suspension JAGUAR XFR 2010 1.G Manual PDF

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 421 of 3039

System - V6 3.0L Petrol, Removal and Installation).

19. Refill the fuel tank.

For additional information, refer to: Fuel Tank Draining (310-00 Fuel System - General Information, General Procedures).

20. Bleed the brake system.

For additional information, refer to: Brake System Bleeding (206-00 Brake System - General Information, General Procedures).

21. Install the rear wheels and tires.

For additional information, refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

22. Connect the battery ground cable.

For additional information, refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

23. Using only four-wheel alignment equipment approved by Jaguar, check

and adjust the wheel alignment.

For additional information, refer to: Camber and Caster Adjustment (204-00 Suspension System - General Information, General Procedures).

Page 428 of 3039

2.

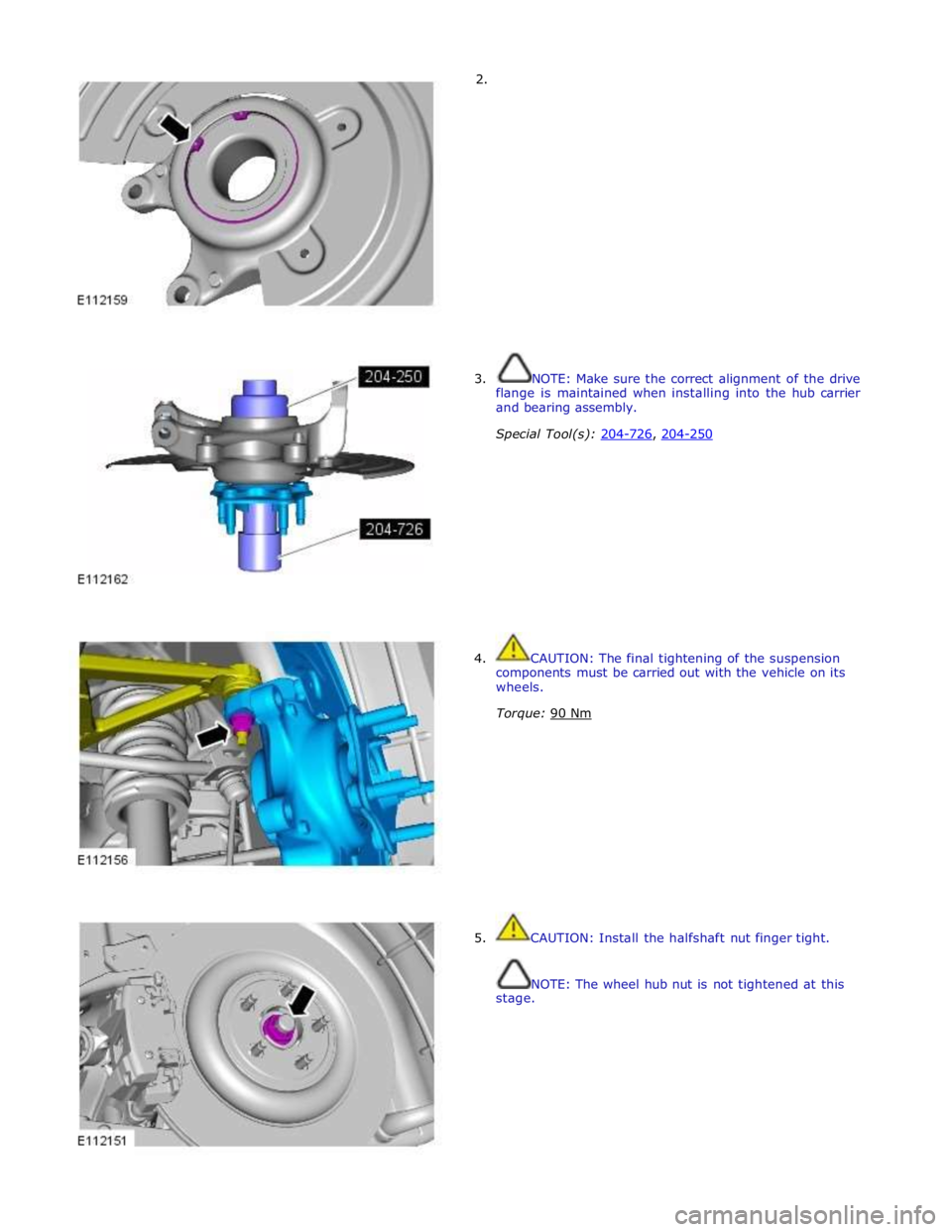

3. NOTE: Make sure the correct alignment of the drive

flange is maintained when installing into the hub carrier

and bearing assembly.

Special Tool(s): 204-726, 204-250

4. CAUTION: The final tightening of the suspension

components must be carried out with the vehicle on its

wheels.

Torque: 90 Nm

5. CAUTION: Install the halfshaft nut finger tight.

NOTE: The wheel hub nut is not tightened at this

stage.

Page 429 of 3039

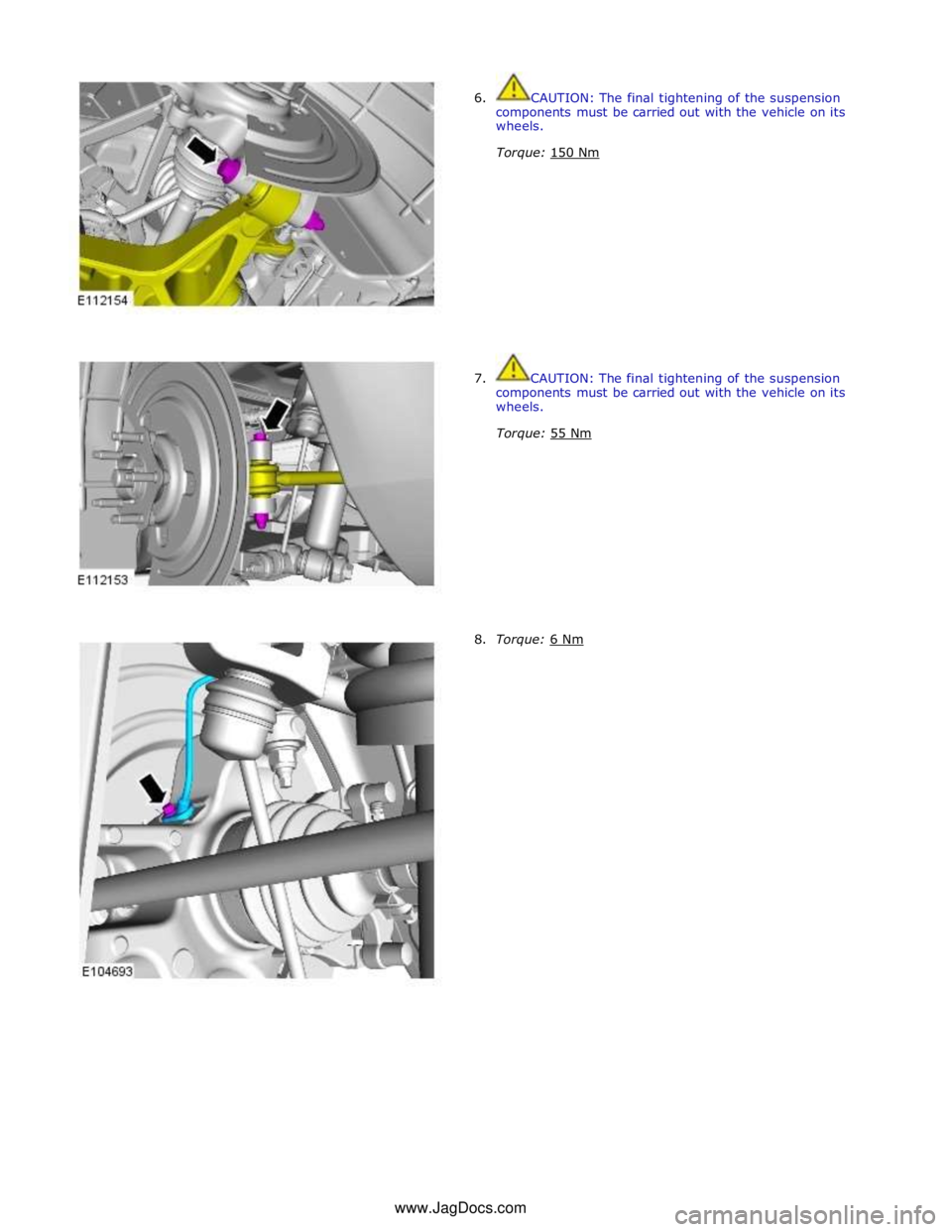

6. CAUTION: The final tightening of the suspension

components must be carried out with the vehicle on its

wheels.

Torque: 150 Nm

7. CAUTION: The final tightening of the suspension

components must be carried out with the vehicle on its

wheels.

Torque: 55 Nm

8. Torque: 6 Nm www.JagDocs.com

Page 431 of 3039

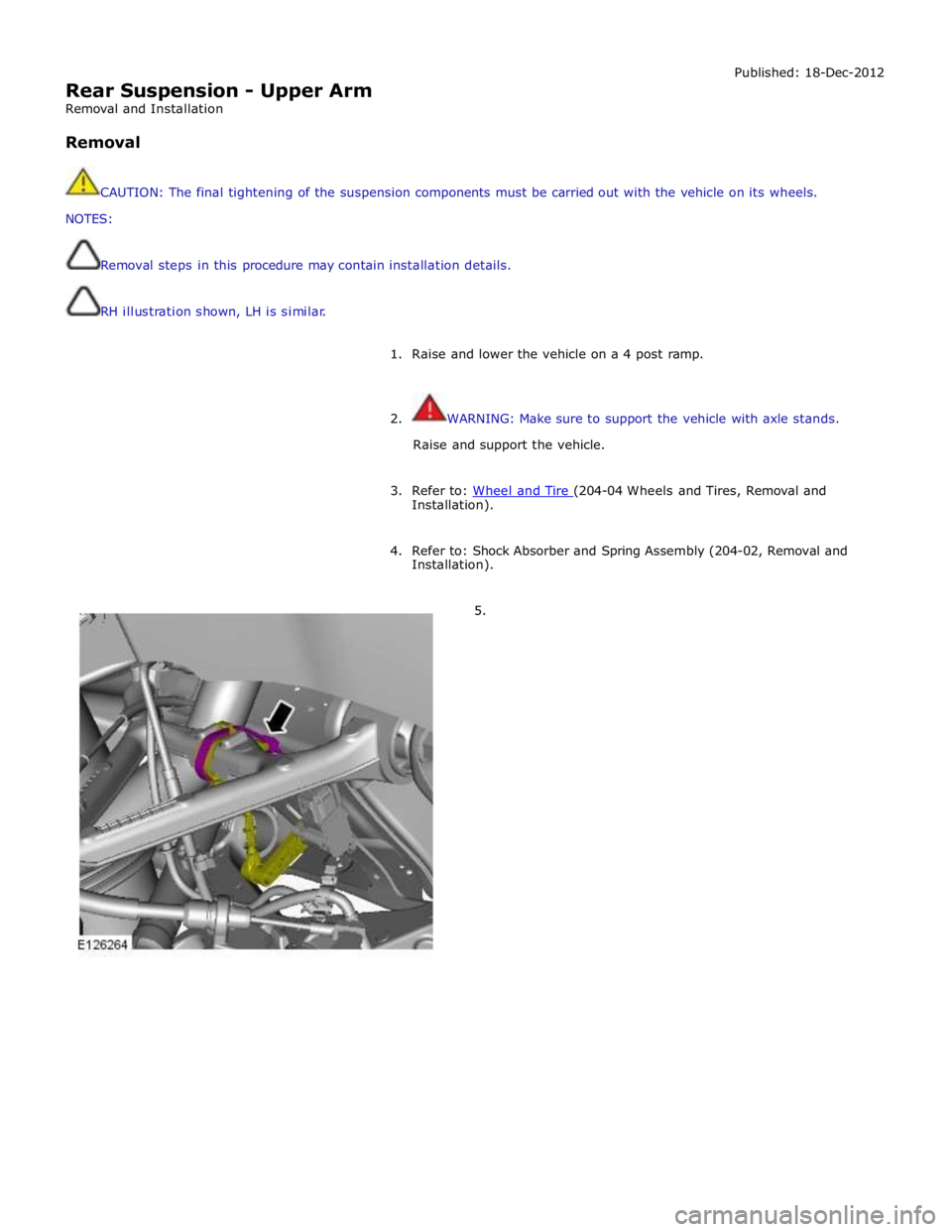

Rear Suspension - Upper Arm

Removal and Installation

Removal Published: 18-Dec-2012

CAUTION: The final tightening of the suspension components must be carried out with the vehicle on its wheels.

NOTES:

Removal steps in this procedure may contain installation details.

RH illustration shown, LH is similar.

1. Raise and lower the vehicle on a 4 post ramp.

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

4. Refer to: Shock Absorber and Spring Assembly (204-02, Removal and

Installation).

5.

Page 434 of 3039

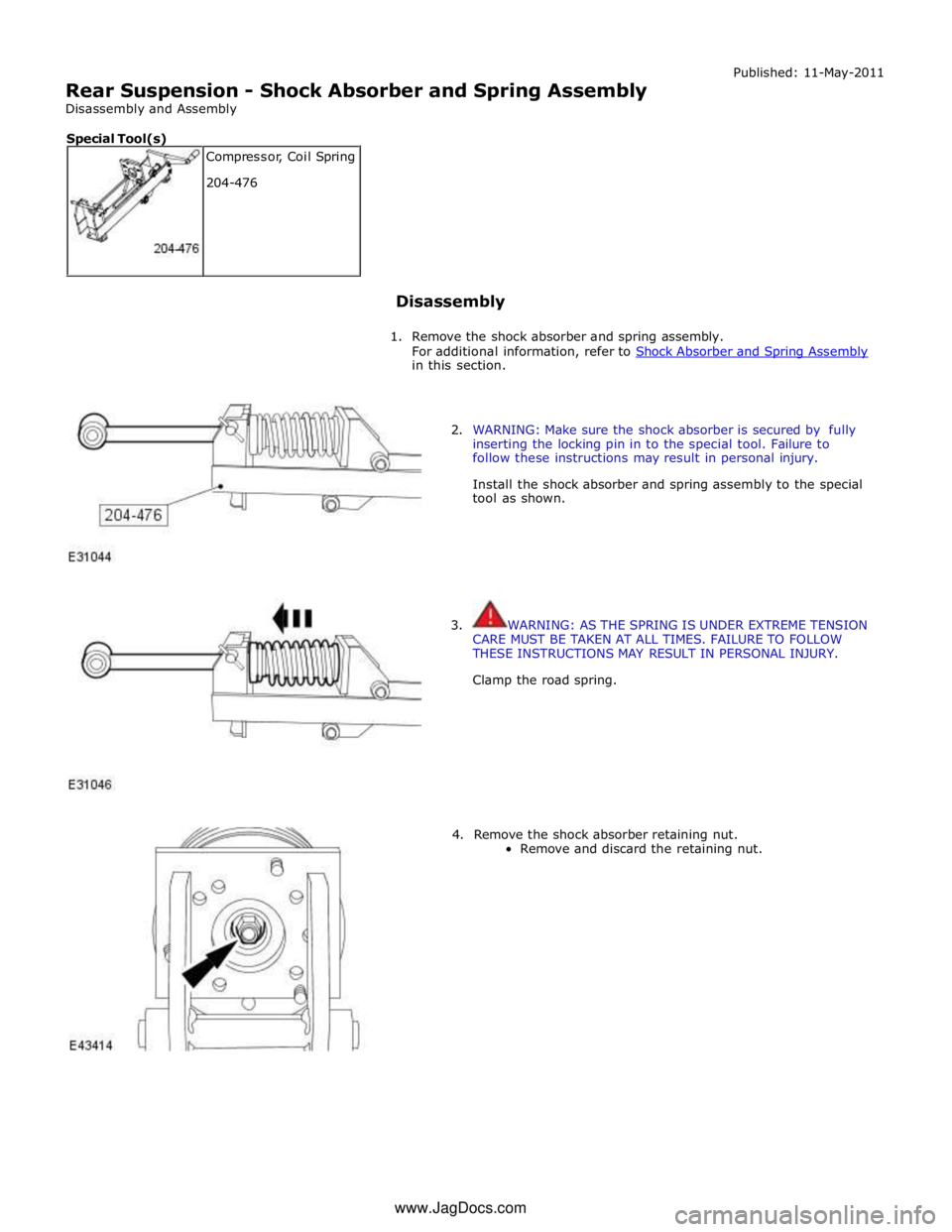

Rear Suspension - Shock Absorber and Spring Assembly

Disassembly and Assembly Published: 11-May-2011

Disassembly

1. Remove the shock absorber and spring assembly.

For additional information, refer to Shock Absorber and Spring Assembly in this section.

2. WARNING: Make sure the shock absorber is secured by fully

inserting the locking pin in to the special tool. Failure to

follow these instructions may result in personal injury.

Install the shock absorber and spring assembly to the special

tool as shown.

3. WARNING: AS THE SPRING IS UNDER EXTREME TENSION

CARE MUST BE TAKEN AT ALL TIMES. FAILURE TO FOLLOW

THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

Clamp the road spring.

4. Remove the shock absorber retaining nut.

Remove and discard the retaining nut. Compressor, Coil Spring

204-476 Special Tool(s) www.JagDocs.com

Page 479 of 3039

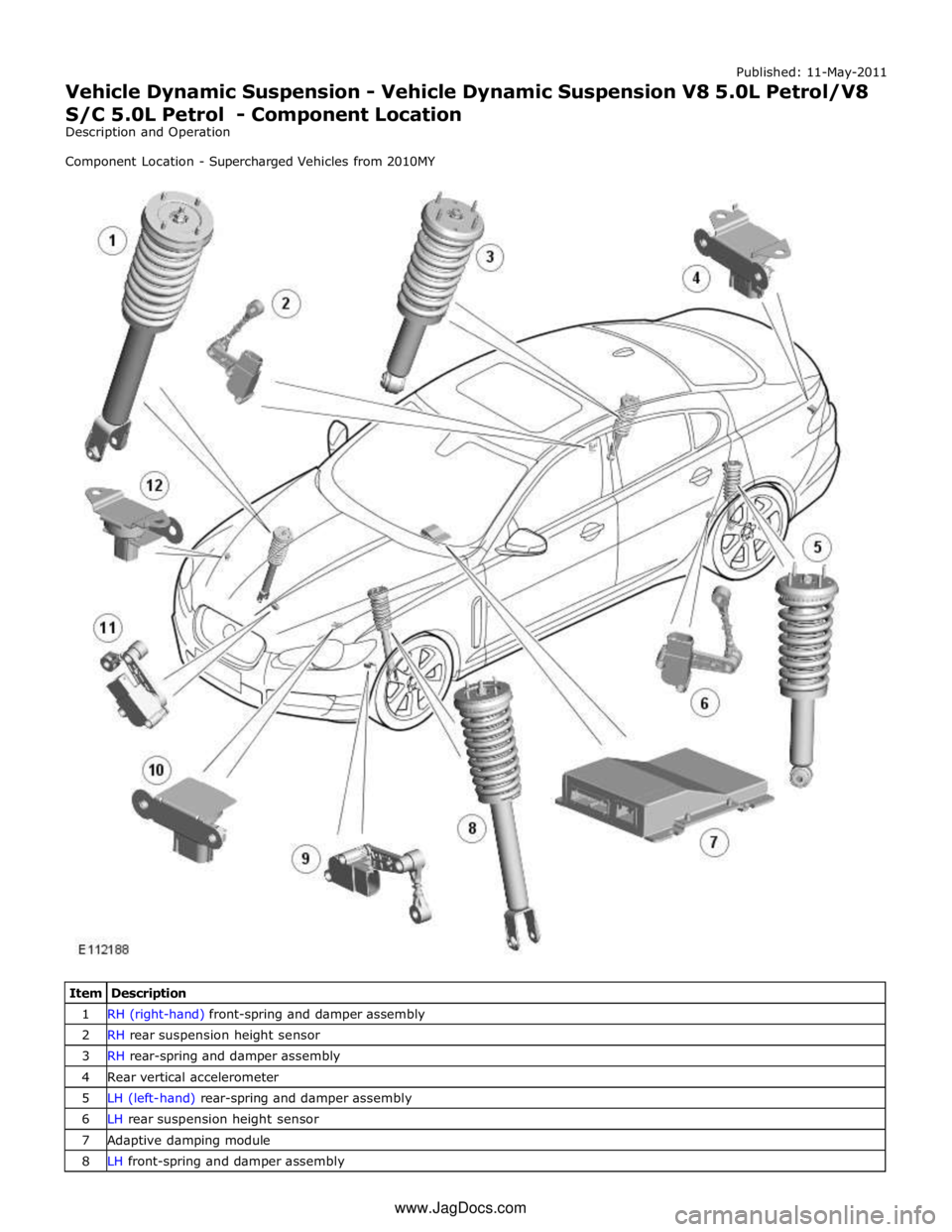

1 RH (right-hand) front-spring and damper assembly 2 RH rear suspension height sensor 3 RH rear-spring and damper assembly 4 Rear vertical accelerometer 5 LH (left-hand) rear-spring and damper assembly 6 LH rear suspension height sensor 7 Adaptive damping module 8 LH front-spring and damper assembly www.JagDocs.com

Page 480 of 3039

10 LH front vertical accelerometer 11 RH front suspension height sensor 12 RH front vertical accelerometer

Page 481 of 3039

Published: 11-May-2011

Vehicle Dynamic Suspension - Vehicle Dynamic Suspension V8 5.0L Petrol/V8 S/C 5.0L Petrol - Overview

Description and Operation

OVERVIEW

Adaptive Dynamics - Supercharged Vehicles from 2010MY

The adaptive dynamics system, is an electronically controlled suspension system which constantly adjusts the damping

characteristics of the suspension dampers in reaction to the existing driving conditions. The adaptive dynamics system is

available on specified models.

The system is controlled by an Adaptive Damping Module (ADM), located beneath the right-hand front seat. The module

receives signals from three dedicated vertical accelerometers; two at the front of the vehicle and one at the rear, which,

together with four suspension height sensors, determine the state of the body and wheel motions. In addition to these inputs,

further signals from other vehicle electronic system components to determine vehicle state and driver inputs are monitored by

the adaptive damping module. These combined signals are used by the adaptive damping module to continuously adjust the

damping characteristics of each of the suspension dampers in reaction to the current driving conditions to give the optimum

body control and vehicle ride.

Page 482 of 3039

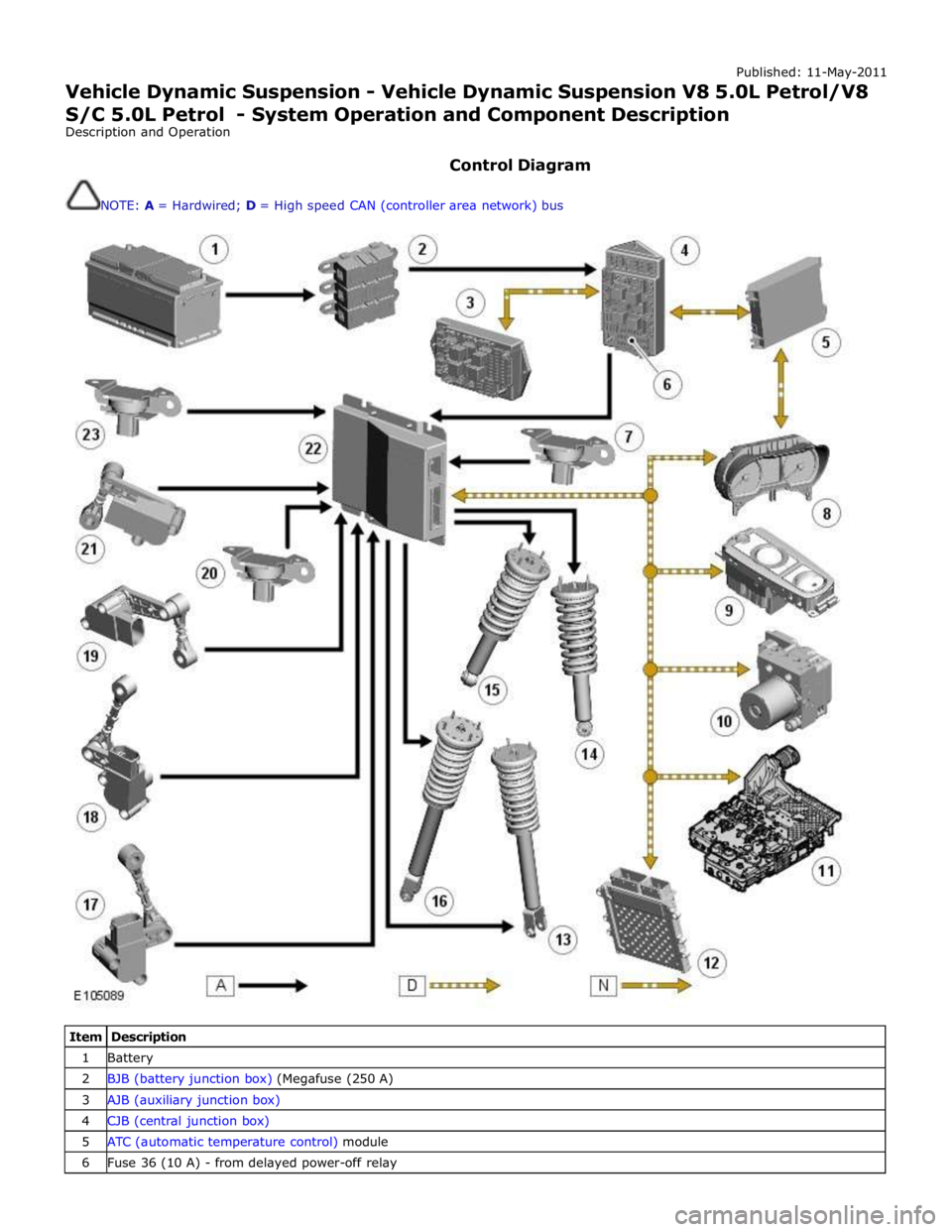

Published: 11-May-2011

Vehicle Dynamic Suspension - Vehicle Dynamic Suspension V8 5.0L Petrol/V8 S/C 5.0L Petrol - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired; D = High speed CAN (controller area network) bus

Item Description 1 Battery 2 BJB (battery junction box) (Megafuse (250 A) 3 AJB (auxiliary junction box) 4 CJB (central junction box) 5 ATC (automatic temperature control) module 6 Fuse 36 (10 A) - from delayed power-off relay

Page 483 of 3039

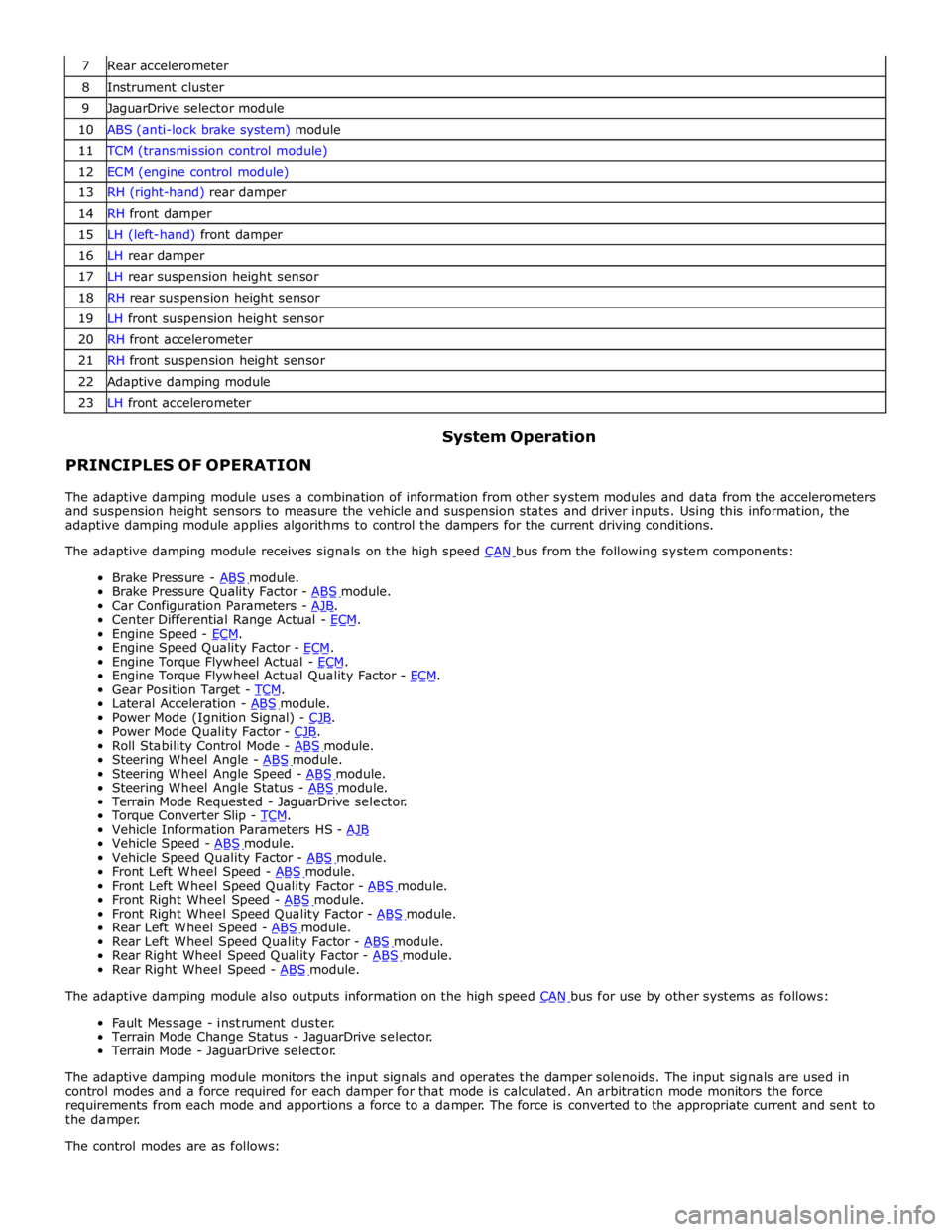

7 Rear accelerometer 8 Instrument cluster 9 JaguarDrive selector module 10 ABS (anti-lock brake system) module 11 TCM (transmission control module) 12 ECM (engine control module) 13 RH (right-hand) rear damper 14 RH front damper 15 LH (left-hand) front damper 16 LH rear damper 17 LH rear suspension height sensor 18 RH rear suspension height sensor 19 LH front suspension height sensor 20 RH front accelerometer 21 RH front suspension height sensor 22 Adaptive damping module 23 LH front accelerometer

PRINCIPLES OF OPERATION System Operation

The adaptive damping module uses a combination of information from other system modules and data from the accelerometers

and suspension height sensors to measure the vehicle and suspension states and driver inputs. Using this information, the

adaptive damping module applies algorithms to control the dampers for the current driving conditions.

The adaptive damping module receives signals on the high speed CAN bus from the following system components: Brake Pressure - ABS module. Brake Pressure Quality Factor - ABS module. Car Configuration Parameters - AJB. Center Differential Range Actual - ECM. Engine Speed - ECM. Engine Speed Quality Factor - ECM. Engine Torque Flywheel Actual - ECM. Engine Torque Flywheel Actual Quality Factor - ECM. Gear Position Target - TCM. Lateral Acceleration - ABS module. Power Mode (Ignition Signal) - CJB. Power Mode Quality Factor - CJB. Roll Stability Control Mode - ABS module. Steering Wheel Angle - ABS module. Steering Wheel Angle Speed - ABS module. Steering Wheel Angle Status - ABS module. Terrain Mode Requested - JaguarDrive selector.

Torque Converter Slip - TCM. Vehicle Information Parameters HS - AJB Vehicle Speed - ABS module. Vehicle Speed Quality Factor - ABS module. Front Left Wheel Speed - ABS module. Front Left Wheel Speed Quality Factor - ABS module. Front Right Wheel Speed - ABS module. Front Right Wheel Speed Quality Factor - ABS module. Rear Left Wheel Speed - ABS module. Rear Left Wheel Speed Quality Factor - ABS module. Rear Right Wheel Speed Quality Factor - ABS module. Rear Right Wheel Speed - ABS module. The adaptive damping module also outputs information on the high speed CAN bus for use by other systems as follows: Fault Message - instrument cluster.

Terrain Mode Change Status - JaguarDrive selector.

Terrain Mode - JaguarDrive selector.

The adaptive damping module monitors the input signals and operates the damper solenoids. The input signals are used in

control modes and a force required for each damper for that mode is calculated. An arbitration mode monitors the force

requirements from each mode and apportions a force to a damper. The force is converted to the appropriate current and sent to

the damper.

The control modes are as follows: