service JAGUAR XJ6 1994 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 124 of 521

Manual Transmission & Clutch (AJ16)

GEARSHIFT LEVER KNOB, RENEW

:RY 37.16.11

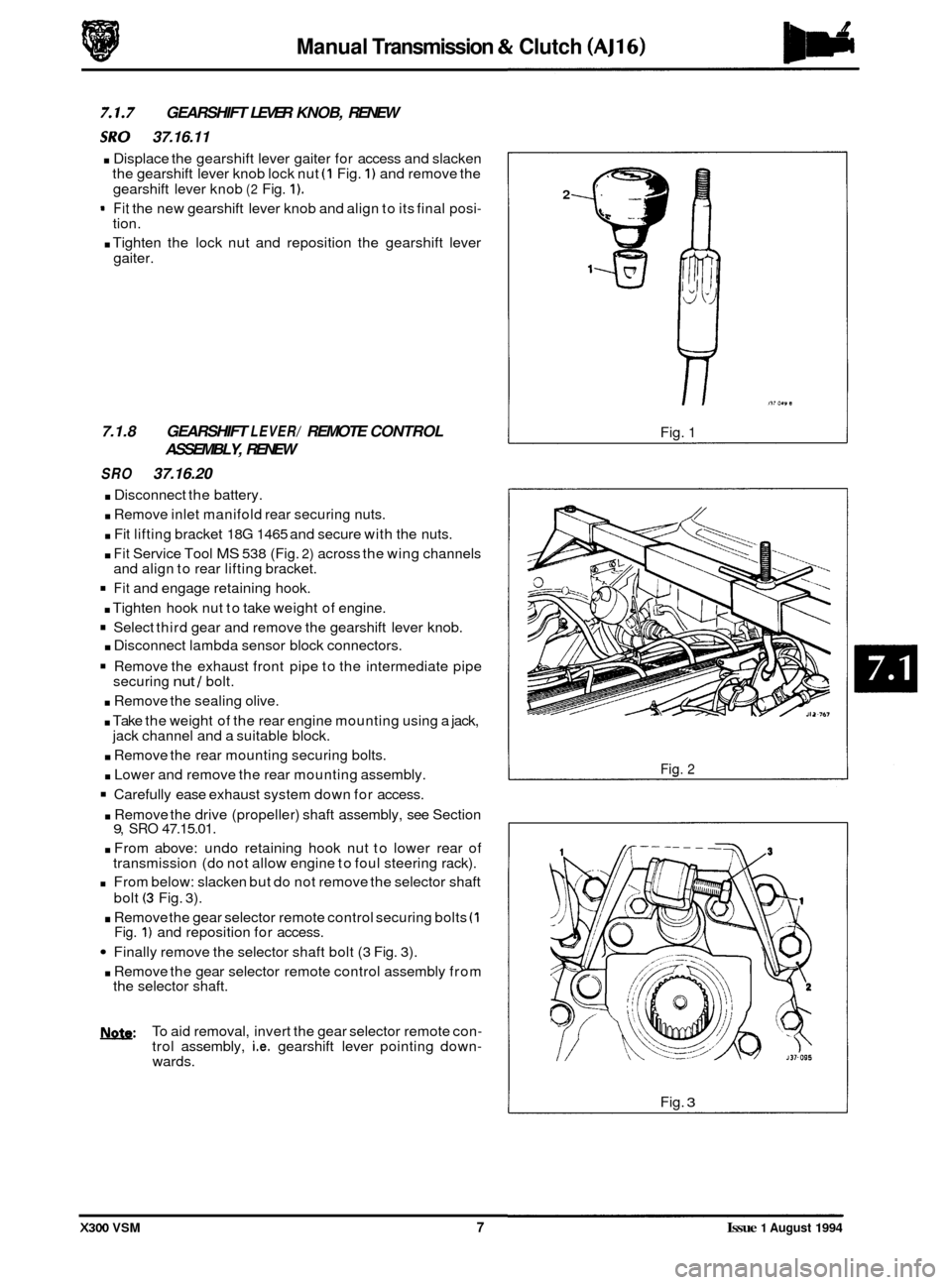

. Displace the gearshift lever gaiter for access and slacken

the gearshift lever knob lock nut (1 Fig. 1) and remove the

gearshift lever knob

(2 Fig. 1).

- Fit the new gearshift lever knob and align to its final posi- tion.

. Tighten the lock nut and reposition the gearshift lever

gaiter.

7.1.8 GEARSHIFT LEVER/ REMOTE CONTROL

ASSEMBLY, RENEW

SRO 37.16.20

. Disconnect the battery.

. Remove inlet manifold rear securing nuts.

. Fit lifting bracket 18G 1465 and secure with the nuts.

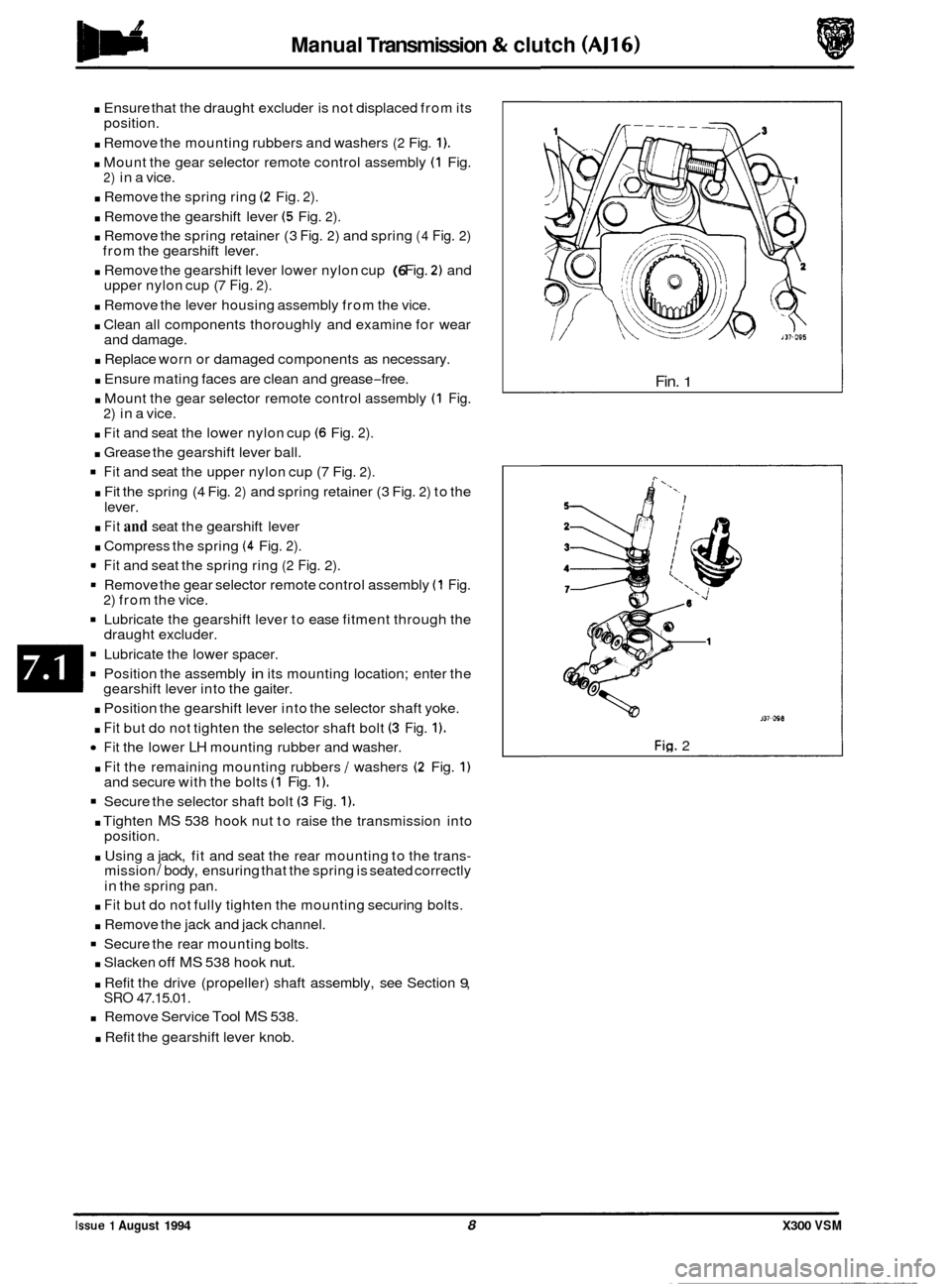

. Fit Service Tool MS 538 (Fig. 2) across the wing channels

and align to rear lifting bracket.

Fit and engage retaining hook.

. Tighten hook nut to take weight of engine.

Select third gear and remove the gearshift lever knob.

. Disconnect lambda sensor block connectors.

Remove the exhaust front pipe to the intermediate pipe

securing nut / bolt.

. Remove the sealing olive.

. Take the weight of the rear engine mounting using a jack,

. Remove the rear mounting securing bolts.

. Lower and remove the rear mounting assembly.

Carefully ease exhaust system down for access.

jack channel

and a suitable block.

. Remove the drive (propeller) shaft assembly, see Section 9, SRO 47.15.01.

. From above: undo retaining hook nut to lower rear of

transmission (do not allow engine to foul steering rack).

From below: slacken but do not remove the selector shaft

bolt

(3 Fig. 3).

. Remove the gear selector remote control securing bolts (1 Fig. 1) and reposition for access.

Finally remove the selector shaft bolt (3 Fig. 3).

. Remove the gear selector remote control assembly from

the selector shaft.

b: To aid removal, invert the gear selector remote con- trol assembly, i.e. gearshift lever pointing down- wards.

2

Fig. 1

Fig. 2

Fig. 3

X300 VSM 7 Issue 1 August 1994

Page 125 of 521

Manual Transmission & clutch (AJ16)

. Ensure that the draught excluder is not displaced from its

. Remove the mounting rubbers and washers (2 Fig. 1).

. Mount the gear selector remote control assembly (1 Fig.

. Remove the spring ring (2 Fig. 2).

. Remove the gearshift lever (5 Fig. 2).

. Remove the spring retainer (3 Fig. 2) and spring (4 Fig. 2)

. Remove the gearshift lever lower nylon cup (6 Fig. 2) and

. Remove the lever housing assembly from the vice.

. Clean all components thoroughly and examine for wear

. Replace worn or damaged components as necessary.

. Ensure mating faces are clean and grease-free.

. Mount the gear selector remote control assembly (1 Fig.

. Fit and seat the lower nylon cup (6 Fig. 2).

. Grease the gearshift lever ball.

Fit and seat the upper nylon cup (7 Fig. 2).

. Fit the spring (4 Fig. 2) and spring retainer (3 Fig. 2) to the

. Fit and seat the gearshift lever

. Compress the spring (4 Fig. 2).

* Fit and seat the spring ring (2 Fig. 2).

= Remove the gear selector remote control assembly (1 Fig.

Lubricate the gearshift lever to ease fitment through the

Lubricate the lower spacer.

Position the assembly in its mounting location; enter the

. Position the gearshift lever into the selector shaft yoke.

. Fit but do not tighten the selector shaft bolt (3 Fig. 1).

Fit the lower LH mounting rubber and washer.

. Fit the remaining mounting rubbers / washers (2 Fig. 1)

Secure the selector shaft bolt (3 Fig. 1).

. Tighten MS 538 hook nut to raise the transmission into

position.

. Using a jack, fit and seat the rear mounting to the trans- mission / body, ensuring that the spring is seated correctly

in the spring pan.

position.

2) in

a vice.

from the gearshift lever.

upper nylon cup (7

Fig. 2).

and damage.

2) in a vice.

lever.

2) from the vice.

draught excluder.

gearshift lever into the gaiter.

and secure with the bolts

(1 Fig. 1).

. Fit but do not fully tighten the mounting securing bolts.

. Remove the jack and jack channel.

Secure the rear mounting bolts.

. Slacken off MS 538 hook nut.

. Refit the drive (propeller) shaft assembly, see Section 9, SRO 47.15.01.

Remove Service Tool MS 538.

. Refit the gearshift lever knob.

Fin. 1

J37-WB

Fig. 2

Issue 1 August 1994 8 X300 VSM

Page 131 of 521

Manual Transmission & Clutch (AJ16) IBh

7.1.14 ClUTCHASSEMBLY, RENEW

SRO 33.10.01

. Remove the rear inlet manifold securing nuts and

. Fit lifting eye 18G 1465 to rear inlet manifold studs and

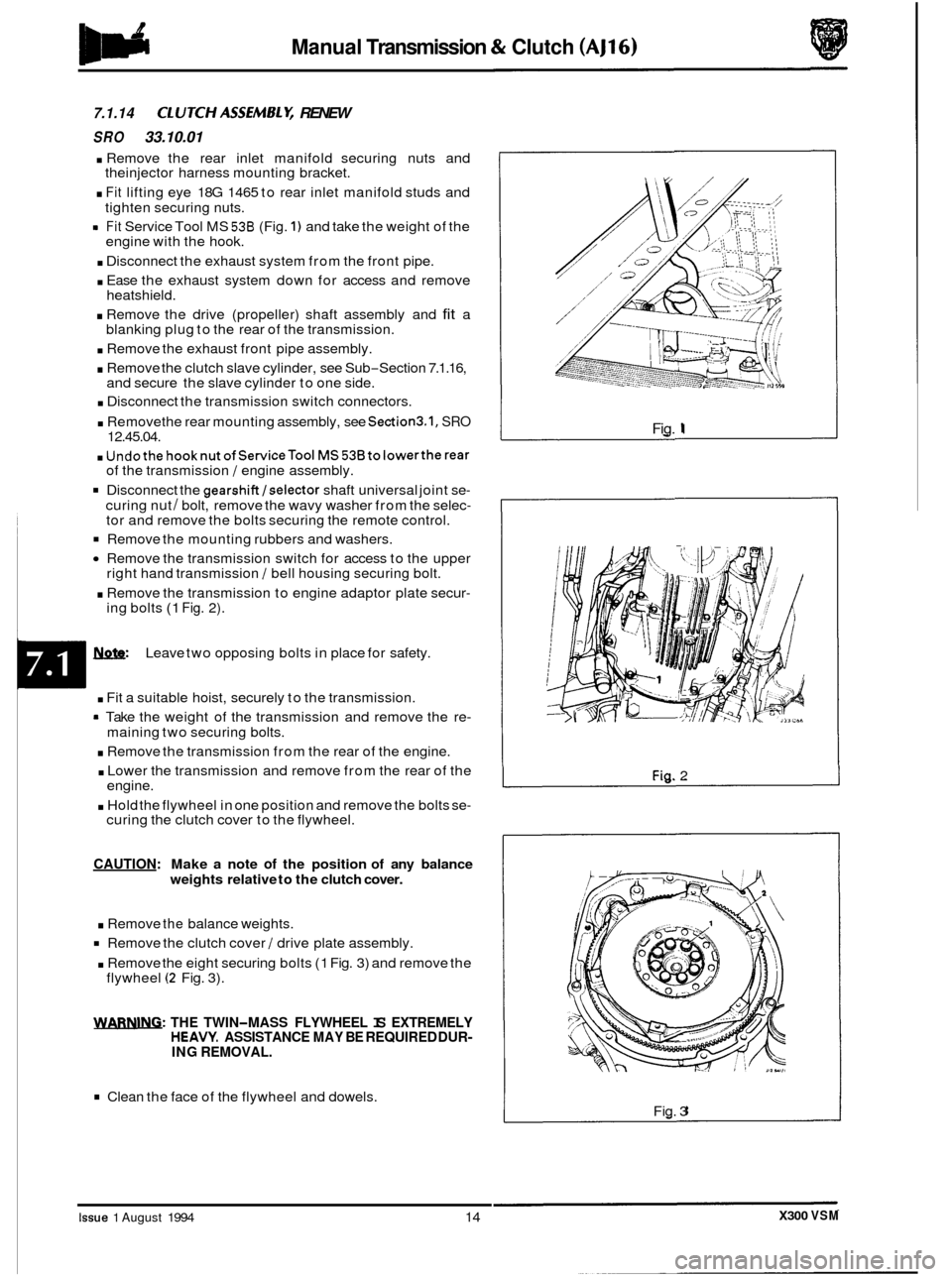

rn Fit Service Tool MS 538 (Fig. 1) and take the weight of the

. Disconnect the exhaust system from the front pipe.

. Ease the exhaust system down for access and remove

. Remove the drive (propeller) shaft assembly and fit a

. Remove the exhaust front pipe assembly.

. Remove the clutch slave cylinder, see Sub-Section 7.1.16,

and secure the slave cylinder to one side.

. Disconnect the transmission switch connectors.

. Removethe rear mounting assembly, see Section3.1, SRO 12.45.04.

. Undothe hooknutofServiceTool MS53Btolowertherear of the transmission / engine assembly.

Disconnect the gearshift/selector shaft universal joint se-

curing nut / bolt, remove the wavy washer from the selec- tor and remove the bolts securing the remote control.

Remove the mounting rubbers and washers.

Remove the transmission switch for access to the upper

. Remove the transmission to engine adaptor plate secur-

theinjector harness mounting bracket.

tighten securing nuts.

engine with the hook.

heatshield.

blanking plug to the rear of the transmission.

right hand transmission

/ bell housing securing bolt.

ing bolts

(1 Fig. 2).

Leave two opposing bolts in place for safety.

m . Fit a suitable hoist, securely to the transmission.

= Take the weight of the transmission and remove the re-

. Remove the transmission from the rear of the engine.

. Lower the transmission and remove from the rear of the

. Hold the flywheel in one position and remove the bolts se-

maining two securing bolts.

engine.

curing the clutch cover to the flywheel.

CAUTION: Make a note of the position of any balance

weights relative to the clutch cover.

. Remove the balance weights.

Remove the clutch cover / drive plate assembly.

. Remove the eight securing bolts (1 Fig. 3) and remove the

flywheel (2 Fig. 3).

WARNING: THE TWIN-MASS FLYWHEEL IS EXTREMELY HEAVY. ASSISTANCE MAY BE REQUIRED DUR- ING REMOVAL.

Clean the face of the flywheel and dowels.

Fig. 1

Fig. 2

Fig. 3

X300 VSM Issue 1 August 1994 14

Page 132 of 521

Manual Transmission & Clutch (AJ16)

. Check the flywheel face for scoring; should this be excess-

Fit a new spigot bearing to the flywheel (2 Fig. 1).

. Refit the flywheel to the crankshaft and tighten the secur-

. Fit the clutch assembly to the flywheel ensuring that the

. Align the clutch with an input shaft.

. Fit the balance weights to the clutch cover and tighten the

. Remove the input shaft.

ive,

skim within tolerance.

ing bolts (1

Fig. 1).

larger, rounded boss faces the flywheel.

securing bolts. Remove the circlip

(1 Fig. 2) securing the clutch release

arm to the pivot and remove the assembly (2 Fig. 2).

. Slacken and remove the release arm pivot pin.

. Remove the bearing (3 Fig. 2) from the release arm assem- bly (2 Fig. 21, grease the bearing seat, fit the new bearing

to the release arm assembly.

Re-assemble the release arm ensuring that the pivots are

greased.

. Select third forward gear.

. Move the transmission under the ramp and raise it into

position against the adaptor plate and secure with the

bolts.

. Remove the securing chain from the unit lift and fit front

clamp.

. Refit the transmission switch and fit the multi-plug into

the securing clip.

. Refit the clutch slave cylinder, see 33.35 01.

. Fit the mounting rubbers and spacers, reconnect the re-

. Refit the selector to the gearshift lever.

. Refit the exhaust front pipes to the manifold.

. Remove the blanking plug from the rear of the trans-

. Refit the drive (propeller) shaft.

. Refit the heat shield and reconnect the exhaust system.

. Lower the ramp.

. Remove the Service Tool MS 53B.

. Remove the engine lifting eye 18G 1465.

= Refit the injector harness mounting bracket and tighten

the rear inlet manifold securing nuts.

mote control.

mission.

Fig. 2

Issue 1 August 1994 X300 VSM 15

-~

Page 137 of 521

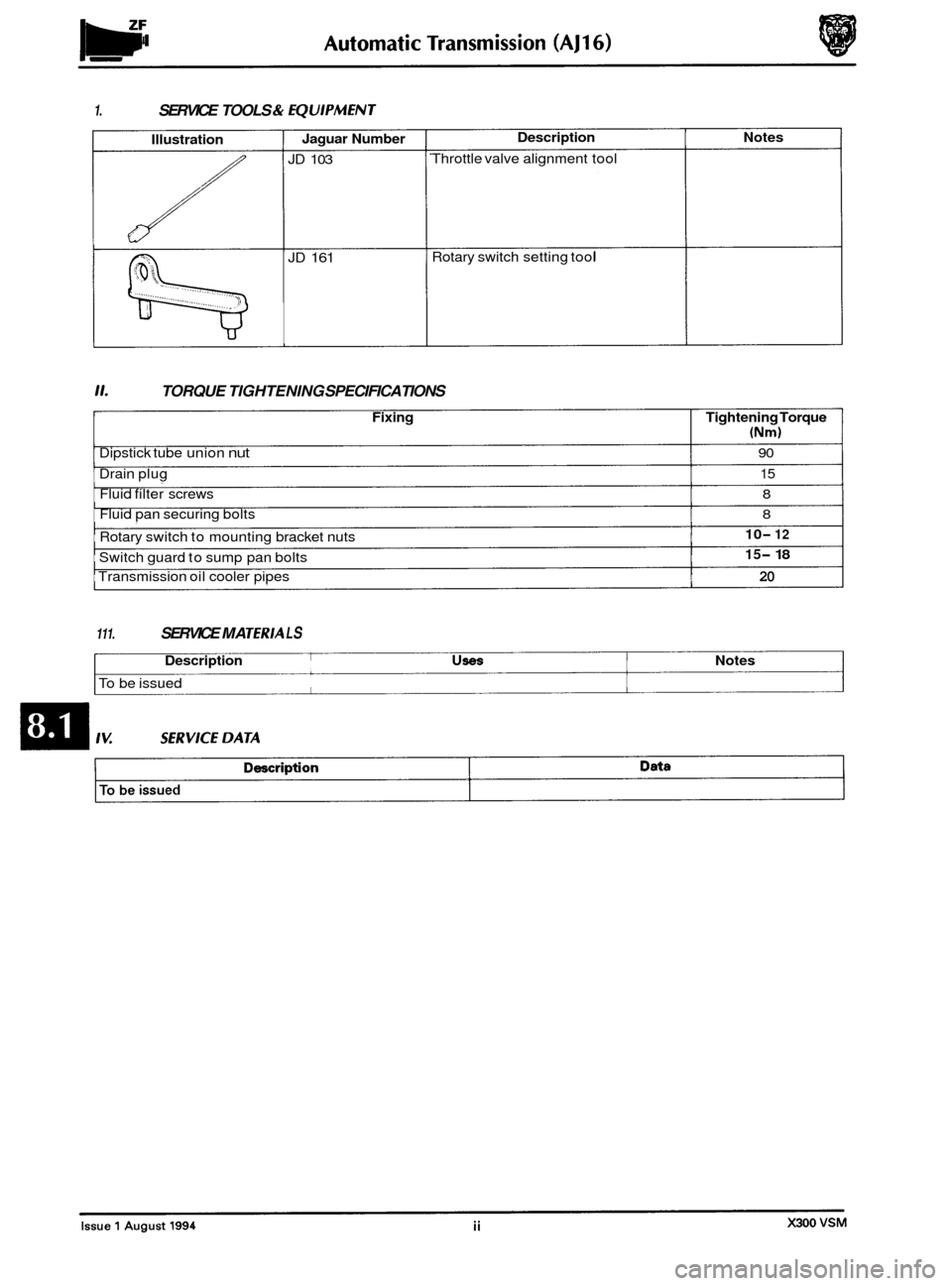

1. SERVICE TOOLS & fQUlPMENT

Illustration

::(())(((((

Jaguar Number

JD 103

JD 161

Description Notes

Throttle valve alignment tool

Rotary switch setting tool

11. TORQUE TIGHTENING SPECIFICATIONS

Fixing Tightening Torque

(Nm)

Dipstick tube union nut 90

Drain plug 15

Fluid filter screws 8

Fluid pan securing bolts 8

Rotary switch to mounting bracket nuts

Transmission oil cooler pipes

20

10- 12

15- 18 Switch guard to sump pan bolts

111. SERVICE MA TERlA L S

Description USeS Notes

To be issued

Page 143 of 521

bZF Automatic Transmission (AJ16) -

0

8.1.2 TRANSMISSION FLUID, RENEW

SRO 44.24.02

= Raise the hood and fit a fender cover.

. Raise the vehicle on a ramp.

. Place a drain tin in position beneath the transmission drain

Release and remove the transmission drain plug; allow

. Fit the drain plug with a new washer and torque tighten.

Reposition the drain tin beneath the dipstick tube union.

Remove the screw securing the dipstick tube bracket.

. Release the dipstick tube union nut and disconnect the

tube from the fluid pan.

. Drain the transmission fluid.

Clean the tube unions, reconnect the dipstick tube to the

. Lower the vehicle on the ramp.

. Remove the transmission dipstick.

. Renew the transmission fluid filter, see Subsection 8.1.6.

Fill the transmission with the correct fluid, see the ZF Auto-

Note: It will not be possible to get all the initial fill quantity

of fluid into the transmission.

. Refit the dipstick.

. Startthe engine, apply all brakes and run the transmission

With the engine still running, remove the dipstick.

Clean the dipstick and refit.

Remove the dipstick and check the transmission fluid

. Add fluid until the correct level is achieved.

. Stop the engine and refit the dipstick.

. Checkfluidleveltothe'HOT'marksaftera20mileroad run

(3,2L AND 4,OL)

Plug.

the fluid to drain.

fluid pan and torque tighten the union nut.

0

matic Transmissions Service Manual, General Data.

through

all gear positions and select 'Park'.

level. Remove the fender cover and lower the hood.

to ensure accurate results.

m

e

0

X300 VSM Issue 1 August 1994 6

Page 145 of 521

Automatic Transmission (AJ16)

8.1.4 TRANSMISSION ROTARY SWITCH, ADjUST

SRO 44.15.37

. Raise the vehicle on a ramp.

. Position the shift lever to 'N' ensuring that the stalk enters

the gate

'N' notch centrally.

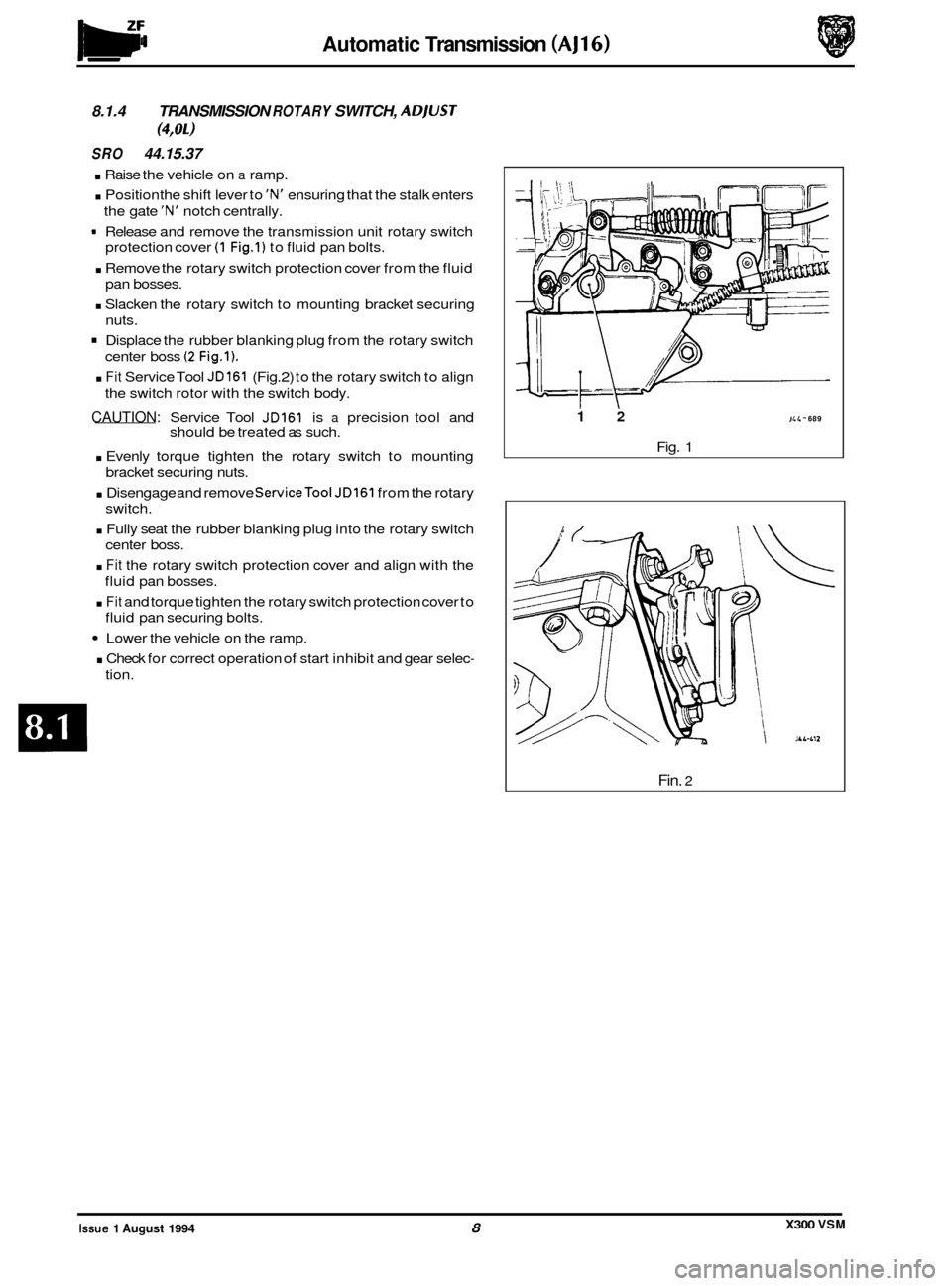

9 Release and remove the transmission unit rotary switch

protection cover

(1 Fig.1) to fluid pan bolts.

. Remove the rotary switch protection cover from the fluid

pan bosses.

. Slacken the rotary switch to mounting bracket securing

nuts.

Displace the rubber blanking plug from the rotary switch

center boss

(2 Fig.1).

. Fit Service Tool JD161 (Fig.2) to the rotary switch to align

the switch rotor with the switch body.

CAUTION: Service Tool JD161 is a precision tool and

. Evenly torque tighten the rotary switch to mounting

. Disengage and remove ServiceTool JD161 from the rotary

. Fully seat the rubber blanking plug into the rotary switch

. Fit the rotary switch protection cover and align with the

. Fit and torque tighten the rotary switch protection cover to

Lower the vehicle on the ramp.

. Check for correct operation of start inhibit and gear selec-

(4,011

should be treated as such.

bracket securing nuts.

switch.

center boss.

fluid pan bosses.

fluid pan securing bolts.

tion.

12 JL 4 - 689

Fig. 1

Fin. 2

X300 VSM Issue 1 August 1994 8

Page 147 of 521

Automatic Transmission (AJl6)

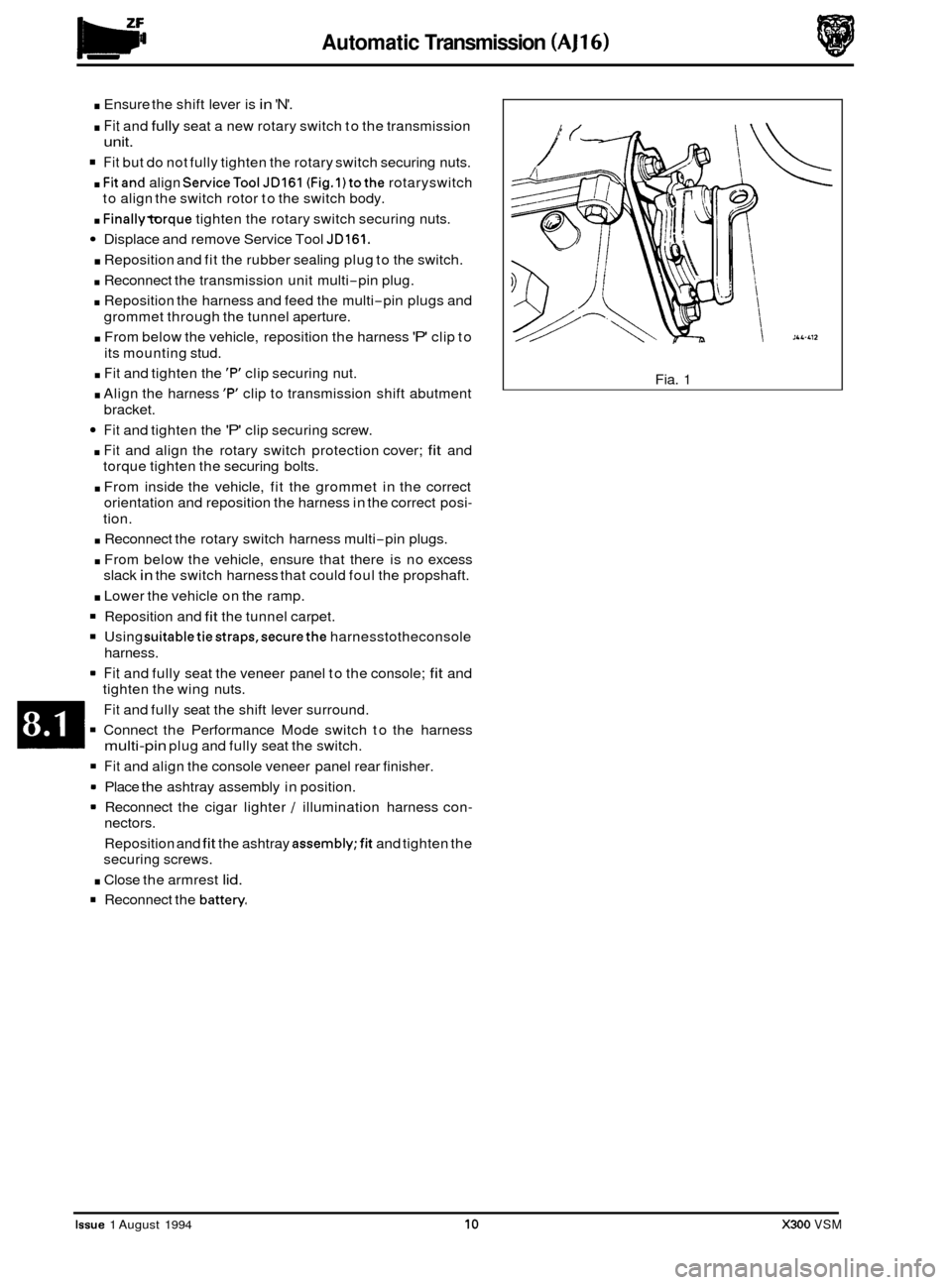

. Ensure the shift lever is in 'N'.

. Fit and fully seat a new rotary switch to the transmission

unit.

Fit but do not fully tighten the rotary switch securing nuts.

. Fitand align ServiceTool JD161 (Fig.l)tothe rotaryswitch

. Finallytorque tighten the rotary switch securing nuts.

Displace and remove Service Tool JD161.

. Reposition and fit the rubber sealing plug to the switch.

. Reconnect the transmission unit multi-pin plug.

. Reposition the harness and feed the multi-pin plugs and

. From below the vehicle, reposition the harness 'P' clip to

. Fit and tighten the 'F" clip securing nut.

. Align the harness 'P' clip to transmission shift abutment

Fit and tighten the 'P' clip securing screw.

. Fit and align the rotary switch protection cover; fit and

torque tighten the securing bolts.

. From inside the vehicle, fit the grommet in the correct

orientation and reposition the harness in the correct posi

-

tion.

to

align the switch rotor to the switch body.

grommet through the tunnel aperture.

its mounting stud.

bracket.

. Reconnect the rotary switch harness multi-pin plugs.

. From below the vehicle, ensure that there is no excess

slack

in the switch harness that could foul the propshaft.

. Lower the vehicle on the ramp.

Reposition and fit the tunnel carpet.

Using suitabletiestraps,securethe harnesstotheconsole

= Fit and fully seat the veneer panel to the console; fit and

harness.

tighten the wing nuts.

Fit and fully seat the shift lever surround.

multi-pin plug and fully seat the switch.

Connect the Performance Mode switch to the harness

Fit and align the console veneer panel rear finisher.

9 Place the ashtray assembly in position.

= Reconnect the cigar lighter / illumination harness con-

nectors.

Reposition and

fit the ashtray assemb1y;fit and tighten the

securing screws.

. Close the armrest lid.

Reconnect the battery

Fia. 1

Issue 1 August 1994 10 X300 VSM

Page 148 of 521

Automatic Transmission (AJl6)

8.1.6 TRANSMISSION FLUID FILTER, RENEW

SRO 44.24.07

9 Raise the hood and fit a fender cover.

. Raise the vehicle on a ramp.

. Drain the transmission lubrication system, see Sub-sec-

. Removethefluid pan,seeSub-section8.1.7 (4,OL)orSub-

. Release and remove the fluid filter securing screws; dis-

. Remove and discard the filter '0' ring.

. Clean the new filter and mating faces.

. Fit the '0' ring to the new filter; fit and seat the filter assem-

. Fit and torque tighten the filter securing screws.

. Refitthefluidpan,seeSub-section8.1.7 (4,OL)orSub-sec-

. Lower the vehicle on the ramp.

. Refill the transmission unit with fluid, see Subsection

8.1.2.

Remove the fender cover and lower the hood.

(3,2L AND 4,011

tion 8.1.2.

section

8.1.8 (3,2L).

place and remove the fluid filter.

bly to the valve body.

tion 8.1.8

(3,2L).

8.1.7 FLUID PAN, RENEW (4,OL)

SRO 44.24.04

. Raise the hood and fit a fender cover.

. Raise the vehicle on a ramp.

. Drain the transmission lubrication system, see Sub-sec-

tion 8.1.2.

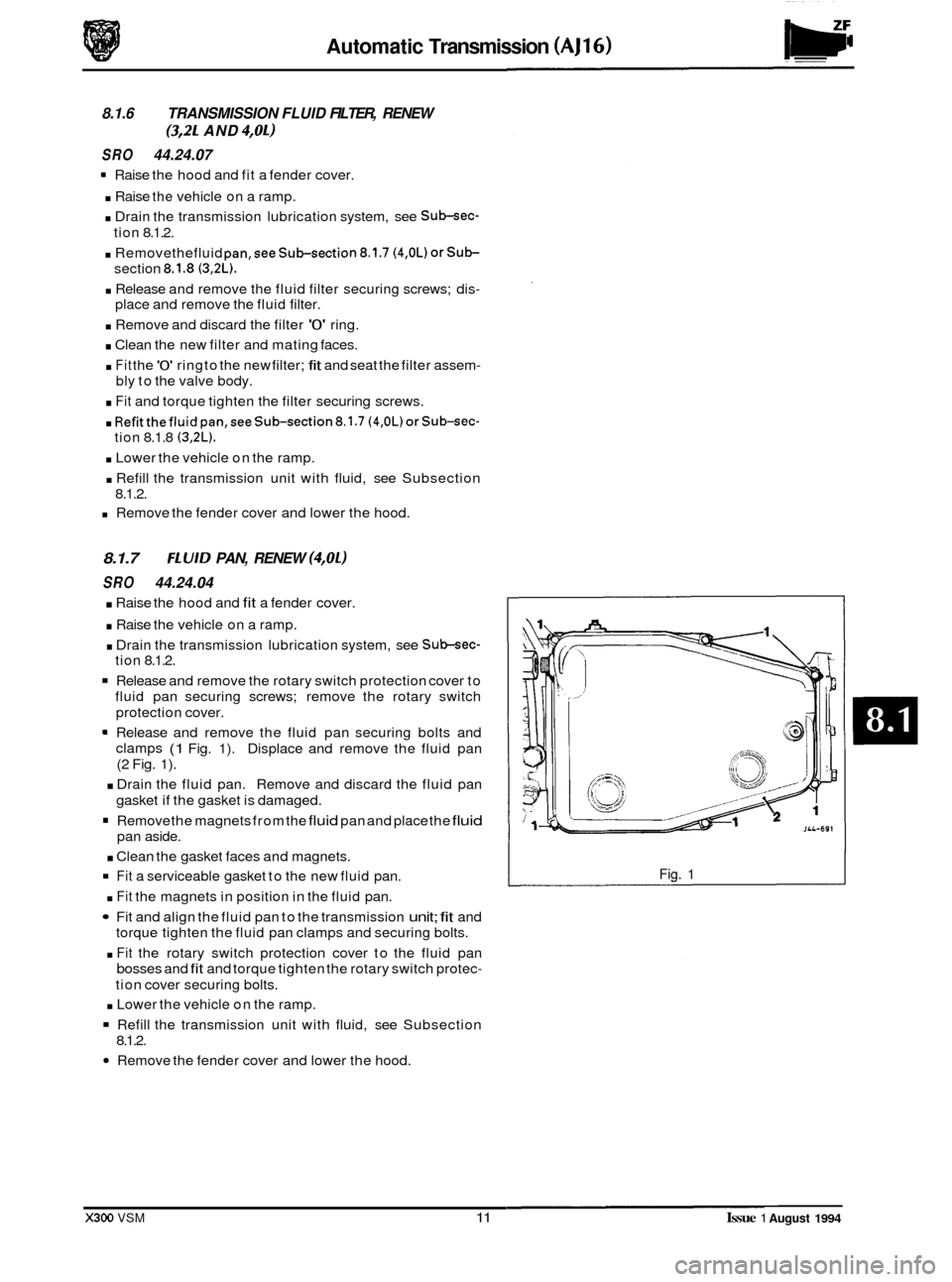

Release and remove the rotary switch protection cover to

fluid pan securing screws; remove the rotary switch

protect ion cover.

Release and remove the fluid pan securing bolts and

clamps

(1 Fig. 1). Displace and remove the fluid pan

(2 Fig. 1).

. Drain the fluid pan. Remove and discard the fluid pan

gasket if the gasket is damaged.

Remove the magnets from the fluid pan and place the fluid

pan aside.

. Clean the gasket faces and magnets.

Fit a serviceable gasket to the new fluid pan.

. Fit the magnets in position in the fluid pan.

Fit and align the fluid pan to the transmission unit; fit and

torque tighten the fluid pan clamps and securing bolts.

. Fit the rotary switch protection cover to the fluid pan

bosses and fit and torque tighten the rotary switch protec-

tion cover securing bolts.

. Lower the vehicle on the ramp.

Refill the transmission unit with fluid, see Subsection

Remove the fender cover and lower the hood.

8.1.2.

Fig. 1

X300 VSM 11 Issue 1 August 1994

Page 149 of 521

Automatic Transmission (AJ16)

8.1.8 FLUID PAN, RENEW (3,2L)

SRO 44.24.04

. Raise the vehicle on a ramp.

. Drain the transmission lubrication system, see Sub-sec-

tion 8.1.2.

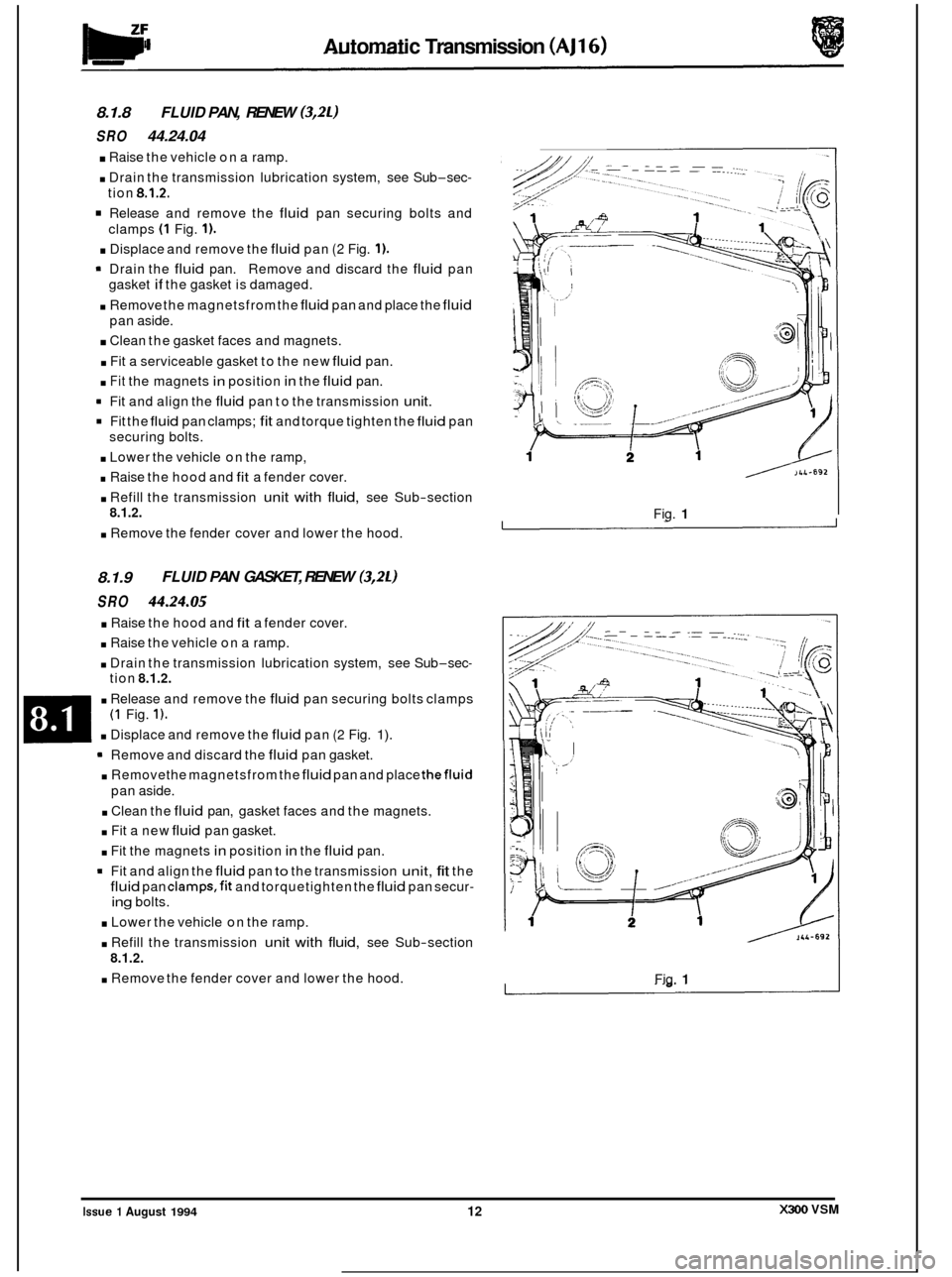

Release and remove the fluid pan securing bolts and

clamps

(1 Fig. 1).

. Displace and remove the fluid pan (2 Fig. 1).

= Drain the fluid pan. Remove and discard the fluid pan

. Remove the magnetsfrom the fluid pan and place the fluid

. Clean the gasket faces and magnets.

. Fit a serviceable gasket to the new fluid pan.

. Fit the magnets in position in the fluid pan.

9 Fit and align the fluid pan to the transmission unit.

Fit the fluid pan clamps; fit and torque tighten the fluid pan

. Lower the vehicle on the ramp,

. Raise the hood and fit a fender cover.

. Refill the transmission unit with fluid, see Sub-section

. Remove the fender cover and lower the hood.

gasket

if the

gasket is damaged.

pan aside.

securing bolts.

8.1.2.

8.1.9

SRO 44.24.05

. Raise the hood and fit a fender cover.

. Raise the vehicle on a ramp.

. Drain the transmission lubrication system, see Sub-sec-

FLUID PAN GASKET, RENEW (3,2L)

tion 8.1.2.

. Release and remove the fluid pan securing bolts clamps

. Displace and remove the fluid pan (2 Fig. 1).

(1 Fig. 1).

Remove and discard the fluid pan gasket.

pan aside.

. Removethe magnetsfrom the fluid pan and place thefluid

. Clean the fluid pan, gasket faces and the magnets.

. Fit a new fluid pan gasket.

. Fit the magnets in position in the fluid pan.

9 Fit and align the fluid pan to the transmission unit, fit the

fluid pan clamps,fit and torquetighten the fluid pan secur-

ing bolts.

. Lower the vehicle on the ramp.

. Refill the transmission unit with fluid, see Sub-section

. Remove the fender cover and lower the hood.

8.1.2.

/>U492

Fig. 1

Fig. 1

j

X300 VSM Issue 1 August 1994 12