service JAGUAR XJ6 1994 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 45 of 521

Engine (AJ16)

3.1.5 FRONT ENGINEMOUNTING BRACKETASSEMBLY, RENEW

SRO 12.45.01 LH

SRO 12.45.03 RH

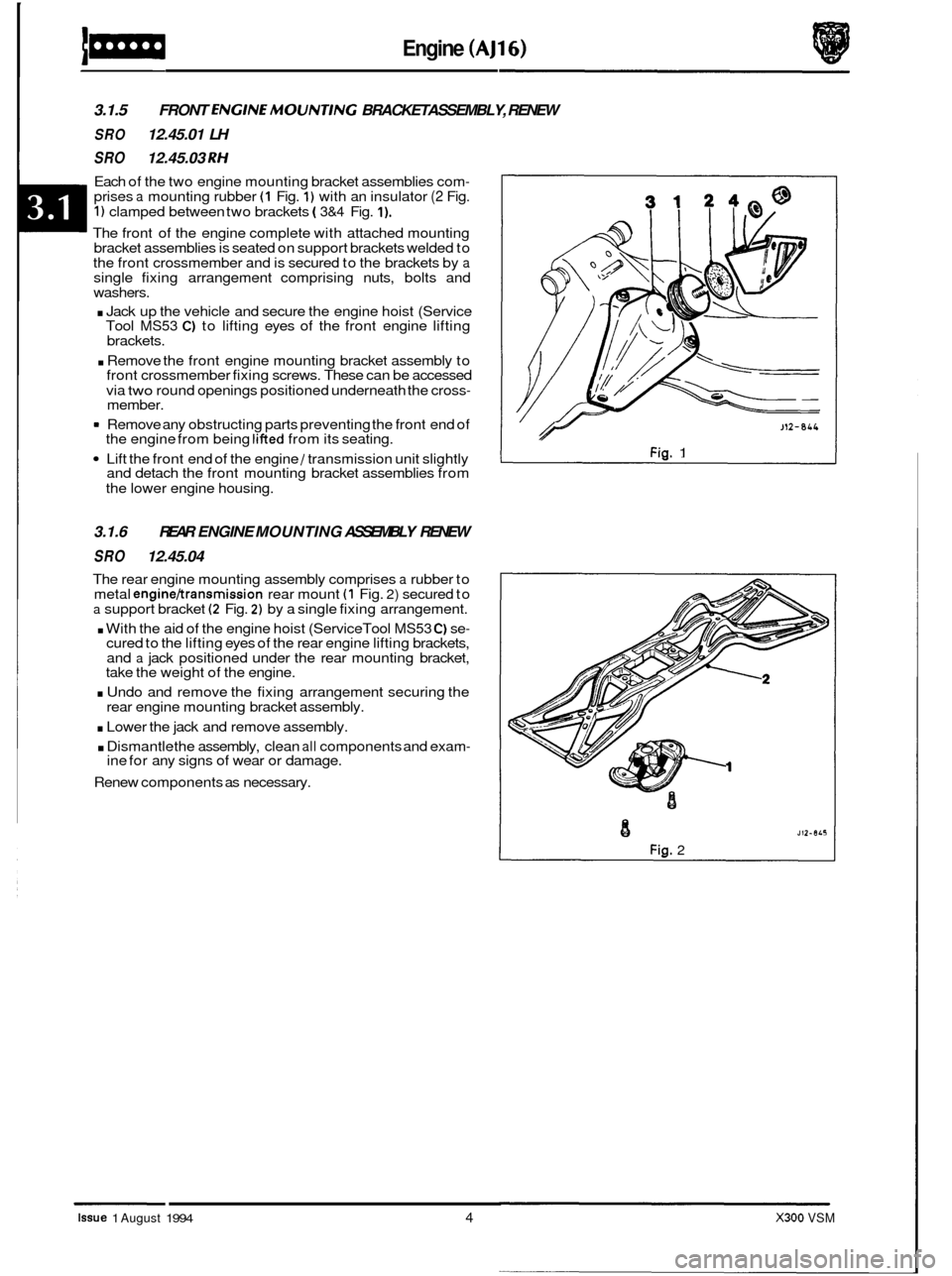

Each of the two engine mounting bracket assemblies com- prises a mounting rubber (1 Fig. 1) with an insulator (2 Fig.

1) clamped between two brackets ( 3&4 Fig. I).

The front of the engine complete with attached mounting

bracket assemblies is seated on support brackets welded to

the front crossmember and is secured to the brackets by

a single fixing arrangement comprising nuts, bolts and

washers.

. Jack up the vehicle and secure the engine hoist (Service

Tool MS53 C) to lifting eyes of the front engine lifting

brackets.

. Remove the front engine mounting bracket assembly to

front crossmember fixing screws. These can be accessed

via

two round openings positioned underneath the cross- member.

= Remove any obstructing parts preventing the front end of

the engine from being lifted from its seating.

Lift the front end of the engine / transmission unit slightly

and detach the front mounting bracket assemblies from

the lower engine housing.

3.1.6

SRO 12.45.04 REAR

ENGINE MOUNTING ASSEMBLY RENEW

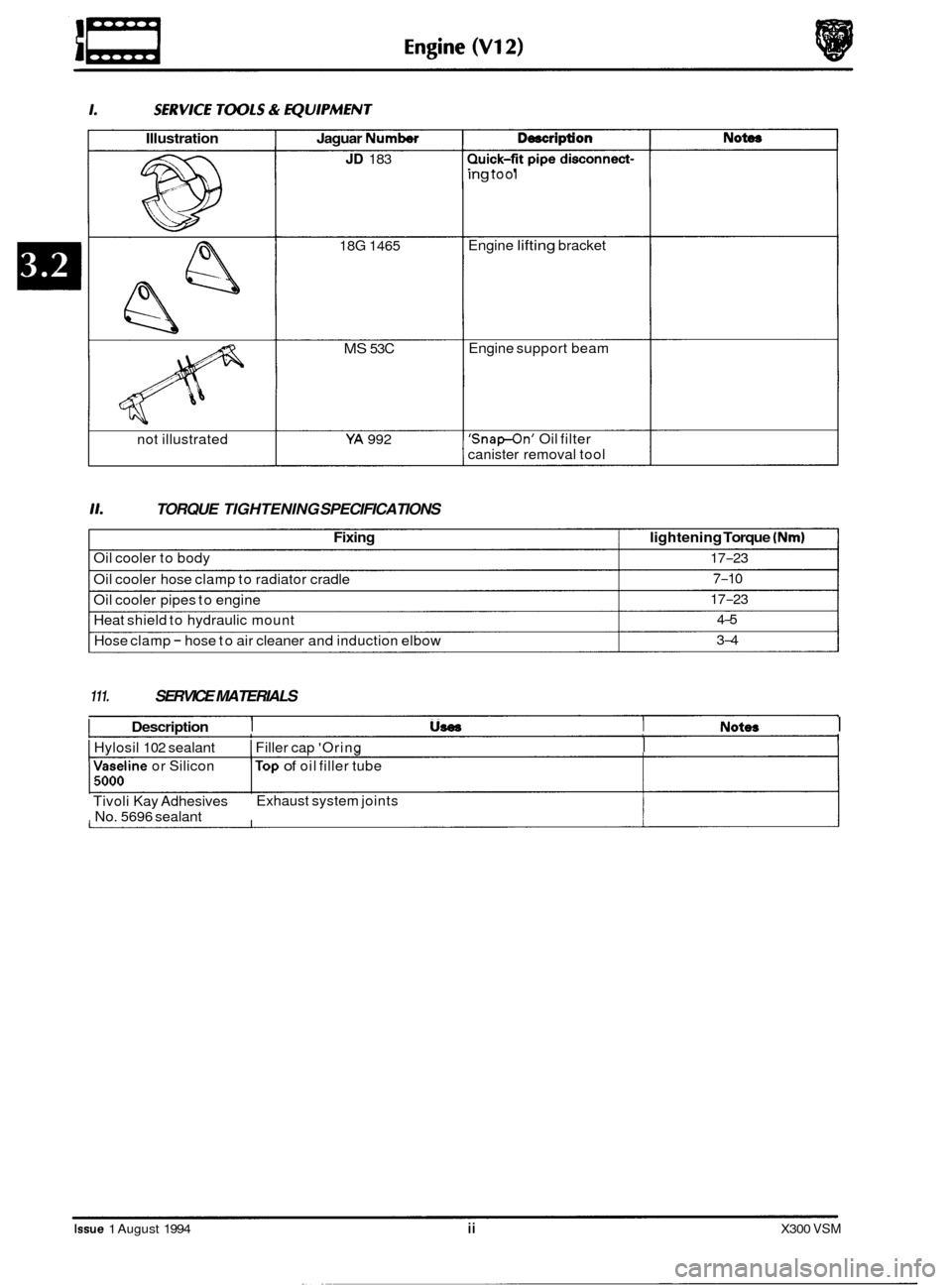

The rear engine mounting assembly comprises a rubber to

metal engine/transmission rear mount (1 Fig. 2) secured to a support bracket (2 Fig. 2) by a single fixing arrangement.

. With the aid of the engine hoist (Service Tool MS53 C) se- cured to the lifting eyes of the rear engine lifting brackets,

and a jack positioned under the rear mounting bracket,

take the weight of the engine.

. Undo and remove the fixing arrangement securing the

rear engine mounting bracket assembly.

. Lower the jack and remove assembly.

. Dismantle the assembly, clean all components and exam- ine for any signs of wear or damage.

Renew components as necessary.

J12-8LL

Fig. 1

J 12- 8 LS

Fig. 2

8

Issue 1 August 1994 4 X300 VSM

Page 47 of 521

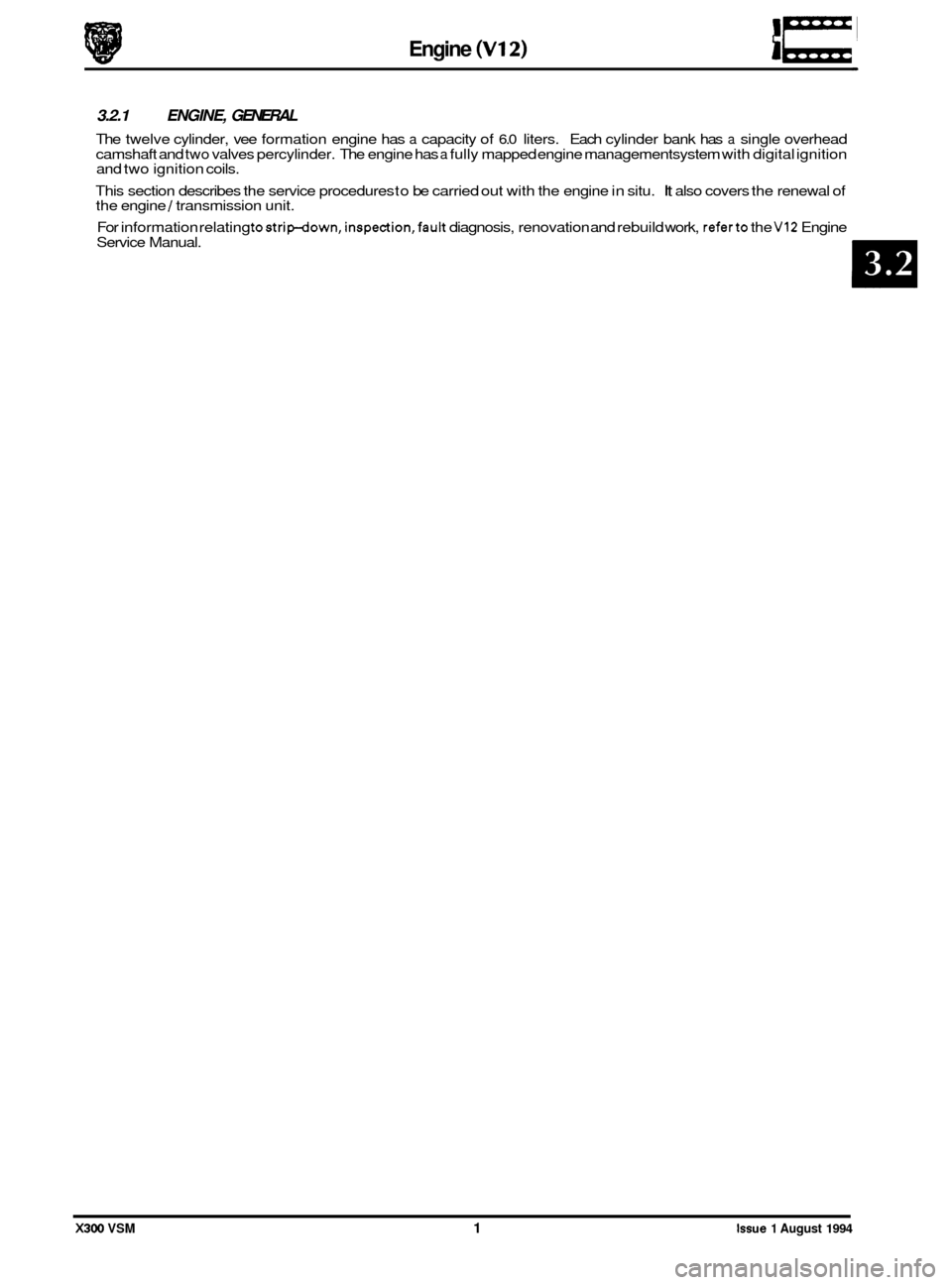

Illustration

not illustrated

Jaguar Number

JD 183

18G 1465

MS 53C

YA 992

11. TORQUE TIGHTENING SPECIFICATIONS

ing tool

Engine

lifting bracket

Engine support beam

'Snap-On' Oil filter

canister removal tool

Fixing lightening Torque (Nm)

Oil cooler to body 17-23

Oil cooler hose clamp to radiator cradle

Oil cooler pipes to engine

Heat shield to hydraulic mount

Hose clamp

- hose to air cleaner and induction elbow

7-10

17

-23

4

-5

3

-4

111. SERVICE MATERIALS

I Description I US88 I Notem I

I Hylosil 102 sealant I Filler cap 'Oring I I

Vaseline or Silicon lTop of oil filler tube 15000

Tivoli Kay Adhesives

No. 5696 sealant Exhaust

system joints

Issue 1 August 1994 ii X300 VSM

Page 48 of 521

Engine (V12)

3.2.1 ENGINE, GENERAL

The twelve cylinder, vee formation engine has a capacity of 6.0 liters. Each cylinder bank has a single overhead

camshaft and two valves percylinder. The engine has a fully mapped engine management system with digital ignition

and two ignition coils.

This section describes the service procedures to be carried out with the engine in situ.

It also covers the renewal of

the engine / transmission unit.

For information relating

tostrip-down, inspedion,fault diagnosis, renovation and rebuild work, referto the VI2 Engine

Service Manual.

X300 VSM 1 Issue 1 August 1994

Page 49 of 521

3.2.2 ENGINE - GEARBOX/ TRANSMISSION

ASSEMBLY, RENEW

SRO 12.37.01/90

The engine /transmission unit on the V12 6.0 liter model is mounted on three engine mounting / bracket assemblies

fitted to the front crossmember on either side of the engine bay. The engine/ transmission rear mount is a mounting

bracket and spring assembly fitted and secured to body underframe longitudinal members. For access to remove the

engine carry

out the following procedures:

WARNING: WHEN WORKING WITHIN THE ENGINE COMPARTMENT, KEEP CLEAR OF THE RADIATOR COOLING

FANS AS THEY COULD START WITHOUT WARNING, EVEN IF THE ENGINE IS NOT RUNNING.

. Remove the hood, see SRO 76.16.01, section 13.

. Remove the two air cleaner assemblies, see SRO’s 19.10.01 & 19.10.02.

. Remove the engine cover, see SRO 12.29.93 (V12 Engine Service Manual).

Depressurize the fuel system, see SRO 19.50.02, section 5.1.

In line with the relevant SRO’s and sections, remove all appropriate obstructing parts, including their fixing and

. Disconnect all mechanical and isolate all electrical linkages leading to and from the engine.

. De-gas the air conditioning system, see section 14, Charge Recovery (System depressurization).

Disconnect

the battery.

mounting arrangements.

CAUTION: Do

not vent refrigerant directly to the atmosphere and always use Jaguar approved recovery/recycle/ra charge equipment.

Drain the engine oil, see 3.2.3 this section.

Drain the coolant, see SRO 26.10.01, section 4.1.

WARNING: DO NOT REMOVE THE HEADER TANK PRESSURE CAP WHILE THE ENGINE IS HOT. IF THE CAP MUST

BE REMOVED, PROTECT THE HANDS AGAINST ESCAPING STEAM AND SLOWLY TURN THE CAP ANTI- CLOCKWISE UNTIL THE EXCESS PRESSURE CAN ESCAPE. LEAVE THE CAP IN THIS POSITION UNTIL ALL

STEAM AND PRESSURE HAS ESCAPED AND THEN REMOVE THE CAP COMPLETELY.

Before

lifting the complete engine/transmission unit with an engine hoist from the engine bay, ensure that two engine

lifting brackets (tool 18G. 1465) are secured equallyspaced to the inlet manifold studs. The four engine lifting brackets

should be positioned towards the front and the rear of the assembly. Ensure the front of thevehicle is jacked

up secure- ly on stands when removing the assembly.

X300 VSM Issue 1 August 1994 2

Page 51 of 521

Engine (V12)

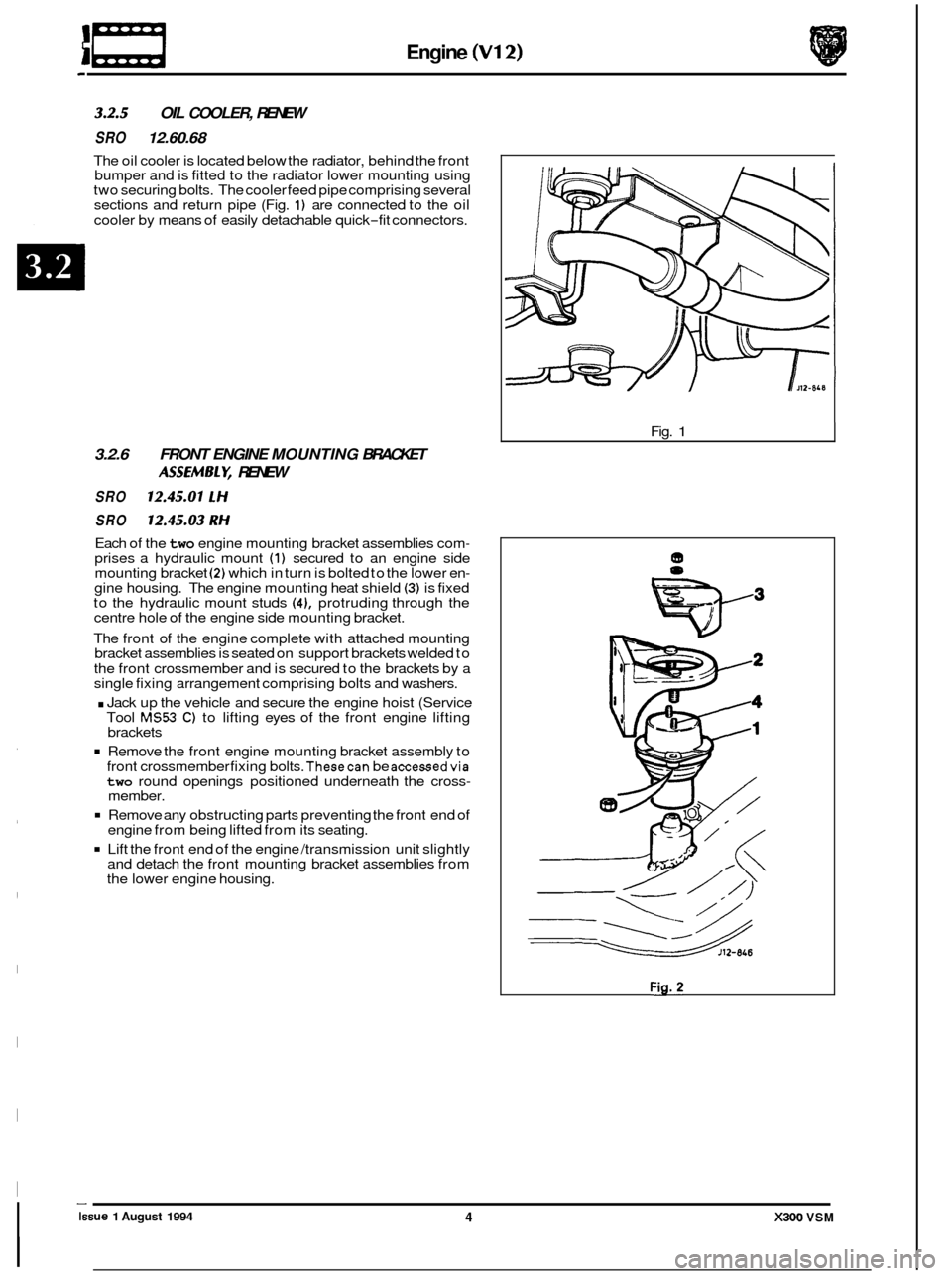

3.2.5 OIL COOLER, RENEW

SRO 12.60.68

The oil cooler is located below the radiator, behind the front

bumper and is fitted to the radiator lower mounting using

two securing bolts. The cooler feed pipe comprising several

sections and return pipe (Fig.

1) are connected to the oil

cooler by means of easily detachable quick

-fit connectors.

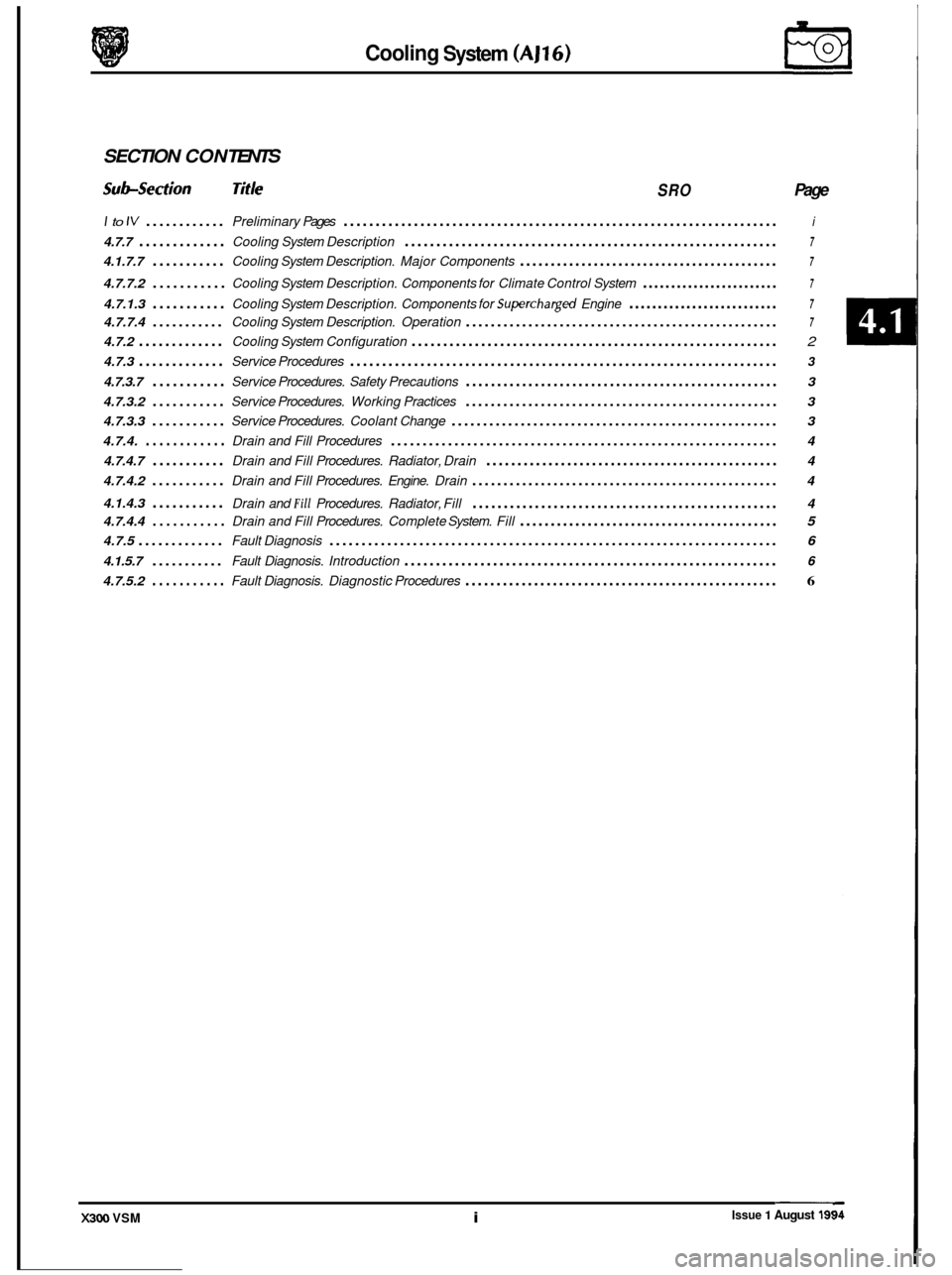

3.2.6 FRONT ENGINE MOUNTING BRACKET

SRO 12.45.01 LH

SRO 12.45.03 RH

Each of the two engine mounting bracket assemblies com- prises a hydraulic mount (1) secured to an engine side

mounting bracket (2) which in turn is bolted to the lower en- gine housing. The engine mounting heat shield (3) is fixed

to the hydraulic mount studs (41, protruding through the

centre hole of the engine side mounting bracket.

The front of the engine complete with attached mounting

bracket assemblies is seated on support brackets welded to

the front crossmember and is secured to the brackets by a

single fixing arrangement comprising bolts and washers.

. Jack up the vehicle and secure the engine hoist (Service

Tool MS53 C) to lifting eyes of the front engine lifting

brackets

Remove the front engine mounting bracket assembly to

front crossmember fixing bolts.

Thesecan be accessedvia two round openings positioned underneath the cross- member.

Remove any obstructing parts preventing the front end of

engine from being lifted from its seating.

Lift the front end of the engine /transmission unit slightly

and detach the front mounting bracket assemblies from

the lower engine housing.

ASSEMBLV, RENEW

Fig. 1

4 X300 VSM Issue 1 August 1994

Page 52 of 521

Engine (V12)

3.2.7 REAR ENGINEMOUNTlNGASSEMBLY, RENEW

SRO

12.45.04

The rear engine mounting assembly (Fig. 1) comprises a

mounting bracket and spring assembly, secured to body un- derframe longitudinal members using nuts and washers.

With the aid of the engine hoist (Service Tool MS53 C) se- cured to the lifting eyes of the rear engine lifting brackets,

and a jack positioned underthe rear mounting brackettake

the weight of the engine.

. Undo and remove the mounting bracket and spring as-

sembly fixing arrangement.

rn Lower the jack and remove assembly.

Dismantle the assembly, clean all components and exam-

ine for any signs of wear or damage.

Renew components as necessary.

8 112-8'7

Fig. 1

I Issue 1 August 1994 X300 VSM 5

Page 54 of 521

Cooling System

SECTION CON TENTS

Sub-section Title SRO Page

I to IV ............ Preliminary Pages .................................................................... i

4.7.7 ............. Cooling System Description ........................................................... 7

4.1.7.7 ........... Cooling System Description. Major Components .......................................... 7

4.7.7.2 ........... Cooling System Description. Components for Climate Control System ........................ 7

4.7.1.3 ........... Cooling System Description. Components for Superchargwl Engine .......................... 7

4.7.7.4 ........... Cooling System Description. Operation .................................................. 7

4.7.2 ............. Cooling System Configuration .......................................................... 2

4.7.3 ............. Service Procedures ................................................................... 3

4.7.3.7 ........... Service Procedures. Safety Precautions .................................................. 3

4.7.3.2

........... Service Procedures. Working Practices .................................................. 3

4.7.3.3

........... Service Procedures. Coolant Change .................................................... 3

4.7.4.

............ Drain and Fill Procedures ............................................................. 4

4.7.4.7

........... Drain and Fill Procedures. Radiator, Drain ............................................... 4

4.7.4.2

........... Drain and Fill Procedures. Engine. Drain ................................................. 4

4.1.4.3

........... Drain and Fill Procedures. Radiator, Fill ................................................. 4

4.7.4.4

........... Drain and Fill Procedures. Complete System. Fill .......................................... 5

4.7.5 ............. Fault Diagnosis ...................................................................... 6

4.1.5.7 ........... Fault Diagnosis. Introduction ........................................................... 6

4.7.5.2 ........... Fault Diagnosis. Diagnostic Procedures .................................................. 6

Issue 1 August 19! X300 VSM i

Page 55 of 521

€3 Cooling System (AJ16)

Fixing

Fan cowl assembly to radiator

Header tank bracket to body

Header tank to body

Hose clip,

all except those shown below

Hose clip, bleed hose to radiator

Radiator drain plug

Radiator temperature switch

Lower

radiator cradle to body

Supercharger pump mounting

Supercharger pump to instrumounts

Supercharger radiator to body

Top radiator panel to body

1. SERVICE TOOLS & EQUIPMENT

No Jaguar service tools are required for working on the cooling system. Some normal workshop items will be required,

including

a pressure tester, hydrometer and thermometer.

Tightening Torque

(Nm)

8-9

7-1 0

2,5-3,5

2,5-3,5

1,5-2,5

1,5-2,5

13-17

7

-1 0

7-10

5-7

7-10

7

-10

Description UseS

To be issued

111. SERVICE MATERIALS

Notes

Iv: SZRVICE DATA

Application

Engine thermostat temperature rating

Coolant header cap pressure rating

Generator

/ water pump drive belt tension, new belt

Generator

/ water pump drive belt tension, service

tension

_____ ~~ Generator / water

pump drive belt tension measuring

point

Smcification

88OC

1,2 bar

Set to:

Run for one minute and allow belt to cool.

Reset to: (Burroughs method) 511 to

534 N;

Burroughs method: 51 1 to 534 N.

Clavis method: 167 to 173 Hz

Mid

-way between crankshaft and generator pulleys

(Burroughs method)

556 to 578

N;

(Clavis method) 174 to 180 Hz.

(Clavis method) 167 to 173

Hz

0

0

0

0

X300 VSM Issue 1 August 1994 ii

Page 58 of 521

area washed to remove all traces of coolant.

CAUTION: To prevent the possibility of damage to the heater circuit pump and supercharger pump (where fitted),

the pumps should be electrically isolated if the ignition has to be turned ON while the cooling system is

drained.

WARNING: DO NOT REMOVE THE HEADER TANK PRESSURE CAP WHILE THE ENGINE IS HOT. IF THE CAP MUST

BE REMOVED, PROTECT THE HANDS AGAINST ESCAPING STEAM AND SLOWLY TURN THE CAP ANTI

- CLOCKWISE UNTIL THE EXCESS PRESSURE CAN ESCAPE. LEAVE THE CAP IN THIS POSITION UNTIL

ALL THE STEAM AND PRESSURE HAS ESCAPED AND THEN REMOVE THE CAP COMPLETELY.

WARNING: WHEN DRAINING THE COOLANT WITH THE ENGINE HOT, PROTECT THE HANDS AGAINST CONTACT

WITH HOT COOLANT.

WARNING: WHEN WORKING WITHIN THE ENGINE COMPARTMENT, KEEP CLEAR OF THE RADIATOR COOLING

FANS. THE FANS COULD START WITHOUT WARNING EVEN IF THE ENGINE IS NOT RUNNING.

4.1.3.2 Working Practices

Whenfilling thesystem with coolant,ensurethatthevehicle isstanding on a level surfaceandthatthecoolant is poured

in slowly so that airlocks are not introduced into the system. Airlocks can seriously affect the operation of the climate

control system and can cause damage to the heater circuit pump (and supercharger circuit pump if fitted).

Cooling System (AJ16)

4.1.3 SERVICE PROCEDURES

4.1.3.1 Safety Precautions

The anti-freeze specified in Appendix AI must be used wherever possible. It is designed to afford the maximum cor- rosion protection to all metals found in the engine cooling system, as well as having the frost protection properties

necessary during the winter months.

Should

it not be available, then anti-freeze conforming to Ford Motor Company specification ESLbM97B49-A may be

used. To provide optimum temperature and corrosion protection, the specified anti-freeze concentration must always

be used.

Once coolant has been drained from the system,

it must be discarded and not reused. Anti-freeze is harmful to the

environment. Used coolant must be disposed of safely and never poured down a drain connected to the public sewer.

CAUTION: Never fill or topup the system with water only.

CAUTION : Anti-freeze is harmful to paintwork. Coolant spillages must be wiped up immediately and the affected

Hose clips should always be positioned so that there is proper access for tightening and that the clip does not foul or

interfere with the operation of any components.

Drive belts must always be tensioned to the specified value and the tension checked

at the correct point on the belt.

This information is given in Subsection IV in the preliminary pages.

0

When tightening components, the torque figures given in Sukection II in the preliminary pages should always be

used for the fastenings listed.

4.1.3.3 Coolant Change

The coolant must be changed at intervals of four years. The system should be drained from the radiator drain plug,

flushed and filled with fresh coolant. Flushing should be carried out thoroughly to remove all the old coolant from the

engineand heater matrix. (The heatervalve isopen withthe ignition OFF). AfterfiIling,checkthecoolant concentration

with a hydrometer. For the specified anti-freeze and coolant concentration, see Appendix AI.

X300 VSM 3 Issue 1 August 1994

Page 64 of 521

SECTION CON TENTS

Subsection Titie SRO Page

it0 IV ............ Preliminarypages .................................................................... i

4.2.1 ............. Cooling System Description ........................................................... 1

4.2.1.1 ........... Cooling System Description. Major Components .......................................... 1

4.2.1.2 ........... Cooling System Description. Components for Climate Control System ........................ 1

4.2.1.3 ........... Cooling System Description. Operation .................................................. 1

4.2.2 ............. Cooling System Configuration .......................................................... 2

4.2.3

............. Service Procedures ................................................................... 3

4.2.3.1

........... Service Procedures. Safety Precautions .................................................. 3

4.2.3.2

........... Service Procedures. Working Practices .................................................. 3

4.2.3.3

........... Service Procedures. Coolant Change .................................................... 3

4.2.4

............. Drain and Fill Procedures ............................................................. 4

4.2.4.1

........... Drain and Fill Procedures. Radiator, Drain ............................................... 4

4.2.4.2

........... Drain and Fill Procedures. Radiator, Fill ................................................. 4

* 4.2.4.3 ........... Drain and Fill Procedures. Complete System. Fill .......................................... 4

4.2.4.4

........... Drain and Fill Procedures. System. Air Bleeding ........................................... 4

4.2.5

............. Fault Diagnosis ...................................................................... 5

4.2.5.1

........... Fault Diagnosis. introduction ........................................................... 5

4.2.5.2

........... Fault Diagnosis. Diagnostic Procedures .................................................. 5

X300 VSM i Issue 1 August 1994