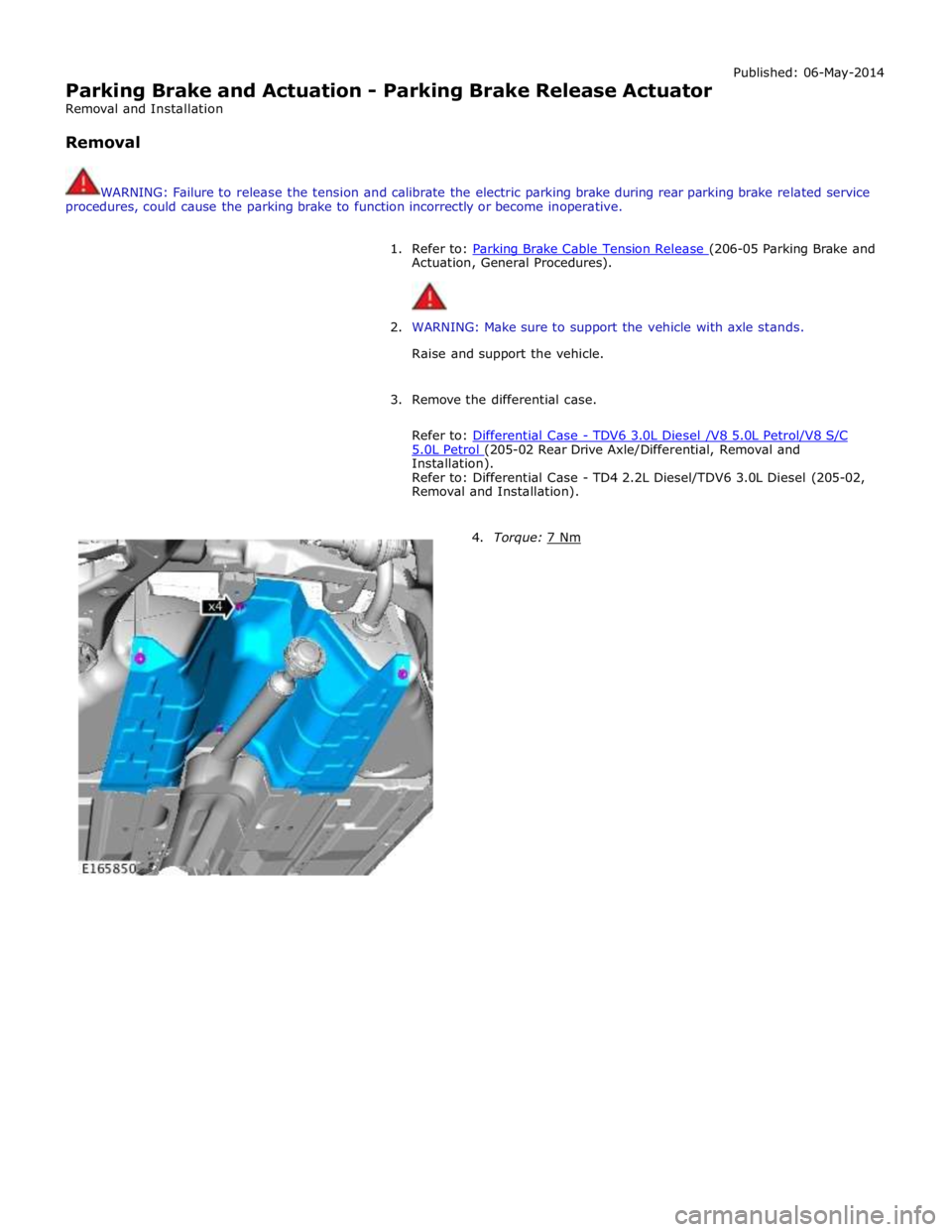

Parking Brake and Actuation - Parking Brake Release Actuator

Removal and Installation

Removal Published: 06-May-2014

WARNING: Failure to release the tension and calibrate the electric parking brake during rear parking brake related service

procedures, could cause the parking brake to function incorrectly or become inoperative.

1. Refer to: Parking Brake Cable Tension Release (206-05 Parking Brake and Actuation, General Procedures).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Remove the differential case.

Refer to: Differential Case - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol (205-02 Rear Drive Axle/Differential, Removal and Installation).

Refer to: Differential Case - TD4 2.2L Diesel/TDV6 3.0L Diesel (205-02,

Removal and Installation).

4. Torque: 7 Nm

Page 1348 of 3039

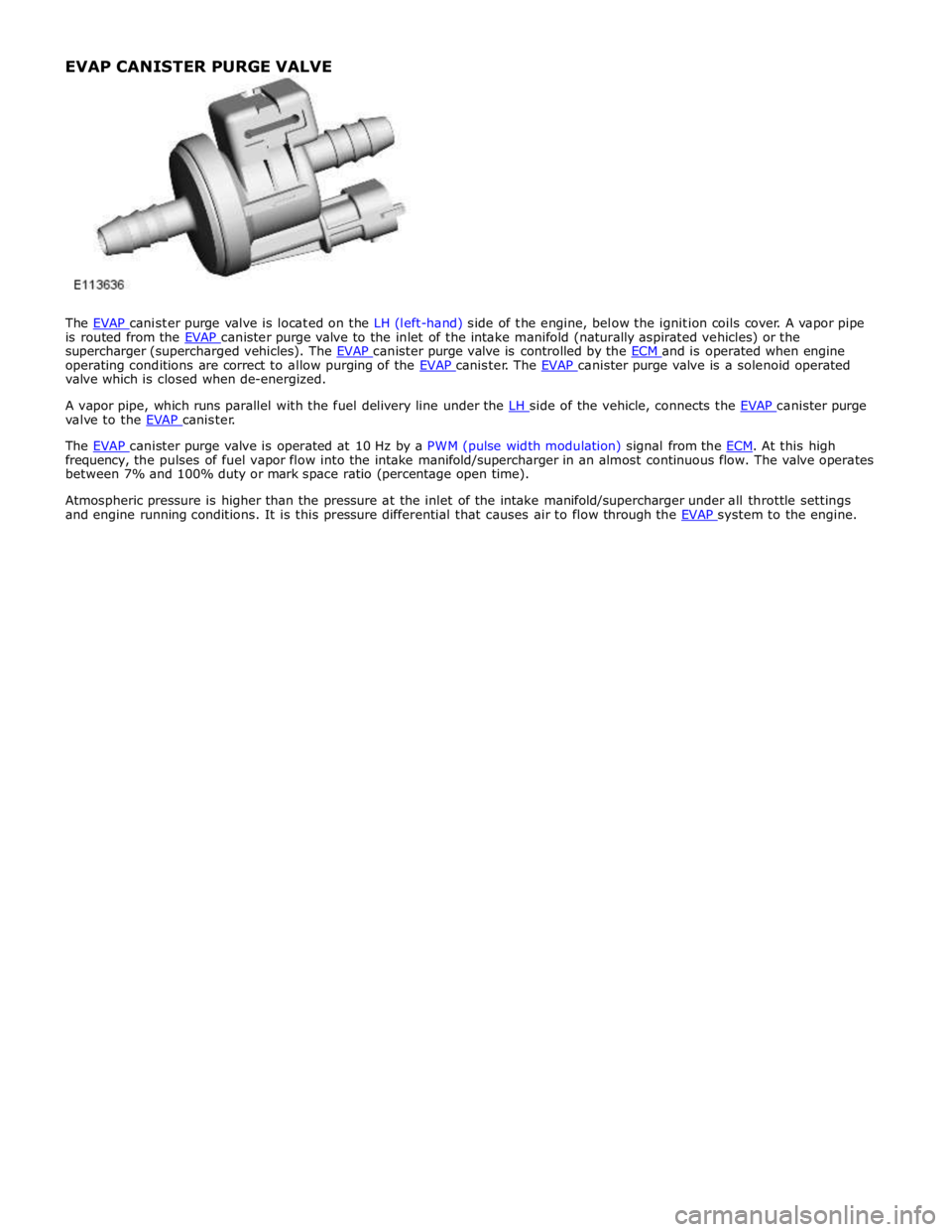

is routed from the EVAP canister purge valve to the inlet of the intake manifold (naturally aspirated vehicles) or the supercharger (supercharged vehicles). The EVAP canister purge valve is controlled by the ECM and is operated when engine operating conditions are correct to allow purging of the EVAP canister. The EVAP canister purge valve is a solenoid operated valve which is closed when de-energized.

A vapor pipe, which runs parallel with the fuel delivery line under the LH side of the vehicle, connects the EVAP canister purge valve to the EVAP canister.

The EVAP canister purge valve is operated at 10 Hz by a PWM (pulse width modulation) signal from the ECM. At this high frequency, the pulses of fuel vapor flow into the intake manifold/supercharger in an almost continuous flow. The valve operates

between 7% and 100% duty or mark space ratio (percentage open time).

Atmospheric pressure is higher than the pressure at the inlet of the intake manifold/supercharger under all throttle settings

and engine running conditions. It is this pressure differential that causes air to flow through the EVAP system to the engine. EVAP CANISTER PURGE VALVE

Page 1350 of 3039

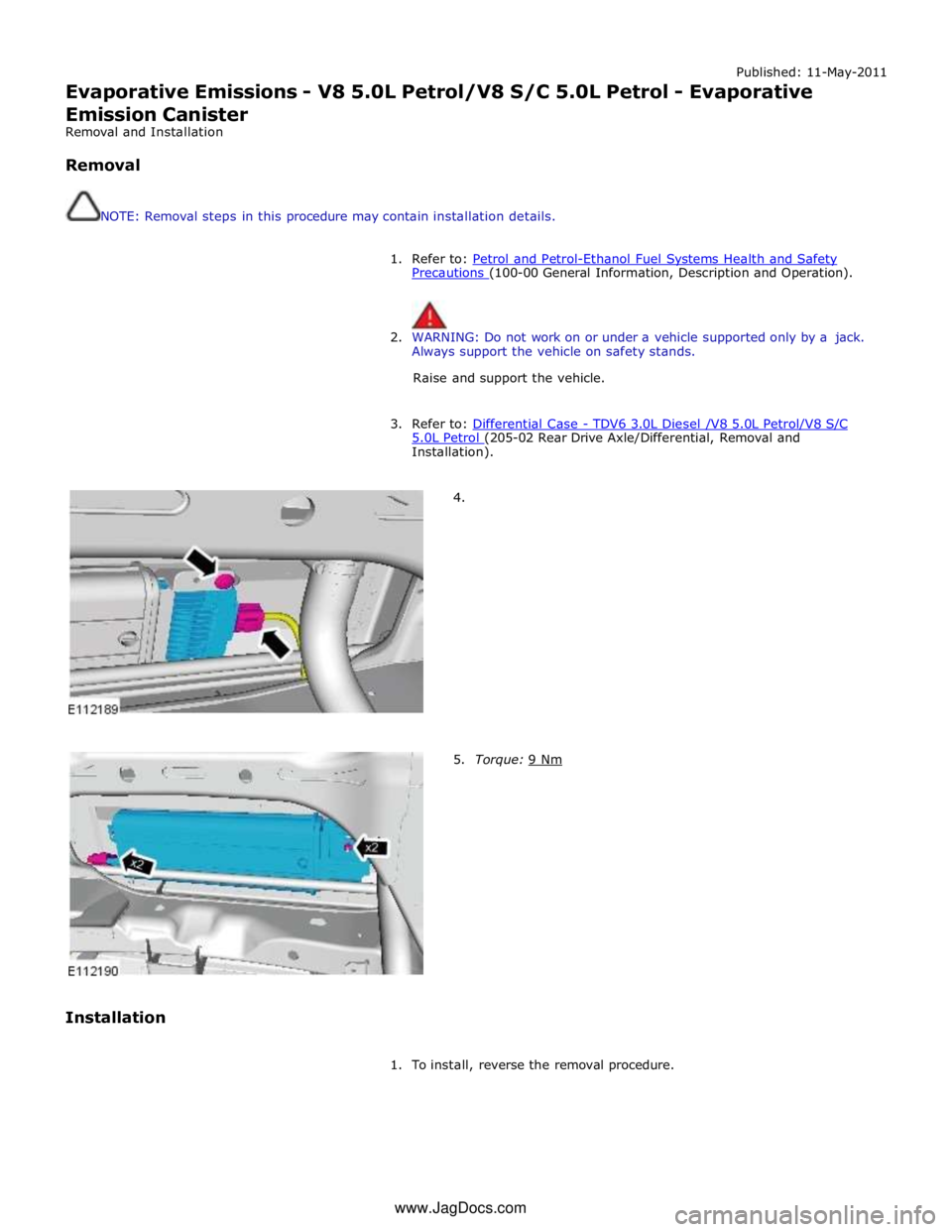

Published: 11-May-2011

Evaporative Emissions - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Evaporative

Emission Canister

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Petrol and Petrol-Ethanol Fuel Systems Health and Safety Precautions (100-00 General Information, Description and Operation).

2. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

3. Refer to: Differential Case - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol (205-02 Rear Drive Axle/Differential, Removal and Installation).

Installation

4.

5. Torque: 9 Nm

1. To install, reverse the removal procedure. www.JagDocs.com

Page 1436 of 3039

Visual Inspection

Mechanical Electrical Hydraulic

Damaged/stuck shift mechanism

Damaged automatic transmission casing

Blown fuse(s)

Damaged, loose or corroded connectors

Wiring harness

Fluid level too high/low

Poor condition of fluid

Fluid leak

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident check for diagnostic trouble codes (DTCs) and refer to the DTC Index.

DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00.

NOTES:

If the control module/transmission is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to the

installation of a new module/transmission.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Cause Action P0121-86 Throttle/Pedal Position

Sensor A Circuit

Range/Performance - signal

invalid

Throttle/Pedal Position

Sensor Fault (Data

received over CAN Bus) Check Engine Control Module for stored DTCs P0219-86 Engine Overspeed Condition

- signal invalid

Engine speed too low or

too high (Data received

over CAN Bus) Check Engine Control Module for stored DTCs P0500-81

Vehicle Speed Sensor A -

invalid serial data received

Vehicle Speed Sensor

fault (Data received over

CAN Bus) Check DSC module for stored DTCs P0501-81 Vehicle Speed Sensor A

Vehicle Speed receive Check Anti-lock braking system module for stored Range/Performance invalid DTCs. Check correct Differential is installed to the serial data received over CAN Bus does not

vehicle match Transmission Output-Shaft speed P0561-1C

System Voltage Unstable -

Circuit voltage out of range

Power supply voltage out

of range when engine

running Check Engine control module for stored DTCs. Check

Charging System and Battery condition P0562-21

System Voltage Low - signal

amplitude < minimum

Circuit low voltage.

Battery supply voltage to

Transmission Control

Module (Transmission Refer to Circuit diagrams and check Power and Ground

Circuit for fault. Check Engine control module for

stored DTCs. Check Charging System and Battery

condition

Page 1694 of 3039

inlet duct downstream of the blower, where any heat generated during operation is dissipated by the air flow.

Auxiliary Coolant Pump

On all vehicles except 3.0L, an auxiliary coolant pump is installed on the rear right side of the radiator housing, in the return

line from the heater core. The auxiliary coolant pump is an electric pump that boosts the flow of coolant through the heater

core.

Ventilation Outlets

The ventilation outlets allow the free flow of air through the passenger compartment. The outlets are installed in the LH and

RH rear quarter panels, below the rear lamps. Each ventilation outlet consists of a grille covered by a soft rubber flap, and is

effectively a non-return valve. The flaps open and close automatically depending on the pressure differential between the air

inside and outside the vehicle.

Page 1706 of 3039

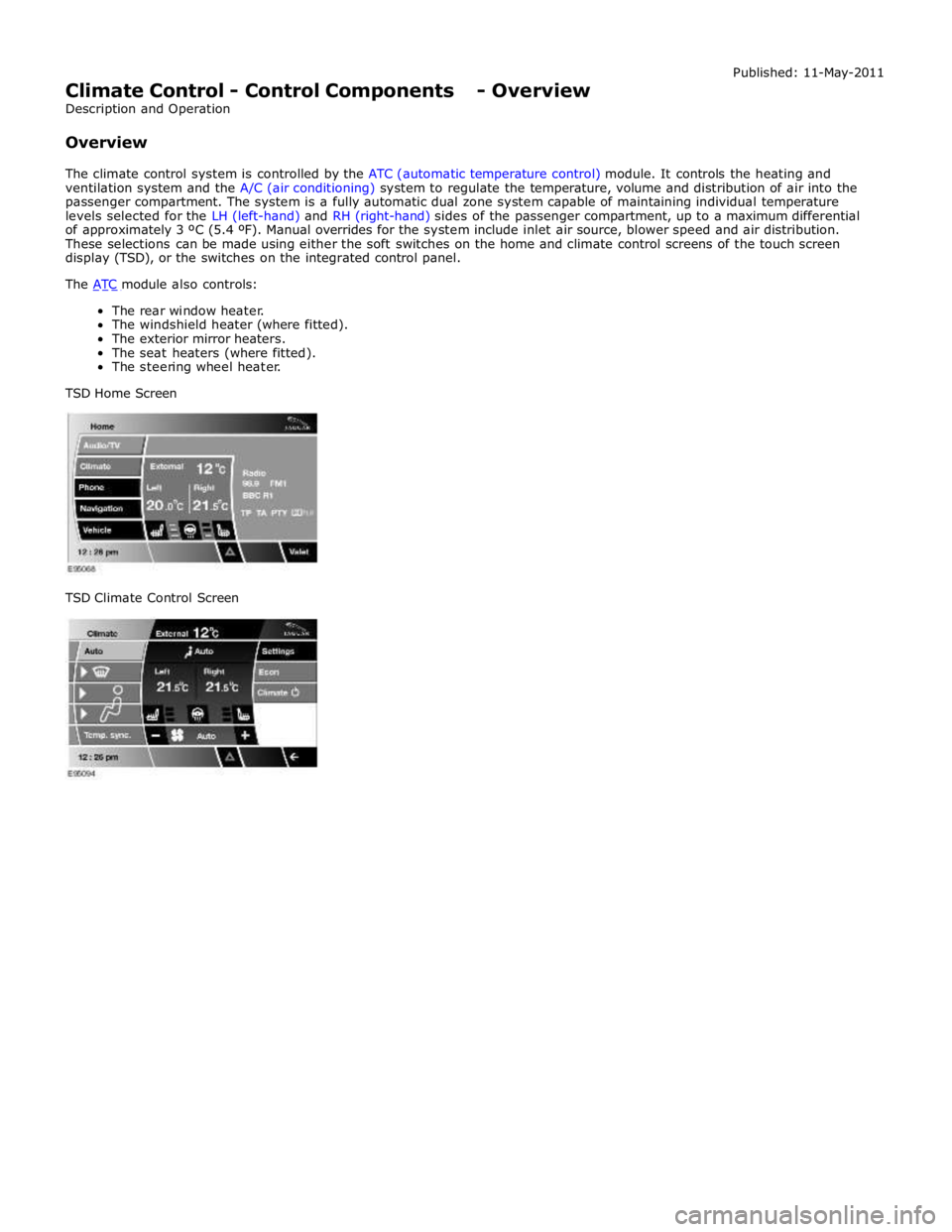

Climate Control - Control Components - Overview

Description and Operation

Overview Published: 11-May-2011

The climate control system is controlled by the ATC (automatic temperature control) module. It controls the heating and

ventilation system and the A/C (air conditioning) system to regulate the temperature, volume and distribution of air into the

passenger compartment. The system is a fully automatic dual zone system capable of maintaining individual temperature

levels selected for the LH (left-hand) and RH (right-hand) sides of the passenger compartment, up to a maximum differential

of approximately 3 ºC (5.4 ºF). Manual overrides for the system include inlet air source, blower speed and air distribution.

These selections can be made using either the soft switches on the home and climate control screens of the touch screen

display (TSD), or the switches on the integrated control panel.

The ATC module also controls: The rear window heater.

The windshield heater (where fitted).

The exterior mirror heaters.

The seat heaters (where fitted).

The steering wheel heater.

TSD Home Screen

TSD Climate Control Screen

Page 1828 of 3039

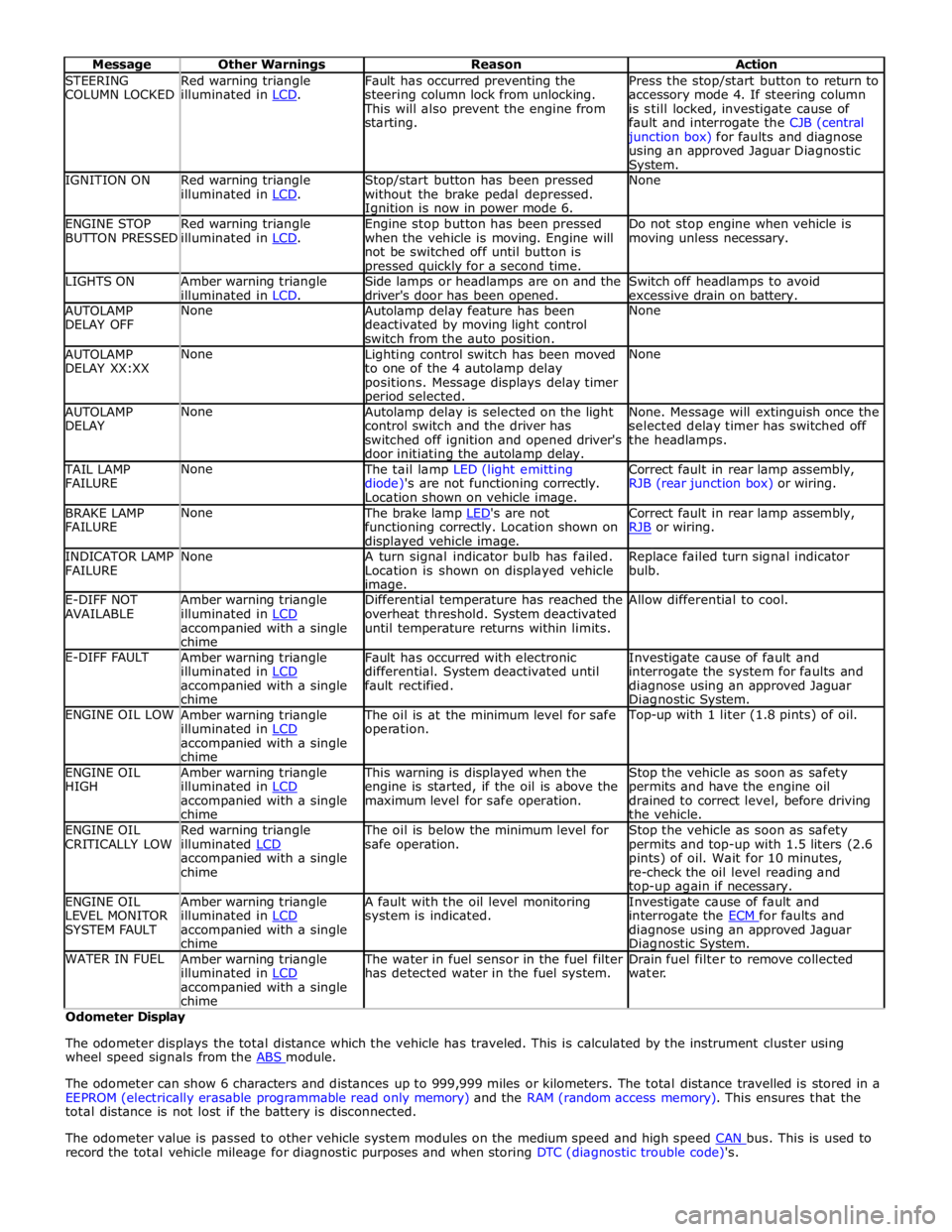

STEERING

COLUMN LOCKED Red warning triangle

illuminated in LCD. Fault has occurred preventing the

steering column lock from unlocking. This will also prevent the engine from

starting. Press the stop/start button to return to

accessory mode 4. If steering column

is still locked, investigate cause of

fault and interrogate the CJB (central junction box) for faults and diagnose

using an approved Jaguar Diagnostic System. IGNITION ON

Red warning triangle

illuminated in LCD. Stop/start button has been pressed

without the brake pedal depressed. Ignition is now in power mode 6. None ENGINE STOP

BUTTON PRESSED Red warning triangle

illuminated in LCD. Engine stop button has been pressed

when the vehicle is moving. Engine will

not be switched off until button is pressed quickly for a second time. Do not stop engine when vehicle is

moving unless necessary. LIGHTS ON

Amber warning triangle

illuminated in LCD. Side lamps or headlamps are on and the

driver's door has been opened. Switch off headlamps to avoid

excessive drain on battery. AUTOLAMP

DELAY OFF None

Autolamp delay feature has been

deactivated by moving light control

switch from the auto position. None AUTOLAMP

DELAY XX:XX None

Lighting control switch has been moved

to one of the 4 autolamp delay

positions. Message displays delay timer period selected. None AUTOLAMP

DELAY None

Autolamp delay is selected on the light

control switch and the driver has

switched off ignition and opened driver's

door initiating the autolamp delay. None. Message will extinguish once the

selected delay timer has switched off

the headlamps. TAIL LAMP

FAILURE None The tail lamp LED (light emitting

diode)'s are not functioning correctly.

Location shown on vehicle image. Correct fault in rear lamp assembly,

RJB (rear junction box) or wiring. BRAKE LAMP

FAILURE None The brake lamp LED's are not functioning correctly. Location shown on displayed vehicle image. Correct fault in rear lamp assembly,

RJB or wiring. INDICATOR LAMP

FAILURE None

A turn signal indicator bulb has failed.

Location is shown on displayed vehicle image. Replace failed turn signal indicator

bulb. E-DIFF NOT

AVAILABLE Amber warning triangle

illuminated in LCD accompanied with a single

chime Differential temperature has reached the

overheat threshold. System deactivated

until temperature returns within limits. Allow differential to cool. E-DIFF FAULT

Amber warning triangle

illuminated in LCD accompanied with a single

chime Fault has occurred with electronic

differential. System deactivated until

fault rectified. Investigate cause of fault and

interrogate the system for faults and

diagnose using an approved Jaguar Diagnostic System. ENGINE OIL LOW

Amber warning triangle

illuminated in LCD accompanied with a single

chime The oil is at the minimum level for safe

operation. Top-up with 1 liter (1.8 pints) of oil. ENGINE OIL

HIGH Amber warning triangle

illuminated in LCD accompanied with a single

chime This warning is displayed when the

engine is started, if the oil is above the

maximum level for safe operation. Stop the vehicle as soon as safety

permits and have the engine oil

drained to correct level, before driving

the vehicle. ENGINE OIL

CRITICALLY LOW Red warning triangle

illuminated LCD accompanied with a single

chime The oil is below the minimum level for

safe operation. Stop the vehicle as soon as safety

permits and top-up with 1.5 liters (2.6

pints) of oil. Wait for 10 minutes,

re-check the oil level reading and top-up again if necessary. ENGINE OIL

LEVEL MONITOR

SYSTEM FAULT Amber warning triangle

illuminated in LCD accompanied with a single

chime A fault with the oil level monitoring

system is indicated. Investigate cause of fault and

interrogate the ECM for faults and diagnose using an approved Jaguar Diagnostic System. WATER IN FUEL

Amber warning triangle

illuminated in LCD accompanied with a single

chime The water in fuel sensor in the fuel filter

has detected water in the fuel system. Drain fuel filter to remove collected

water. Odometer Display

The odometer displays the total distance which the vehicle has traveled. This is calculated by the instrument cluster using

wheel speed signals from the ABS module.

The odometer can show 6 characters and distances up to 999,999 miles or kilometers. The total distance travelled is stored in a

EEPROM (electrically erasable programmable read only memory) and the RAM (random access memory). This ensures that the

total distance is not lost if the battery is disconnected.

The odometer value is passed to other vehicle system modules on the medium speed and high speed CAN bus. This is used to record the total vehicle mileage for diagnostic purposes and when storing DTC (diagnostic trouble code)'s.