sensor JAGUAR XJ6 1994 2.G Electrical Diagnostic Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 327, PDF Size: 13.73 MB

Page 151 of 327

Electrical rl

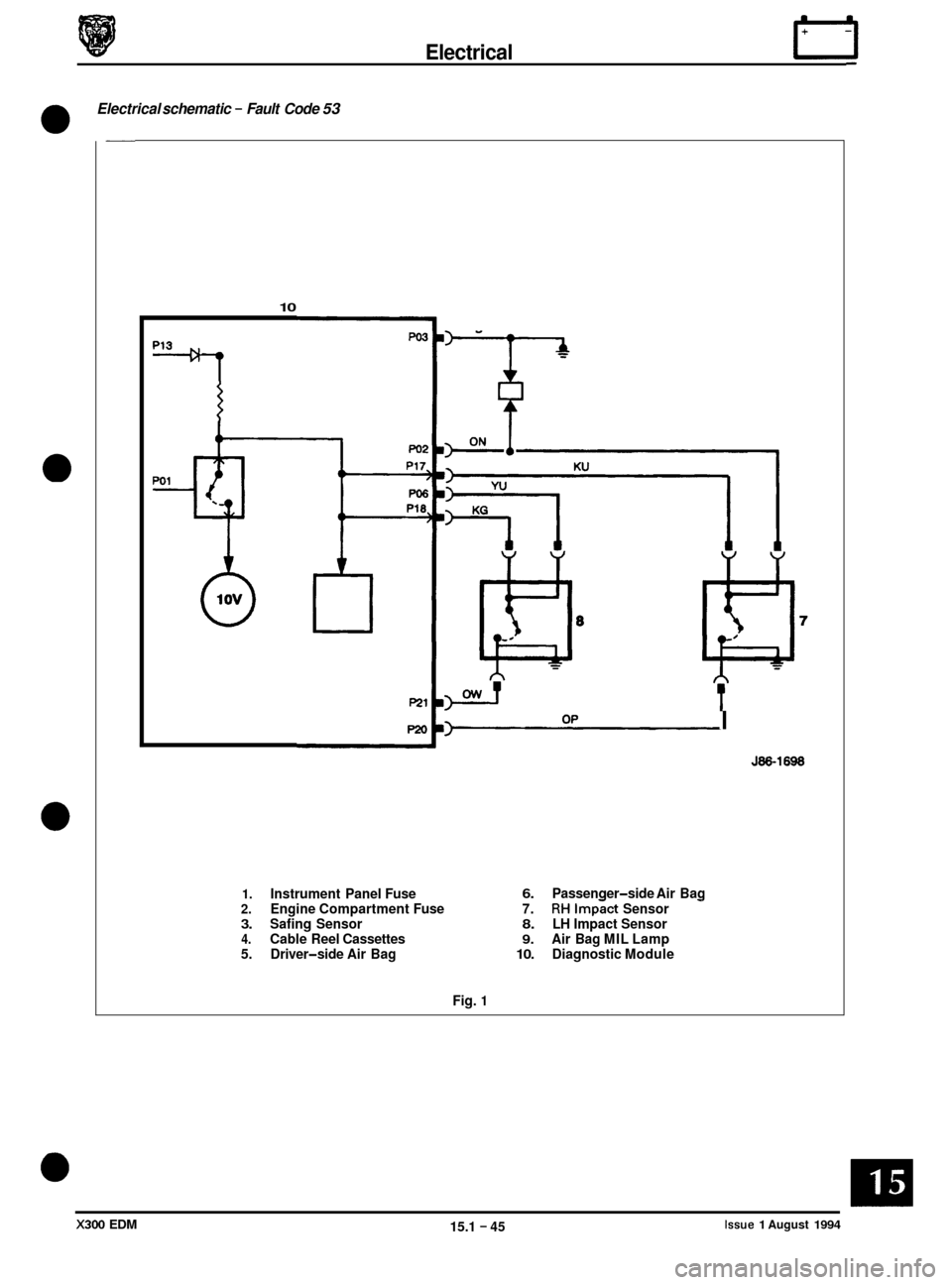

Electrical schematic - Fault Code 53

0

10

T

w?

P21

m

‘T

i OP I

J86-1698

1. Instrument Panel Fuse 6. Passenger-side Air Bag

7. RH Impact Sensor 2. Engine Compartment Fuse 3. Safing Sensor 8. LH Impact Sensor 4. Cable Reel Cassettes 9. Air Bag MIL Lamp 5. Driver-side Air Bag 10. Diagnostic Module

-

Fig. 1

X300 EDM 15.1 - 45 Issue 1 August 1994

Page 152 of 327

Electrical

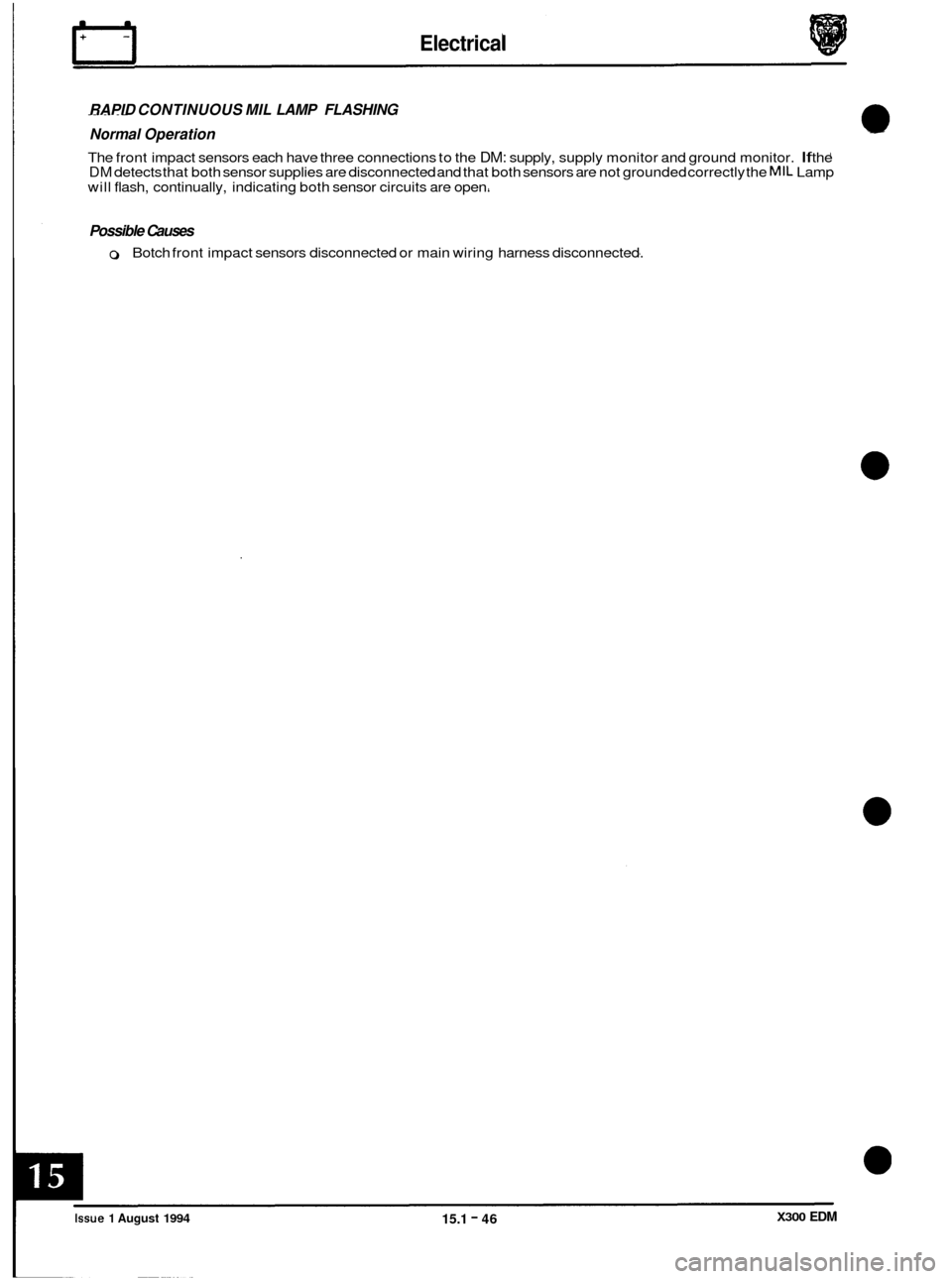

RAPID CONTINUOUS MIL LAMP FLASHING

Normal Operation

The front impact sensors each have three connections to the DM: supply, supply monitor and ground monitor. If the DM detects that both sensor supplies are disconnected and that both sensors are not grounded correctly the MIL Lamp

will flash, continually, indicating both sensor circuits are open.

Possible Causes

0 Botch front impact sensors disconnected or main wiring harness disconnected.

X300 EDM Issue 1 August 1994 15.1 - 46

Page 153 of 327

E I ect r ica I cl

Electrical schematic - Rapid Continuous MIL Lamp Flashing

a

0

0

10

I P20

1. Instrument Panel Fuse

586-1881

6. Passenger-side Air Bacr

7. RH tmpict Sensor 2. Engine Compartment Fuse 3. Safing Sensor 8. LH Impact Sensor

4. Cable Reel Cassettes 9. Air Bag MIL Lamp 5. Driver-side Air Bag 10. Diagnostic Module

-

Fig. 1

X300 EDM 15.1 - 47 Issue 1 August 1994

Page 154 of 327

Electrical n

15.2 INSTRUMENTS

15.2.1 Introduction

The instrument pack is a self-contained, removable unit, which incorporates all the main display gauges and warning

indicators that are used to present vehicle condition information. The instrument pack is programmed during vehicle

build, to match the vehicle's individual requirements using 'Programmable Electronic Control Units System'

(PECUS). This is achieved via the diagnostic communication line, and therefore, should be renewed like-for-like. The primary

function of the instrument display is to provide the driver with information usual to normal driving requirements. The

secondary function is to display trip computer information.

The trip computer functions are selected via the steering column stalk switch

(LH). The messages are displayed in the

following order:

Odometer

- Distance - Range - Fuel Used -Average Fuel -Average Speed - Instant Fuel - Odometer (return).

Two trip computer switches, 'Reset' and 'Odo', are incorporated into the facia switch panel.

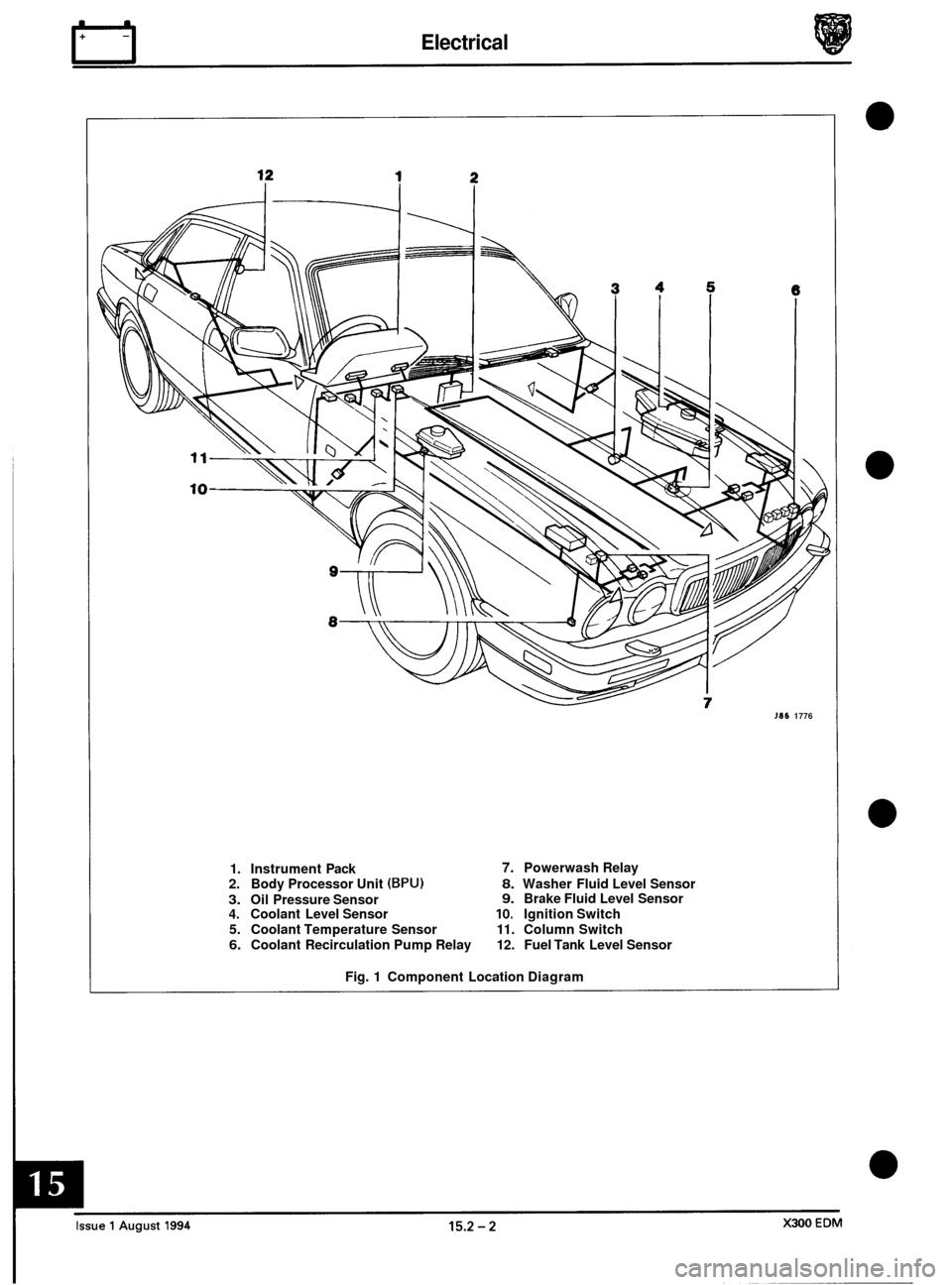

Instrument pack information is received from sensors positioned

at various locations about the vehicle (Fig. 1, follow-

ing page) via one of the two multi-pin sockets located at the rear of the instrument pack.

Information concerning vehicle condition and operation is displayed in one of three ways:

0 Information necessary to confirm normal vehicle operation: road speed, engine speed, oil pressure, battery

condition, fuel level, coolant temperature. This information is displayed using analogue gauges.

0 Information indicating the presence of a hazard/fault condition (low oil pressure/door open etc.) or operational

action (indicator flashing / headlamp full beam 'on' etc.). This information is provided by twenty two warning

lampsltell-tales, arranged in four groups; two groups of seven at the left and right sides of the instrument pack

and two groups of four

at the bottom of the instrument pack.

0 A Liquid Crystal Display (LCD) is located at the bottom-centre of the instrument pack and is normally used to

display the odometer reading, but it can also be used to display SRS fault conditions and trip computer informa-

tion such as vehicle speed, fuel usage and distance travelled.

0

X300 EDM 15.2 - 1 Issue 1 August 1994

Page 155 of 327

Electrical rl

JOS 1776

1. Instrument Pack 7. Powerwash Relay

2. Body Processor Unit

(BPU) 8. Washer Fluid Level Sensor

3. Oil Pressure Sensor 9. Brake Fluid Level Sensor

4. Coolant Level Sensor 10. Ignition Switch 5. Coolant Temperature Sensor 11. Column Switch

6. Coolant Recirculation Pump Relay 12. Fuel Tank Level Sensor

Fig. 1 Component Location Diagram

Page 157 of 327

E I ect r ical

15.2.3 COMPONENT DESCRIPTION

15.2.3.1 Speedometer

The speed indication input signal, sent as a pulse rate, is generated by an open collectortransistor within the ABS con- trol module. The instrument pack converts the frequency of this signal to drive the speedometer and to provide two

road speed outputs:

Speed output

1 (pin 2,48 way connector)

This output is connected to the radio head unit, security control module and the power steering module.

Speed output 2 (pin

3,48 way connector)

This output is connected to the body processor unit, cruise control control module, air conditioning control module

and the engine management system.

15.2.3.2 Tachometer

The tachometer input, all engine variants, is provided by the engine management control module. When the engine

is running the control module generates three high state pulses per engine revolution.

15.2.3.3

This signal comes direct from the variable resistance type oil pressure sensor, mounted on the engine. The sensor

resistance values range from 75Q (8 Bar) to 330Q (0 Bar).

When the gauge reaches

a pre-determined reading the instrument pack illuminates the warning light.

Engine Oil Pressure and Warning lamp

15.2.3.4 Engine Coolant Temperature

This signal comes direct from the coolant temperature sensor (variable resistance type), mounted on the engine. The

sensor resistance values range from 34Q (hot) to 241Q (cold), when disconnected from the vehicle.

Note: The coolant temperature gauge is calibrated to indicate at approximately 'Normal' for a wide range of normal

engine operating temperatures.

15.2.3.5 Fuel Tank level Gauge and Warning lamp

This signal (pin 20,24-way connector) comes direct from the variable resistor type fuel level sensor. The sensor resis- tance values range from 80 ohms (full tank) to 900 ohms (empty tank).

When the gauge reaches a pre

-determined reading, the instrument pack illuminates the warning lamp.

15.2.3.6

Battery voltage is displayed on the gauge by measuring the ignition voltage.

The red charge warning lamp will illuminate if either the voltage is too low (below

10.5V) or too high (above 15.5V). In addition, the generator provides a low signal to the instrument pack (pin 9,48-way connector) when battery charging

is unsatisfactory.

Battery Voltage Gauge and Warning lamp

15.2.3.7 Liquid Crystal Display

A single line, six digit, 7 segment display with six trip function flags used for odometer, trip computer and driver mess- ages.

!Y,Q&: If the instrument pack has not been PECUS programmed, the back illumination of the LCD will not switch on.

Check that a PECUS label is attached to the back of the pack.

Issue 1 August 1994 15.2 - 4 X300 EDM

Page 158 of 327

15.2.3.8 Trip Computer

The instrument pack provides the trip computer functions, selected via the momentary stalk input and two action in- puts: 'Reset' and 'Odo'.

The signal used for each function are:

Distance:

Computed from the speed signal from the ABS control module.

Average Speed

Computed from the speed signal from the ABS control module.

Fuel Used

Computed from a pulsed signal from the engine management system.

Average Fuel Consumption

Computed from the speed signal and the fuel used signal.

Range

Computed from the speed signal, the fuel used signal and fuel level.

instantaneous Fuel

Computed from the speed signal and the fuel used signal.

15.2.4 PRIMARY WARNING LAMPS - ILLUMINATED RED

15.2.4.1 Exhaust Temperature (Japan only)

The exhaust temperature input (pin 23,48 way connector) is provided by the catalyst switching module (pin 6), which

pulls the line low when a fault occurs.

15.2.4.2 Low Oil Pressure

This signal comes direct from the variable resistance type oil pressure sensor. The sensor resistancevalues range from

7552 to 310Q.

15.2.4.3 Seat Selt

The seat belt input (pin 15,48 way connector) is provided by the seat belt stalk switch, via the body processor unit

(pin 26).

The seat belt lamp will illuminate when

a low signal is seen on the instrument pack input.

15.2.4.4 Trunk Lid Open

A microswitch located in the trunk lid lock provides a signal (pin 16,4&wayconnector) causing the trunk lid open indi- cator to illuminate whenever the trunk lid is opened or not closed correctly.

The trunk lid open indicator will illuminate when

a low signal is seen on the instrument pack input.

15.2.4.5 Door Ajar

Switches located in each door closing mechanism supply signals to indicate when any door is either open, or has not

been closed correctly. The system operates from two signals; an input from the driver's door (pin 46, 48-way con- nector) or a combined signal input from the passenger doors (pin 47,4&way connector).

The door ajar lamp will illuminate when

a low signal is detected on either of the two inputs.

X300 EDM 15.2 - 5 Issue 1 August 1994

Page 160 of 327

15.2.5 SECONDARY WARNING LAMPS - ILLUMINATED AMBER

15.2.5.1 Transmission Fault

The transmission fault indicator is controlled by a signal from the Transmission Control Module (TCM). The signal to

the instrument pack (pin 44,48-way connector) is switched high when a transmission fault occurs, and the indicator

lamp is illuminated.

15.2.5.2 Washer Fluid Level

The washer fluid level sensor, mounted in the fluid reservoir, provides a signal (pin 13, 48-way connector) when the

amount of fluid drops below a predetermined level. The switch is normally in the closed position, providing a low sig-

nal to the instrument pack, when the fluid level is acceptable. If the fluid level drops, the switch will open, removing

the low signal and illuminating the indicator lamp.

15.2.5.3 Bulb Fail

Bulb failure indication is controlled from two different sources:

If a direction indicator lamp fails, a signal is sent to the instrument pack (pin 18,48-way connector) from the Body. :o- cessor Unit (BPU). The signal is normally low but switched high if a bulb failure occurs; thuscausing the bulbfail indica-

If any of the other bulbs, monitored by the three lamp control modules, fail, a signal is sent direct to the instrument

pack (pin 43, 48-way connector). The signal is normally low but switched high if a bulb failure occurs; thus causing

the bulb failure indicator lamp to illuminate.

tor lamp to illuminate.

15.2.5.4 Traction Control Fail

Two traction control lamps are provided: control fail and control off. Both lamps are controlled from one input from

the ABS / TC Control Module.

Under normal operating conditions, the input signal should be high.

If the input line is continuously low, traction con- trol has failed and both lamps will illuminate. If the input signal is a 4 Hz square wave the traction control system is

switched off, therefore the ‘traction off lamp will illuminate.

15.2.5.5 Anti-lock Fail

The input to the instrument pack (pin 7,24-way connector) is provided by the ABS Control Module. The warning lamp

illuminates if the signal voltage is less than 5.0 volts or greater than 11.9 volts.

- 15.2.5.6 Low Fuel Level

This signal (pin 20,24-way connector) comes direct from the variable resistor type fuel level sensor. The sensor resis-

tance values range from 80 ohms (full tank) to 900 ohms (empty tank).

When the gauge reaches

a pre-determined reading, the instrument pack illuminates the warning lamp.

15.2.5.7 Check Engine

The ’checkeng’ indicator will illuminate when the Engine Control Module (ECM) detects a fault within the system, and

sends a signal to the instrument pack (pin 22,48-wayconnector). The signal line is pulled low by the ECM when a fault

is detected.

The indicator lamp will illuminate during each ignition cycle, until the engine fires.

X300 EDM 15.2-7 Issue 1 August 1994

Page 163 of 327

rl E I ect r ica I

15.2.8 INSTRUMENT PACK PIN-POINT TESTS

15.2.8.1 Oil Pressure, Battery Condition, Coolant Temperature and Fuel Gauges

Gauge reads zero, full scale, too high or low

1.

2.

3. Oil

pressure and coolant gauges only; check relevant fluid level is within limits, top up if required and re-check

indication. If fluid levels are within limits on checking proceed to step 2.

Check connections to sensor are correct and secure. For battery gauge only check battery voltage is present at the

battery terminal posts.

Check resistance of sensor (if applicable) to ground, correct readings are as detailed in the following table:

Sensor title Resistance value

Oil pressure 3108 - 3308

Temperature

Fuel level 3461

(warm engine)

- 2418 (cold engine)

8061 (full tank) - 9008 (empty tank)

If resistance is out of range renew sensor.

If sensor resistance is proved correct, check the harness wiring continuity between the sensor and instrument pack

pin as detailed in the table below:

4.

I Sensor title I Instrument pack pin !

I Oil pressure I 21 (24-way connector) I Temperature I 19 (24-way connector) I

Fuel level 120 (24-way connector)

For battery condition gauge, checkvoltage between instrument pack 24

-way connector pins 2 and 4 is 13 f 2.5V. Refer to Section 15.5 for battery diagnostics.

If all previous checks prove correct remove and open the instrument pack. Examine flexi-circuit connections to

relevant gauge, ensuring correct and secure fitment.

Check continuity of flexi

-circuit tracks to gauge connections.

Check continuity of gauge driver windings by disconnecting gauge from flexi

-circuit and testing between the

upper central connection pin and each of the other two pins. If open circuit is recorded renew gauge.

5.

6.

7.

Gauge fluctuates

or gives erratic readings

1. Carry out steps 1 -4 above.

2.

Fit new sensor (where applicable) and re-check gauge.

3. Carry out steps 5

- 7 above

15.2.8.2 Speedometer

Gauge reads zero, full scale, too high or low

1.

2.

3.

4.

5. Refer

to Section 12,

ABS / Traction Control for fault diagnosis of wheel speed sensor.

Check harness wirin and connection from Instrument pack pin 15 (24

-way connector) and ABS /Traction Control

Control Module (AB!! /TC CM).

If all previous checks prove correct remove and open the instrument pack. Examine flexi

-circuit connections to

speedometer, ensuring correct and secure fitment.

Check continuity of flexi

-circuit tracks to speedometer connections.

Check continuity of speedometer driver windings by disconnecting from flexi

-circuit and testing between the

upper central connection pin and each of the other two pins. If open circuit is recorded renew speedometer.

Page 166 of 327

Electrical

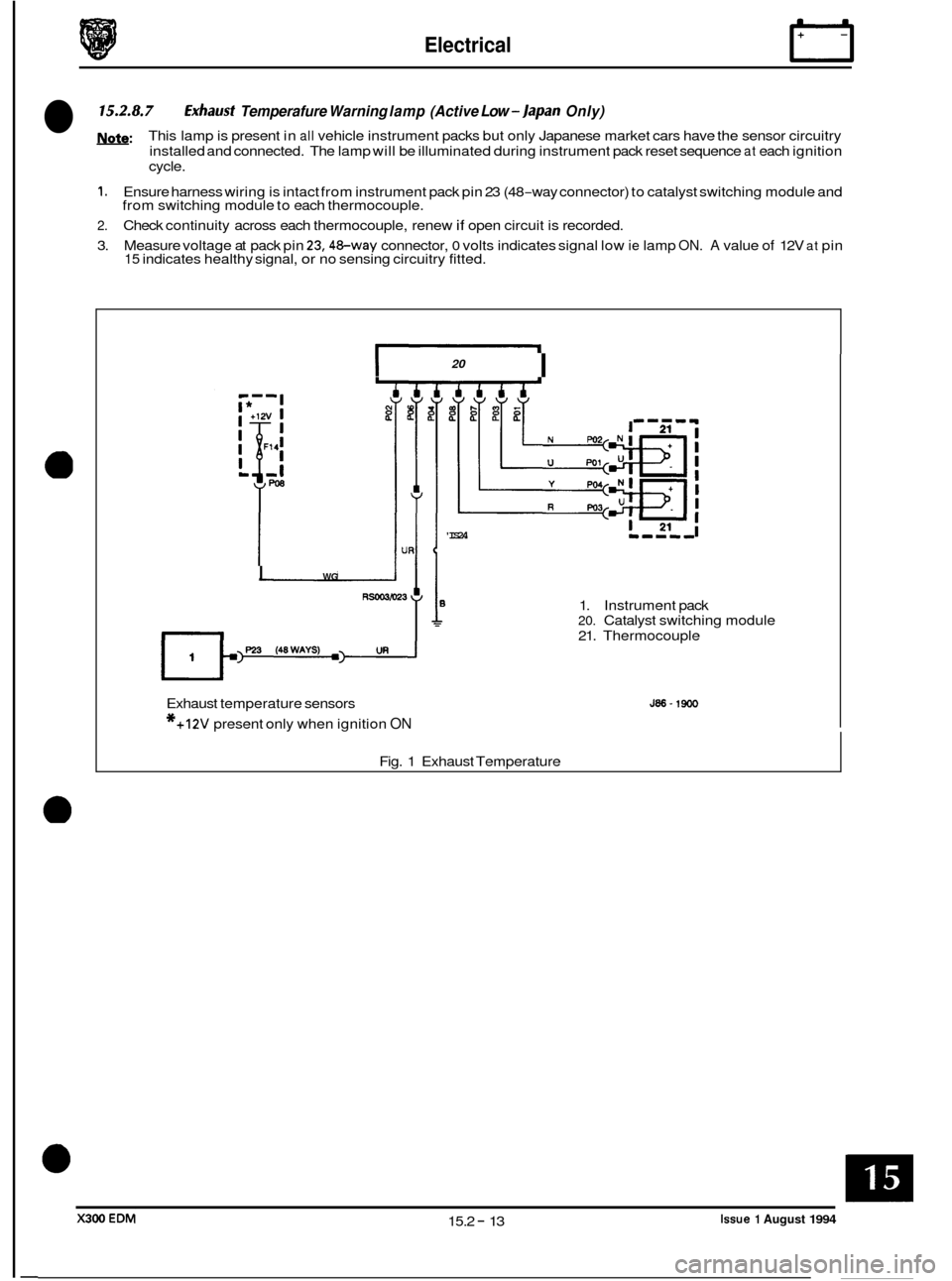

15.2.8.7 fxhausf Temperafure Warning lamp (Active Low -Japan Only)

U: This lamp is present in all vehicle instrument packs but only Japanese market cars have the sensor circuitry

installed and connected. The lamp will be illuminated during instrument pack reset sequence

at each ignition

cycle.

1. Ensure harness wiring is intact from instrument pack pin 23 (48-way connector) to catalyst switching module and

from switching module to each thermocouple.

2. Check continuity across each thermocouple, renew if open circuit is recorded.

3. Measure voltage at pack pin

23,48-way connector, 0 volts indicates signal low ie lamp ON. A value of 12V at pin 15 indicates healthy signal, or no sensing circuitry fitted.

I 20

L

I WG

Exhaust temperature sensors

*+12V present only when ignition ON

'IS24

1. Instrument pack 20. Catalyst switching module

21. Thermocouple

J86-1900

Fig. 1 Exhaust Temperature

x300 EDM 15.2 - 13 Issue 1 August 1994