JAGUAR XJ6 1994 2.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 111 of 521

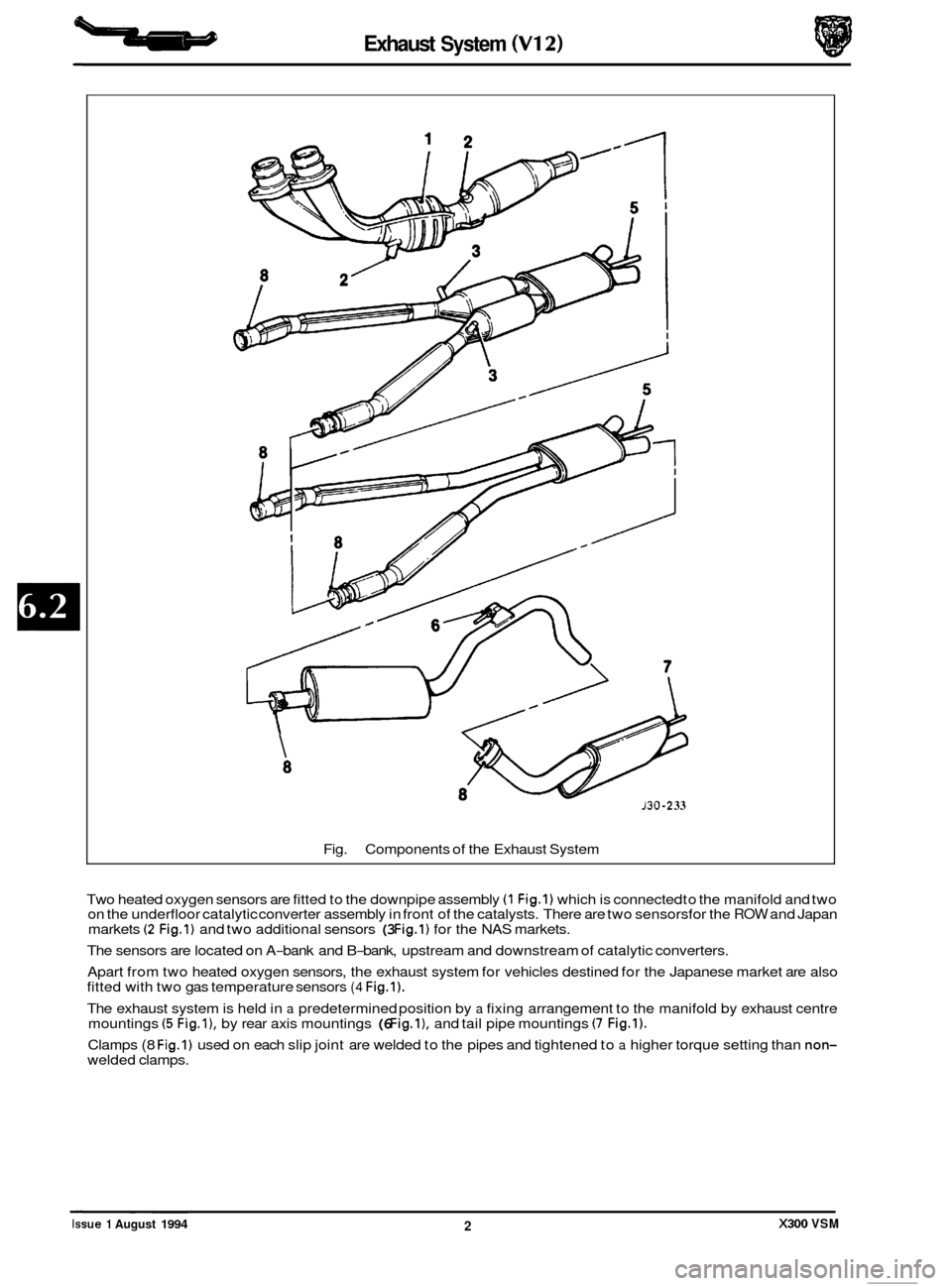

b Exhaust System (V12)

8

Fig.

P

Components of the Exhaust System

130 -2 33

Two heated oxygen sensors are fitted to the downpipe assembly (1 Fig.1) which is connected to the manifold and two

on the underfloor catalytic converter assembly in front of the catalysts. There are two sensorsfor the ROW and Japan

markets (2 Fig.1) and two additional sensors (3 Fig.1) for the NAS markets.

The sensors are located on A

-bank and B-bank, upstream and downstream of catalytic converters.

Apart from two heated oxygen sensors, the exhaust system for vehicles destined for the Japanese market are also

fitted with two gas temperature sensors

(4 Fig.1).

The exhaust system is held in a predetermined position by a fixing arrangement to the manifold by exhaust centre

mountings (5 Fig.l), by rear axis mountings (6 Fig.1). and tail pipe mountings (7 Fig.1).

Clamps (8 Fig.1) used on each slip joint are welded to the pipes and tightened to a higher torque setting than non- welded clamps. ~ ~~~

Issue 1 August 1994 2 X300 VSM

Page 112 of 521

Exhaust System (V12)

The exhaust system must be free of leaks, binding, grounding and excessive vibrations. These conditions are usually

caused by loose, broken, or misaligned clamps, shields, brackets, or pipes.

Should any

of the above mentioned conditions exist, check the exhaust system components and alignment.

Adjust and renew if necessary.

Do not attempt to service brackets clamps and insulators.

6.2.2 DIAGNOSIS AND TESTING

The standard exhaust system Diagnosis and Testing procedures are given in Section 6.1 (Exhaust System (AJ16)).

X300 VSM 3 Issue 1 August 1994

Page 113 of 521

4

Page 114 of 521

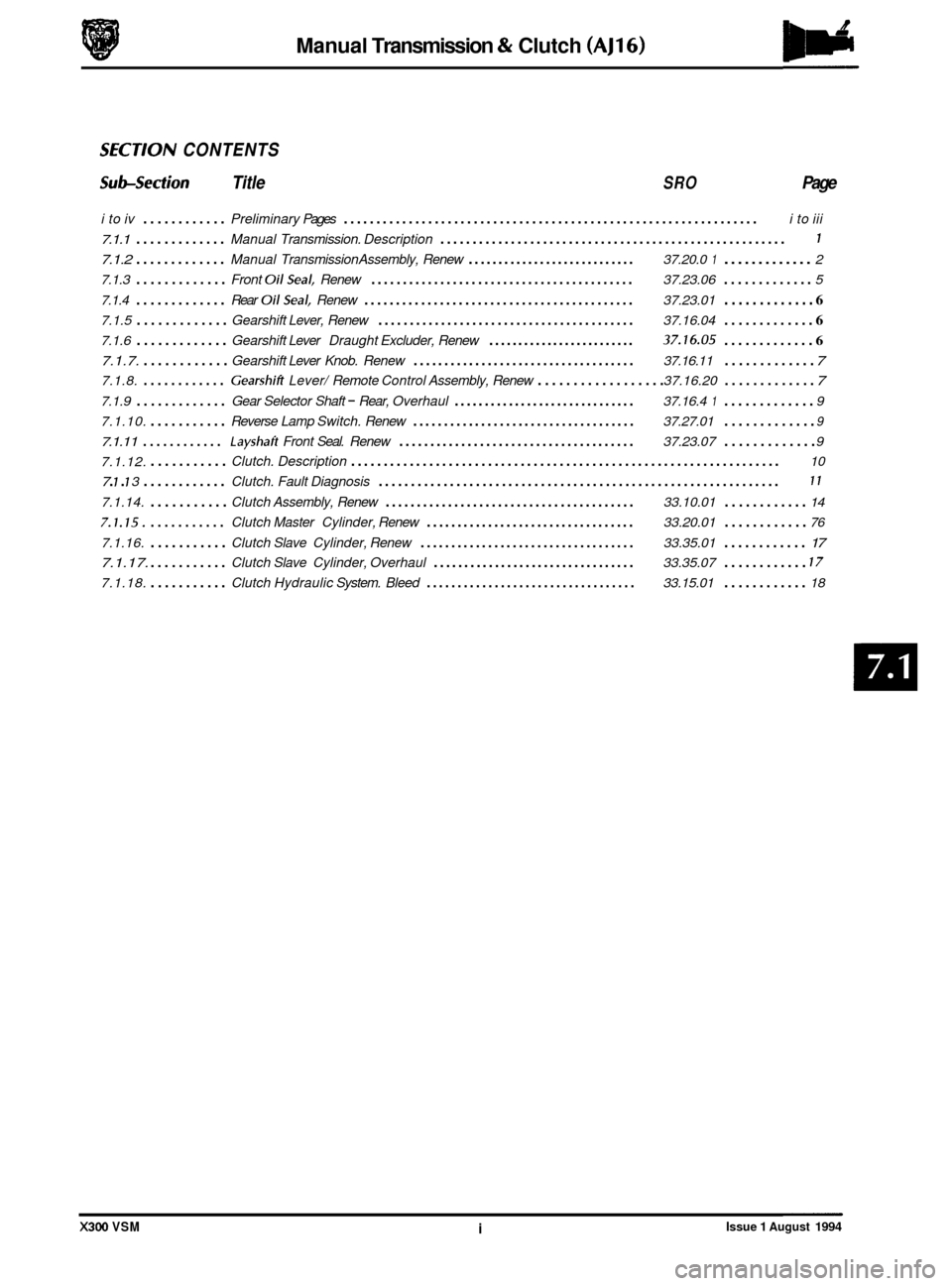

Manual Transmission & Clutch (AJ16)

SECTlON CONTENTS

Sub-section Title SRO Page

i to iv ............ Preliminary Pages ................................................................ i to iii

7.1.1 ............. Manual Transmission. Description ...................................................... 1

7.1.2 ............. Manual Transmission Assembly, Renew ............................ 37.20.0 1 ............. 2

7.1.3

............. Front OilSeal. Renew .......................................... 37.23.06 ............. 5

7.1.4

............. Rear OilSeal. Renew ........................................... 37.23.01 ............. 6

7.1.5 ............. Gearshift Lever, Renew ......................................... 37.16.04 ............. 6

7.1.6 ............. Gearshift Lever Draught Excluder, Renew ......................... 37.16.05 ............. 6

7.1.7. ............ Gearshift Lever Knob. Renew .................................... 37.16.11 ............. 7

7.1.8. ............ Gearshifi Lever/ Remote Control Assembly, Renew .................. 37.16.20 ............. 7

7.1.9 ............. Gear Selector Shaft - Rear, Overhaul .............................. 37.16.4 1 ............. 9

7.1.10.

........... Reverse Lamp Switch. Renew .................................... 37.27.01 ............. 9

7.1.11 ............ Layshaft Front Seal. Renew ...................................... 37.23.07 ............. 9

7.1.12.

........... Clutch. Description .................................................................. 10

7.1.14.

........... Clutch Assembly, Renew ........................................ 33.10.01 ............ 14

7.1.15. ........... Clutch Master Cylinder, Renew .................................. 33.20.01 ............ 76

7.1.16. ........... Clutch Slave Cylinder, Renew ................................... 33.35.01 ............ 17

7.1.17.

........... Clutch Slave Cylinder, Overhaul ................................. 33.35.07 ............ 17

7.1.18. ........... Clutch Hydraulic System. Bleed .................................. 33.15.01 ............ 18

7 . 1 . 7 3 ............ Clutch. Fault Diagnosis .............................................................. 11

X300 VSM i Issue 1 August 1994

Page 115 of 521

1. SERVICE TOOLS & EQUIPMENT

Illustration I JaauarNumber I -

18G 1465

Description Notes

Engine lifting brackets

Engine

fl support beam

11. TORQUE TIGHTEN1 NG SPEC1 FICA TIONS

Fixing Tightening Torque

(Nm)

49 - 54

8- 10

22 - 28

22

- 24

23 - 27

7 - 10

95 - 105

23

- 27

15

-18

23

- 27

Bell housing to adaptor plate

Bleed nipple to slave cylinder

Center bearing to body

Center bearing to mounting plate

Clutch cover to flywheel

Clutch damper to mounting bracket

Flywheel to crankshaft

Front cover to transmission

Front pipe to intermediate pipe

Gearshift lever

housing to transmission

Issue 1 August 1994 ii X300 VSM

Page 116 of 521

Manual Transmission & clutch (AJ16)

I Molykote FB 180 grease

Brake (clutch) fluid

- minimum

DOT 4

Dexron IID Transmission oil

Loctite

573

Tivoli Kay Adhesives No. 5696

Withdrawal arm pivots / Gearshift lever ball

Clutch hydraulic system

Front cover securing bolts

Exhaust sealer also used

in

ZF automatic

transmissions

Application

Material removal to clean up clutch face

IU SERVICE DATA

Specification

Up to lmm maximum

X300 VSM iii Issue 1 August 1994

Page 117 of 521

iv

Page 118 of 521

Manual Transmission & Clutch (AJ16)

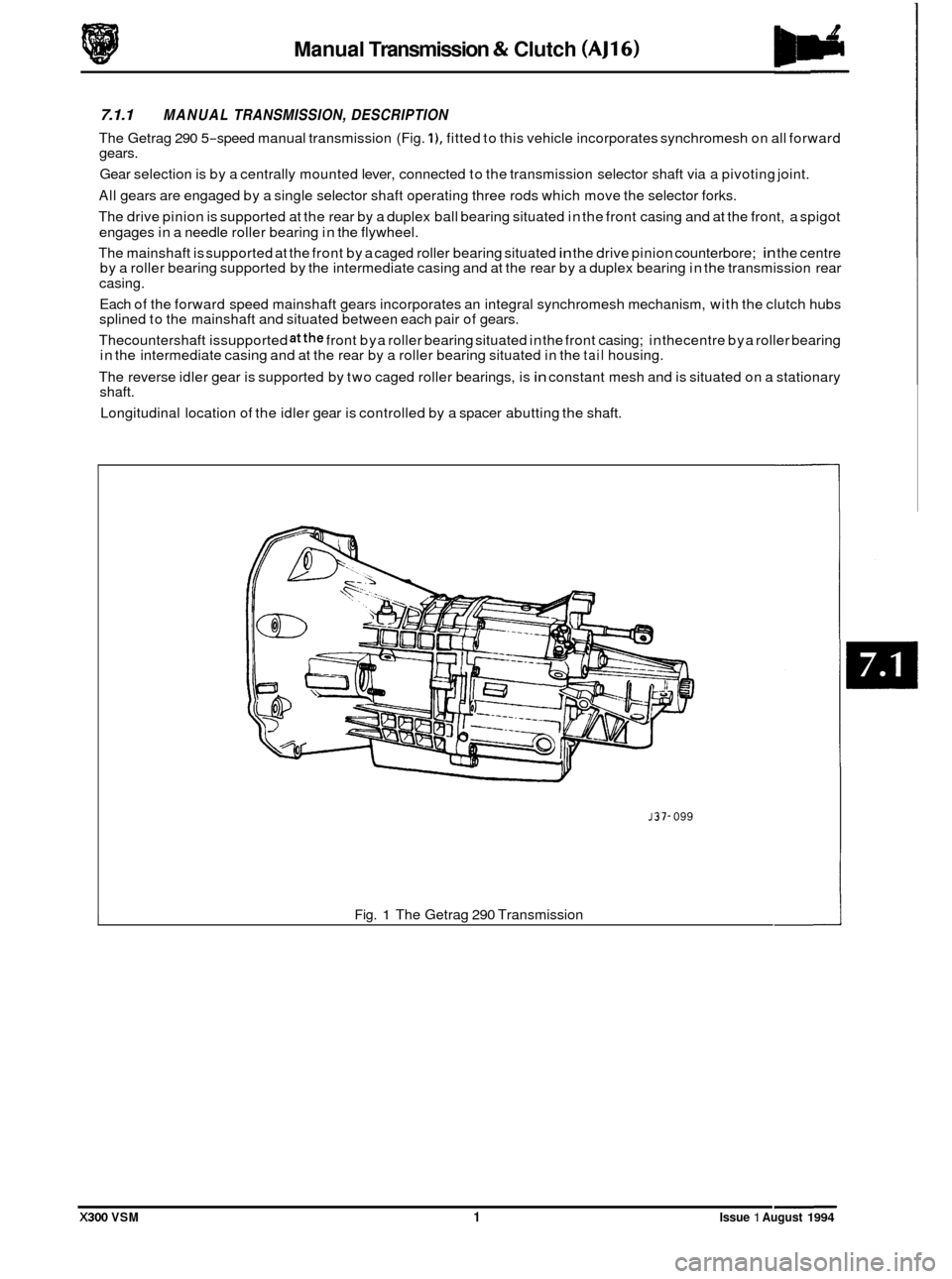

7.1.1 MANUAL TRANSMISSION, DESCRIPTION

The Getrag 290 5-speed manual transmission (Fig. I), fitted to this vehicle incorporates synchromesh on all forward

gears.

Gear selection is by a centrally mounted lever, connected to the transmission selector shaft via a pivoting joint.

All gears are engaged by a single selector shaft operating three rods which move the selector forks.

The drive pinion is supported at the rear by a duplex ball bearing situated in the front casing and at the front, a spigot

engages in a needle roller bearing in the flywheel.

The mainshaft is supported at the front by a caged roller bearing situated

in the drive pinion counterbore; in the centre

by a roller bearing supported by the intermediate casing and at the rear by a duplex bearing in the transmission rear

casing.

Each of the forward speed mainshaft gears incorporates an integral synchromesh mechanism, with the clutch hubs

splined to the mainshaft and situated between each pair of gears.

Thecountershaft issupported

atthe front bya roller bearing situated in the front casing; in thecentre bya roller bearing

in the intermediate casing and at the rear by a roller bearing situated in the tail housing.

The reverse idler gear is supported by two caged roller bearings, is

in constant mesh and is situated on a stationary

shaft.

Longitudinal location of the idler gear is controlled by a spacer abutting the shaft.

J37- 099

Fig. 1 The Getrag 290 Transmission

X300 VSM 1 Issue 1 August 1994

Page 119 of 521

Manual Transmission & Clutch (AJ16)

7.1.2 MANUAL TRANSMISSION ASSEMBLY, RENEW

SRO 37.20.01

. Disconnect the battery.

. Remove inlet manifold rear securing nuts.

. Remove injector harness mounting bracket.

. Fit lifting bracket 18G 1465 and secure with the nuts.

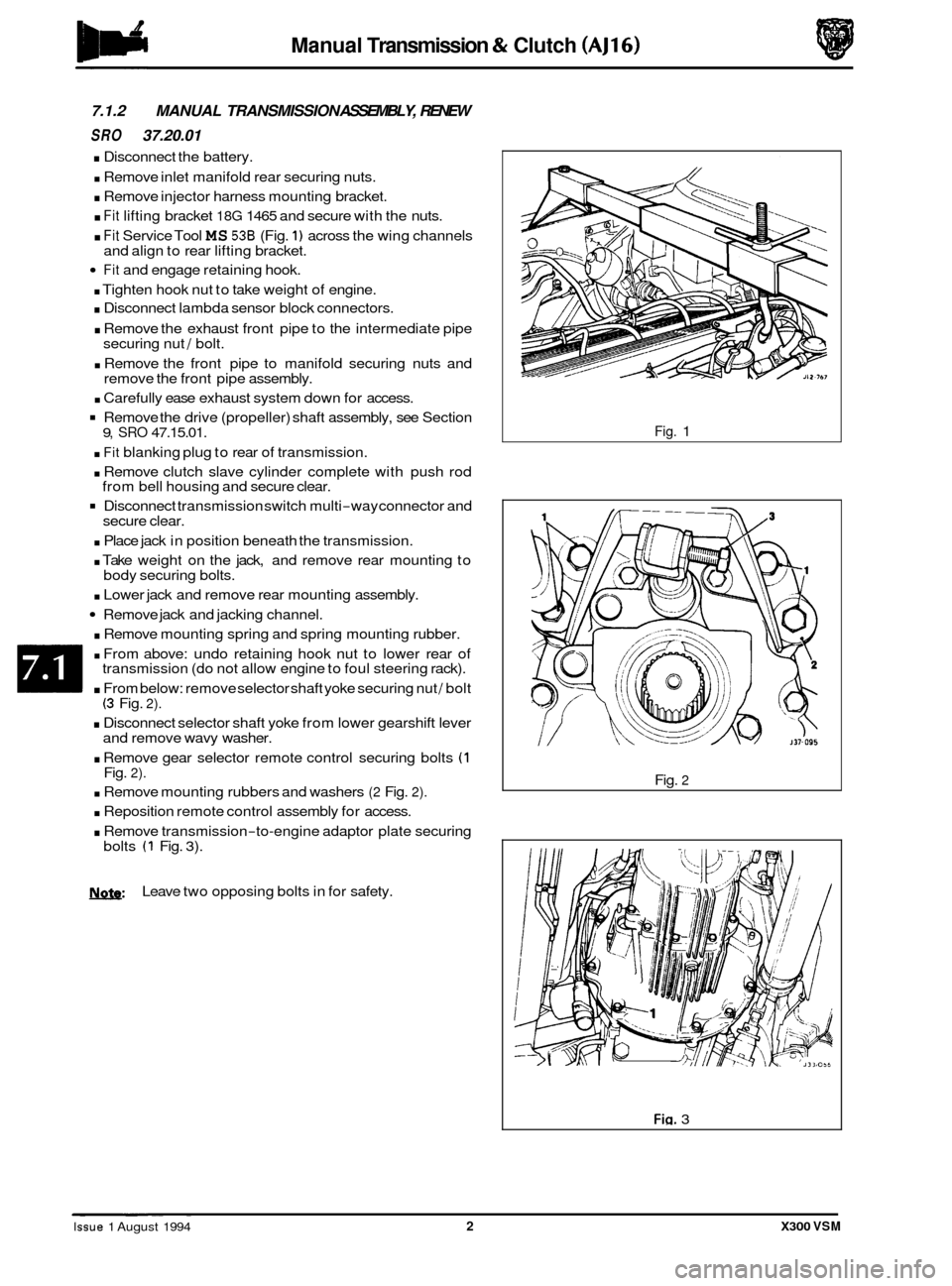

. Fit Service Tool MS 536 (Fig. 1) across the wing channels

Fit and engage retaining hook.

. Tighten hook nut to take weight of engine.

. Disconnect lambda sensor block connectors.

. Remove the exhaust front pipe to the intermediate pipe

securing nut / bolt.

. Remove the front pipe to manifold securing nuts and

remove the front pipe assembly.

. Carefully ease exhaust system down for access.

Remove the drive (propeller) shaft assembly, see Section

. Fit blanking plug to rear of transmission.

. Remove clutch slave cylinder complete with push rod

Disconnect transmission switch multi-way connector and

. Place jack in position beneath the transmission.

. Take weight on the jack, and remove rear mounting to

. Lower jack and remove rear mounting assembly.

Remove jack and jacking channel.

. Remove mounting spring and spring mounting rubber.

. From above: undo retaining hook nut to lower rear of

transmission (do not allow engine to foul steering rack).

. From below: remove selector shaft yoke securing nut / bolt (3 Fig. 2).

. Disconnect selector shaft yoke from lower gearshift lever

and remove wavy washer.

. Remove gear selector remote control securing bolts (1 Fig. 2).

. Remove mounting rubbers and washers (2 Fig. 2).

. Reposition remote control assembly for access.

. Remove transmission-to-engine adaptor plate securing

and

align to rear lifting bracket.

9, SRO 47.15.01.

from bell housing and secure clear.

secure clear.

body securing bolts.

bolts

(1 Fig. 3).

N.&: Leave two opposing bolts in for safety.

Fig. 1

Fig.

2

Fig. 3 ~ ~ ~~ ~

Issue 1 August 1994 2 X300 VSM

Page 120 of 521

Manual Transmission & Clutch (AJ16)

. Remove front clamp from unit lift.

. Raise / lower unit with jack, no stands.

. Traverse lift under ramp and take weight of transmission.

. Adjust jacking platform angles to suit transmission.

. Adjust side and rear clamps to suit transmission and tighten clamp wing nuts.

. Fit the safety chain assembly to left hand arm of lift, and secure with peg.

Pass safety chain over transmission and engage in front arm of lift. Tighten the safety chain adjuster.

. Remove remaining transmission to adaptor plate securing bolts and carefully lower transmission from engine.

. Remove transmission from ramp area.

. Remove clutch release bearing assembly from release lever.

. Remove clutch release lever retaining clip and remove lever.

. Remove release lever pivot pin.

Remove transmission switch.

. Remove rear mounting spring retainer securing nut.

. Reposition selector shaft pin cover.

0

Remove rear mounting spring retainer and remove rear mounting assembly.

Remove selector shaft yoke to selector shaft retaining pin and remove the yoke.

. Remove slave cylinder securing studs.

. Remove the transmission from the unit lift.

. Remove transmission drain plug and allow to drain, refit

the drain plug.

Fit new transmission to unit lift.

Fill transmission with oil and refit the level plug.

. Clean components and mating faces.

. Fit the slave cylinder mounting studs.

. Lubricate the selector output shaft.

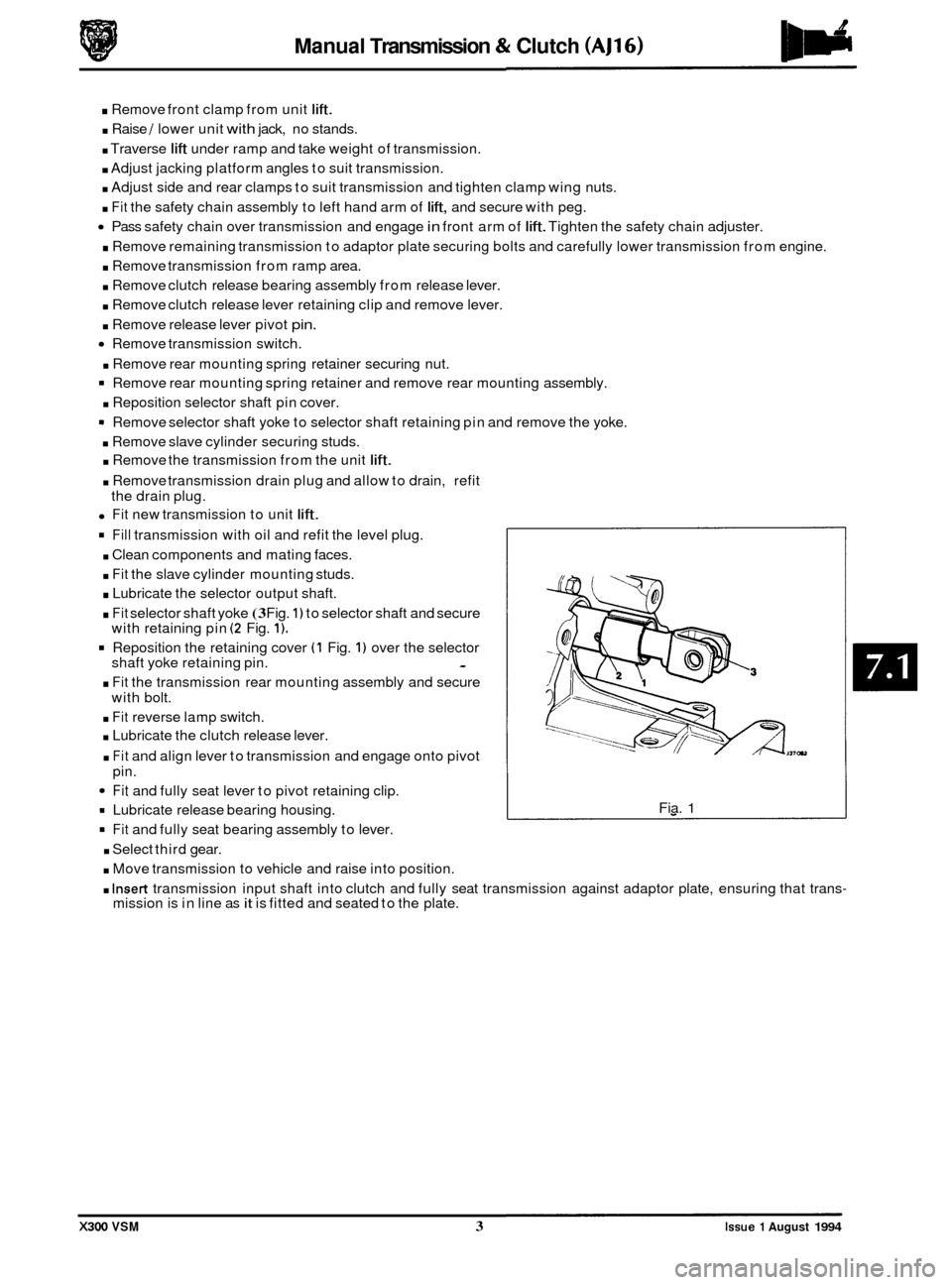

. Fit selector shaft yoke (3 Fig. 1) to selector shaft and secure

with retaining pin (2 Fig. 1).

Reposition the retaining cover (1 Fig. 1) over the selector

shaft yoke retaining pin. -

. Fit the transmission rear mounting assembly and secure

with bolt.

. Fit reverse lamp switch.

. Lubricate the clutch release lever.

. Fit and align lever to transmission and engage onto pivot

pin.

Fit and fully seat lever to pivot retaining clip.

= Lubricate release bearing housing.

9 Fit and fully seat bearing assembly to lever.

. Select third gear.

. Move transmission to vehicle and raise into position.

Fia. 1

. Insert transmission input shaft into clutch and fully seat transmission against adaptor plate, ensuring that trans- mission is in line as it is fitted and seated to the plate.

X300 VSM 3 Issue 1 August 1994