JAGUAR XJ6 1994 2.G Workshop Manual

XJ6 1994 2.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7690/w960_7690-0.png

JAGUAR XJ6 1994 2.G Workshop Manual

Trending: oil additives, heater, timing belt, catalytic converter, automatic transmission, battery location, brake rotor

Page 101 of 521

Page 102 of 521

1 3 4 S

J30-223

Fig. 1 Plan View, Exhaust System (AJ16 Normally Aspirated)

Page 103 of 521

Exhaust System (AJ16)

9

/ 7 I

3;

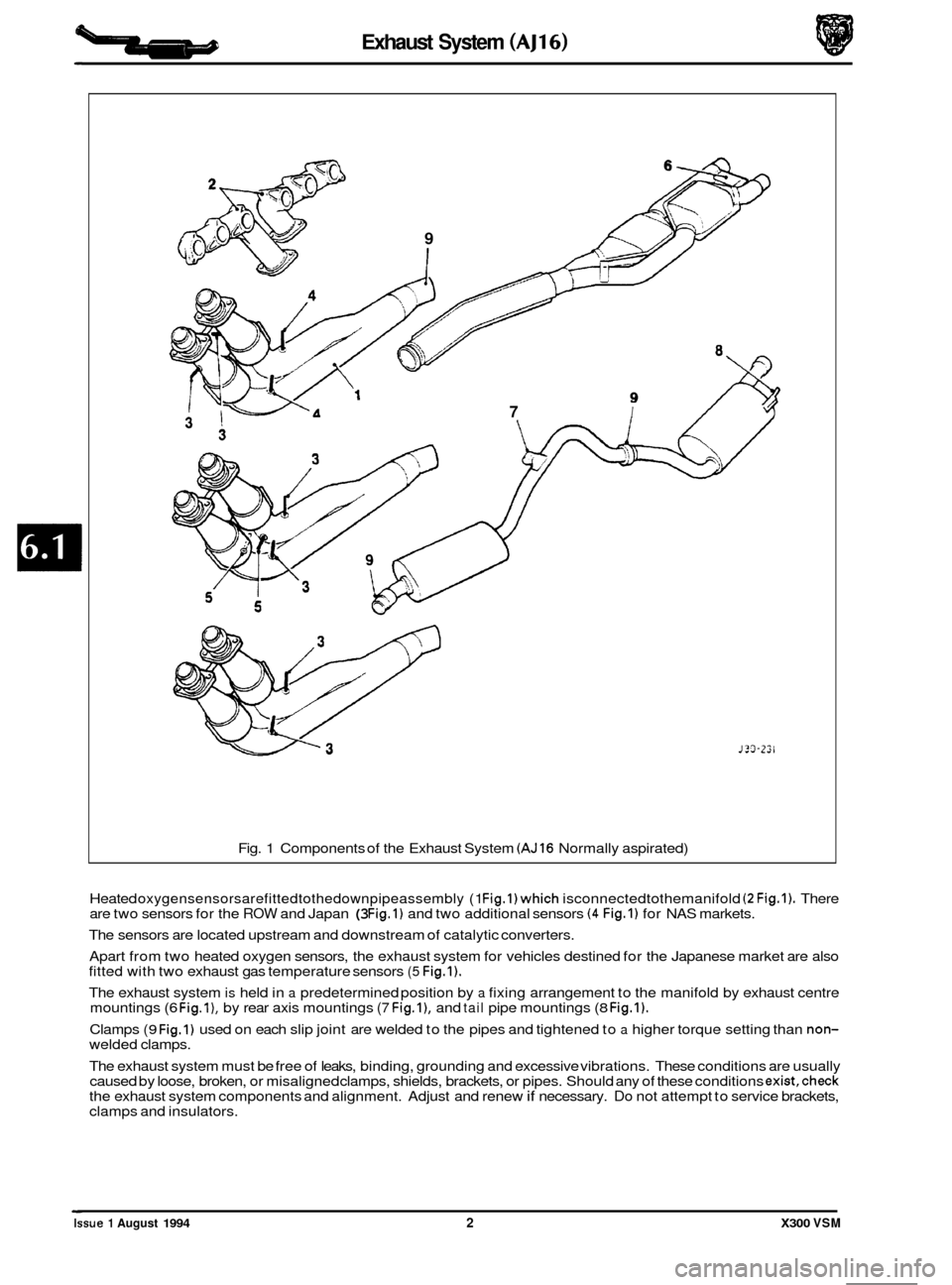

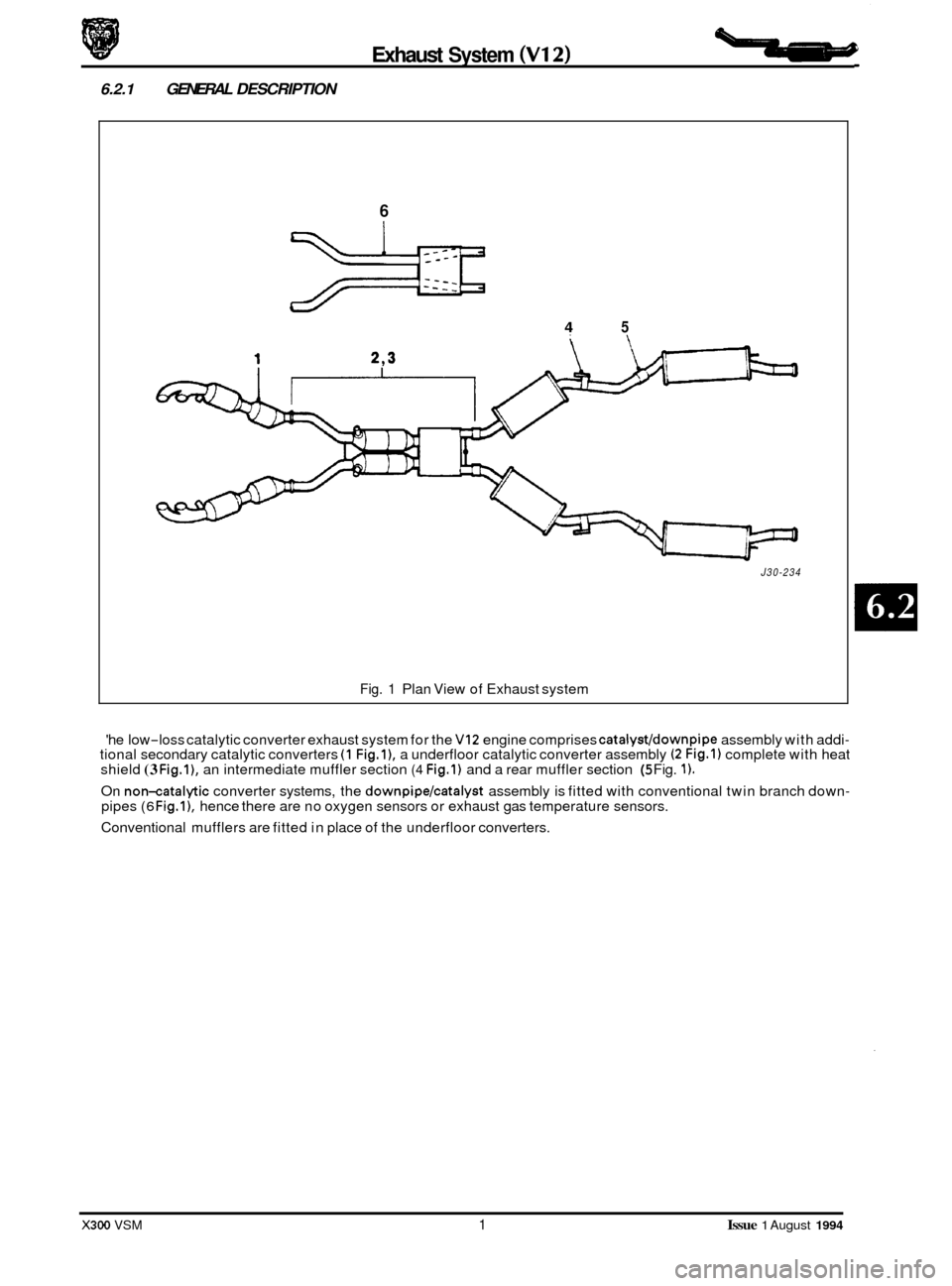

Fig. 1 Components of the Exhaust System (AJ16 Normally aspirated)

J?3-Z2l

Heated oxygensensorsarefittedtothedownpipeassembly (1 Fig.l)which isconnectedtothemanifold (2 Fig.1). There

are two sensors for the ROW and Japan (3 Fig.1) and two additional sensors (4 Fig.1) for NAS markets.

The sensors are located upstream and downstream of catalytic converters.

Apart from two heated oxygen sensors, the exhaust system for vehicles destined for the Japanese market are also

fitted with two exhaust gas temperature sensors

(5 Fig.1).

The exhaust system is held in a predetermined position by a fixing arrangement to the manifold by exhaust centre

mountings (6 Fig.l), by rear axis mountings (7 Fig.l), and tail pipe mountings (8 Fig.1).

Clamps (9 Fig.1) used on each slip joint are welded to the pipes and tightened to a higher torque setting than non- welded clamps.

The exhaust system must be free of leaks, binding, grounding and excessive vibrations. These conditions are usually

caused by loose, broken, or misaligned clamps, shields, brackets, or pipes. Should any of these conditions

exist,check the exhaust system components and alignment. Adjust and renew if necessary. Do not attempt to service brackets,

clamps and insulators.

Issue 1 August 1994 2 X300 VSM

Page 104 of 521

Exhaust System (AJ16)

1 2

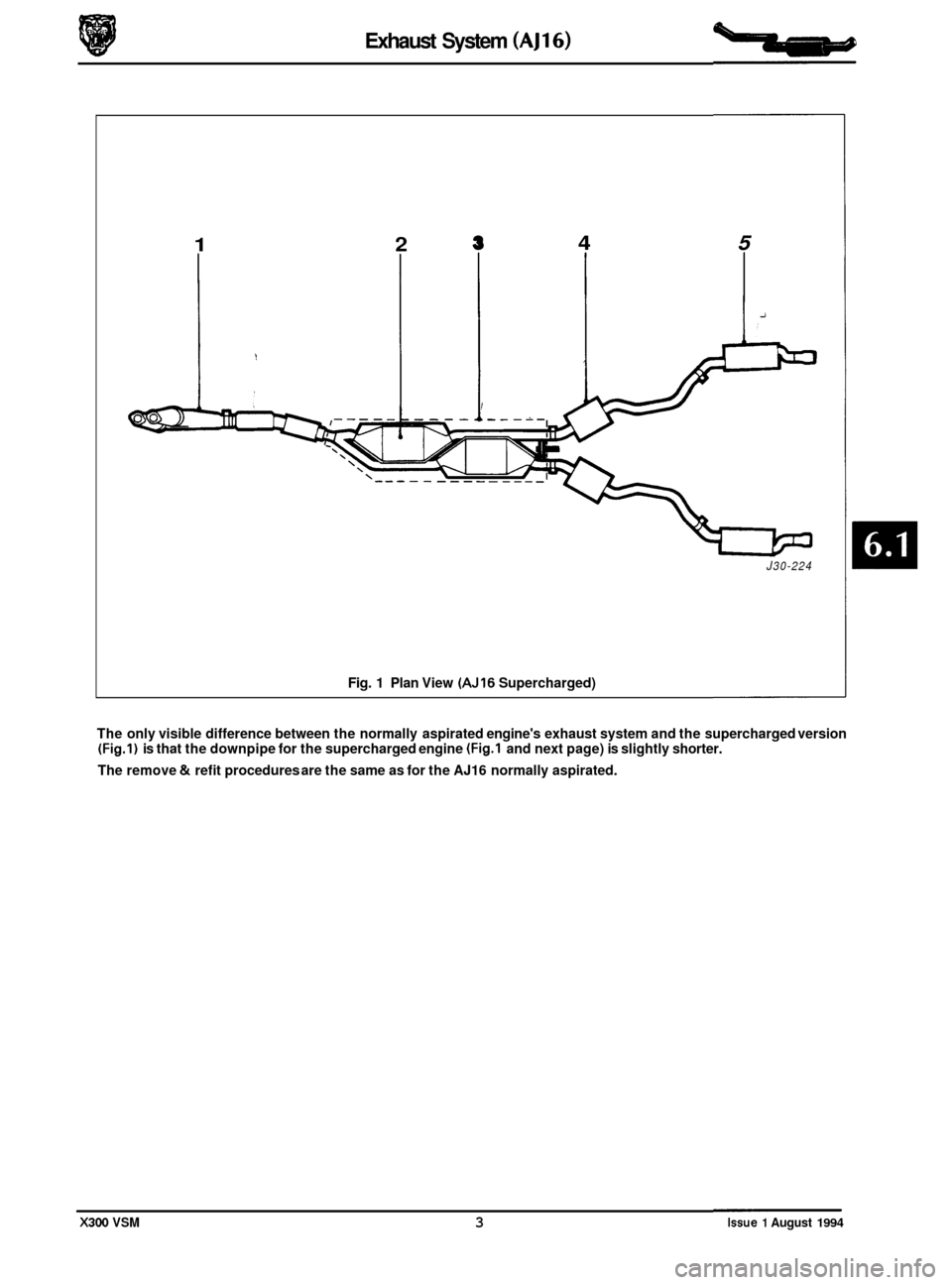

Fig. 1 Plan View (AJ16 Supercharged)

4 5

i

J30-224

The only visible difference between the normally aspirated engine's exhaust system and the supercharged version (Fig.1) is that the downpipe for the supercharged engine (Fig.1 and next page) is slightly shorter.

The remove

& refit procedures are the same as for the AJ16 normally aspirated.

X300 VSM 3 Issue 1 August 1994

Page 105 of 521

W Exhaust System (AJ16)

Fig. 1 Section Layout (AJ16 Supercharged)

0

0

0

0

Issue 1 August 1994 4 X300 VSM

Page 106 of 521

Also look for loose and rusted flange connections, loose or damaged exhaust shields

or clamp and loose or broken exhaust outlet pipe brackets.

6.1.2.1 Symptom Chart

I Condition I Possible Cause

Noises and exhaust fumes Exhaust leak.

Misaligned exhaust.

Loose clamps or fasteners.

Restricted exhaust system.

Electronic engine controls.

Fuel System.

Restricted exhaust system.

Engine lacking

power Ignition system.

Exhaust System (AJ16)

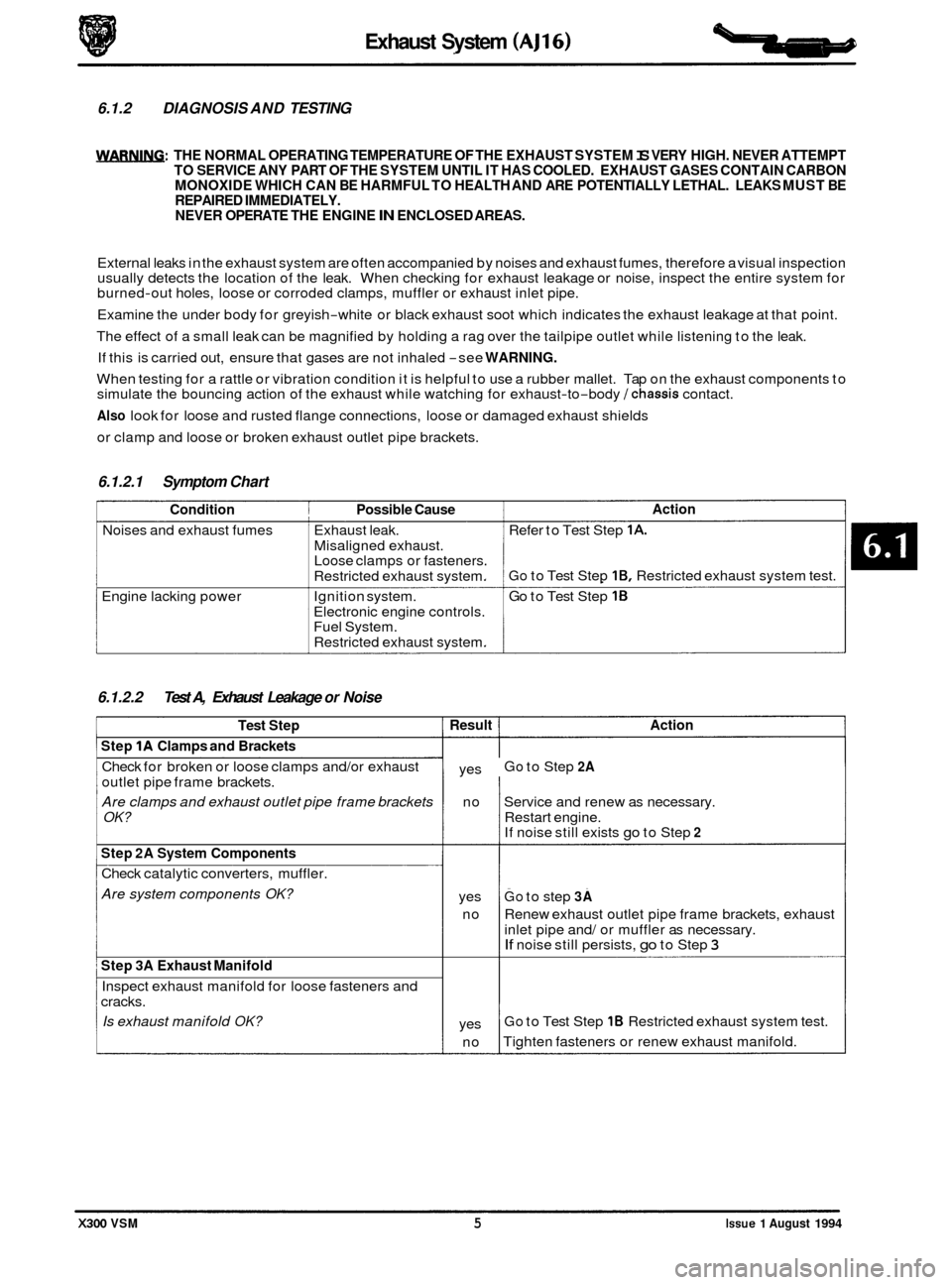

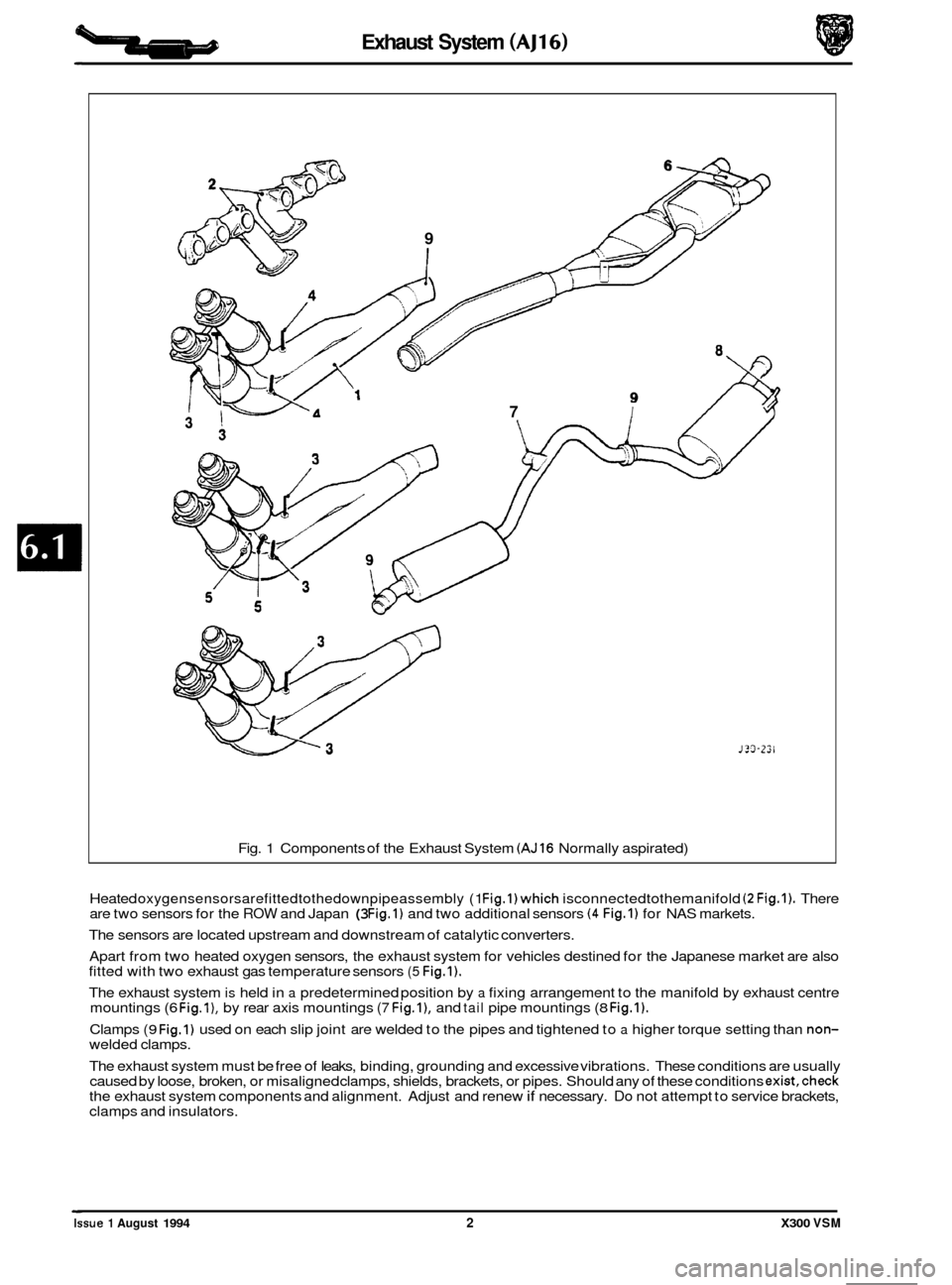

6.1.2 DIAGNOSIS AND TESTING

m: THE NORMAL OPERATING TEMPERATURE OF THE EXHAUST SYSTEM IS VERY HIGH. NEVER ATTEMPT

TO SERVICE ANY PART OF THE SYSTEM UNTIL IT HAS COOLED. EXHAUST GASES CONTAIN CARBON

MONOXIDE WHICH CAN BE HARMFUL TO HEALTH AND ARE POTENTIALLY LETHAL. LEAKS MUST BE

REPAIRED IMMEDIATELY.

NEVER OPERATE THE ENGINE

IN ENCLOSED AREAS.

External leaks in the exhaust system are often accompanied by noises and exhaust fumes, therefore a visual inspection

usually detects the location of the leak. When checking for exhaust leakage or noise, inspect the entire system for

burned

-out holes, loose or corroded clamps, muffler or exhaust inlet pipe.

Examine the under body for greyish

-white or black exhaust soot which indicates the exhaust leakage at that point.

The effect of a small leak can be magnified by holding a rag over the tailpipe outlet while listening to the leak.

If this is carried out, ensure that gases are not inhaled

-see WARNING.

When testing for a rattle or vibration condition it is helpful to use a rubber mallet. Tap on the exhaust components to

simulate the bouncing action of the exhaust while watching for exhaust-to-body /chassis contact.

6.1.2.2 Test A, Exhaust Leakage or Noise

Test Step

Step

1A Clamps and Brackets

Check for broken or loose clamps and/or exhaust

outlet pipe frame brackets.

Are clamps and exhaust outlet pipe frame brackets

OK?

Step 2A System Components

Check catalytic converters, muffler.

Are system components OK?

Step 3A Exhaust Manifold

Inspect exhaust manifold for loose fasteners and

cracks.

Is exhaust manifold OK?

Action

Refer to Test Step 1A.

Go to Test Step IB, Restricted exhaust system test. .-

Go to Test Step 1B

Result Action

yes

1

Go to Step 2A

no Service and renew as necessary.

Restart engine.

If noise still exists

go to Step 2

yes Go to step 3A

no Renew exhaust outlet pipe frame brackets, exhaust

inlet pipe and/ or muffler as necessary.

If noise still persists, go to Step 3

yes

no Go to Test Step 1B Restricted exhaust system test.

Tighten fasteners or renew exhaust manifold.

X300 VSM 5 Issue 1 August 1994

Page 107 of 521

Exhaust

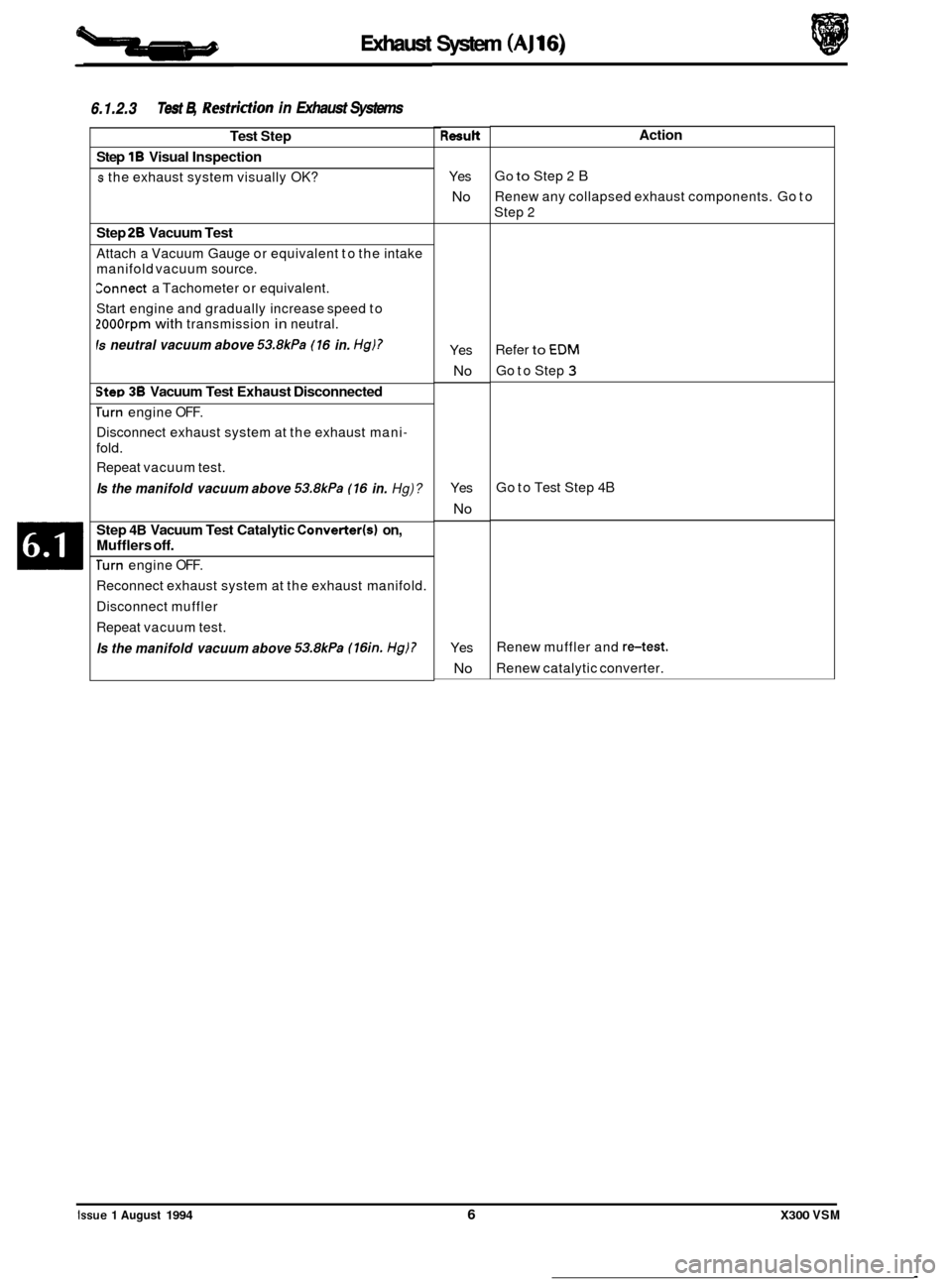

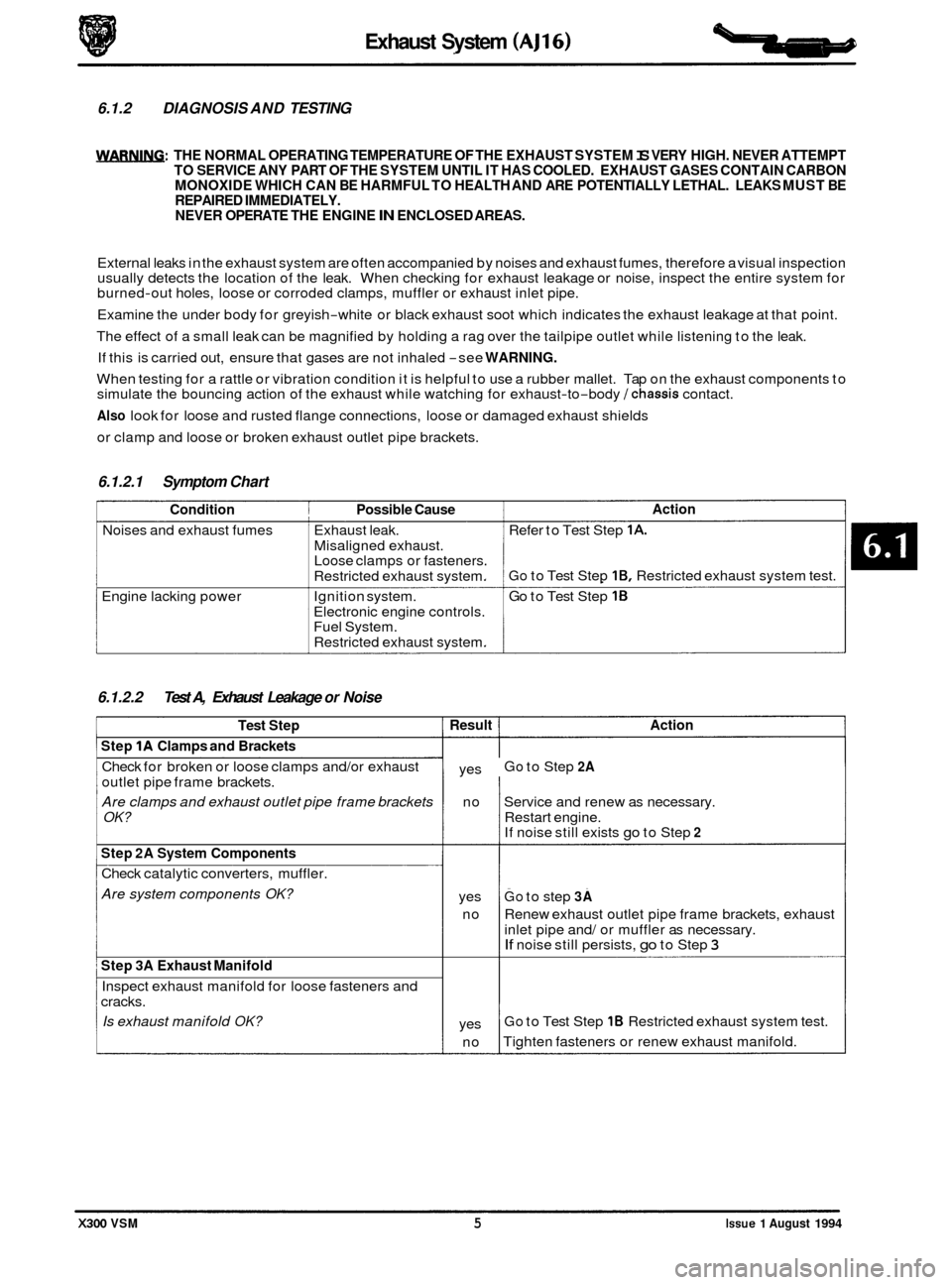

ridion in Exhaust Systems

Test Step

Step

1B Visual Inspection

s the exhaust system visually OK?

Step 28 Vacuum Test

Attach a Vacuum Gauge or equivalent to the intake

manifold vacuum source.

Eonnect a Tachometer or equivalent.

Start engine and gradually increase speed to

2OOOrpm with transmission in neutral.

Is neutral vacuum above 53.8kPa (16 in. Hg)?

Step 38 Vacuum Test Exhaust Disconnected

rurn engine OFF.

Disconnect exhaust system at the exhaust mani-

fold.

Repeat vacuum test.

Is the manifold vacuum above 53.8kPa (16 in. Hg)?

Step 4B Vacuum Test Catalytic Converter(s1 on,

Mufflers off.

+

6.1.2.3 Test B, Rest1

Turn engine OFF.

Reconnect exhaust system at the exhaust manifold.

Disconnect muffler

Repeat vacuum test.

Is the manifold vacuum above 53.8kPa (16in. Hg)?

System (AJ 1 6)

Resutt

Yes

No

Yes

No

Yes

No

Yes

No

Action

Go to Step 2 B

Renew any collapsed exhaust components. Go to

Step

2

Refer to EDM

Go to Step 3

Exhaust System (AJ16)

6.1.2.3 Test B, Restridion in Exhaust Systems

Go to Test Step 4B

Renew muffler and retest.

Renew catalytic converter.

Issue 1 August 1994 6 X300 VSM

Page 108 of 521

Exhaust System (V12) -==mw

SECTION CON TENTS

Subsection Title SRO Page

i ................ Preliminary Page .................................................................... i

6.2.7 .............

6.2.2 ............. Diagnosis& Testing .................................................................. 3

General Description ................................................................. 7

X300 VSM i Issue 1 August 1994

Page 109 of 521

Page 110 of 521

Exhaust System (V12)

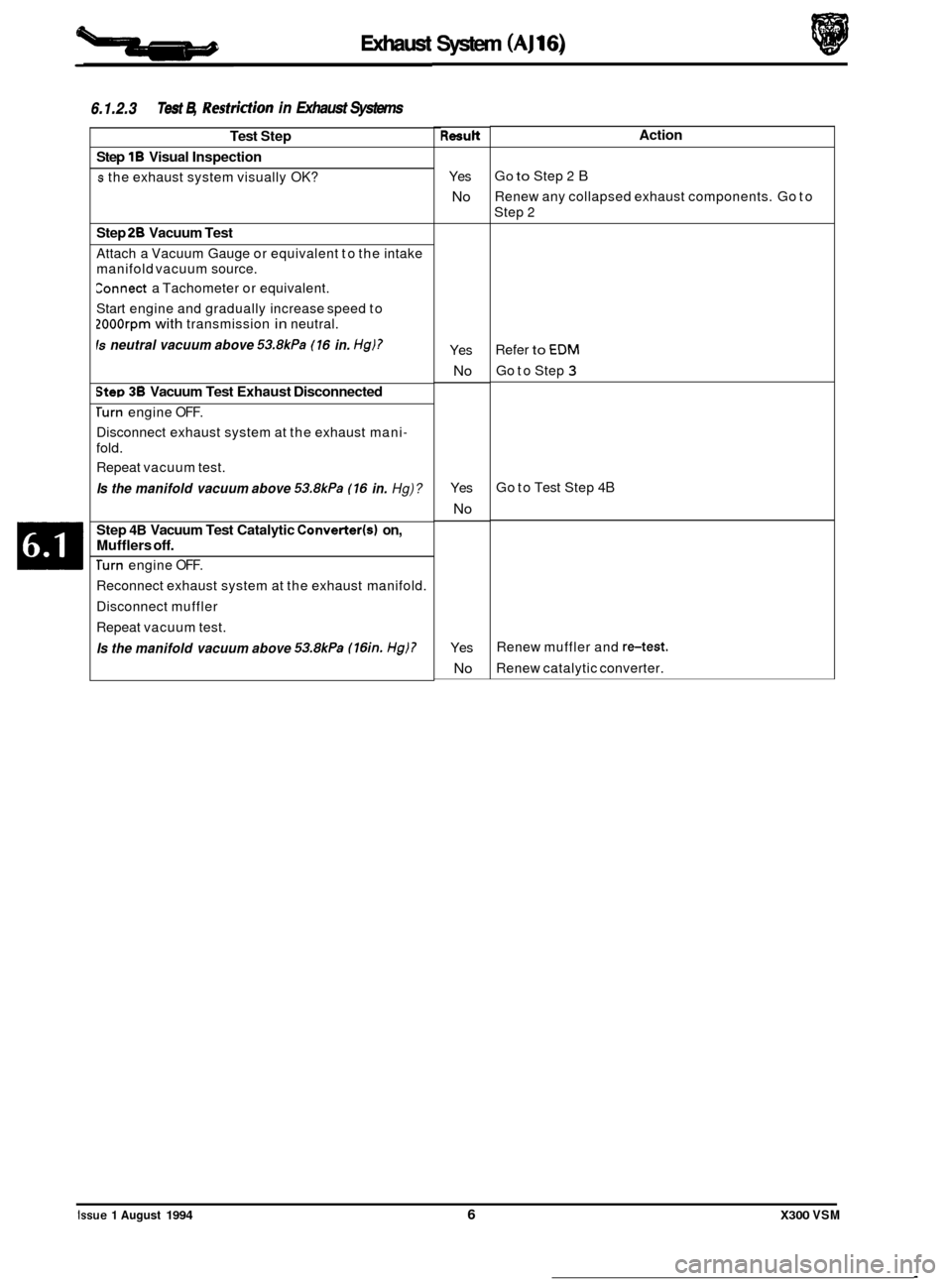

6.2.1 GENERAL DESCRIPTION

6

4 5

J30-234

Fig. 1 Plan View of Exhaust system

'he low

-loss catalytic converter exhaust system for the VI2 engine comprises catalyst/downpipe assembly with addi- tional secondary catalytic converters (1 Fig.11, a underfloor catalytic converter assembly (2 Fig.1) complete with heat

shield (3 Fig.l), an intermediate muffler section (4 Fig.1) and a rear muffler section (5 Fig. 1).

On non-catalytic converter systems, the downpipe/catalyst assembly is fitted with conventional twin branch down- pipes (6 Fig.11, hence there are no oxygen sensors or exhaust gas temperature sensors.

Conventional mufflers are fitted in place of the underfloor converters.

X300 VSM 1 Issue 1 August 1994

Trending: fuel cap release, radiator cap, hood open, beam, warning lights, weight, ESP inoperative