sensor JAGUAR XJ6 1994 2.G Electrical Diagnostic Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 327, PDF Size: 13.73 MB

Page 173 of 327

rl E I ect r ical

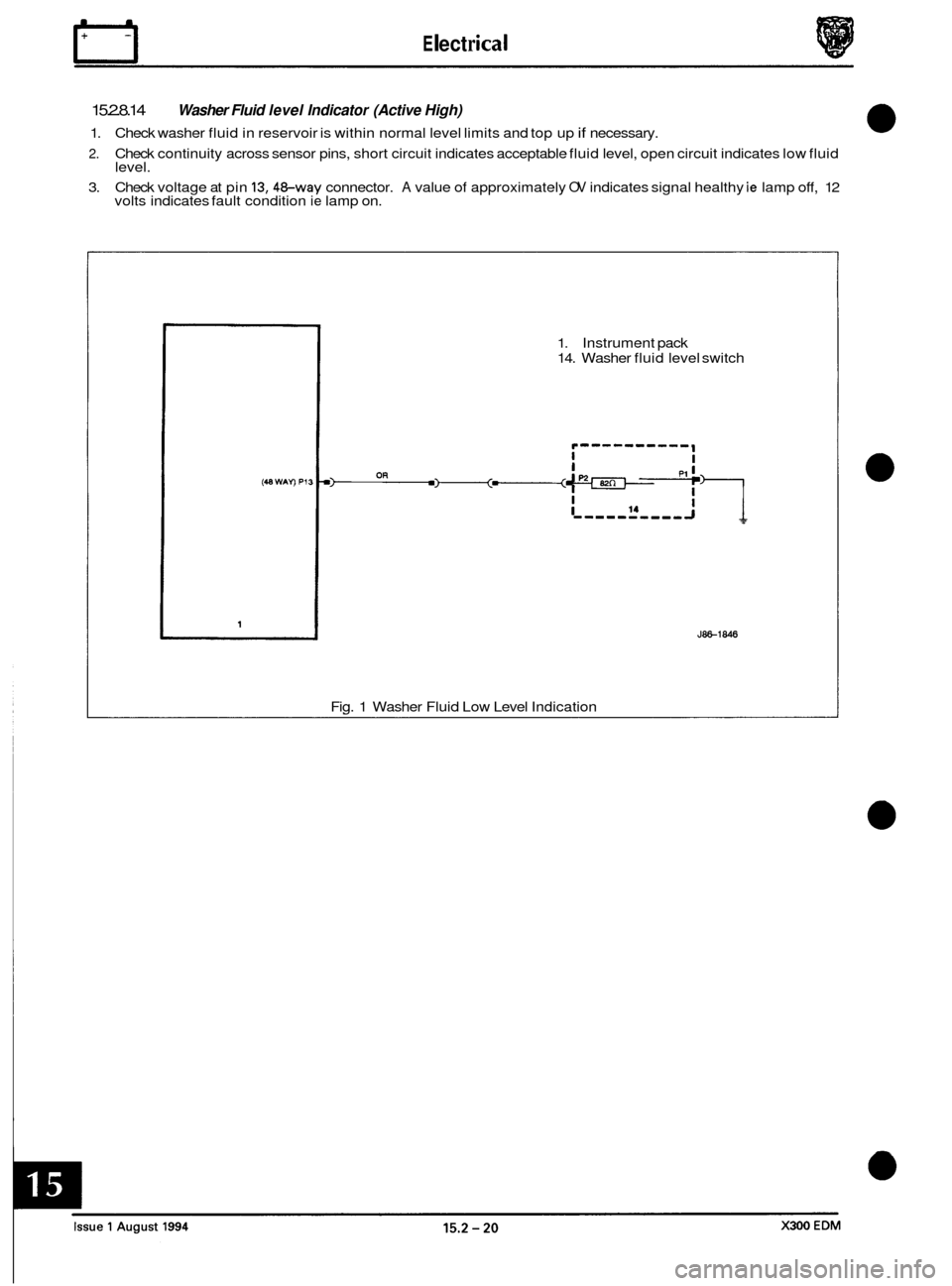

15.2.8.14

1. Check washer fluid in reservoir is within normal level limits and top up if necessary.

2. Check continuity across sensor pins, short circuit indicates acceptable fluid level, open circuit indicates low fluid

level.

3. Check voltage at pin

13,48-way connector. A value of approximately OV indicates signal healthy ie lamp off, 12

volts indicates fault condition ie lamp on.

Washer Fluid level Indicator (Active High)

1. Instrument pack

14. Washer fluid level switch

JE-1846

Fig. 1 Washer Fluid Low Level Indication

Page 174 of 327

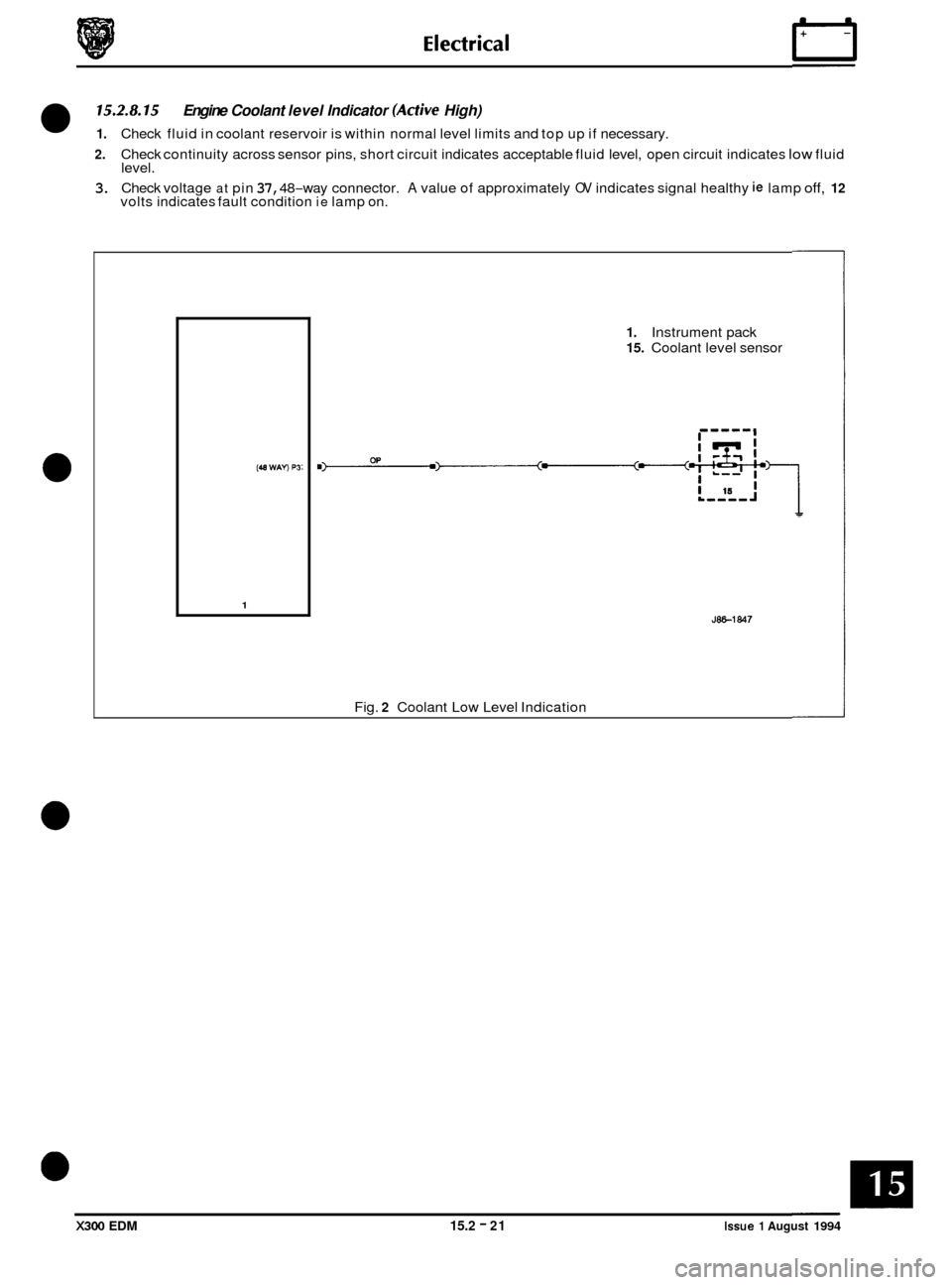

15.2.8.15

2. Check continuity across sensor pins, short circuit indicates acceptable fluid level, open circuit indicates low fluid

level.

3. Check voltage at pin 37, 48-way connector. A value of approximately OV indicates signal healthy ie lamp off, 12 volts indicates fault condition ie lamp on.

Engine Coolant level Indicator (Active High)

1. Check fluid in coolant reservoir is within normal level limits and top up if necessary.

(48 WAV P3i

1

1. Instrument pack

15. Coolant level sensor

JW-1847

Fig. 2 Coolant Low Level Indication

X300 EDM 15.2 - 21 Issue 1 August 1994

Page 175 of 327

rl E I ect r ical

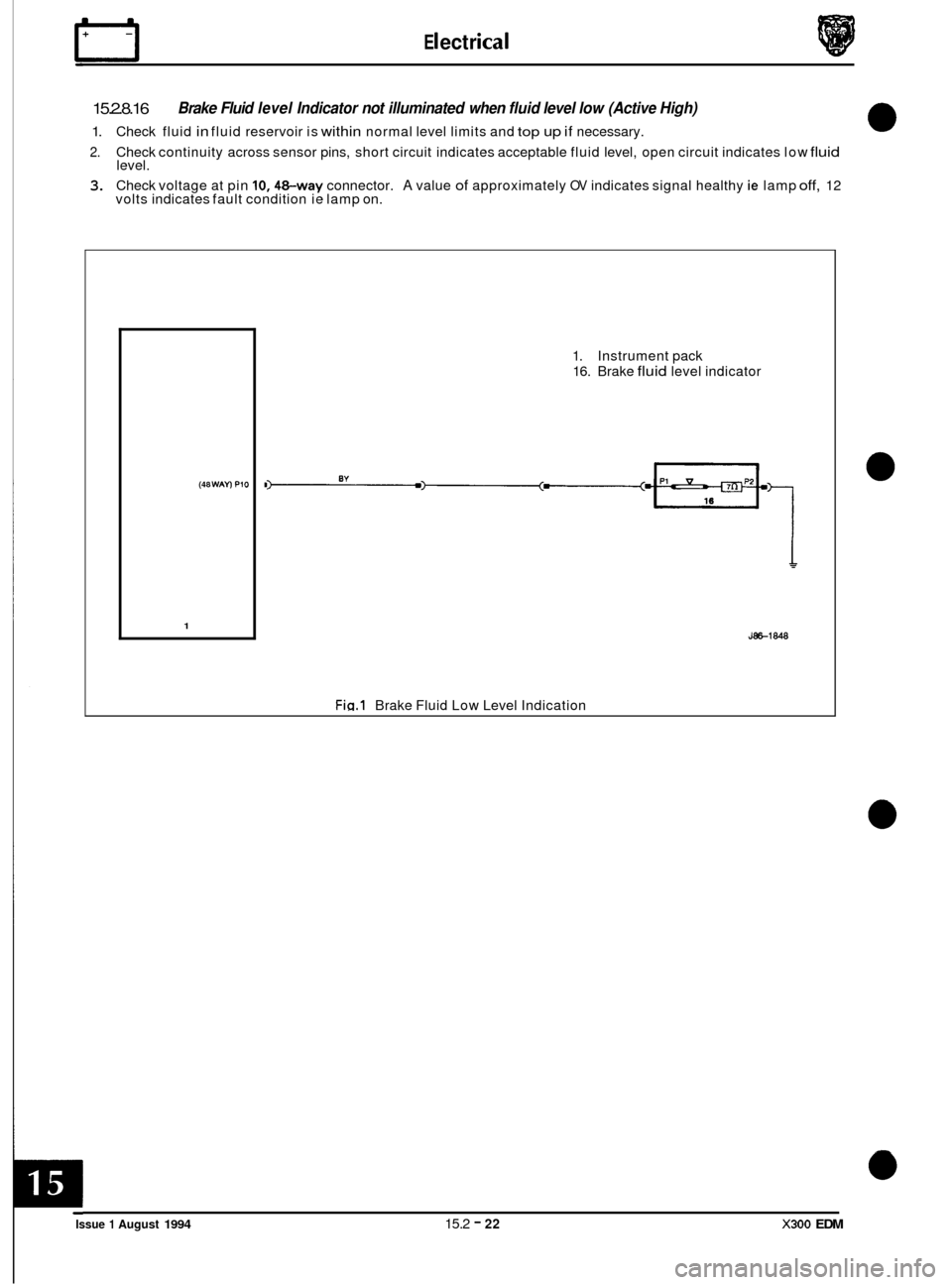

15.2.8.16

1. Check fluid in fluid reservoir is within normal level limits and top up if necessary.

2. Check continuity across sensor pins, short circuit indicates acceptable fluid level, open circuit indicates low fluid level.

3. Check voltage at pin 10,48-way connector. A value of approximately OV indicates signal healthy ie lamp off, 12

volts indicates fault condition ie lamp on.

Brake Fluid level Indicator not illuminated when fluid level low (Active High)

(48 WAYl P10

1

1. Instrument pack

16. Brake

fluid level indicator

J86-1848

Fia.1 Brake Fluid Low Level Indication

0

0

0

0

Issue 1 August 1994 15.2 - 22 X300 EDM

Page 178 of 327

E I ect r ical IT

SPEED CONTROL

System Description

0 15.3 15.3.1

The speed control system provides an automatic cruise facility, allowing a constant speed to be maintained without

accelerator pedal operation. The system comprises the following components:

0 Electronic control unit

0 Vacuum dump valve

0 Control valve

0 Vacuum pump

0 Mechanical throttle linkage and bellows

0 Selection switch

0 Brake and clutch pedal switches

On selection of speed control, via the switches mounted on the driver's side fascia, the vacuum dump valve, pump and

control valve will energize, creating

a partial vacuum in the bellows assembly. The bellows assembly acts upon the

throttle linkage to adjust throttle position, maintaining vehicle speed at the value when control is selected.

Speed control is determined by the Speed Control Control Module

(SC CM) which monitors a speed signal delivered

from the instrument pack (initially from the ABS rear LH wheel speed sensor) to determine vehicle speed.

Speedcontrol isdisabled, returning control tothedriver,

byoperationofthevacuumdumpvalve,ifanyofthefollowing situations occur: 0

0 Braking

0 Clutch operation (3.2 / 4.0 litre manual transmission vehicles only)

o Drive de-select ie P, N or R (automatic transmissions only, both electronic and hydraulic)

0 Traction control system (where fitted) in operation

0 Rapid speed reduction without braking input, ie double brake switch failure

0 Actual speed drop to 3/4 of cruise setting (eg when towing excessive loads under adverse conditions)

0 Vehicle speeds below w 25 mph

0 Ignition OFF

0 De-selection at switch controls

15.3.2 COMPONENT DESCRlPTlO NS

15.3.2.1 Electronic Control Module

The Speed Control Control Module (SC CM), located behind the fascia, adjacent to the steering column, provides sys- tem control and an interface to external input signals from the instrument pack, gear selector module, traction control

system, control switches, and foot pedal switches. The set speed value is retained in SC CM memory and continuously

compared to actual vehicle speed. Adjustments are made, as necessary, to maintain set speed by control of the vac- uum pump and control valve. Connections to the SC CM are listed in the table on page 3.

X300 EDM 15.3 - 1 Issue 1 August 1994

Page 233 of 327

E I ect r ica I

15.4.10 ELECTROCHROMATIC REAR VIEW MIRROR

15.4.10.1 Description

The function of the electrochromatic rearview mirror is to vary the reflectivity of the mirror glass. The mirror automati- cally varies its reflectivity to accommodate changes in traffic and light conditions to provide the driver with optimized

forward and rear vision.

The mirror contains an ambient sensor (forward facing) and

a glare sensor (rearward facing). Sensitivity control is

adjustable and at the lowest end of sensitivity control is system off. A reverse over-ride facility is incorporated; when

reverse gear is selected, the mirror operates in a high reflective state.

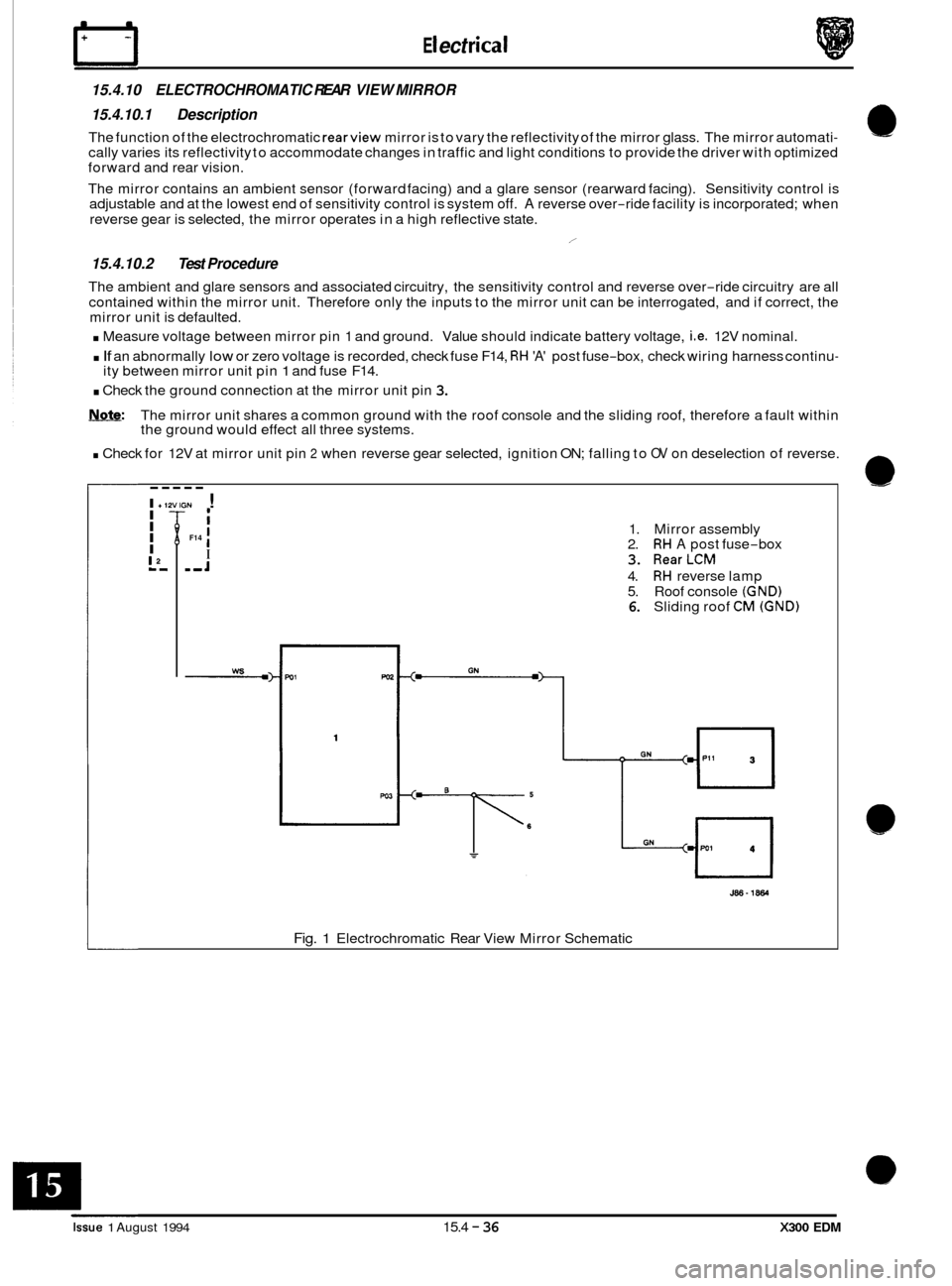

15.4.10.2 Test Procedure

The ambient and glare sensors and associated circuitry, the sensitivity control and reverse over-ride circuitry are all

contained within the mirror unit. Therefore only the inputs to the mirror unit can be interrogated, and if correct, the

mirror unit is defaulted.

. Measure voltage between mirror pin 1 and ground. Value should indicate battery voltage, i.e. 12V nominal.

. If an abnormally low or zero voltage is recorded, check fuse F14, RH 'A' post fuse-box, check wiring harness continu-

. Check the ground connection at the mirror unit pin 3.

Note: The mirror unit shares a common ground with the roof console and the sliding roof, therefore a fault within

the ground would effect all three systems.

. Check for 12V at mirror unit pin 2 when reverse gear selected, ignition ON; falling to OV on deselection of reverse.

/

ity between mirror unit pin 1 and fuse F14.

----- I +12VIGN ! I I I

I

L',

I I

I ,,J

F14 1. Mirror assembly

2. RH A post fuse-box

3. RearLCM

4. RH reverse lamp

5. Roof console (GND) 6. Sliding roof CM (GND)

J86-1864

Fig. 1 Electrochromatic Rear View Mirror Schematic

Issue 1 August 1994 15.4 - 36 X300 EDM